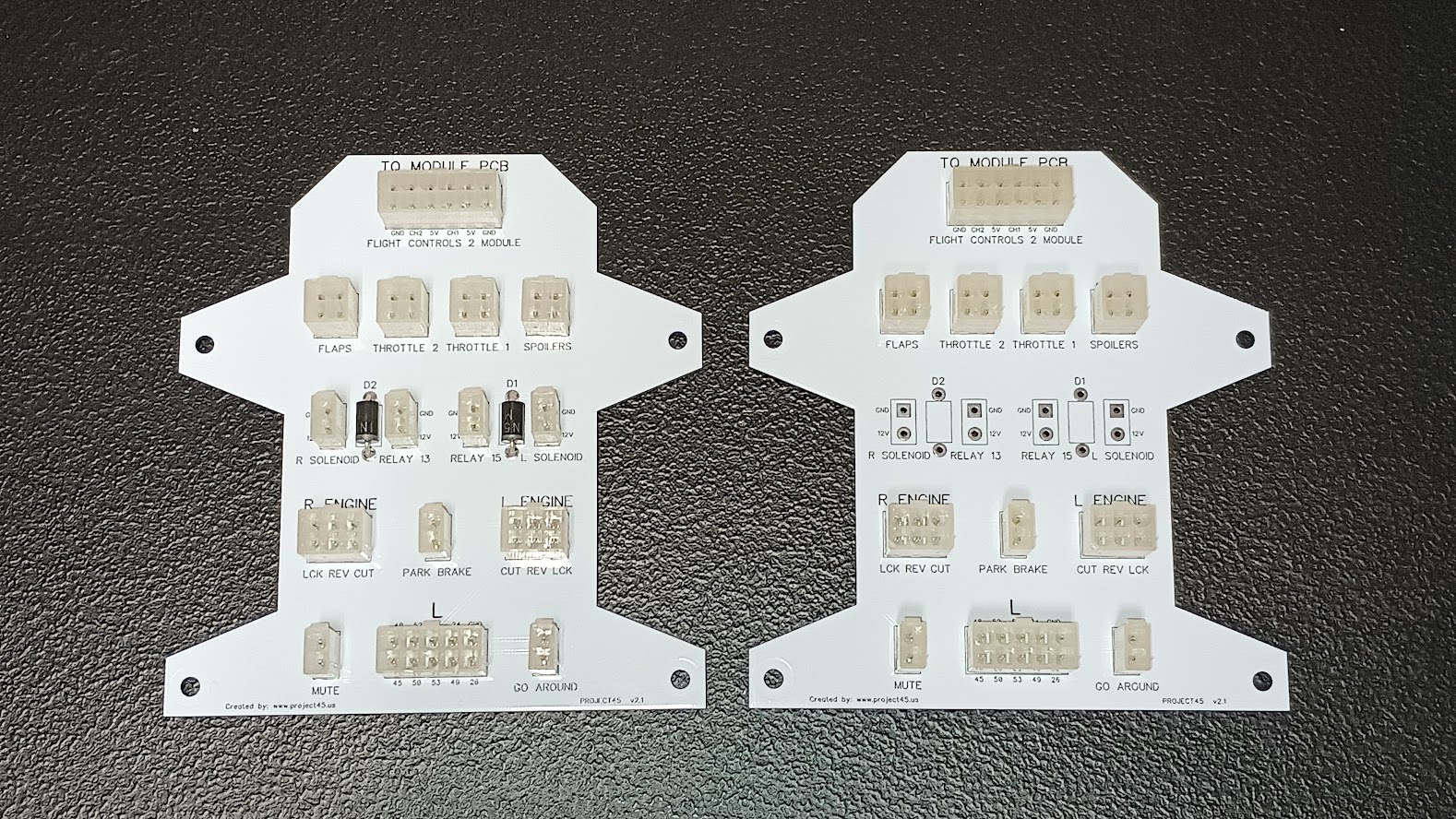

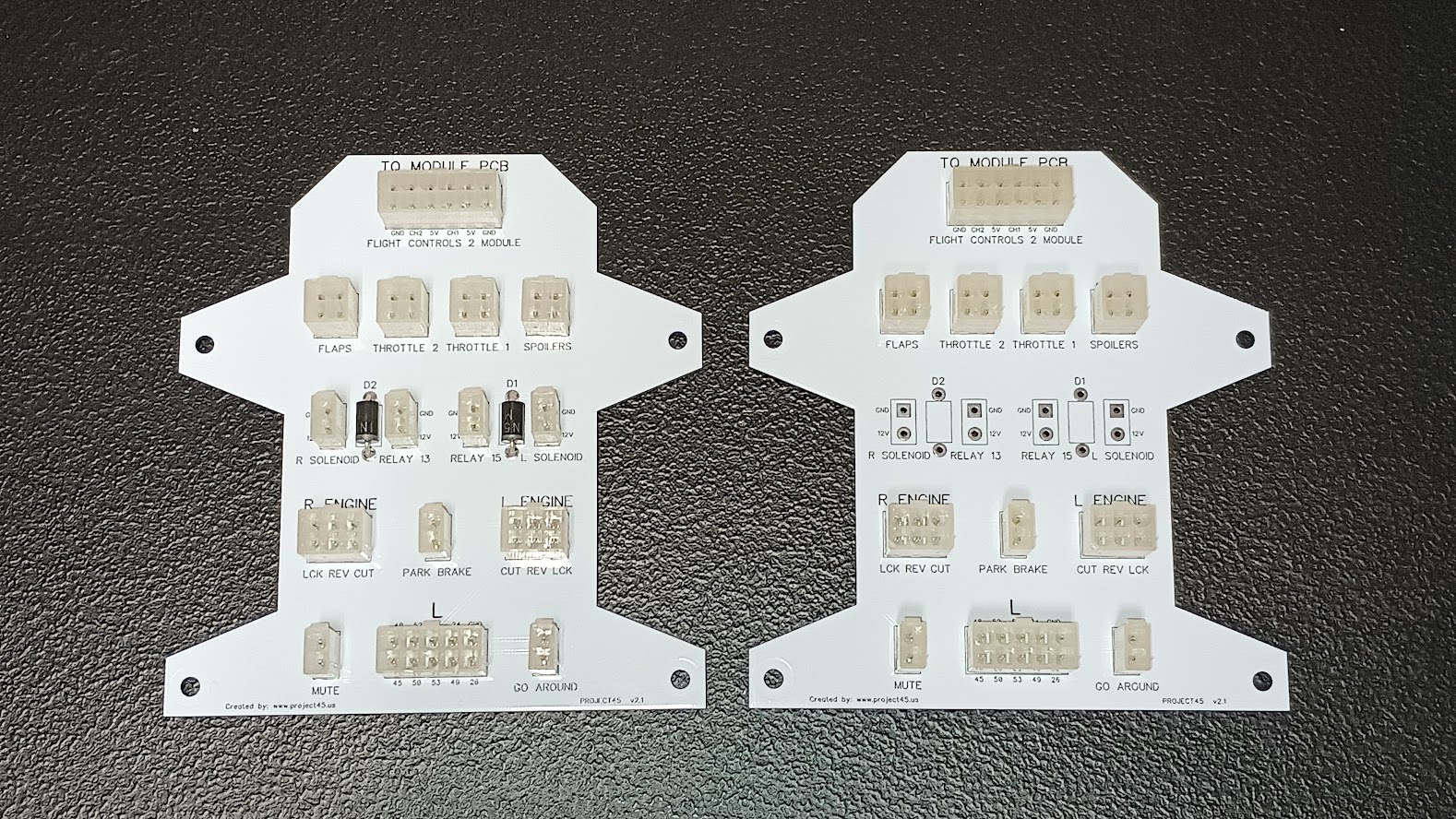

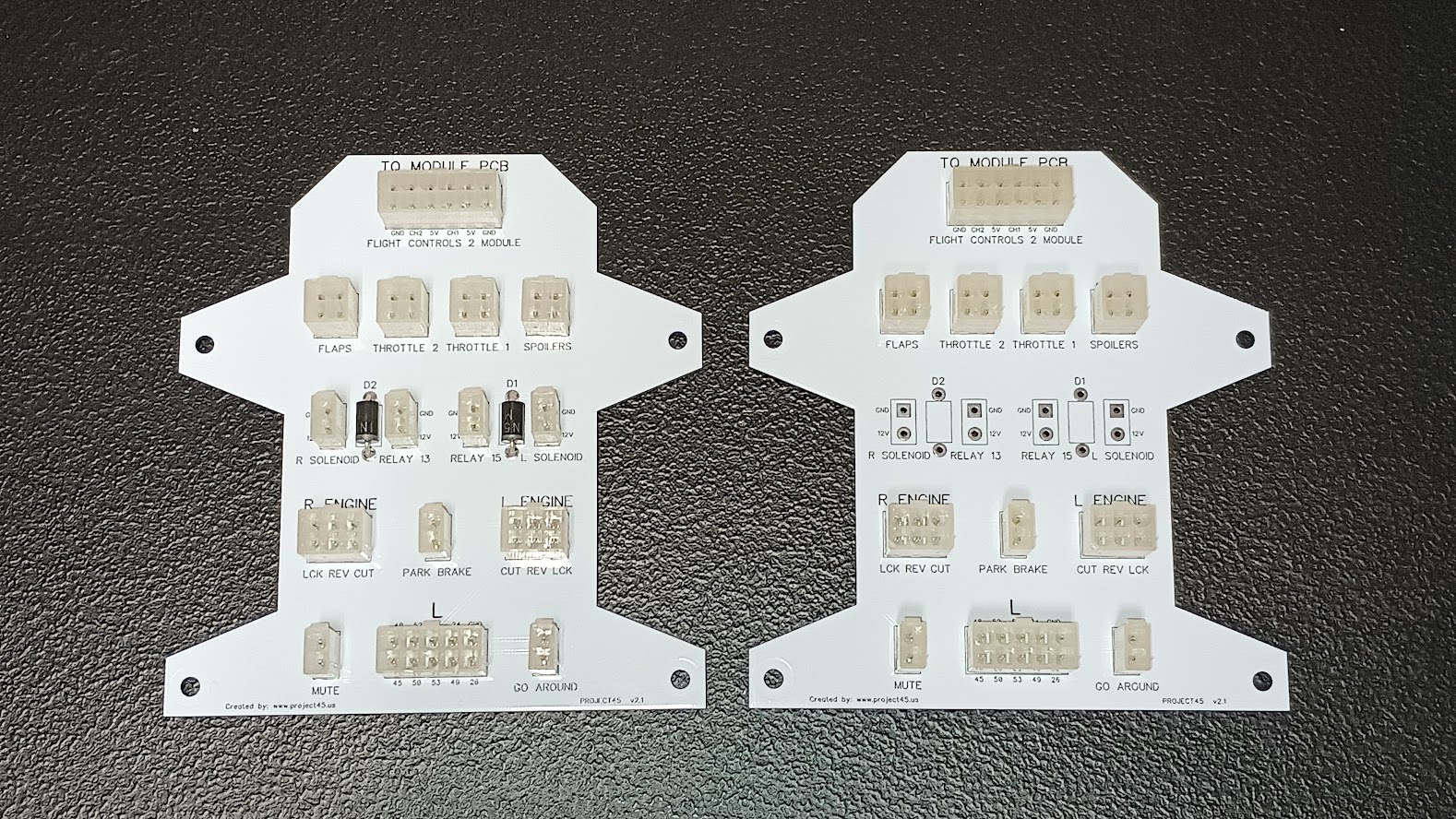

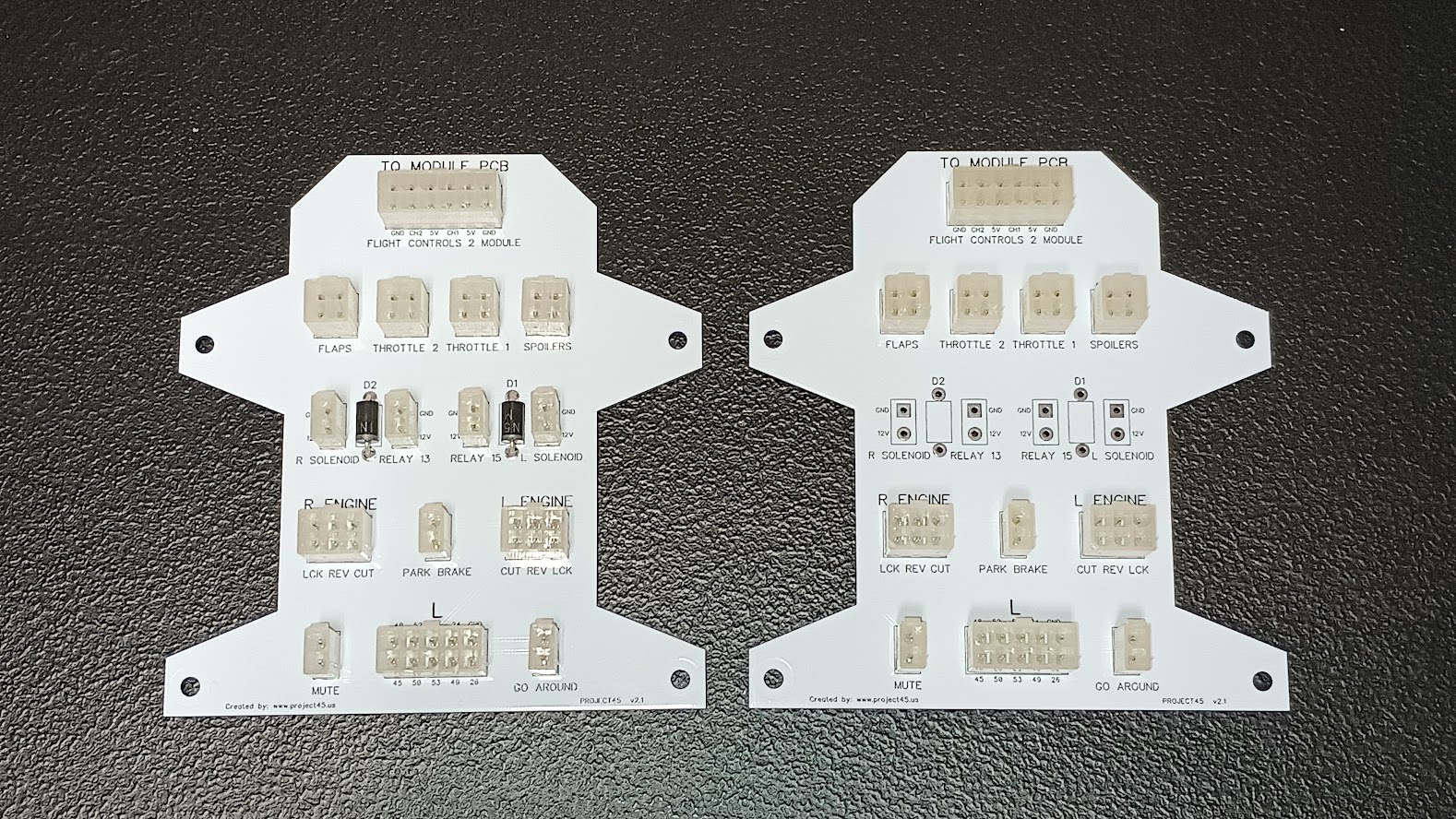

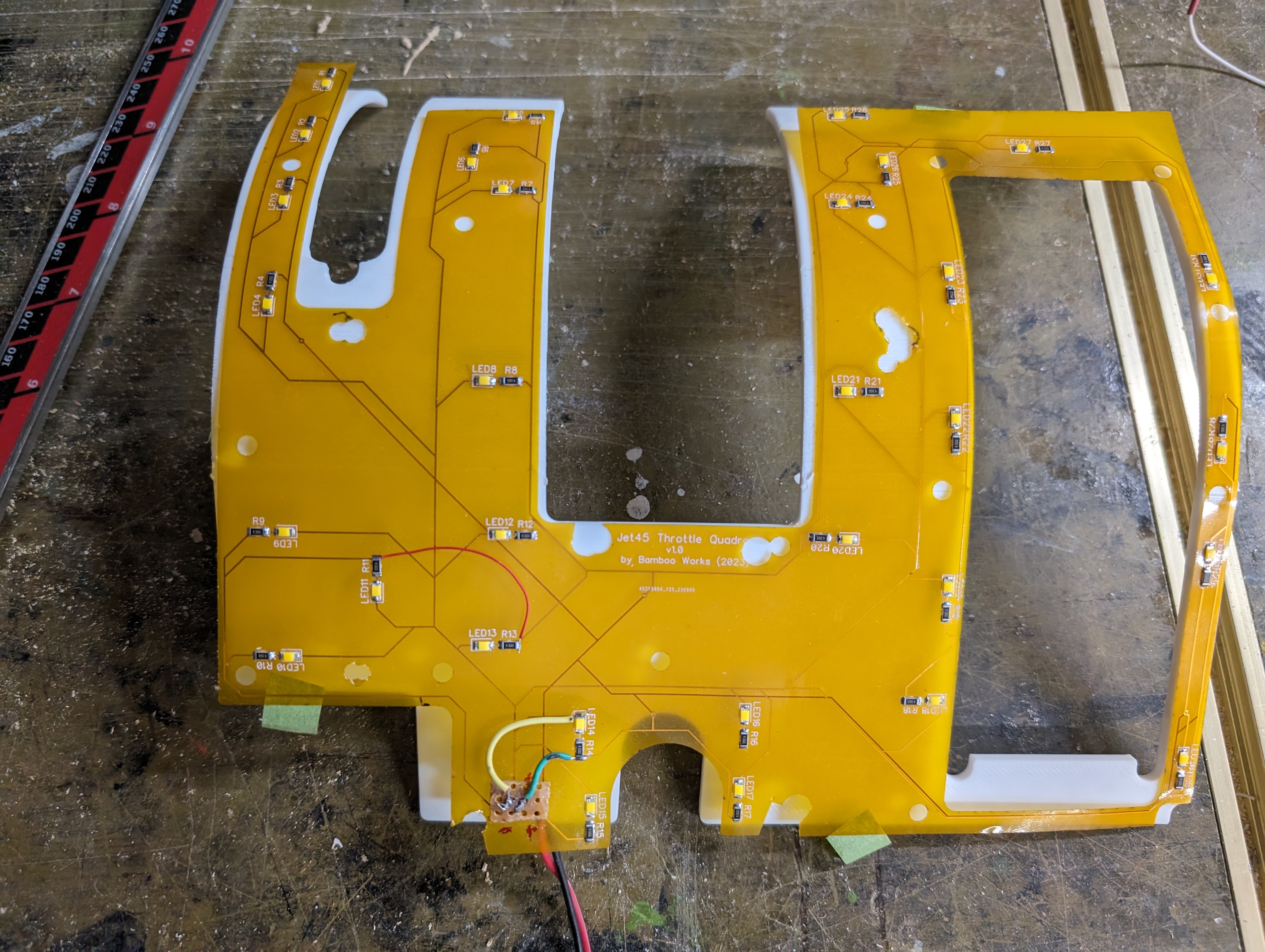

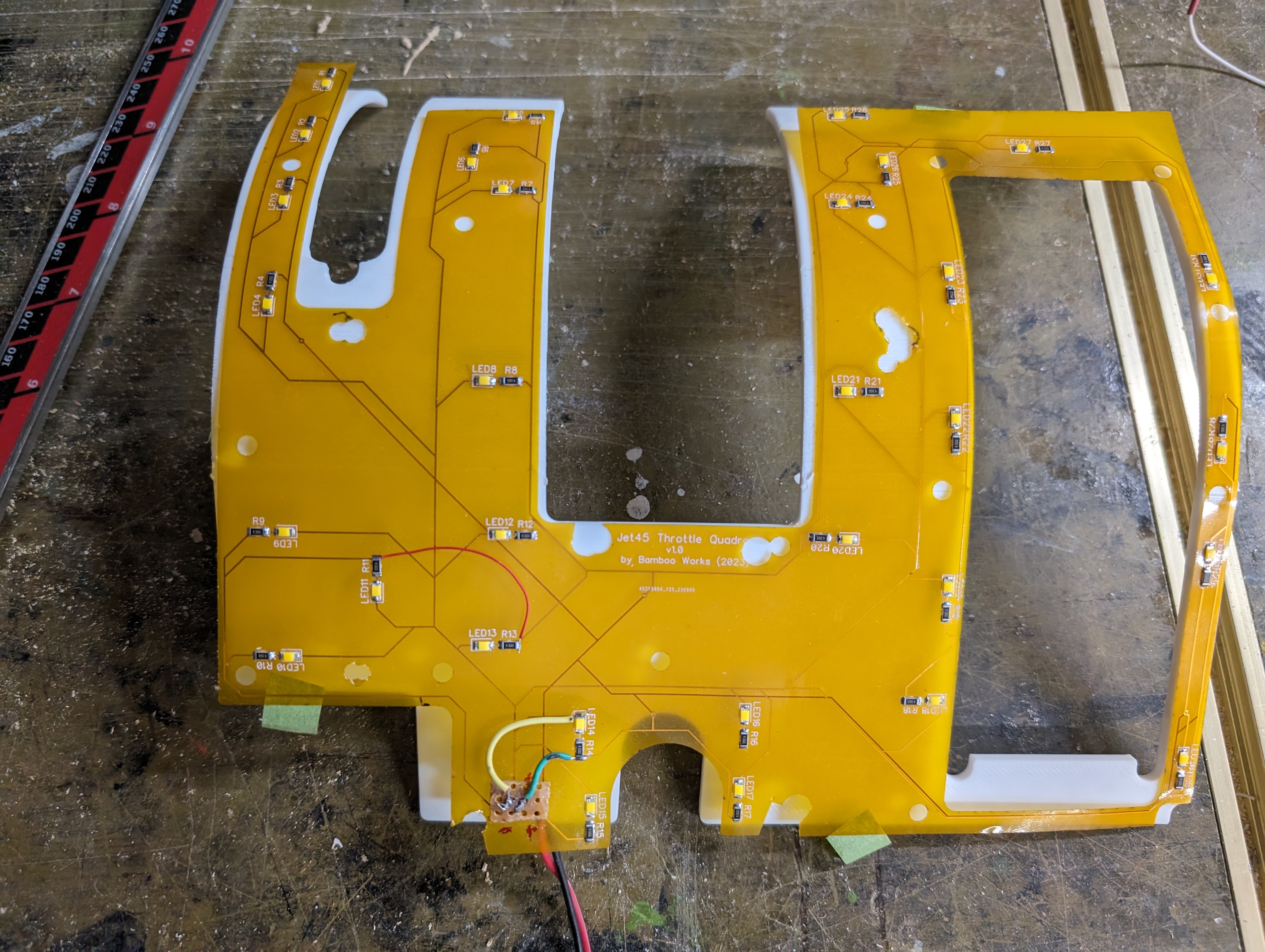

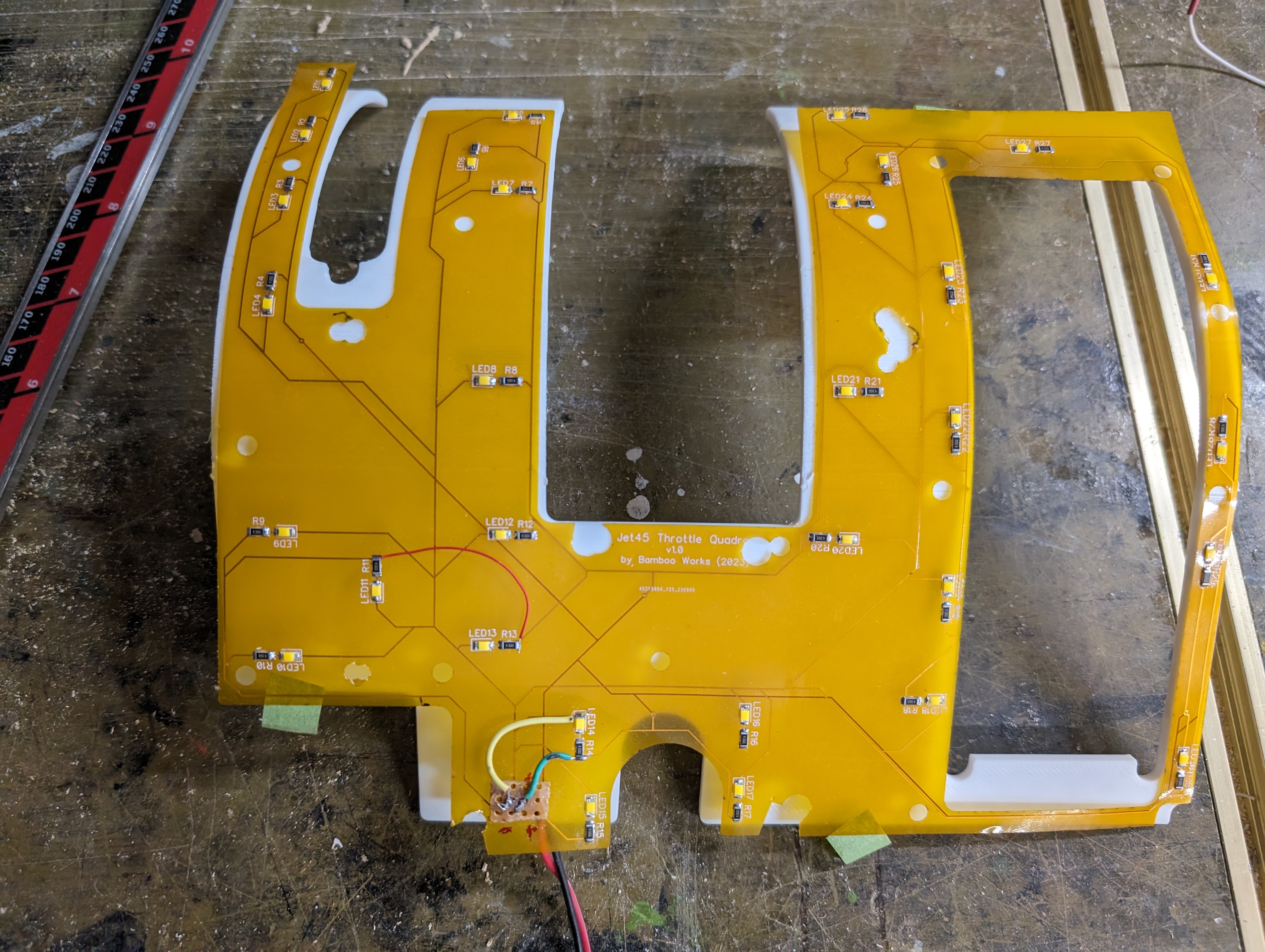

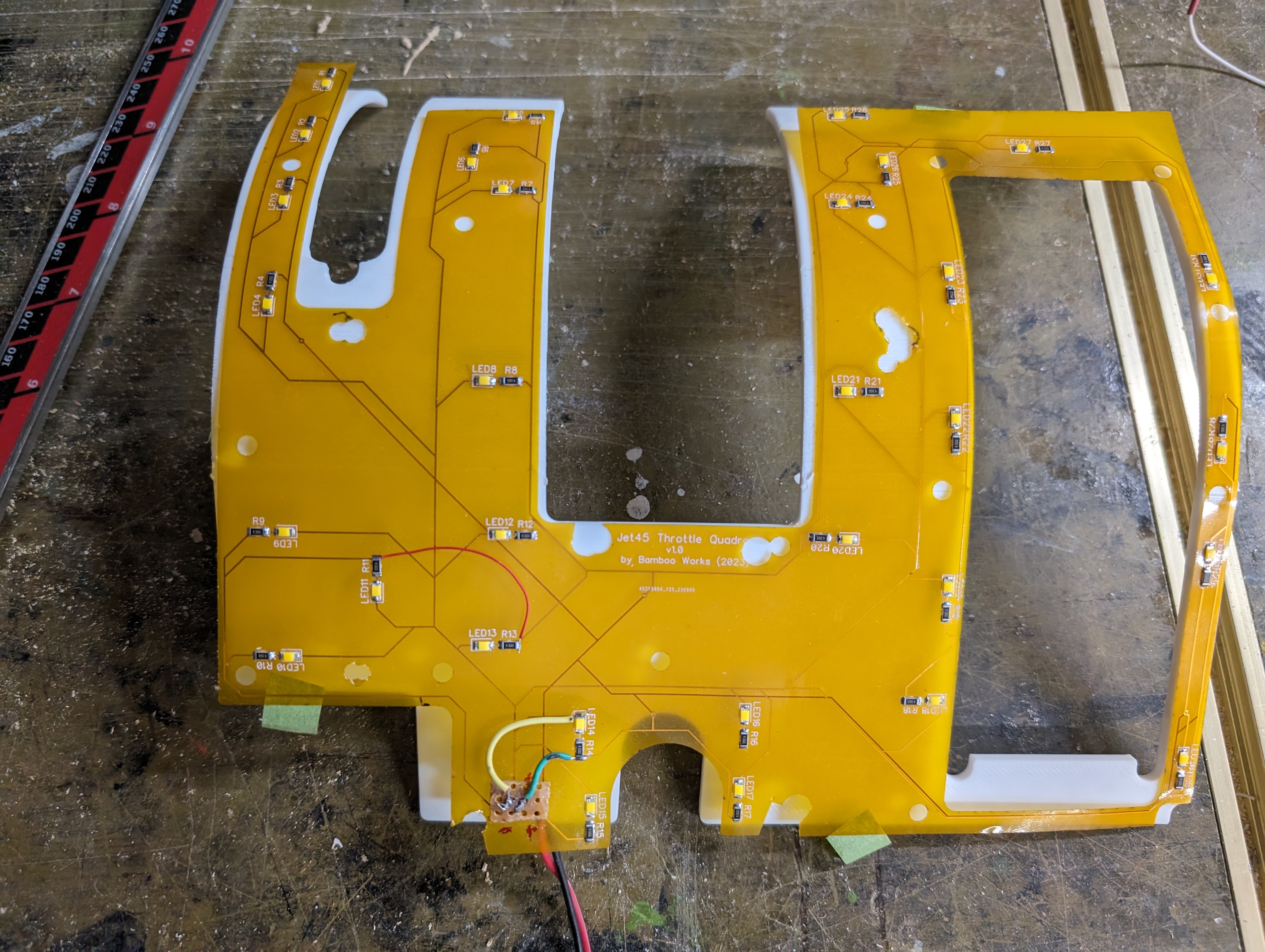

Nice job Roel! I enjoy seeing what can be created using the 3D printers. So many of these options were not available to builders back when we first started the Hangar. We definitely have many more options and tools to choose from to create parts, especially for some of the more difficult parts to replicate. Nice job Roel! I enjoy seeing what can be created using the 3D printers. So many of these options were not available to builders back when we first started the Hangar. We definitely have many more options and tools to choose from to create parts, especially for some of the more difficult parts to replicate. I have discovered the China PCB manufactering.... One is for EFIS and one for the FMS (which i will change i guess) So no more milling PCB's i think... I have discovered the China PCB manufactering.... One is for EFIS and one for the FMS (which i will change i guess) So no more milling PCB's i think... Yes Roel! The pcb manufacturing is so easy and affordable I am going back and reworking everything in my build. I am also sharing the efforts and work with others who have followed our path to this point. Just recently I went back and updated my TQ module. I wanted to straighten out the wiring colors and while I was at it, I updated the wire management board with pcb. Why not, it's so easy and I have found it's cheaper and easier than working with raw clad. Easier to solder too! Here are a couple examples of my latest pcb work: TQ module wire management. WX Radar and EFIS panel pcb. The silk screen is also a great option to take advantage of. Now it is super easy to identify all the plugs, pins and components. Like you, I wish I had discovered how easy it was to design and have pcb made sooner. I wasted a lot of time, effort and money doing it the hard way. I guess that is part of the learning experience. If you need any help or guidance, please ask. I don't know everything about pcb but I feel I have a pretty good handle on it. Yes Roel! The pcb manufacturing is so easy and affordable I am going back and reworking everything in my build. I am also sharing the efforts and work with others who have followed our path to this point. Just recently I went back and updated my TQ module. I wanted to straighten out the wiring colors and while I was at it, I updated the wire management board with pcb. Why not, it's so easy and I have found it's cheaper and easier than working with raw clad. Easier to solder too! Here are a couple examples of my latest pcb work: TQ module wire management. WX Radar and EFIS panel pcb. The silk screen is also a great option to take advantage of. Now it is super easy to identify all the plugs, pins and components. Like you, I wish I had discovered how easy it was to design and have pcb made sooner. I wasted a lot of time, effort and money doing it the hard way. I guess that is part of the learning experience. If you need any help or guidance, please ask. I don't know everything about pcb but I feel I have a pretty good handle on it. Yes, its definately the way to go. I have been using JLCPCB for a while, and recently ordered my first flexible PCB for the curved TQ Panel, 0.12mm thick. Easy to solder components on using solder paste and a heat gun, not so easy with a soldering iron. Ron has a great setup for easy soldering. and it really is flexible! Here it is twisted 180 degrees in the middle: The extra wires you can see in the first photo are to fix traces I broke when soldering power wires to the PCB. I selected the wrong connector type in DipTrace, the PCB Design software, and I did not get a solid pad at that point. Should you have a need for a flexible PCB make sure you order it with a solid pad at any connector points... Yes, its definately the way to go. I have been using JLCPCB for a while, and recently ordered my first flexible PCB for the curved TQ Panel, 0.12mm thick. Easy to solder components on using solder paste and a heat gun, not so easy with a soldering iron. Ron has a great setup for easy soldering. and it really is flexible! Here it is twisted 180 degrees in the middle: The extra wires you can see in the first photo are to fix traces I broke when soldering power wires to the PCB. I selected the wrong connector type in DipTrace, the PCB Design software, and I did not get a solid pad at that point. Should you have a need for a flexible PCB make sure you order it with a solid pad at any connector points... Wow, I didn't know there are flexible PCB's as well to order... cool!! Wow, I didn't know there are flexible PCB's as well to order... cool!! I still wasn't satisfied about my PCB design for the FMS I still wasn't satisfied about my PCB design for the FMS Hey Roel, Incredible work! I love seeing how others find ways to achieve the same goal by different means. This is how we get ideas from one another to make a better design in the future. I never thought of trying to include the Arduino footprint onto the main CDU pcb. All these years I have been building my version in two pieces like this. As you pointed out, this solution requires a couple wire headers to jump from one board to the other. I think we ended up designing ours like this because we were converting real CDU face plates to be used in our sims. Your work will have me looking to see if this is possible with my design or if I have to just leave well enough alone. Again, great work Roel! Hey Roel, Incredible work! I love seeing how others find ways to achieve the same goal by different means. This is how we get ideas from one another to make a better design in the future. I never thought of trying to include the Arduino footprint onto the main CDU pcb. All these years I have been building my version in two pieces like this. As you pointed out, this solution requires a couple wire headers to jump from one board to the other. I think we ended up designing ours like this because we were converting real CDU face plates to be used in our sims. Your work will have me looking to see if this is possible with my design or if I have to just leave well enough alone. Again, great work Roel! Little update of my FMS software. Also added a moving map... just because it is possible 🙂 https://youtu.be/mkFb6Hp-jNU Little update of my FMS software. Also added a moving map... just because it is possible 🙂 Hey Roel, Wow, very cool! Your FMS software is coming along great. Your whole sim is looking good. Reference tuning the frequencies with the FMS, are you saying that you prefer to use the FMS rather than the RMU because you find it easier? Your RMUs are still programmed and operational correct? It's nice to be able to tune the radios form more than one place. Awesome work Roel! Hey Roel, Wow, very cool! Your FMS software is coming along great. Your whole sim is looking good. Reference tuning the frequencies with the FMS, are you saying that you prefer to use the FMS rather than the RMU because you find it easier? Your RMUs are still programmed and operational correct? It's nice to be able to tune the radios form more than one place. Awesome work Roel! Hi Ron yes, it is more that i have to look up the several freqeuncies for a certain airport. rmu’s etc just read the data from the sim, so they are also still fully operational Hi Ron yes, it is more that i have to look up the several freqeuncies for a certain airport. rmu’s etc just read the data from the sim, so they are also still fully operationalRoel's Learjet 45 simulator

![]()

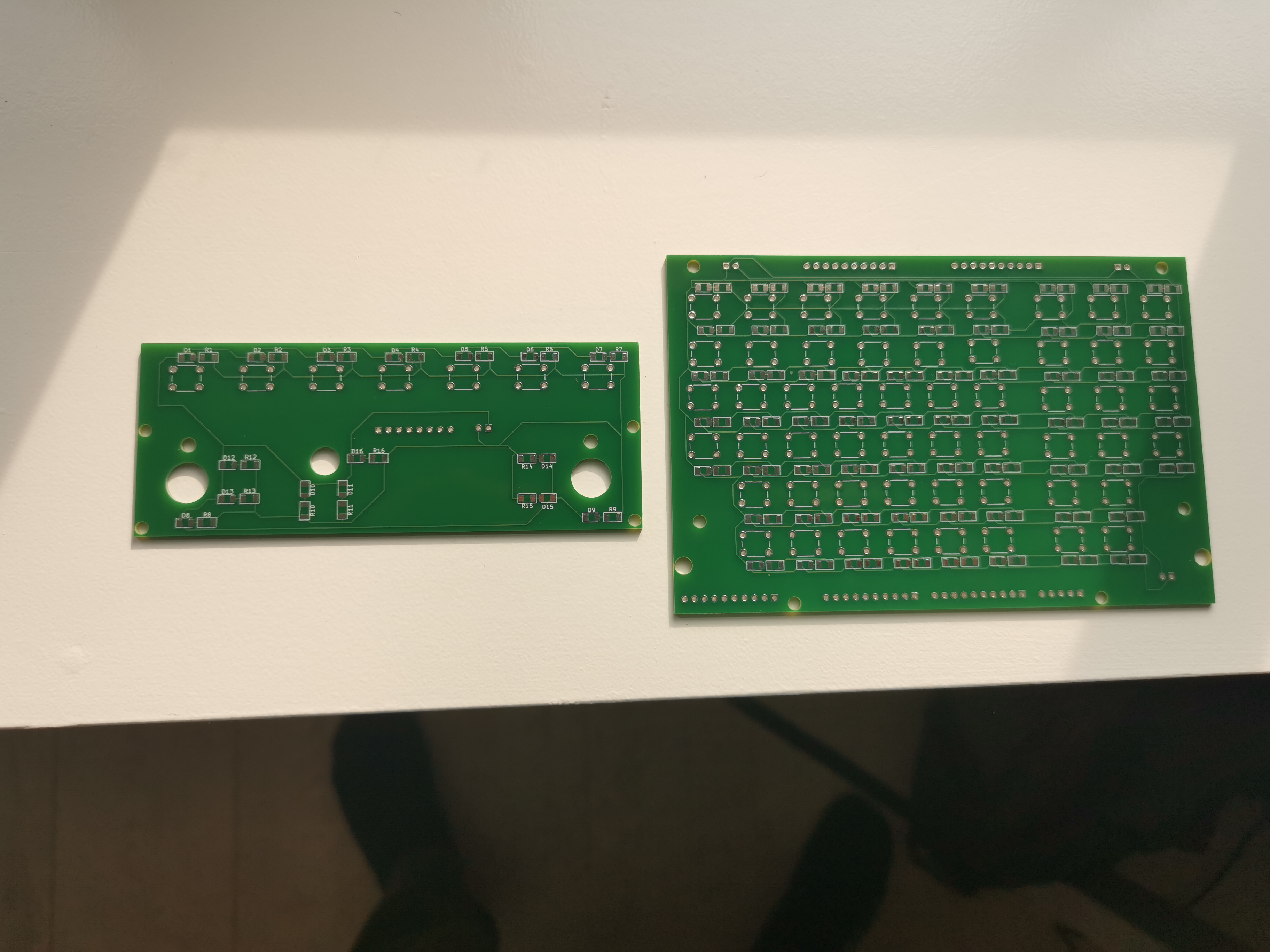

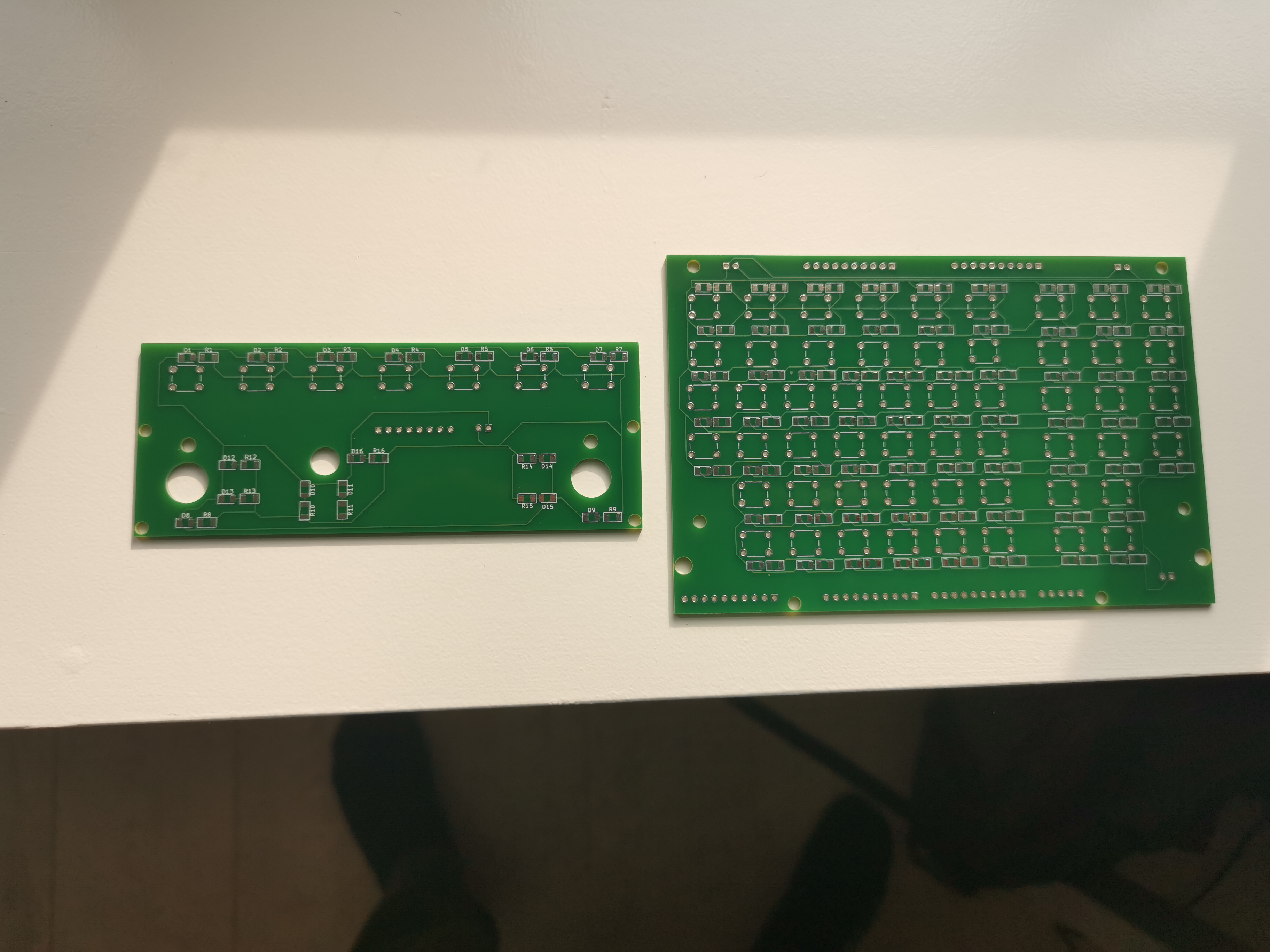

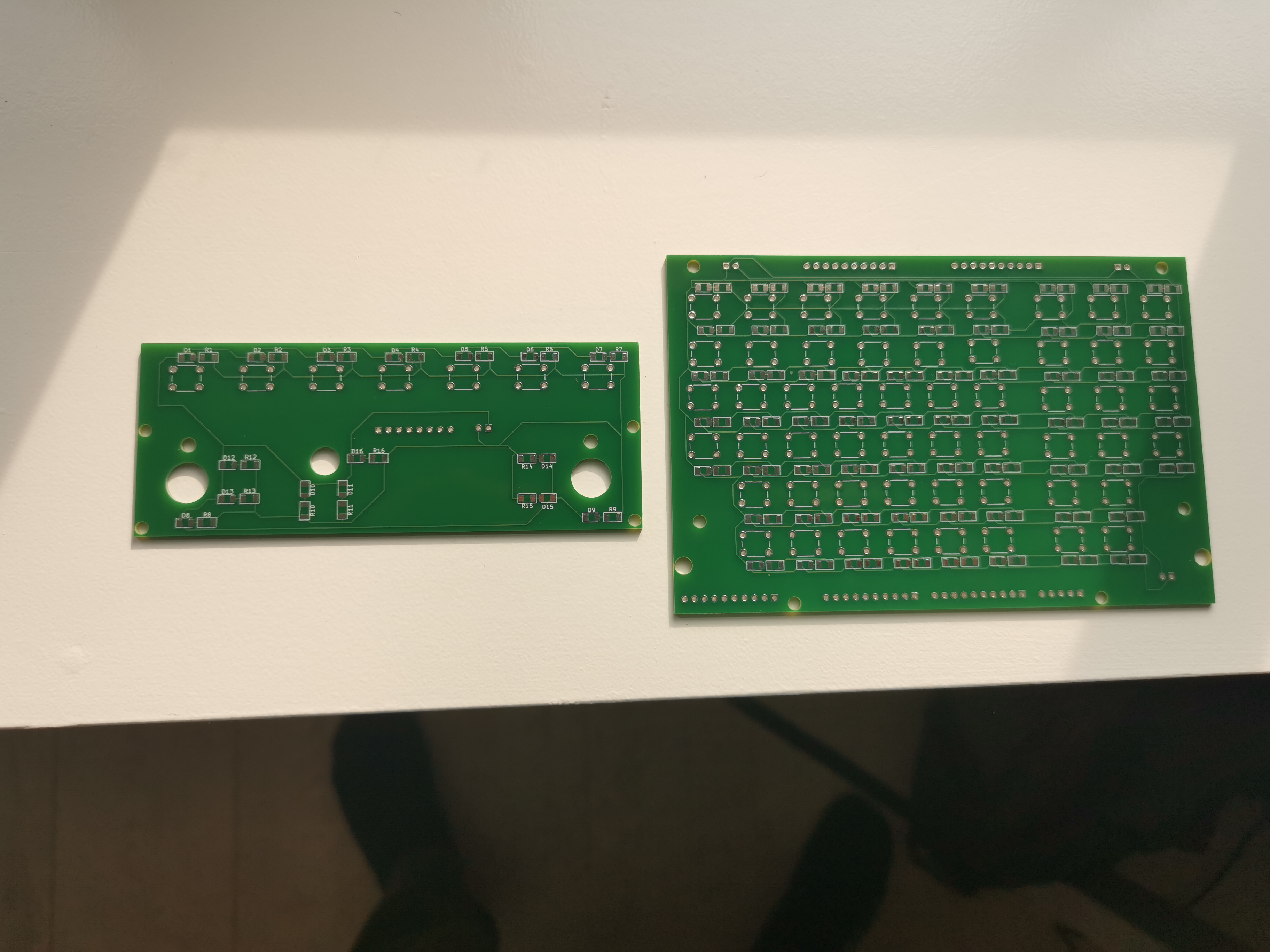

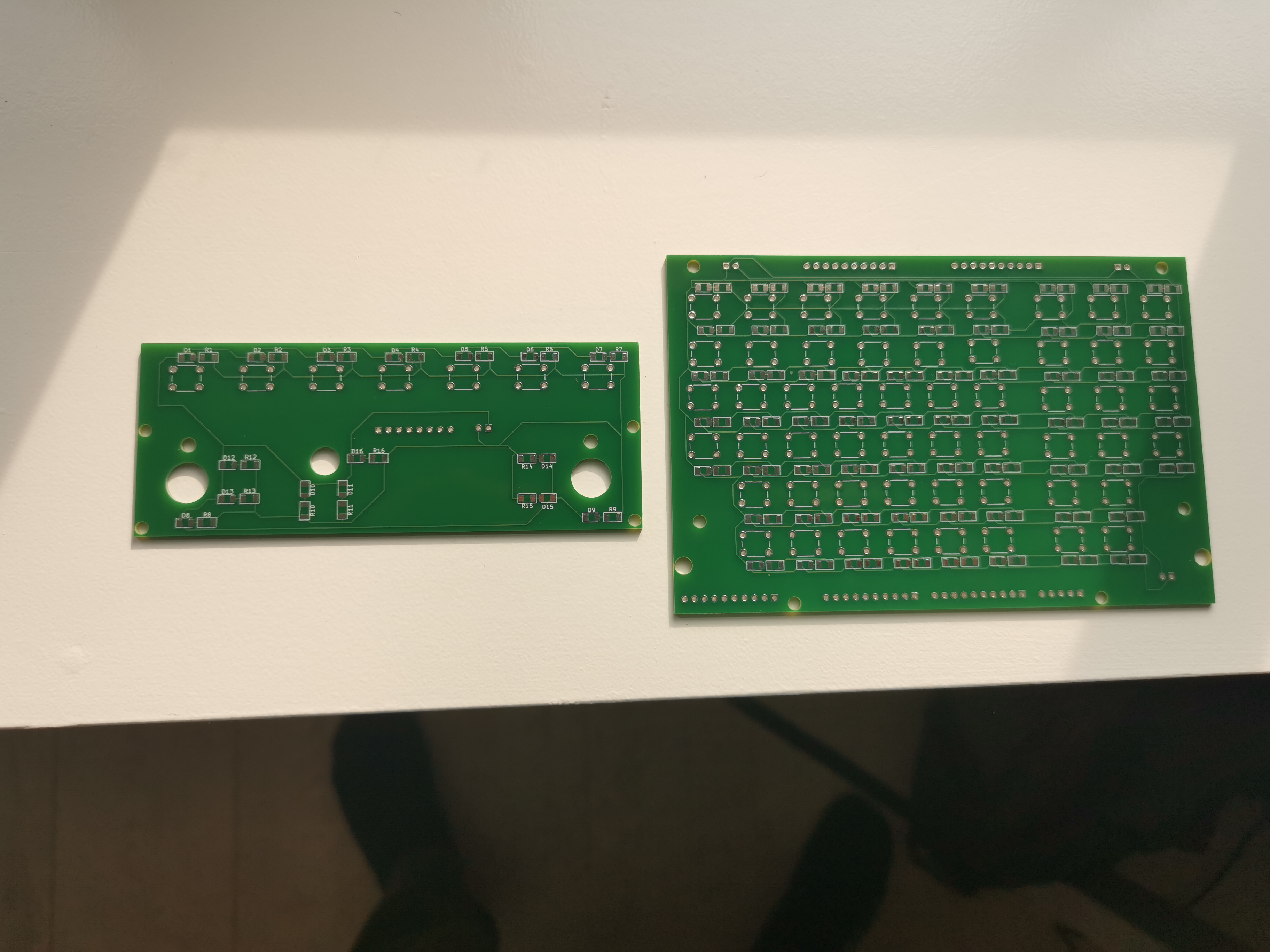

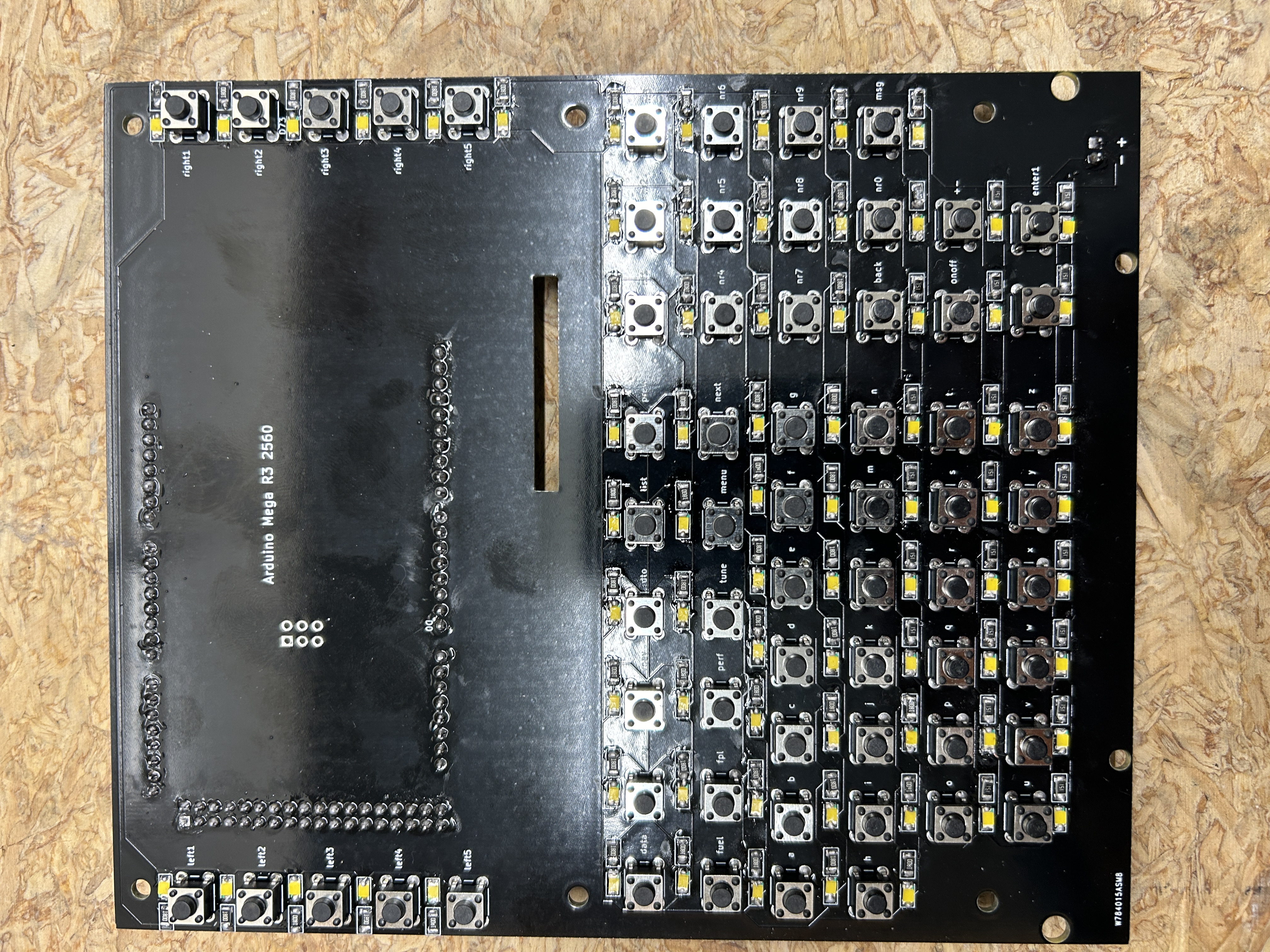

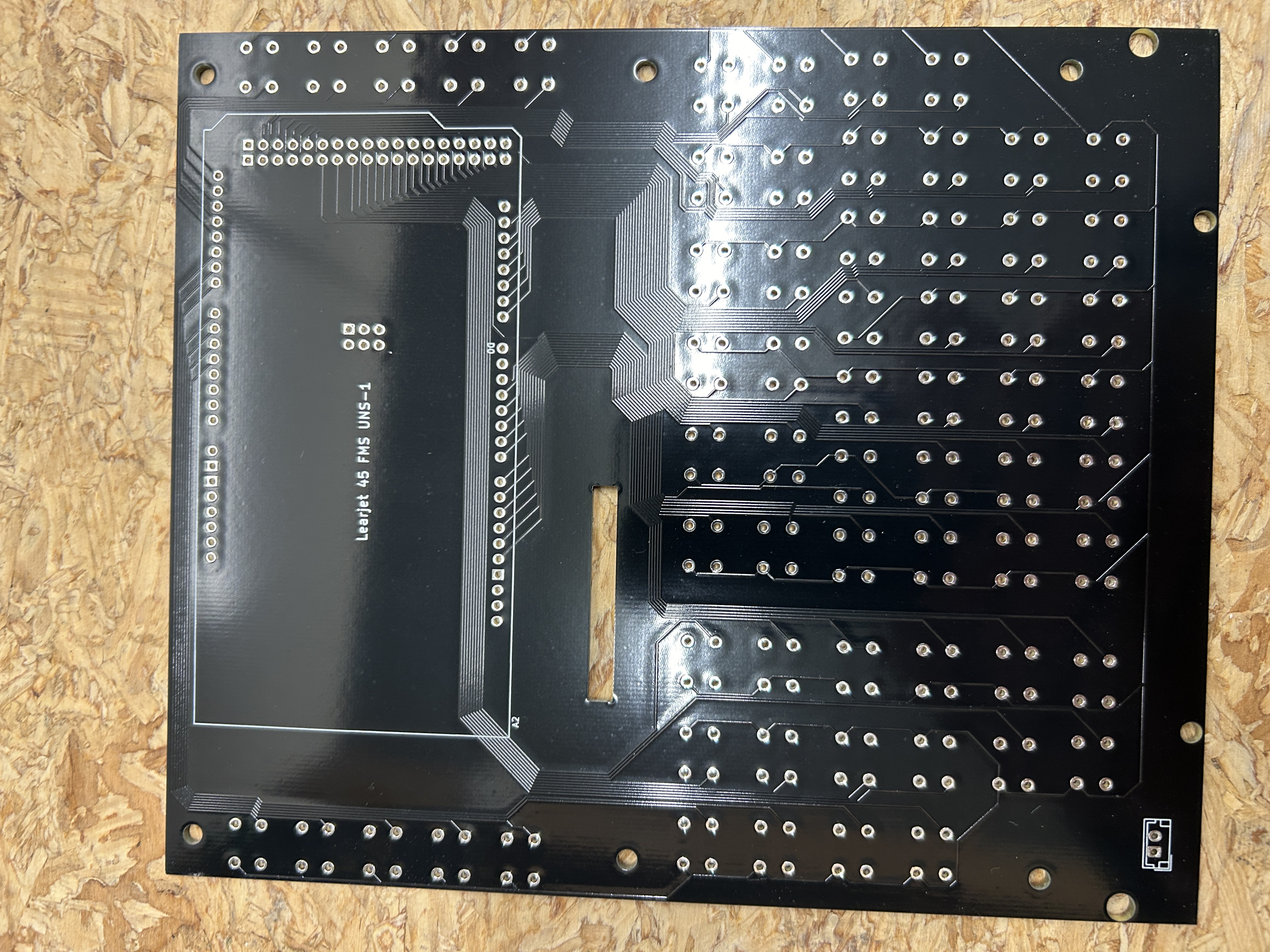

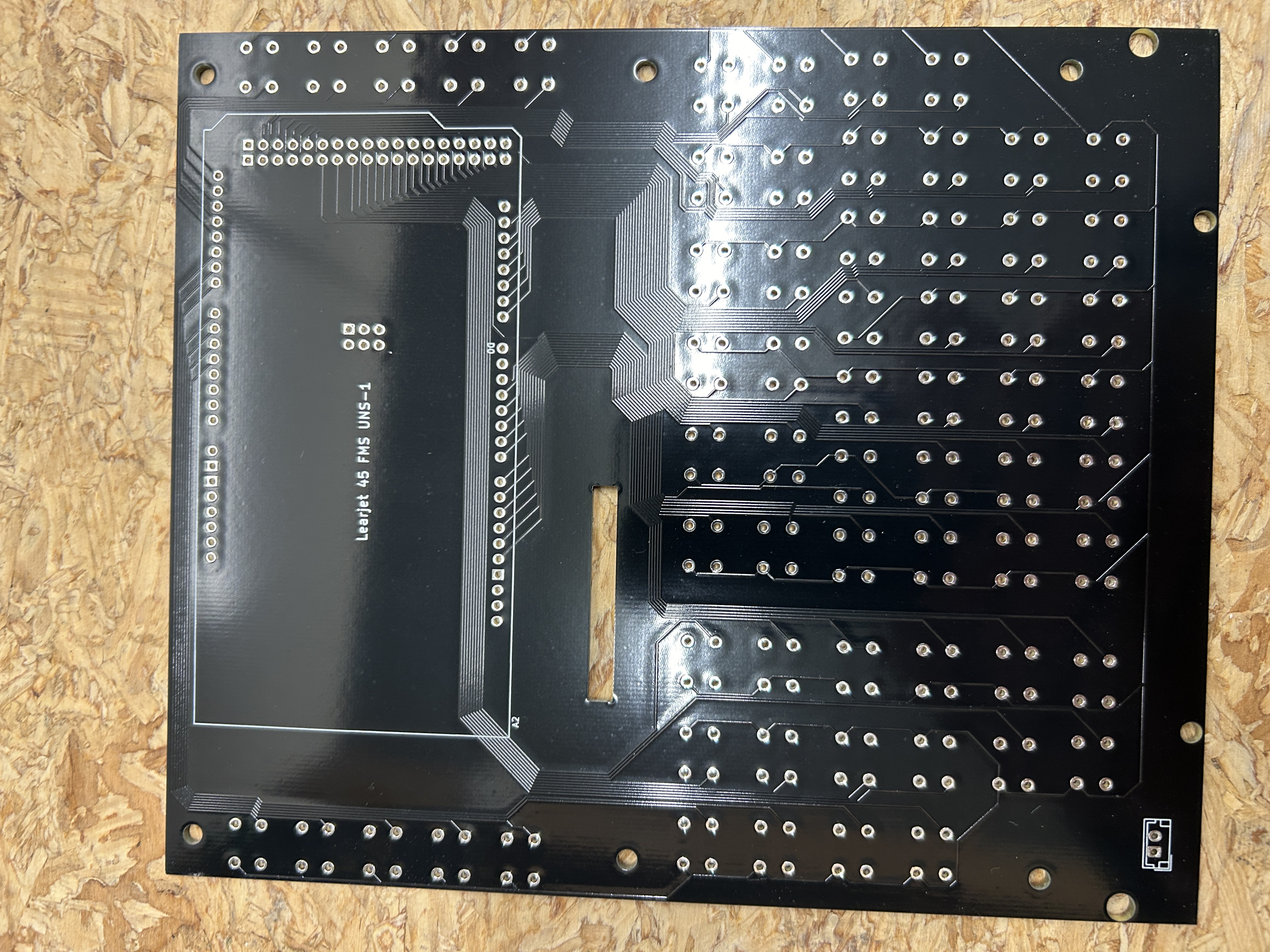

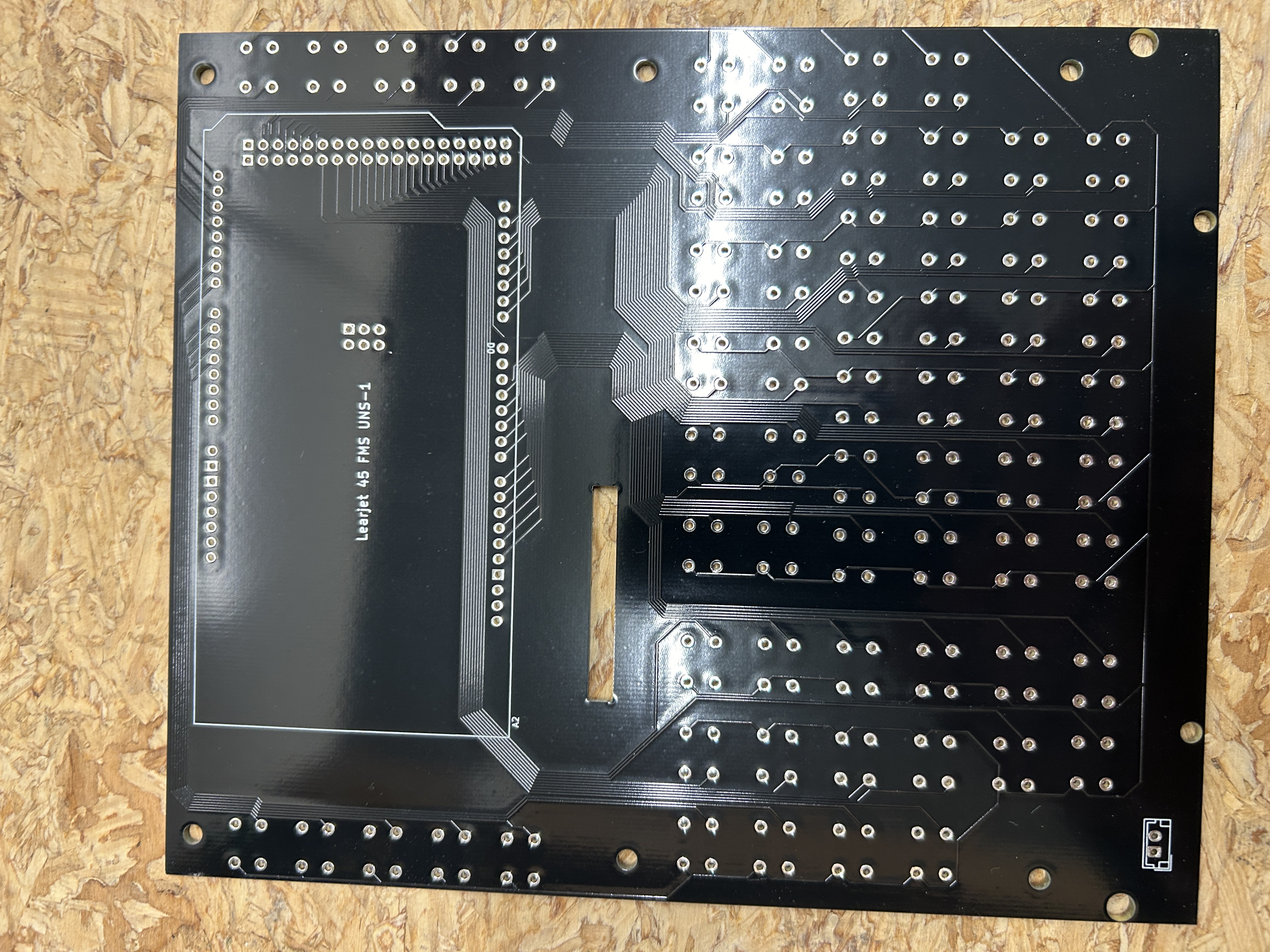

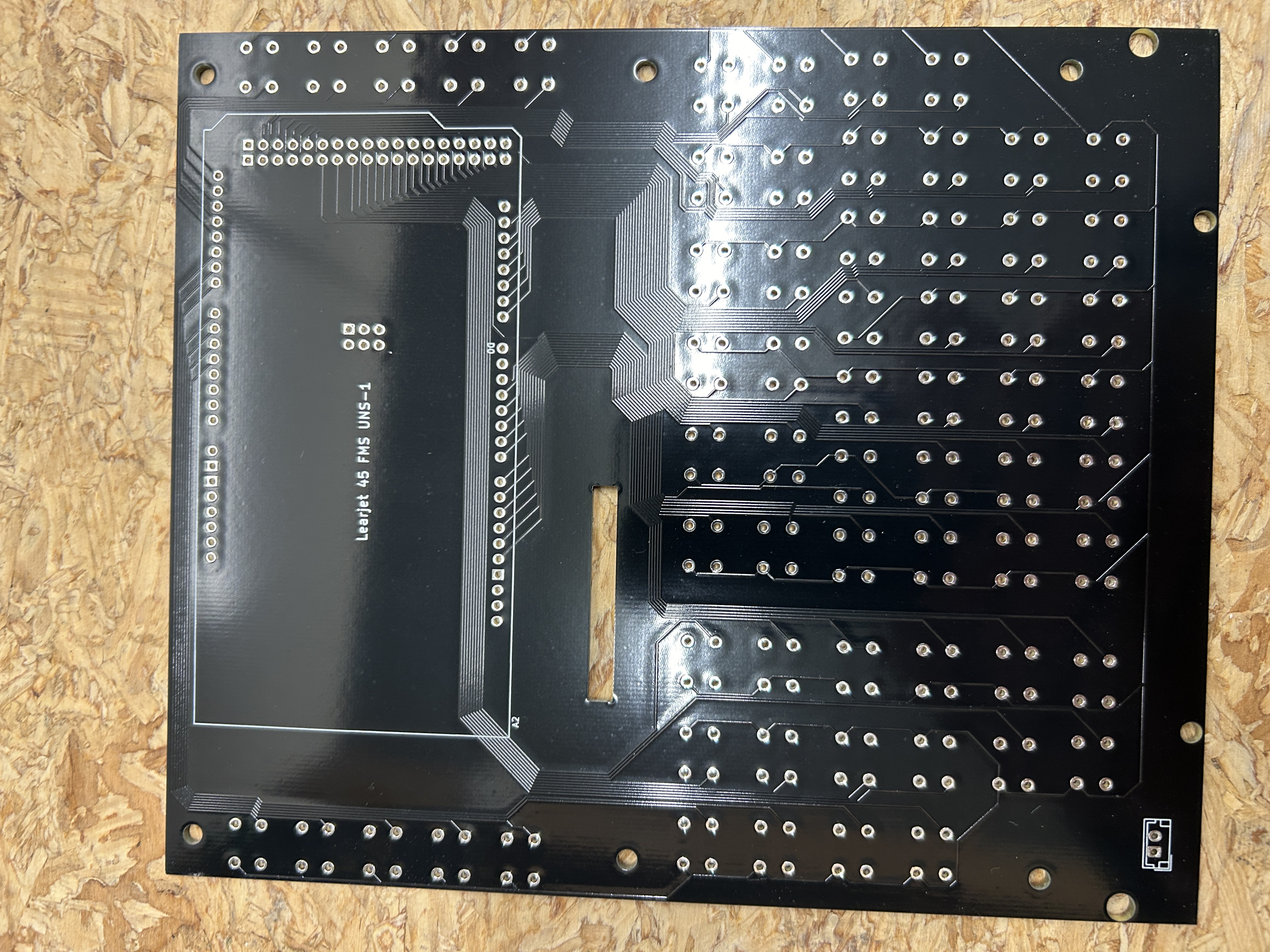

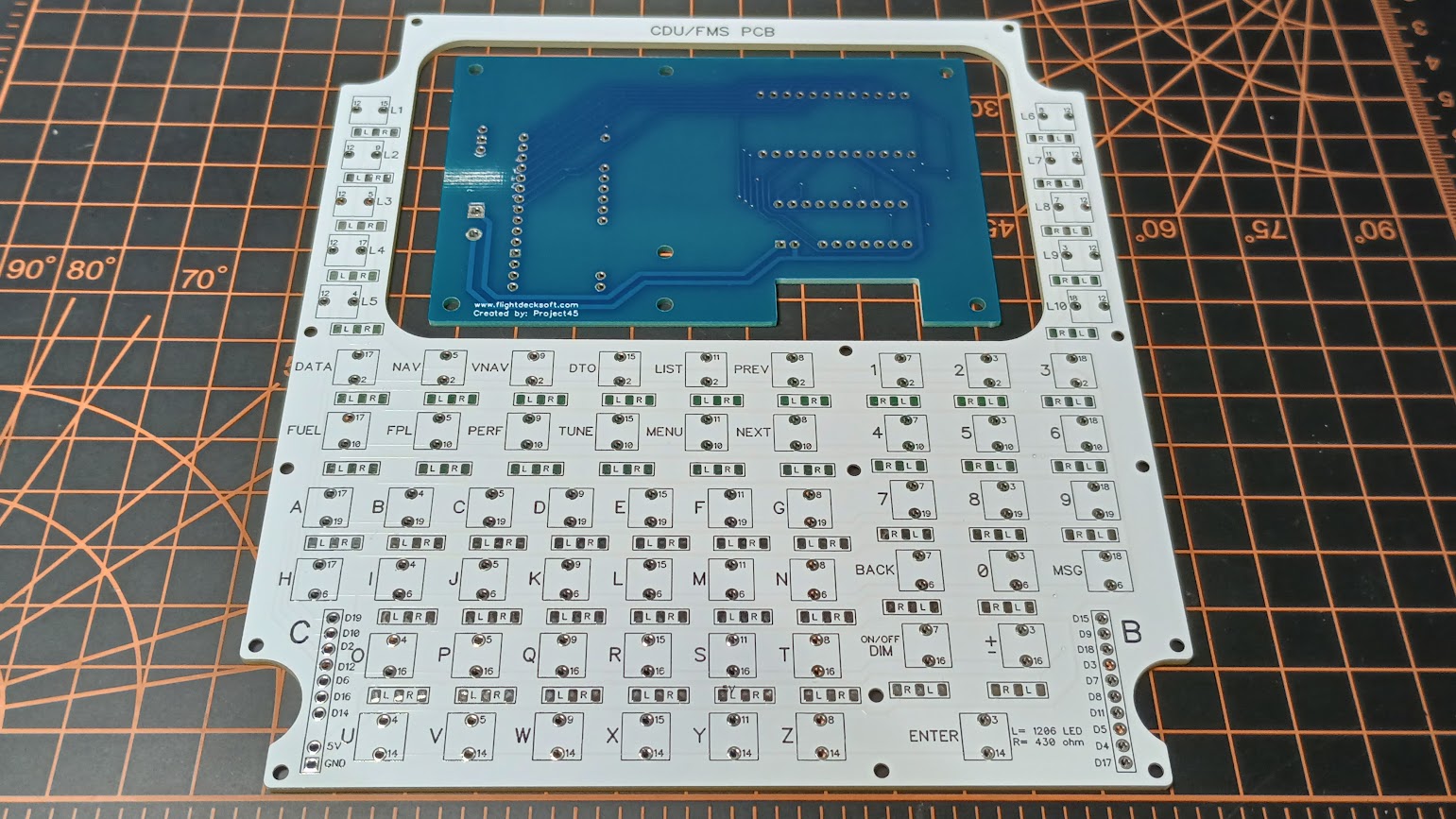

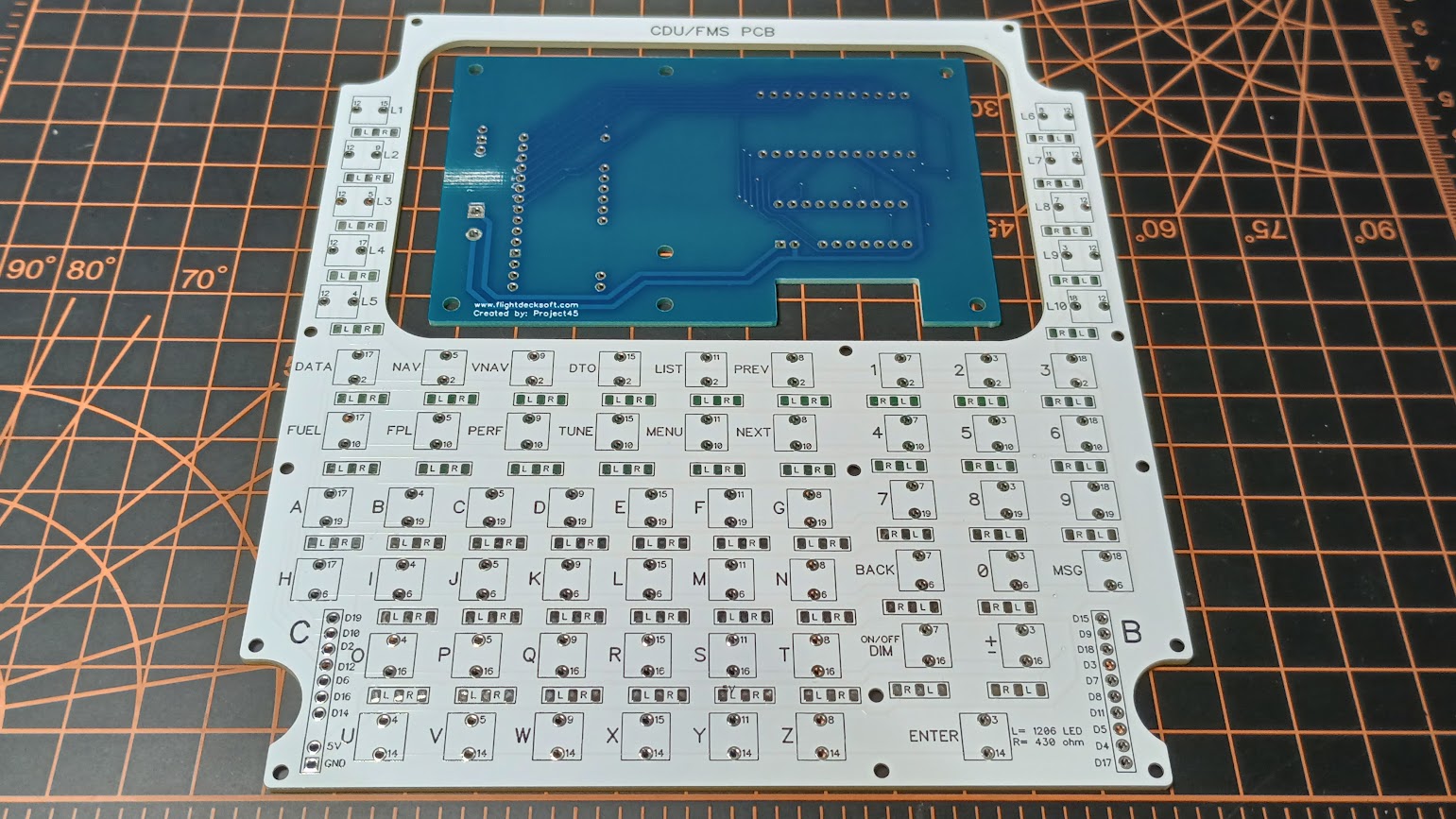

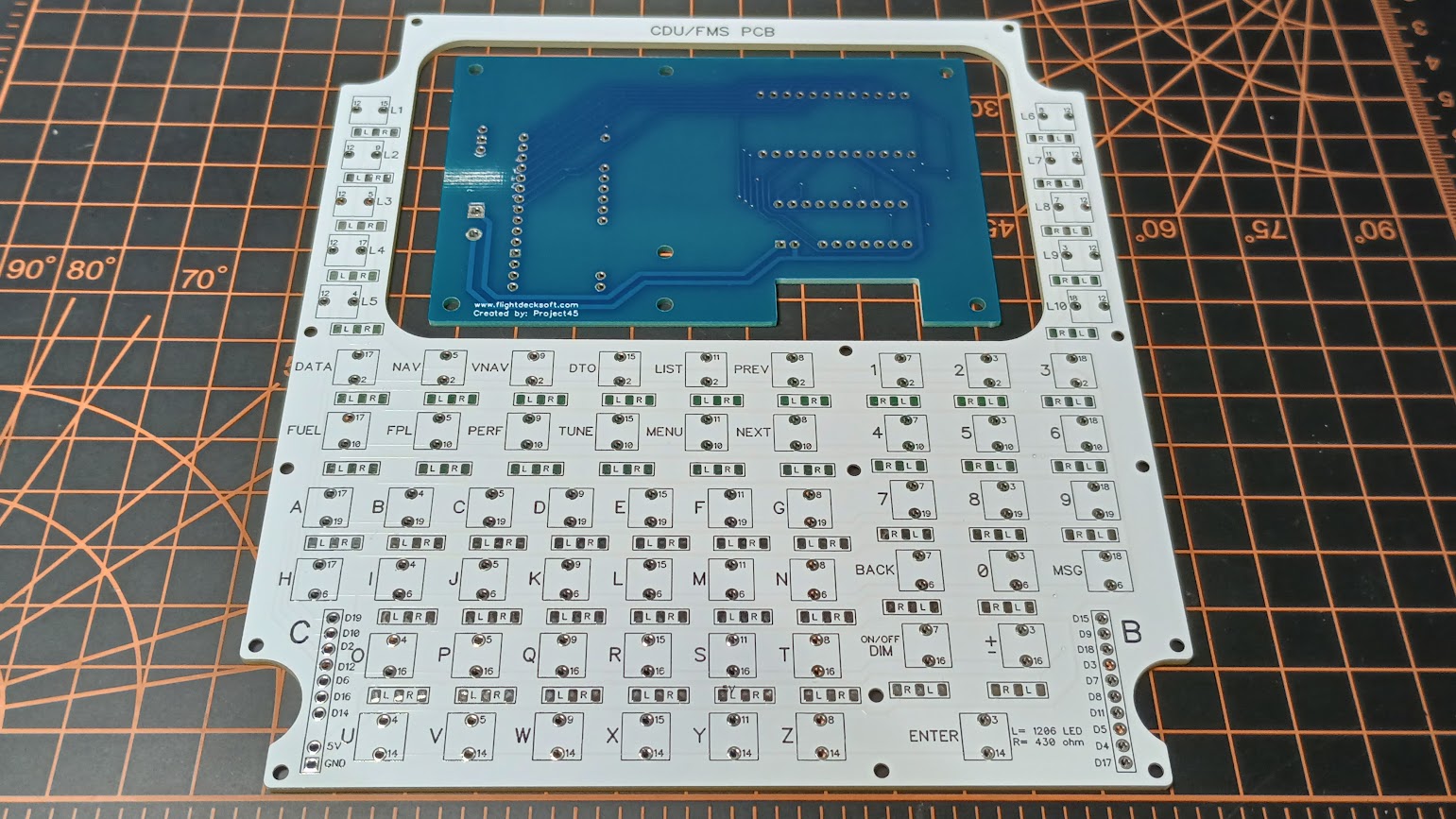

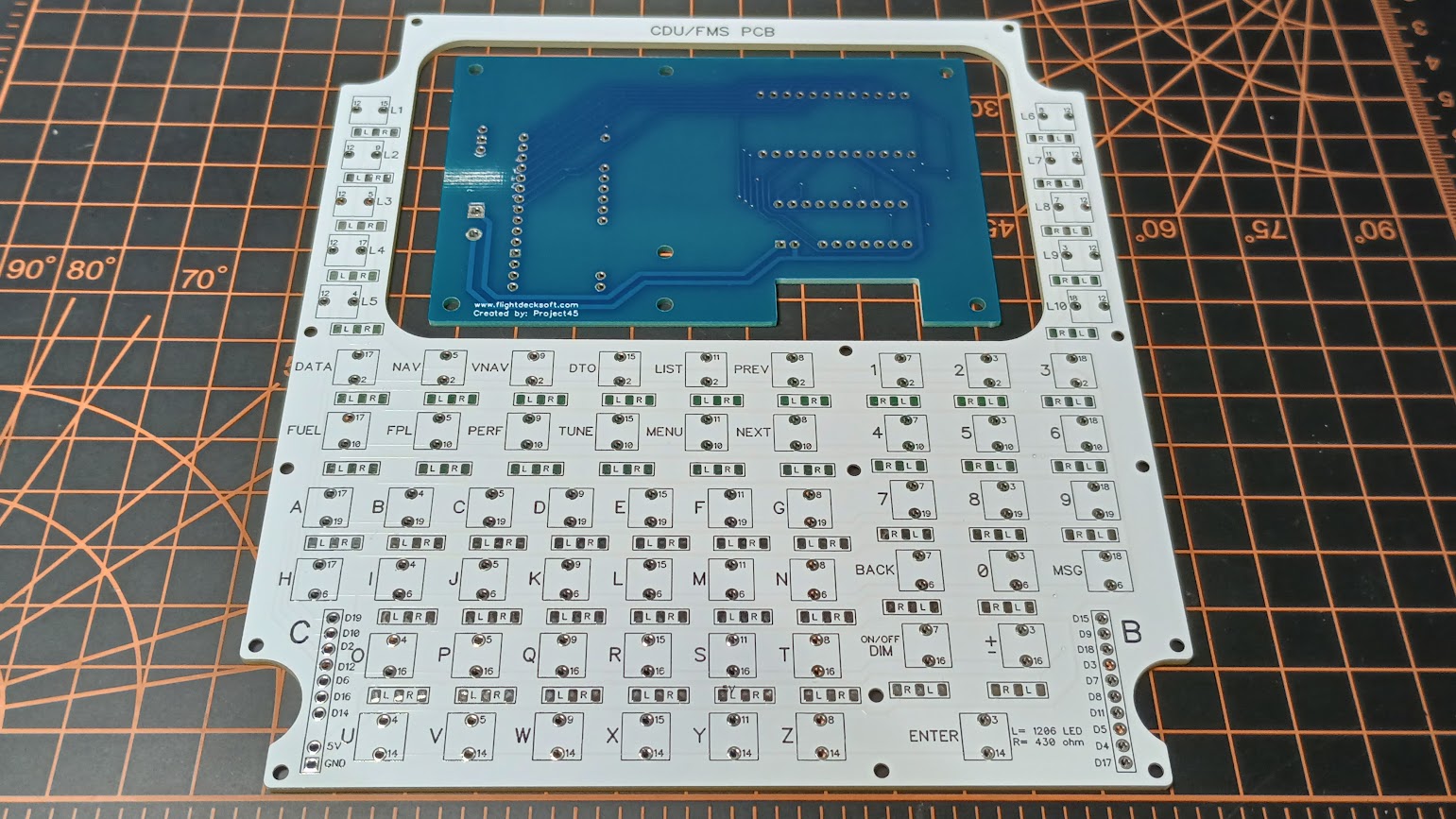

I used KiCad to create PCB's, which is great for this purpose!!

And just now received my first trials.

Very good quality as far as i can judge now.

Minimum order is 5 pcs, but that is ok

I used KiCad to create PCB's, which is great for this purpose!!

And just now received my first trials.

Very good quality as far as i can judge now.

Minimum order is 5 pcs, but that is ok

I am also reworking most of my PCB's to the manufactured PCB's

(at least the ones I can change without tearing down my sim ) 🙂

I am also reworking most of my PCB's to the manufactured PCB's

(at least the ones I can change without tearing down my sim ) 🙂

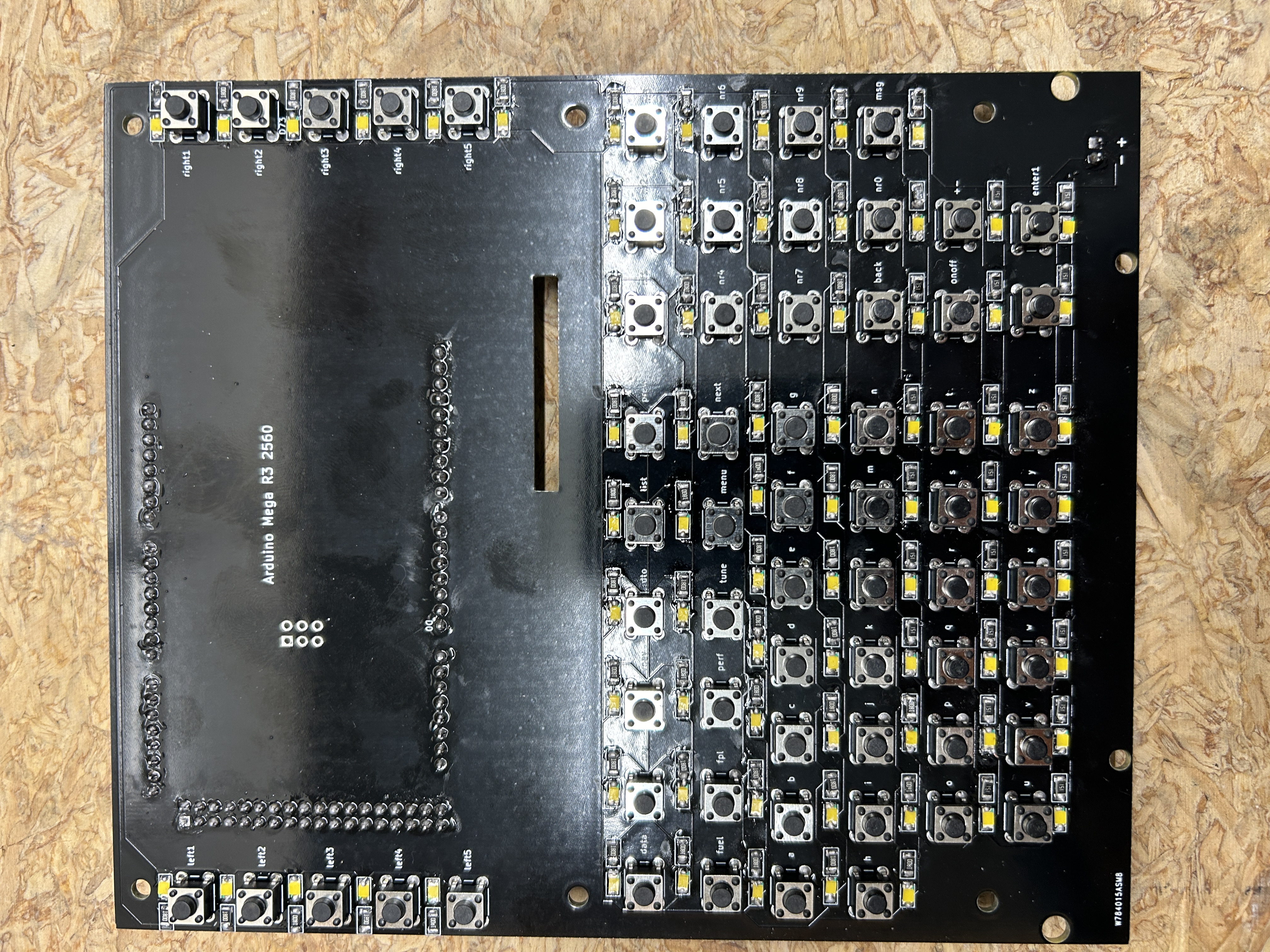

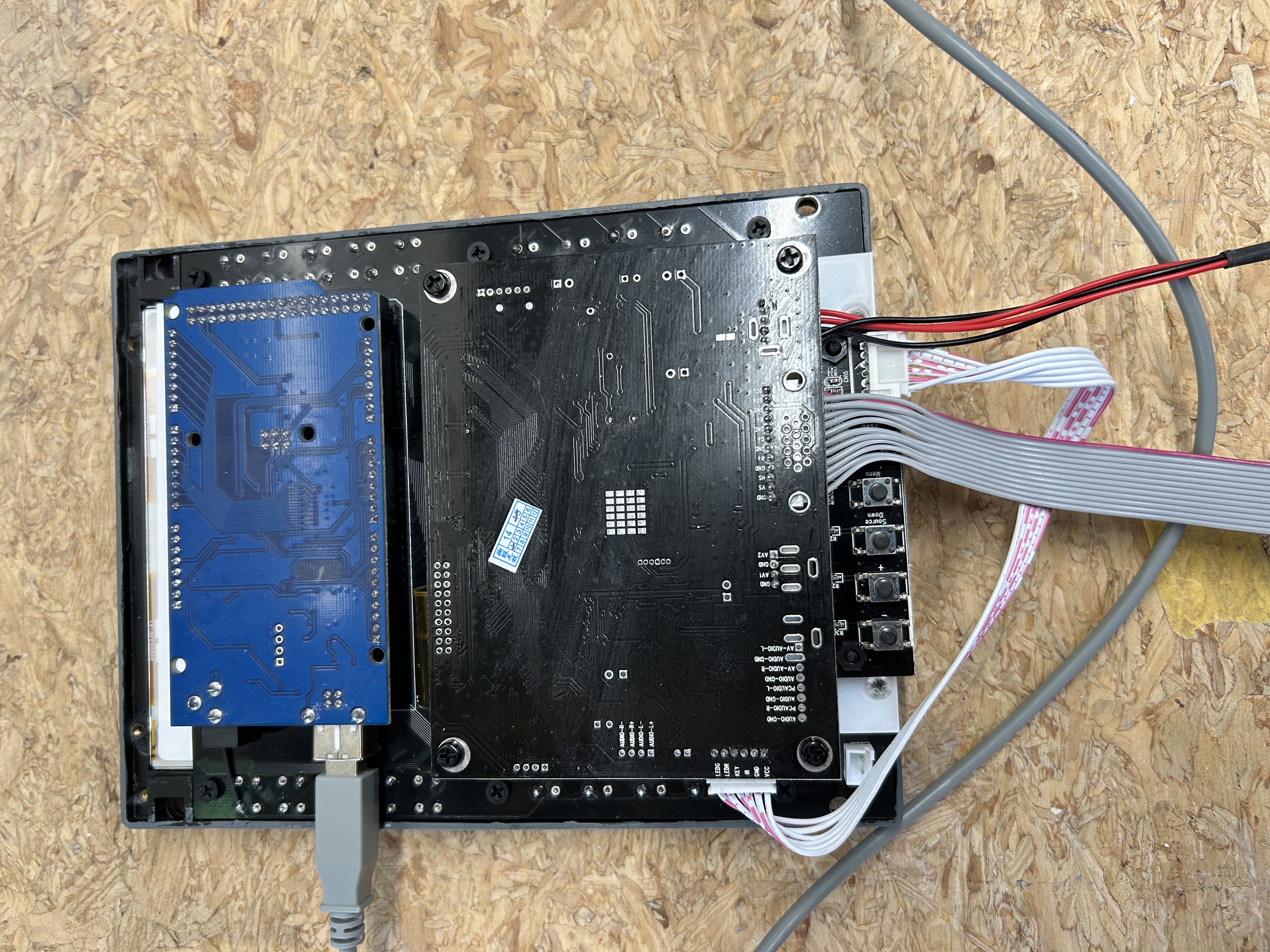

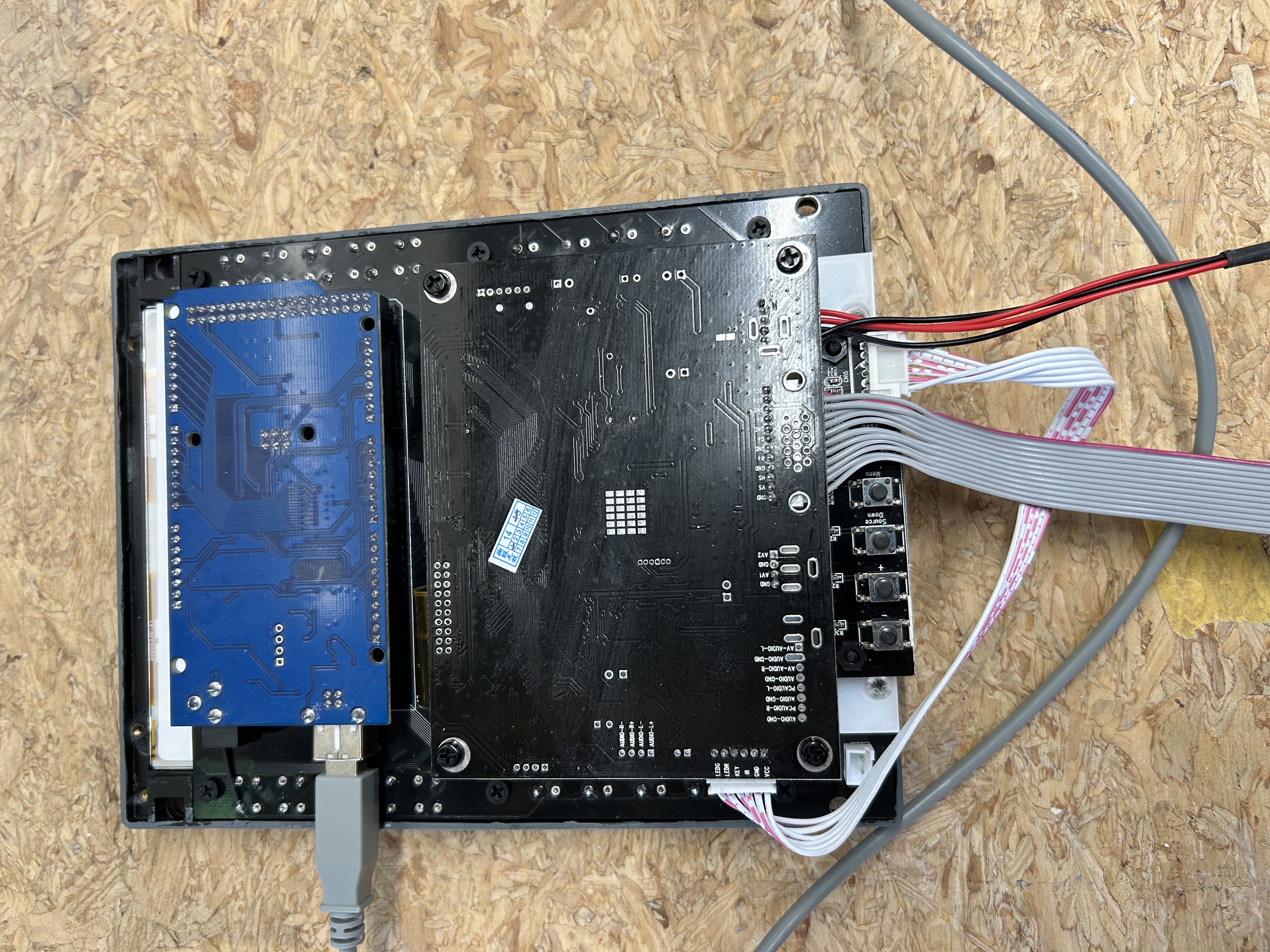

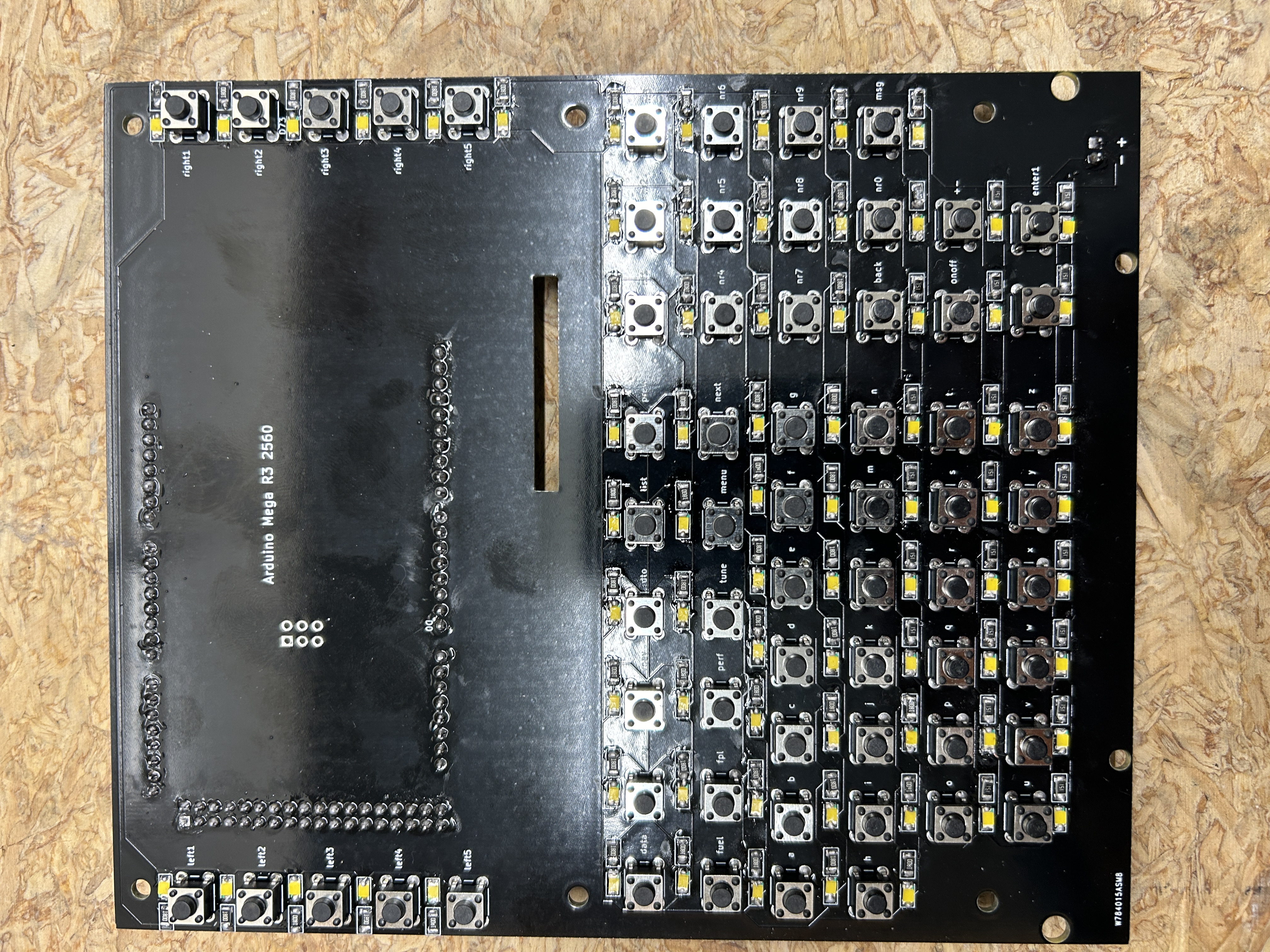

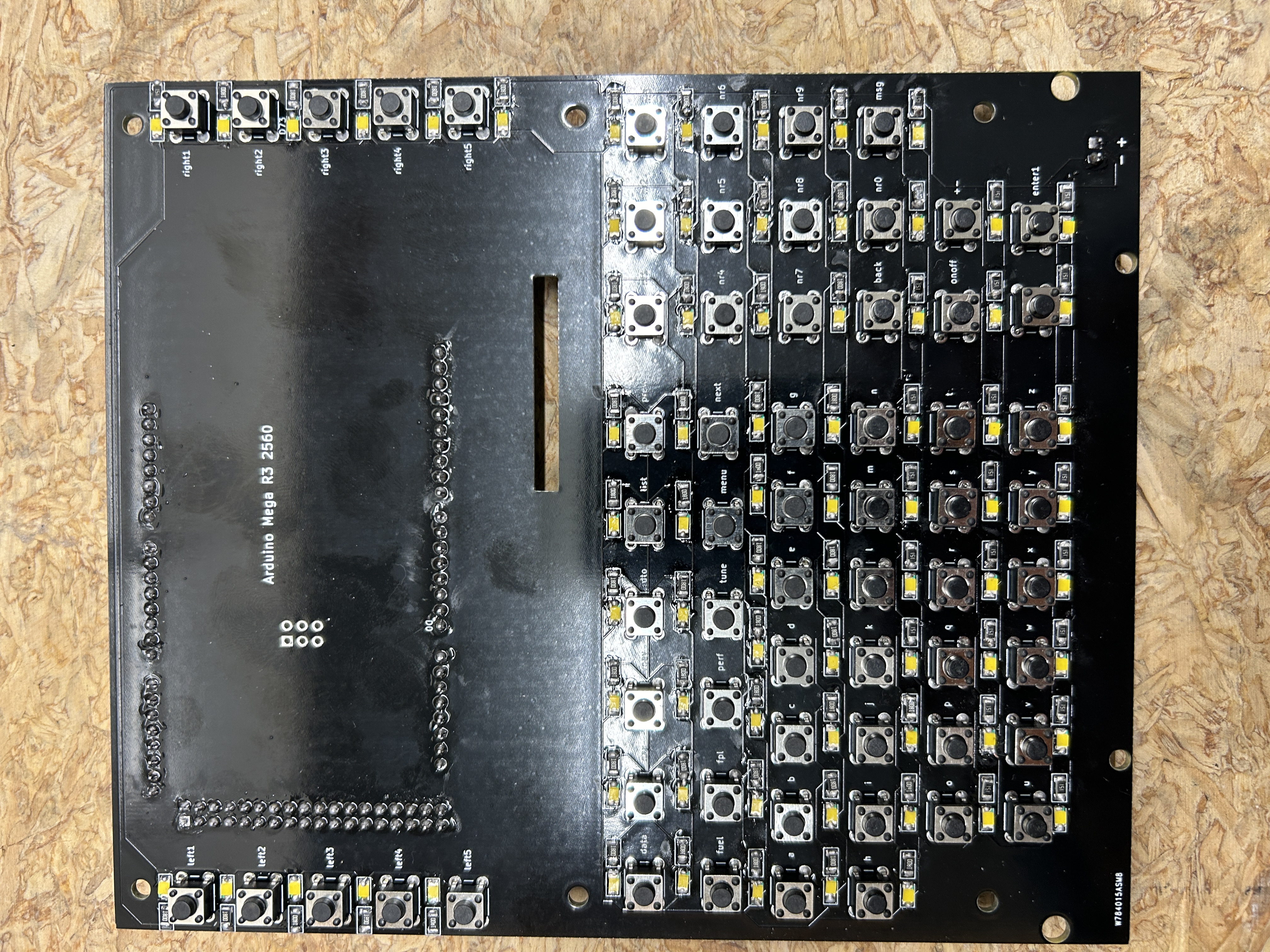

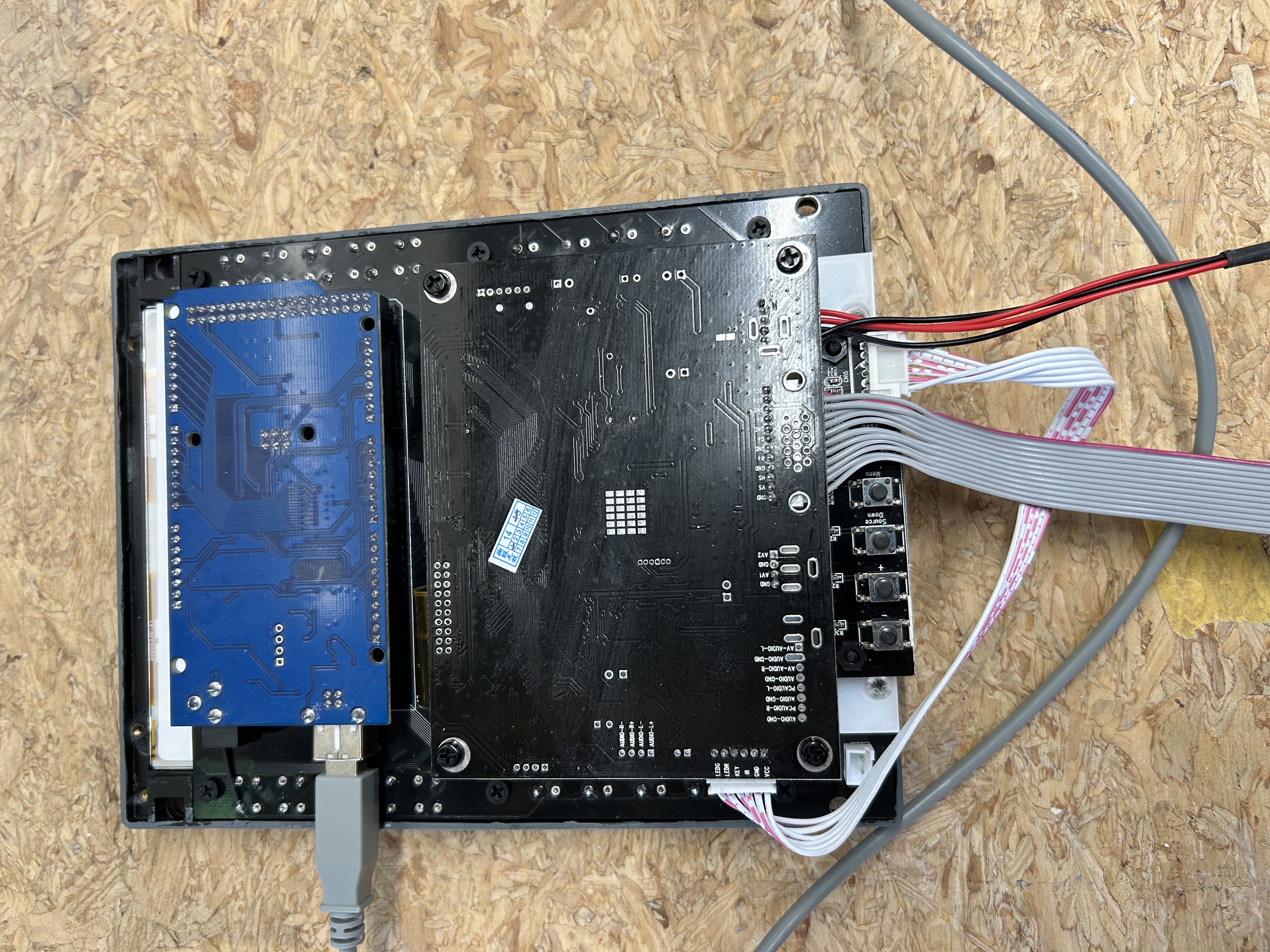

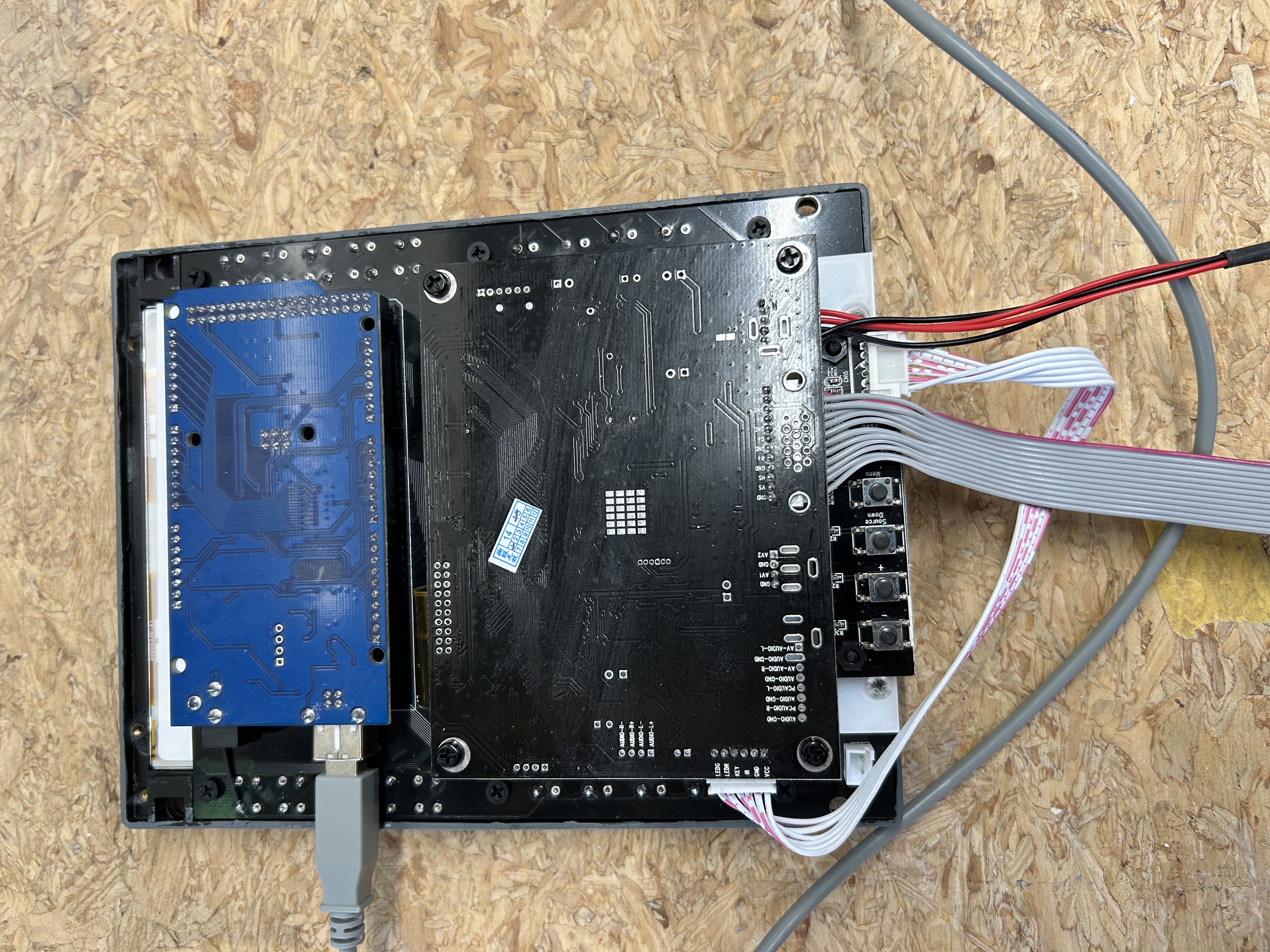

So i made a V2 version where an Arduino Mega is connected to the PCB.

This prevents wiring issues .

So after some stupid design faults, like putting the hole for the flat cable of the lcd at the wrong position, this one seems to be ok... almost.

I forgot the connect the gnd net of the switches to the gnd pin of the Arduino .....

The KiCAD DRC check does not check this offcourse.

So for now i soldered a wire from the gnd net to the Arduino gnd pin.

Not so pretty , but you can't see it and design is changed if i ever order another one. 🙂

So i made a V2 version where an Arduino Mega is connected to the PCB.

This prevents wiring issues .

So after some stupid design faults, like putting the hole for the flat cable of the lcd at the wrong position, this one seems to be ok... almost.

I forgot the connect the gnd net of the switches to the gnd pin of the Arduino .....

The KiCAD DRC check does not check this offcourse.

So for now i soldered a wire from the gnd net to the Arduino gnd pin.

Not so pretty , but you can't see it and design is changed if i ever order another one. 🙂

I found it is easier to control my radio's (espcially the ILS frequencies) with my FMS, which reads NavData Airac info.

I found it is easier to control my radio's (espcially the ILS frequencies) with my FMS, which reads NavData Airac info.

this is easier.

this is easier.

Forum NavigationRoel's Learjet 45 simulator

#171 · December 21, 2023, 5:15 pm#172 · March 20, 2024, 11:02 am#173 · March 20, 2024, 12:48 pm#174 · March 21, 2024, 12:36 am#175 · April 3, 2024, 3:46 am#176 · August 5, 2024, 1:28 pm#177 · August 5, 2024, 9:54 pm#178 · September 13, 2024, 6:00 am#179 · September 13, 2024, 8:15 am#180 · September 13, 2024, 9:35 am

2017-10-10