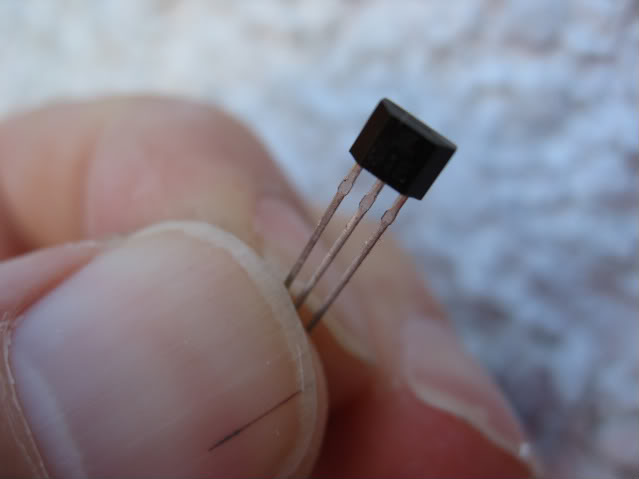

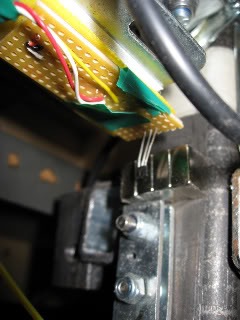

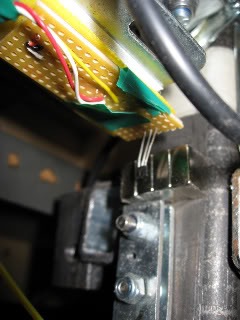

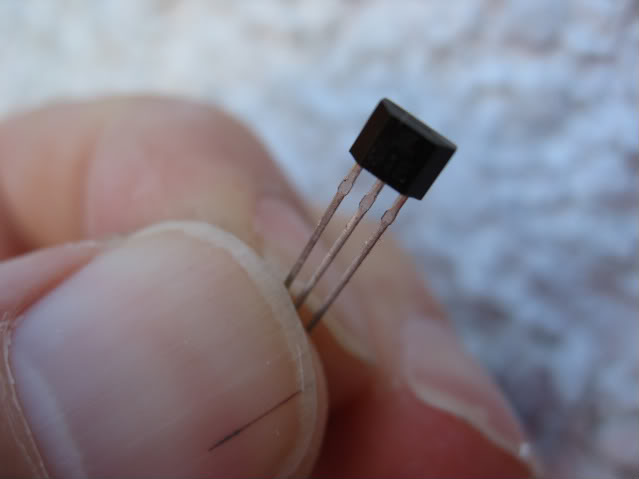

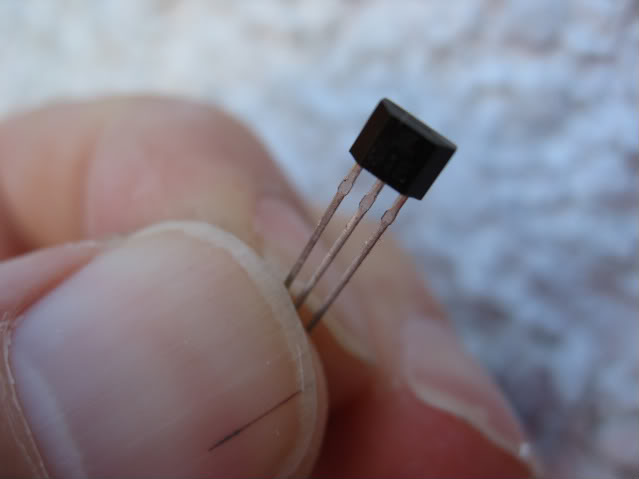

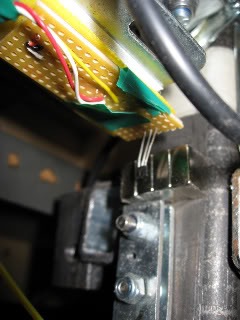

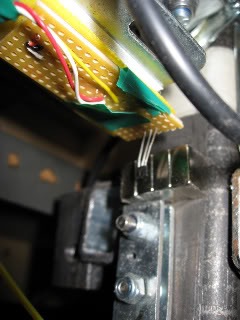

(Original thread started on 05-22-10 by Douglas D.) As part of my build I decided to use Hall Effect sensors rather than pots on my yoke. I must first say that I am no expert in this subject, but have got my yoke system to work using Hall Effect sensors and found them to be very effective. I have included links to where I got most of my information and to people who have far more knowledge on the subject than me. If you decide to you this method please be aware of the safety information when using rare earth magnets. They are very powerful and will attach to or attract metal objects from some distance at speed. There are a number of advantages to Hall Effect sensors in that as they do not work with a resistive carbon track which can wear and cause control spikes, they are smooth in operation throughout their range and are very easy to interface, no mechanical linkage which means no backlash issues. They also are cheap to buy costing only £1.50 GBP: A Hall Effect sensor looks very much like transistor in a small plastic package with three legs. One is positive 5 volts, one is ground and the other is the analogue output: (picture from Leo Bodnars website) The voltage of the analogue output is determined by the proximity of a magnet to the sensor or more so the rotation of the magnet at the face of the sensor. (in the picture above it is described as an `input` this is that it is connected to the `input`on Leos board.) When the positioning of the magnet is correct in the null position the output should be 2.5 volts. Interfacing was a straight forward replacement for the pots on my CH yoke interface. The sensor is mounted on a small servo board which is wired to the interface: This is mounted in a fixed position in my case on an aluminum bar on the top of the column. The rare earth magnet is attached to the yoke at the end of the shaft so that it rotates around the center line of the yoke. I mounted a strip of metal on the end so that the magnet just sticks to it. This also helps in that you can adjust the position by sliding the magnet to get the correct output.The magnet is so strong that when it is in position it will not move. This direct connection ensures that the slightest movement of the yoke can be picked up by the sensor: The pitch sensor is mounted the same way, in my case the columns are made of metal ( the black plastic pipe on my set up is just for effect) so it was just a case of attaching the magnet and positioning the sensor: There is no reason that other parts of the sim cannot use these sensors with just a little imagination on how to mount them. As I said at the start I am no expert in this subject but more detailed technical information can be found in the links below: http://www.mycockpit.org/forums/content.php/88-Hall-Effects-Sensors-to-make-a-joystick http://www.mycockpit.org/forums/content.php/184-The-Mechanics-of-Using-Rotary-Pots-and-Hall-Position-Sensors http://powermagnetstore.com/index.html (Posted by Ron Rollo on 05-22-10) Thank you Douglas for this insight. I was just thinking that we could also use these for Tom's rudder pedal set. The pot that we currently have mounted to it only collects about 70% of the movement of the pedals as we push them back and forth. It is a mechanical limit that is causing this issue. I do believe that this hall sensor idea may be the answer I am looking for. We could simply mount the sensor at the pivot point to capture 100% of the movement of the pedals! Easy and no mechanical mess. (Posted by Douglas Dick on 05-23-10) I never thought about the rudder pedals, (I have not got that far yet, just the CH set on the floor) the small size and lack of mechanical interface make this an ideal solution. Like a pot the range of operation of a hall sensor will depend on how it is set up in the range of the magnetic field. As Mike Powel says though "whatever you use you should try and get 100% of the range," but 70% of a hall sensor especially with a high resolution interface like the Leo Bodnar 12 bit board, should give a better control than 70% of a standard pot. As I said there are some very detailed articles available that explain in much more detail the ups and downs of this method. (Posted be Ron Rollo on 06-01-10) Have you been using your Hall effect sensors with the rare earth magnets? I have been doing some reading about the dangers to people and equipment that the magnets my bring. I read this from one of your recommended sites: "They can also damage televisions, VCRs, computer monitors and other CRT displays. Never place neodymium magnets near electronic appliances." The reason I bring this up is because the sensor that we will be using in the column system for the roll axis will be mounted at the rear of the column head, which is just inches from the LCD screens used for the DU's. If we push the yokes forward, even closer. The warning specifically says CRT monitors, I was just wondering if you have had an opportunity to use yours with your LCD screens operational. If so, do you notice any issues? I am going to order a handful and experiment with them myself a little. (Posted by Douglas Dick on 06-01-10) I have had the rare earth magnet on the back of the yoke for about three weeks now and have not seen any problems with the screen. From what I can remember CRTs use an electron gun to fire an electron at the screen, then a magnetic field to divert it to a point on the screen. Any strong magnetic field will interfere with this causing the image to distort. I would also not recommend placing such a magnet near your favorite video as I am sure that it would rearrange the magnetic particles on the tape. As far as I understand (and I would welcome any correction) TFT screens work by each row or column of the display working as single electrical circuit. The pixels are addressed one at a time by row and column addresses. They do not use magnetic fields to control this, so in principal should not be affected. As soon as I fire up the sim I will try pushing the yoke as close to the screen as possible to see if there is any effect. I will also see how close a metal object needs to be to get attracted to the magnet. As I mentioned in my post the use of these magnet dose come with a safety warning but when they are in place they make a great control system. (Original thread started on 05-22-10 by Douglas D.) As part of my build I decided to use Hall Effect sensors rather than pots on my yoke. I must first say that I am no expert in this subject, but have got my yoke system to work using Hall Effect sensors and found them to be very effective. I have included links to where I got most of my information and to people who have far more knowledge on the subject than me. If you decide to you this method please be aware of the safety information when using rare earth magnets. They are very powerful and will attach to or attract metal objects from some distance at speed. There are a number of advantages to Hall Effect sensors in that as they do not work with a resistive carbon track which can wear and cause control spikes, they are smooth in operation throughout their range and are very easy to interface, no mechanical linkage which means no backlash issues. They also are cheap to buy costing only £1.50 GBP: A Hall Effect sensor looks very much like transistor in a small plastic package with three legs. One is positive 5 volts, one is ground and the other is the analogue output: (picture from Leo Bodnars website) The voltage of the analogue output is determined by the proximity of a magnet to the sensor or more so the rotation of the magnet at the face of the sensor. (in the picture above it is described as an `input` this is that it is connected to the `input`on Leos board.) When the positioning of the magnet is correct in the null position the output should be 2.5 volts. Interfacing was a straight forward replacement for the pots on my CH yoke interface. The sensor is mounted on a small servo board which is wired to the interface: This is mounted in a fixed position in my case on an aluminum bar on the top of the column. The rare earth magnet is attached to the yoke at the end of the shaft so that it rotates around the center line of the yoke. I mounted a strip of metal on the end so that the magnet just sticks to it. This also helps in that you can adjust the position by sliding the magnet to get the correct output.The magnet is so strong that when it is in position it will not move. This direct connection ensures that the slightest movement of the yoke can be picked up by the sensor: The pitch sensor is mounted the same way, in my case the columns are made of metal ( the black plastic pipe on my set up is just for effect) so it was just a case of attaching the magnet and positioning the sensor: There is no reason that other parts of the sim cannot use these sensors with just a little imagination on how to mount them. As I said at the start I am no expert in this subject but more detailed technical information can be found in the links below: http://www.mycockpit.org/forums/content.php/88-Hall-Effects-Sensors-to-make-a-joystick http://powermagnetstore.com/index.html (Posted by Ron Rollo on 05-22-10) Thank you Douglas for this insight. I was just thinking that we could also use these for Tom's rudder pedal set. The pot that we currently have mounted to it only collects about 70% of the movement of the pedals as we push them back and forth. It is a mechanical limit that is causing this issue. I do believe that this hall sensor idea may be the answer I am looking for. We could simply mount the sensor at the pivot point to capture 100% of the movement of the pedals! Easy and no mechanical mess. (Posted by Douglas Dick on 05-23-10) I never thought about the rudder pedals, (I have not got that far yet, just the CH set on the floor) the small size and lack of mechanical interface make this an ideal solution. Like a pot the range of operation of a hall sensor will depend on how it is set up in the range of the magnetic field. As Mike Powel says though "whatever you use you should try and get 100% of the range," but 70% of a hall sensor especially with a high resolution interface like the Leo Bodnar 12 bit board, should give a better control than 70% of a standard pot. As I said there are some very detailed articles available that explain in much more detail the ups and downs of this method. (Posted be Ron Rollo on 06-01-10) Have you been using your Hall effect sensors with the rare earth magnets? I have been doing some reading about the dangers to people and equipment that the magnets my bring. I read this from one of your recommended sites: "They can also damage televisions, VCRs, computer monitors and other CRT displays. Never place neodymium magnets near electronic appliances." The reason I bring this up is because the sensor that we will be using in the column system for the roll axis will be mounted at the rear of the column head, which is just inches from the LCD screens used for the DU's. If we push the yokes forward, even closer. The warning specifically says CRT monitors, I was just wondering if you have had an opportunity to use yours with your LCD screens operational. If so, do you notice any issues? I am going to order a handful and experiment with them myself a little. (Posted by Douglas Dick on 06-01-10) I have had the rare earth magnet on the back of the yoke for about three weeks now and have not seen any problems with the screen. From what I can remember CRTs use an electron gun to fire an electron at the screen, then a magnetic field to divert it to a point on the screen. Any strong magnetic field will interfere with this causing the image to distort. I would also not recommend placing such a magnet near your favorite video as I am sure that it would rearrange the magnetic particles on the tape. As far as I understand (and I would welcome any correction) TFT screens work by each row or column of the display working as single electrical circuit. The pixels are addressed one at a time by row and column addresses. They do not use magnetic fields to control this, so in principal should not be affected. As soon as I fire up the sim I will try pushing the yoke as close to the screen as possible to see if there is any effect. I will also see how close a metal object needs to be to get attracted to the magnet. As I mentioned in my post the use of these magnet dose come with a safety warning but when they are in place they make a great control system.Flight Controls using Hall Effect Sensors

![]()

2017-10-10