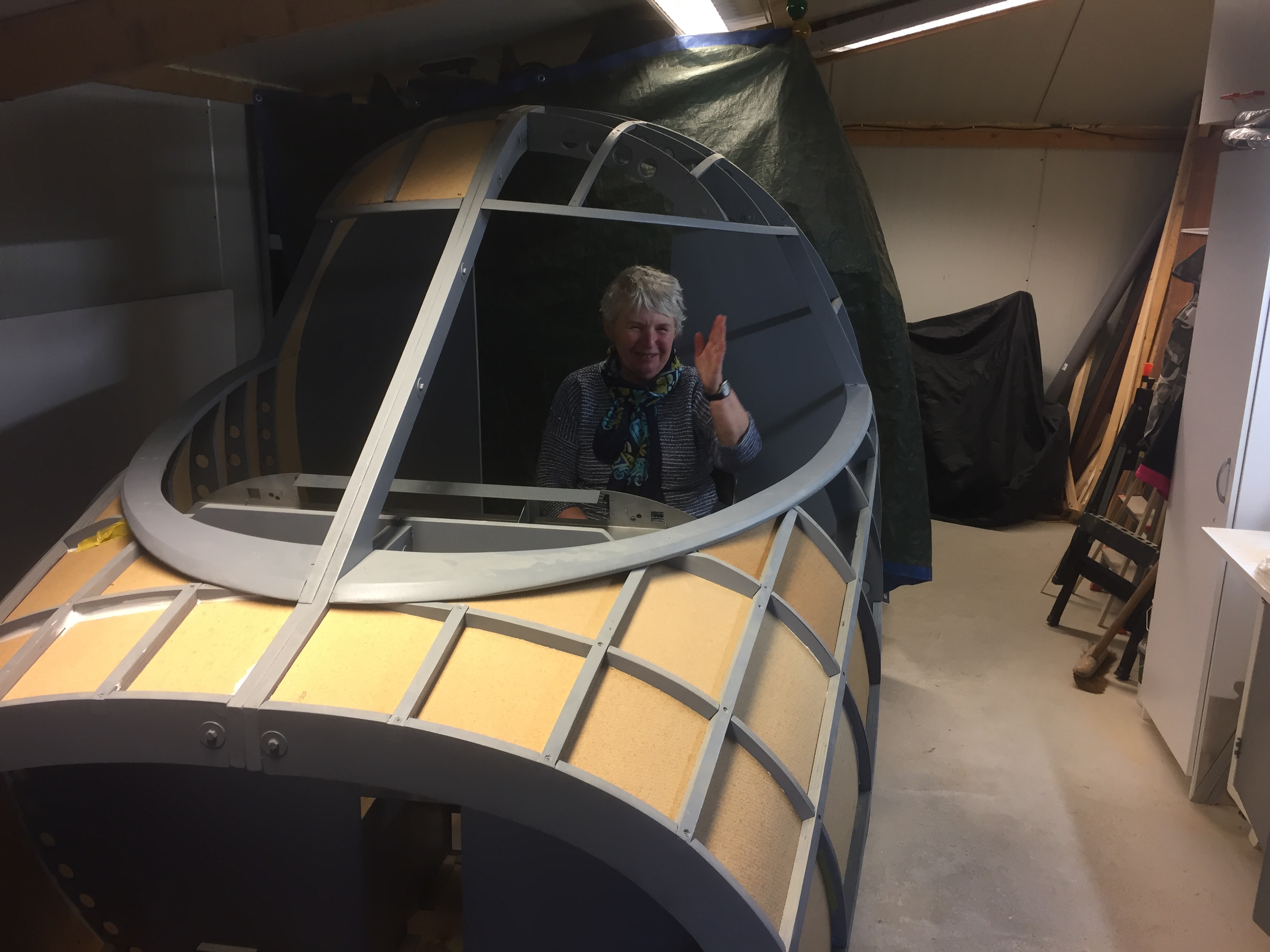

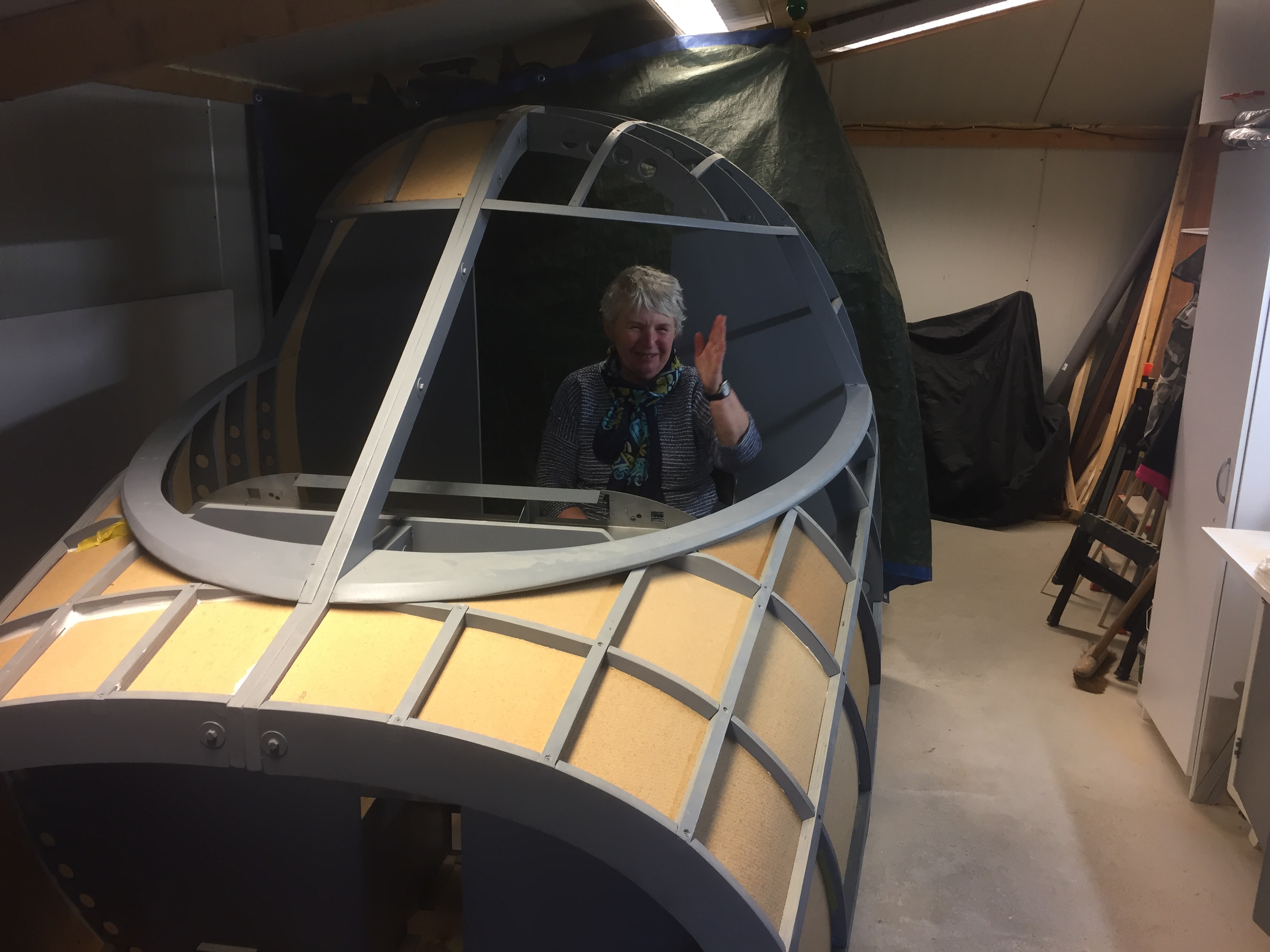

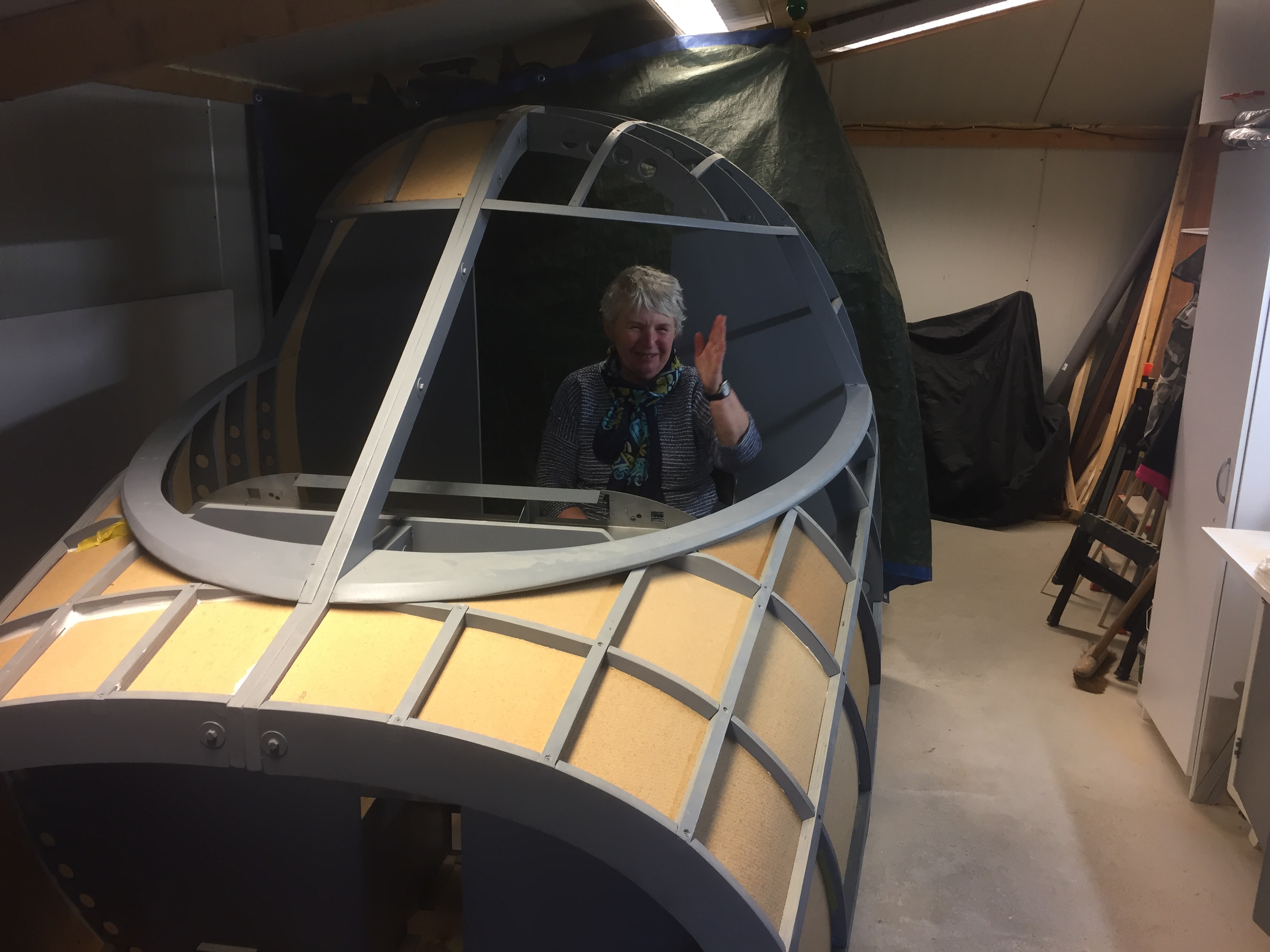

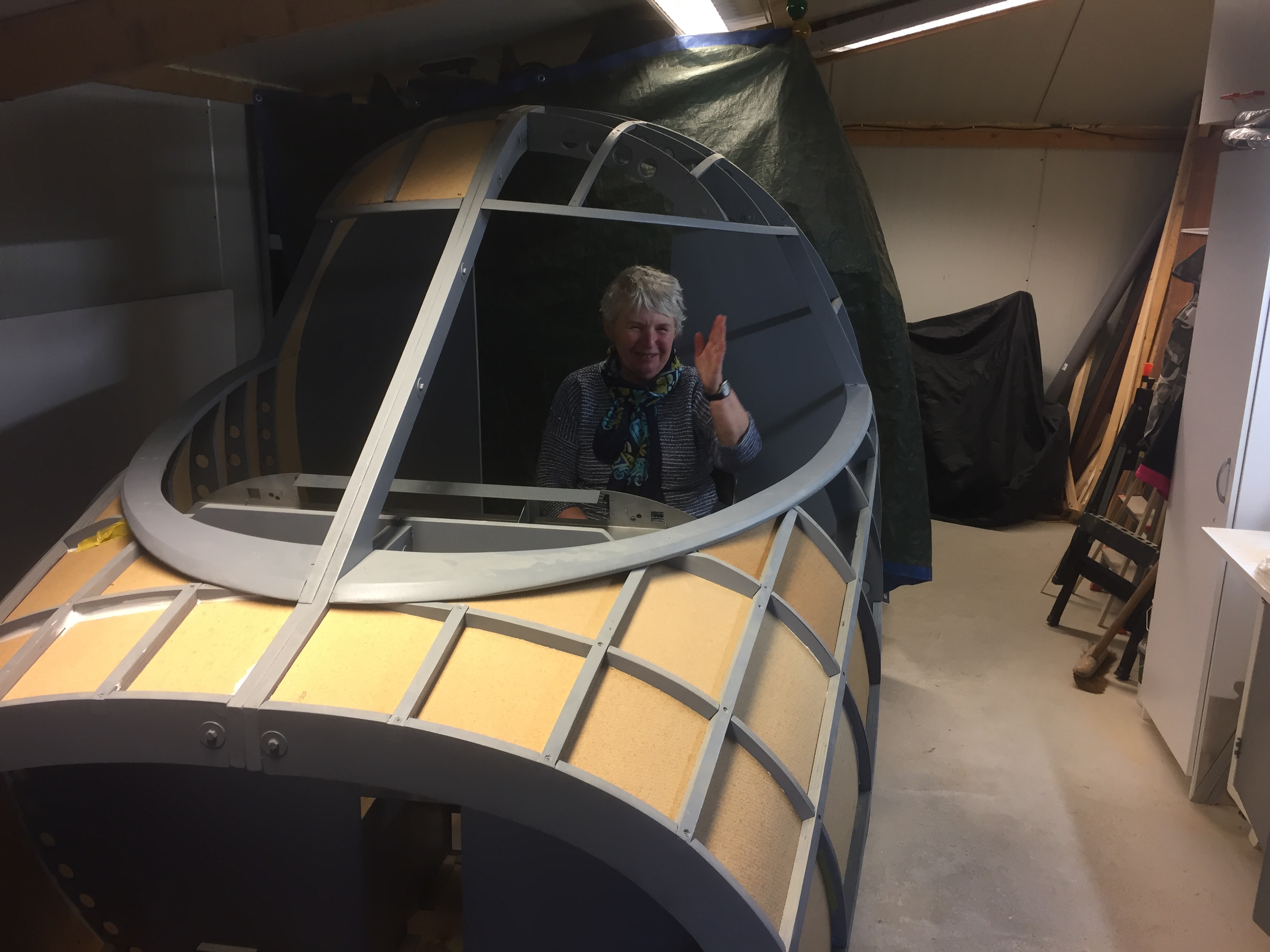

I am half way finished with painting . Painting took me more time then i realized, 1 week for 1 side I first tried a spray can with green paint, but wasn't pleased with the result. I know ALL airplanes are green on the inside (don't know why that is actually). But i saw a shell in here which was grey , and i just liked that more. I also use grey primer and apply it with a roller instead of spraying, it's cheaper and the result is better i think. So it is gonna get grey… 🙂 I am half way finished with painting . Painting took me more time then i realized, 1 week for 1 side I first tried a spray can with green paint, but wasn't pleased with the result. I know ALL airplanes are green on the inside (don't know why that is actually). But i saw a shell in here which was grey , and i just liked that more. I also use grey primer and apply it with a roller instead of spraying, it's cheaper and the result is better i think. So it is gonna get grey… 🙂 I was looking for a replacement for the aluminum roofing which Ron used in the side wall. This is not available in the Netherlands, and aluminum sheet is expensive. So... I used hardboard, don’t know if this the same name in the US. But its flexible and easy to fit. Also it is very cheap. I made a trial piece and it looks good. I was looking for a replacement for the aluminum roofing which Ron used in the side wall. This is not available in the Netherlands, and aluminum sheet is expensive. So... I used hardboard, don’t know if this the same name in the US. But its flexible and easy to fit. Also it is very cheap. I made a trial piece and it looks good. Hi Roel, Your Lear45 project is looking fantastic! Keep up the great work! As for the board replacement, it looks like a form of Masonite. What we have here in the US is a little more darker brown than what you have. The basic idea for whatever you use is to find a suitable material that is flexible and will act as a backer to keep the foam material in place and from going anywhere it wants to go on the inside of the shell. This material you are using is probably heavier than aluminum but the good thing for us all is weight is really not a factor. Our projects are not real aircraft therefor we have some flexibility in the types of materials we can use. Whatever works well and looks good! By the way, as for your photos being posted sideways, the only way to correct this is to take the photos in landscape to begin with. The forum software does not support flipping a photo from portrait to landscape even if you flip it in a third party software program. Strange I know but this is one of those little things we have to learn to live with and work around. Hi Roel, Your Lear45 project is looking fantastic! Keep up the great work! As for the board replacement, it looks like a form of Masonite. What we have here in the US is a little more darker brown than what you have. The basic idea for whatever you use is to find a suitable material that is flexible and will act as a backer to keep the foam material in place and from going anywhere it wants to go on the inside of the shell. This material you are using is probably heavier than aluminum but the good thing for us all is weight is really not a factor. Our projects are not real aircraft therefor we have some flexibility in the types of materials we can use. Whatever works well and looks good! By the way, as for your photos being posted sideways, the only way to correct this is to take the photos in landscape to begin with. The forum software does not support flipping a photo from portrait to landscape even if you flip it in a third party software program. Strange I know but this is one of those little things we have to learn to live with and work around. Hello Roel, You are making good progress with the shell! Good to see another project taking off and it is looking great! I think most of us have had to make small changes to our builds because we could not find certain materials where we live. Hello Roel, You are making good progress with the shell! Good to see another project taking off and it is looking great! I think most of us have had to make small changes to our builds because we could not find certain materials where we live. I have instead of using aluminium , used hardboard material to close the shell. Mother in law allready is flying the sim! 🙂 I have instead of using aluminium , used hardboard material to close the shell. Mother in law allready is flying the sim! 🙂 Looks like you are progressing very well with the build! Nice to see another full shell taking shape in our community of builders! Looks like you are progressing very well with the build! Nice to see another full shell taking shape in our community of builders! Hi Roel, Looking really good! I have always said that where there is a will there is a way. Your definitely have the will! Using this paper material might even be a better idea than the aluminum too. At the very least it is another option for other builders to follow. Great work and keep the updates coming! Hi Roel, Looking really good! I have always said that where there is a will there is a way. Your definitely have the will! Using this paper material might even be a better idea than the aluminum too. At the very least it is another option for other builders to follow. Great work and keep the updates coming! I have made some progress, the shell is all painted and foam is applied. I applied the foam, which went pretty well, there are quite a few holes now that i am shaving it all, but that can be fixed also. One side almost done shaving, next side tomorow 🙂 Shell, all painted grey. Foam applied Still some shaving to do, but i will get there . I have made some progress, the shell is all painted and foam is applied. I applied the foam, which went pretty well, there are quite a few holes now that i am shaving it all, but that can be fixed also. One side almost done shaving, next side tomorow 🙂 Shell, all painted grey. Foam applied Still some shaving to do, but i will get there . Hey Roel, Looking really good! You say you are covered in dust now. Wait until you start sanding the fiberglass! If you don't have an orbital sander, you need to get one. It works like magic finding the high spots and smoothing everything out. All this hard work will pay off big time in the end. It will feel like you have an aircraft in your hangar to work on and eventually will be flying! Hey Roel, Looking really good! You say you are covered in dust now. Wait until you start sanding the fiberglass! If you don't have an orbital sander, you need to get one. It works like magic finding the high spots and smoothing everything out. All this hard work will pay off big time in the end. It will feel like you have an aircraft in your hangar to work on and eventually will be flying! Pfff yeah, the fiberglass is also pretty nasty stuff! Yes I do have a good orbital sander, connected to a vacuum cleaner now, and that is a good thing. The hose was accidentally removed from the sander and in no time one side of my room was covered in white dust. 🤓 I also invested in a good gas mask, also worth the money! I am going to do some more sanding 😉 Pfff yeah, the fiberglass is also pretty nasty stuff! Yes I do have a good orbital sander, connected to a vacuum cleaner now, and that is a good thing. The hose was accidentally removed from the sander and in no time one side of my room was covered in white dust. 🤓 I also invested in a good gas mask, also worth the money! I am going to do some more sanding 😉 Roel's Learjet 45 simulator

![]()

It is easy to use, cheap and bends well to the curves of the shell.

Because it is something like paper, i am going to paint it both sides to prevent moisture getting into the material.

I have to to some caulking but then this phase also is finished!

It is easy to use, cheap and bends well to the curves of the shell.

Because it is something like paper, i am going to paint it both sides to prevent moisture getting into the material.

I have to to some caulking but then this phase also is finished!

I hade an issue with separating the shell parts, i painted over the middel parts which are connected by bolts.

So paint got in between these parts and the shell parts were more or less glued to eachother :S

i had to use an thin aluminium strip and a hammer to seperate them, which caused some damage.

But, nothing a bit of bondo can fix !

What a mess shaving the foam is !!

I attach a newly bought vacuum cleaner to my shaving machine but still i am all covered in powder.

I hade an issue with separating the shell parts, i painted over the middel parts which are connected by bolts.

So paint got in between these parts and the shell parts were more or less glued to eachother :S

i had to use an thin aluminium strip and a hammer to seperate them, which caused some damage.

But, nothing a bit of bondo can fix !

What a mess shaving the foam is !!

I attach a newly bought vacuum cleaner to my shaving machine but still i am all covered in powder.

Forum NavigationRoel's Learjet 45 simulator

#21 · February 23, 2019, 2:02 pm#22 · February 24, 2019, 1:44 pm#23 · February 24, 2019, 4:51 pmRoel has reacted to this post.Roel#24 · February 24, 2019, 9:09 pmRoel has reacted to this post.Roel#25 · March 21, 2019, 5:20 am#26 · March 21, 2019, 5:37 pmRoel has reacted to this post.Roel#27 · March 22, 2019, 1:51 pm#28 · April 2, 2019, 2:51 pm#29 · April 2, 2019, 8:49 pmRoel has reacted to this post.Roel#30 · April 3, 2019, 4:16 pm

2017-10-10