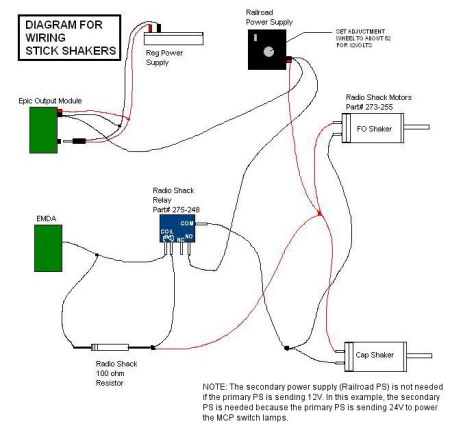

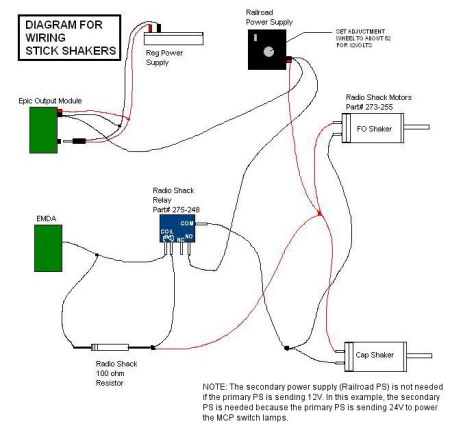

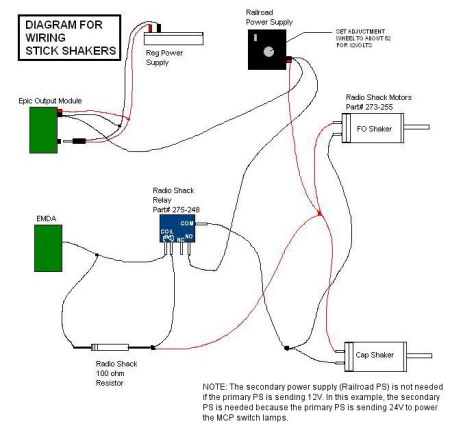

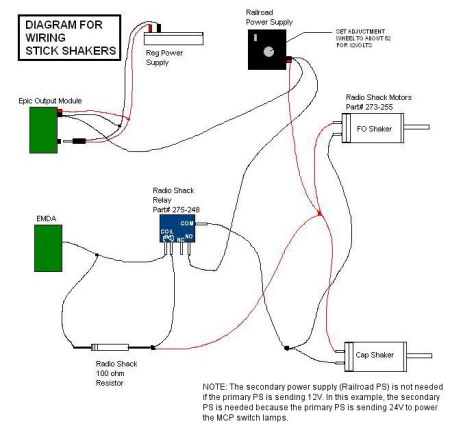

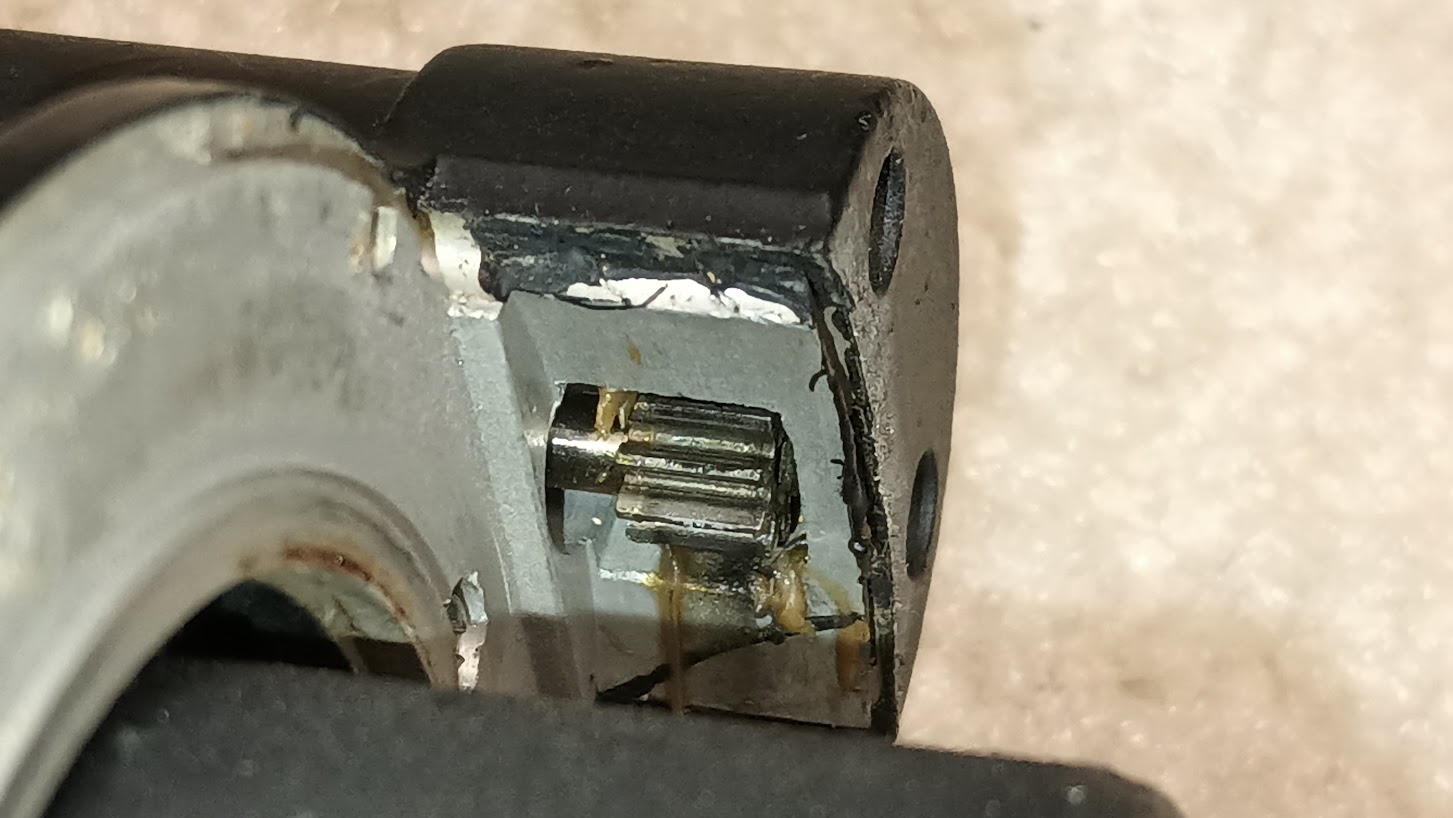

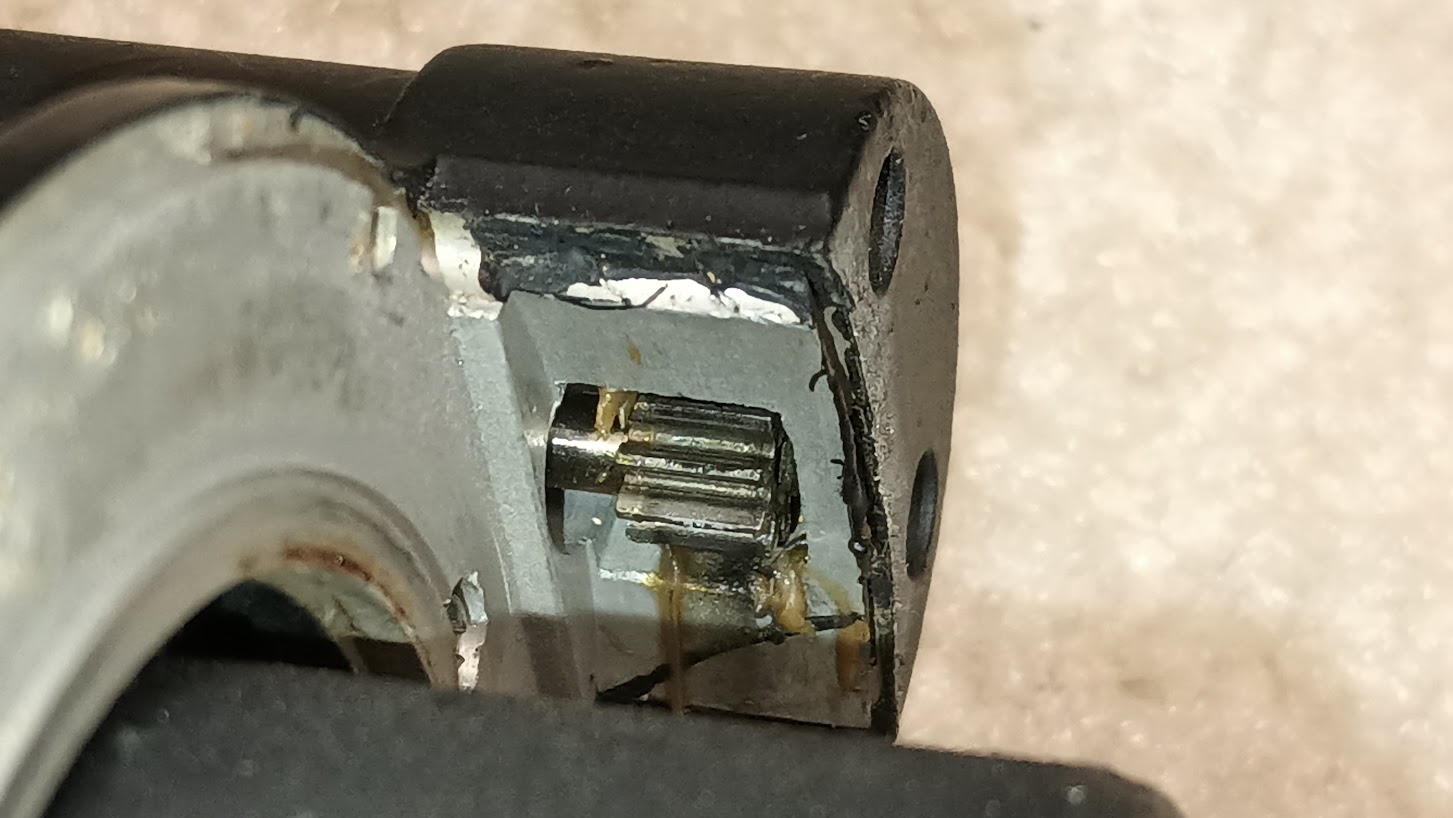

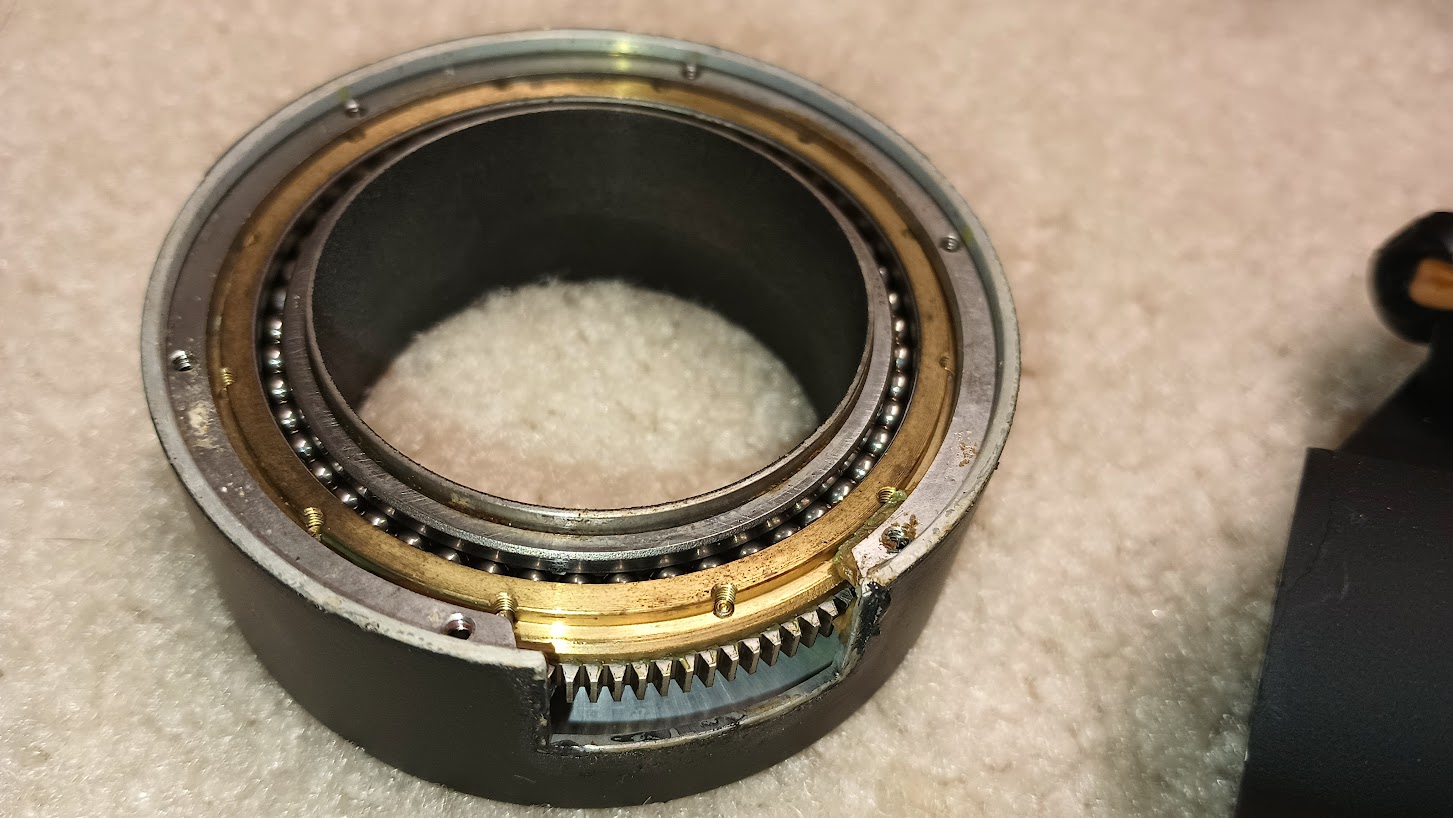

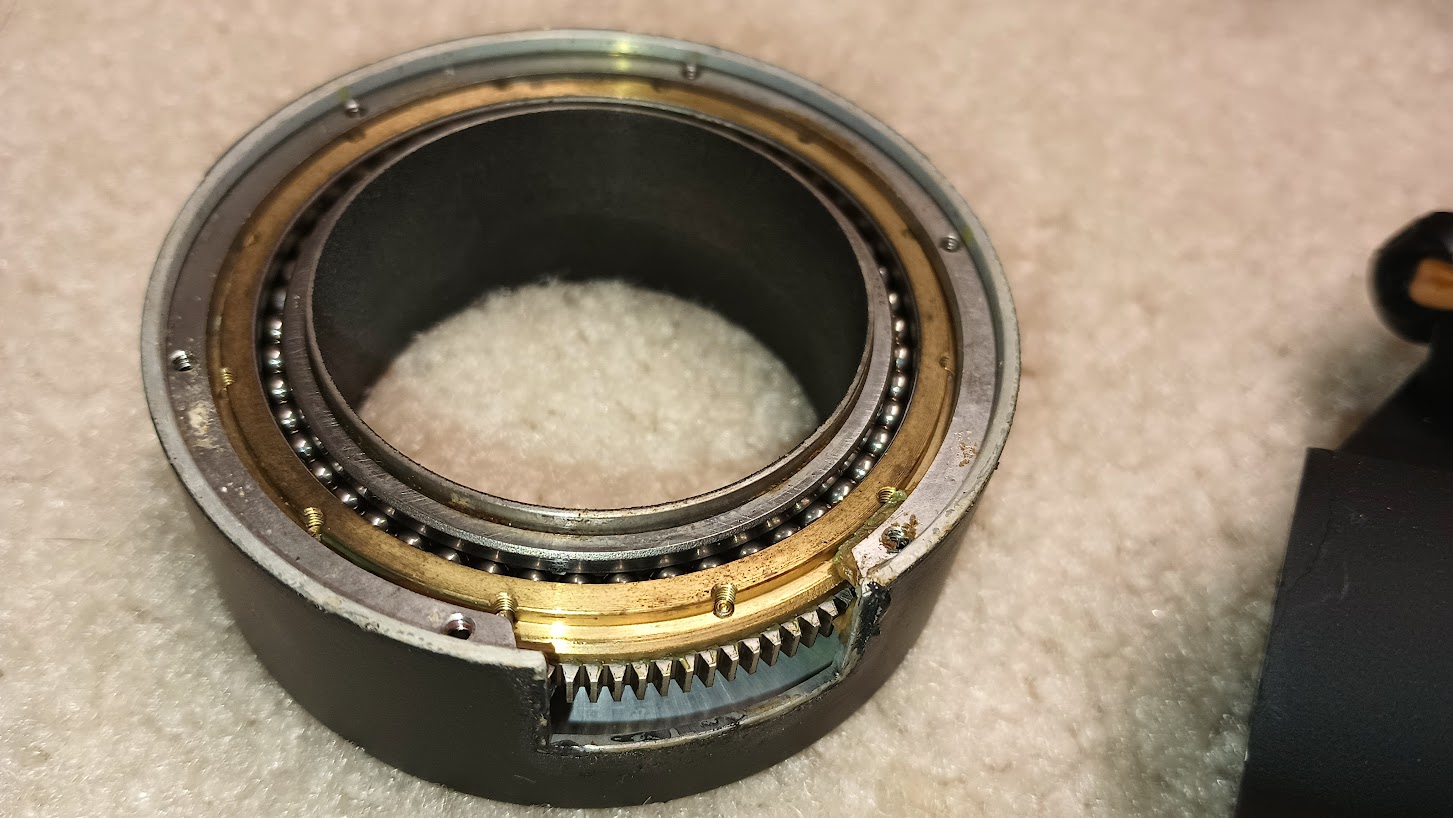

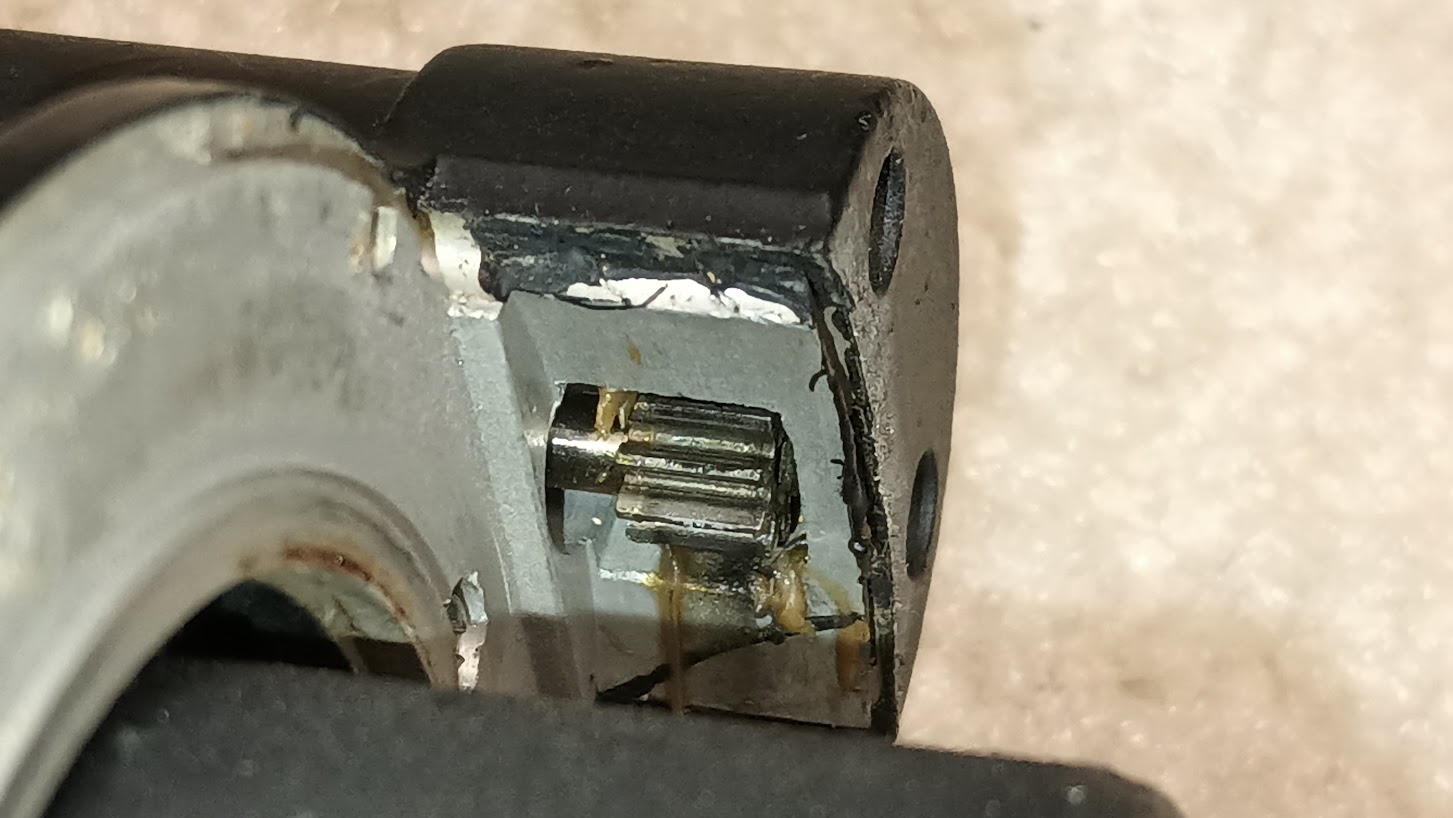

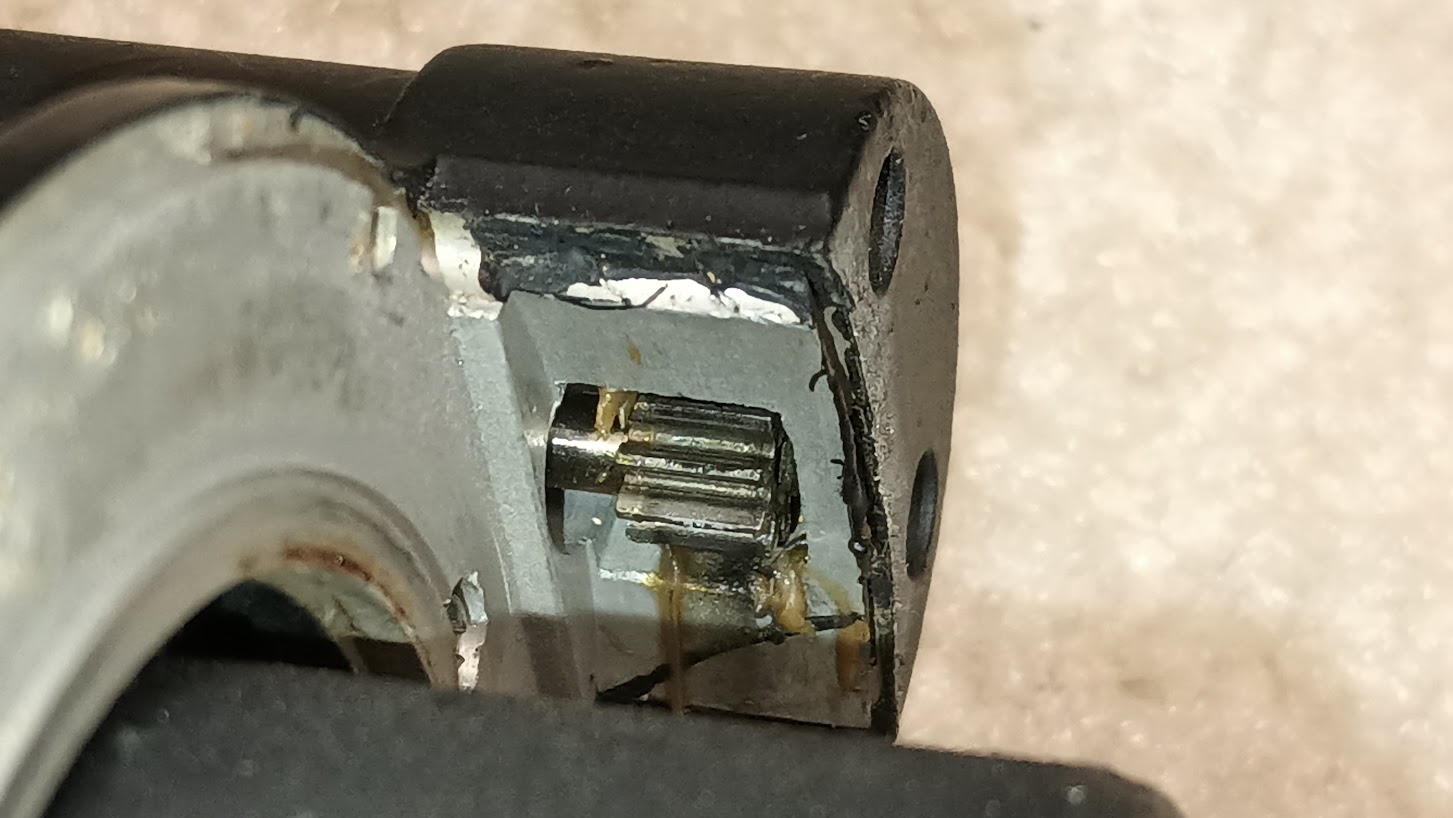

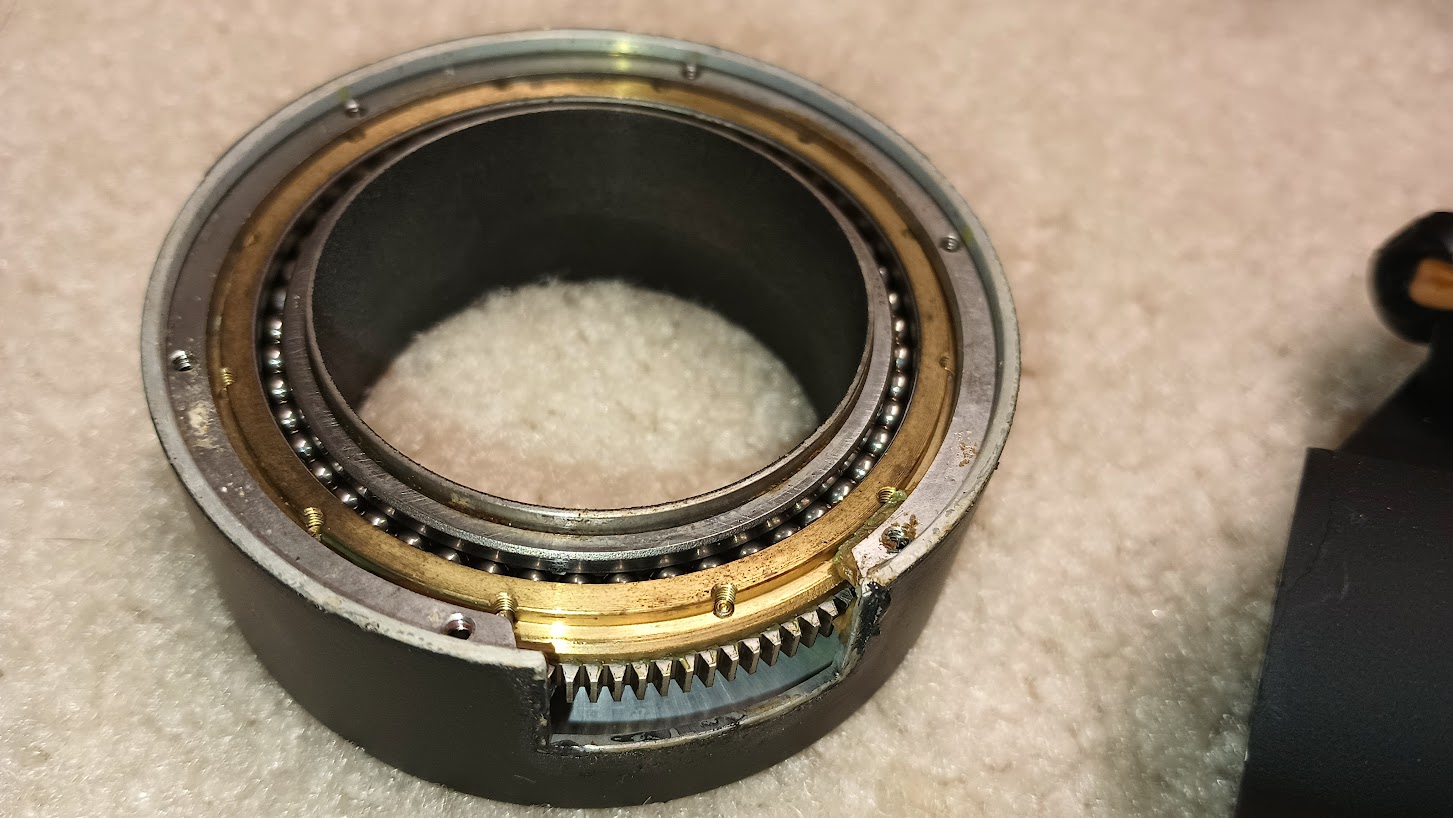

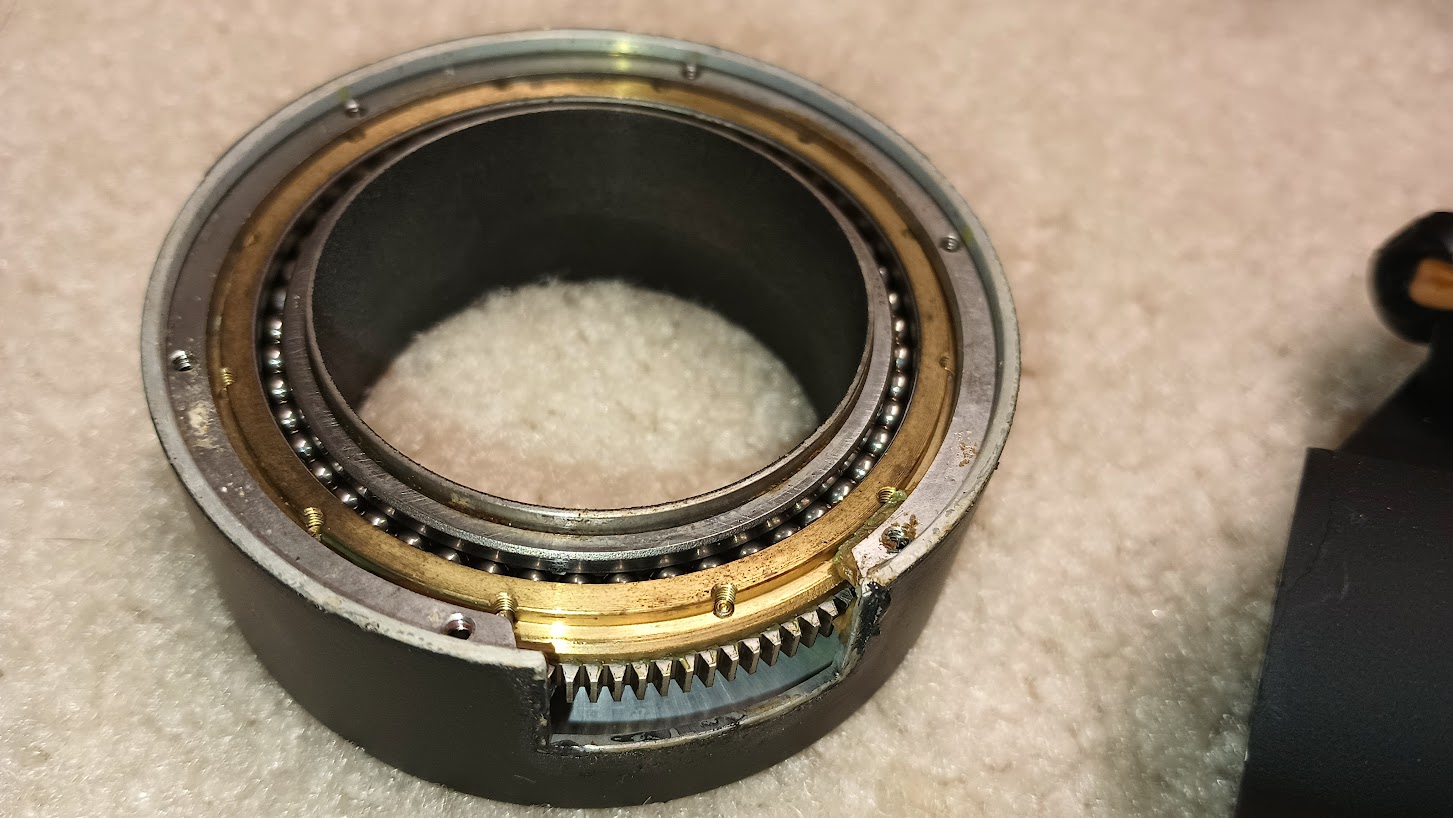

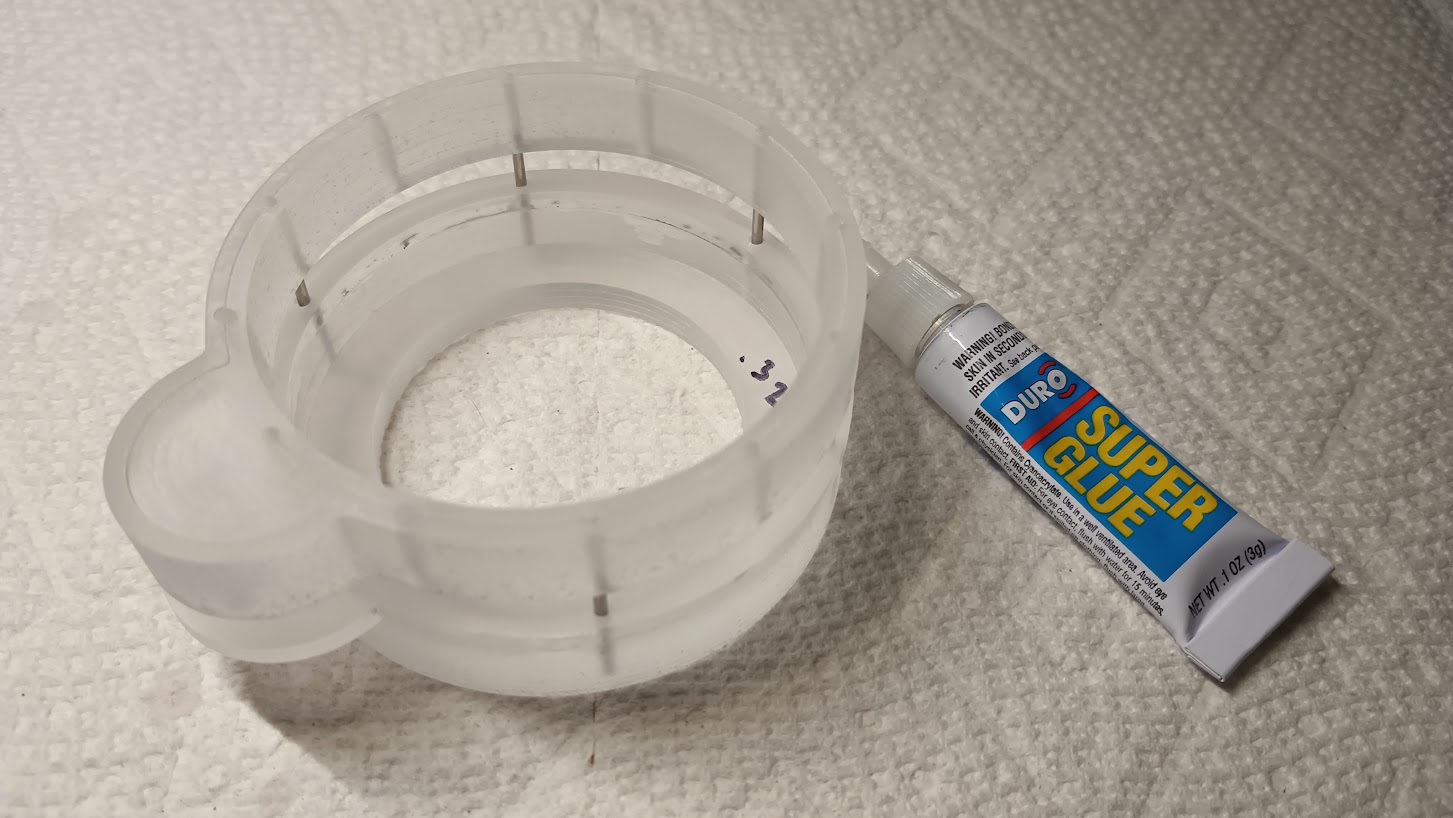

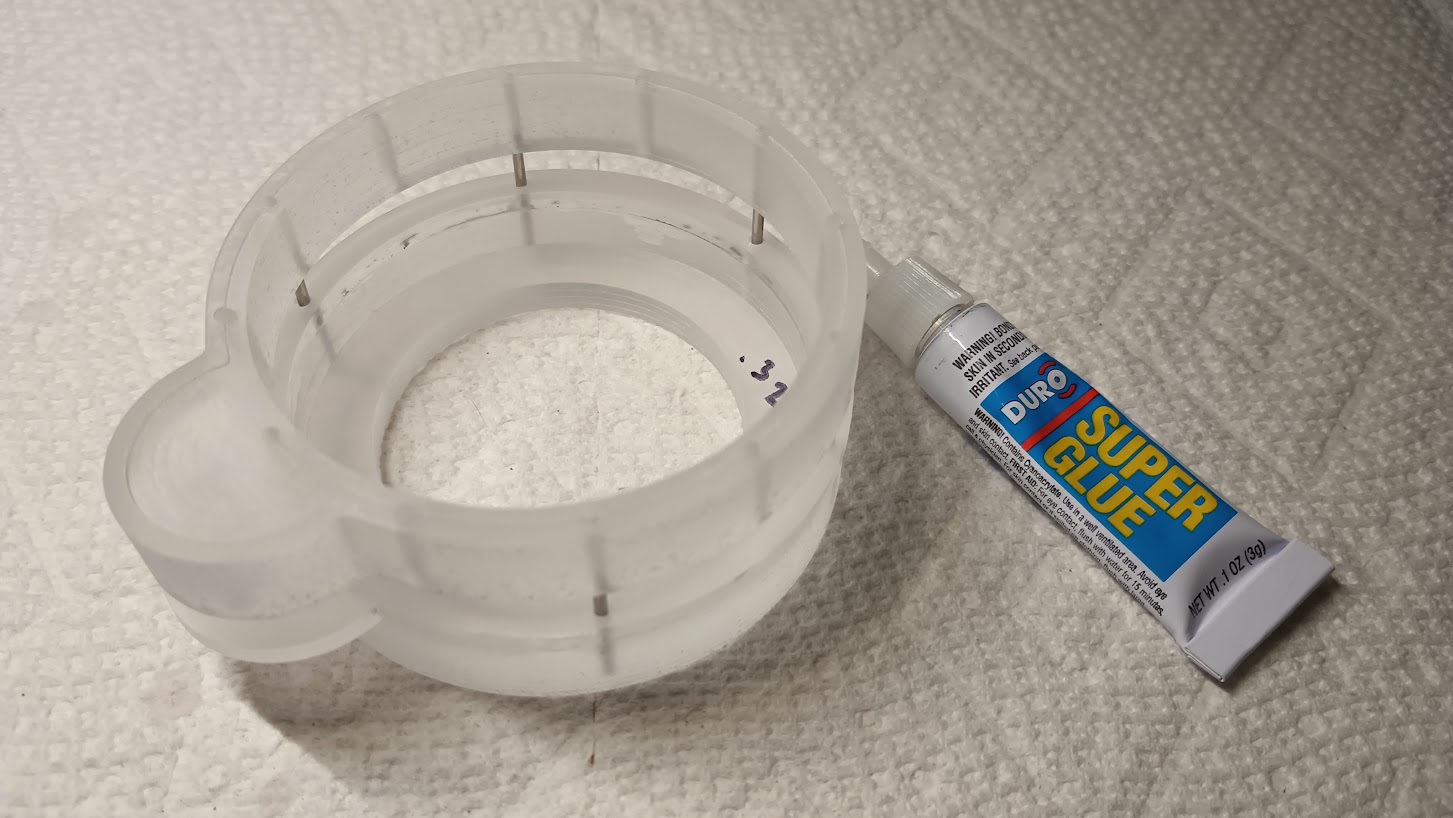

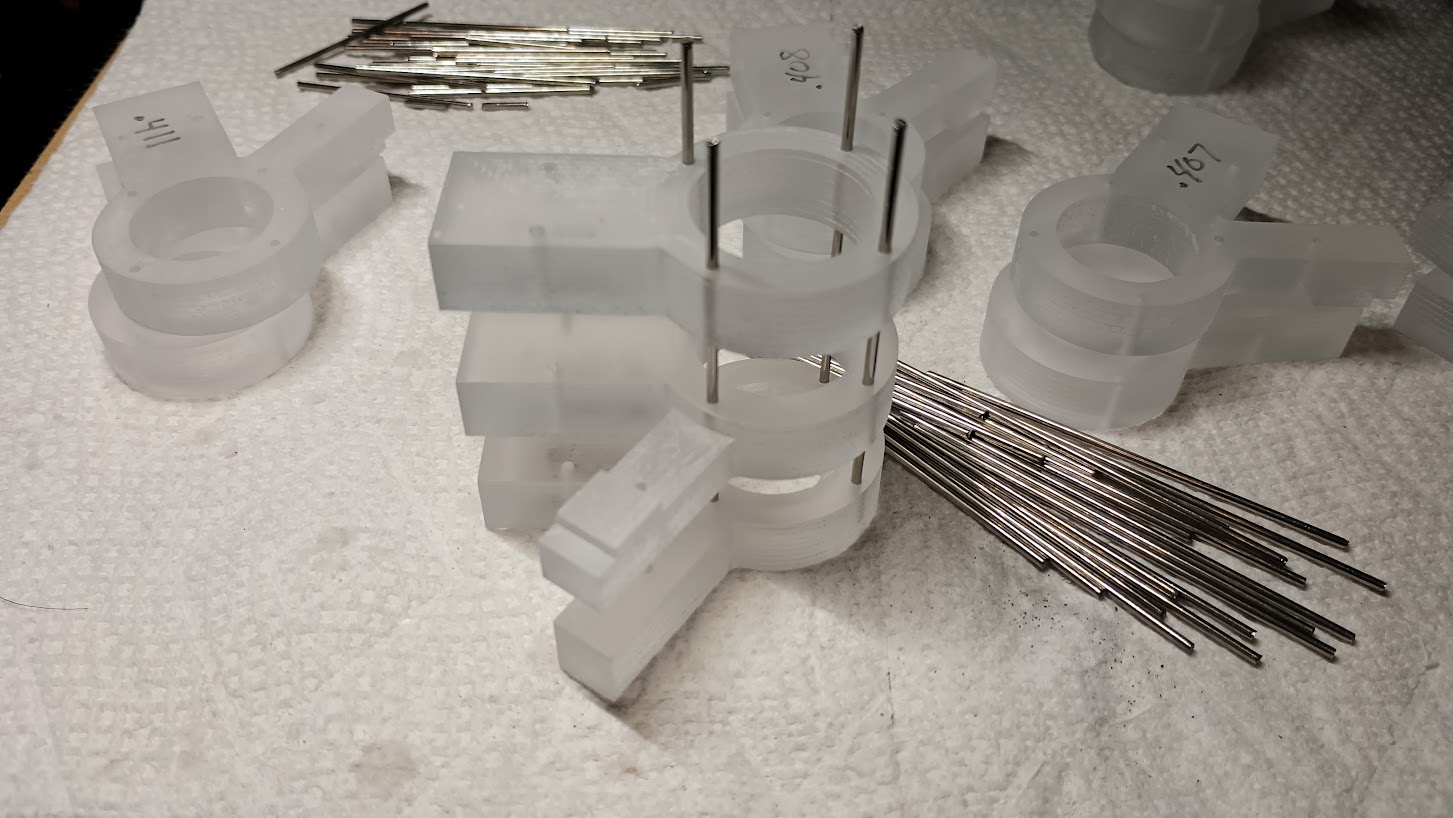

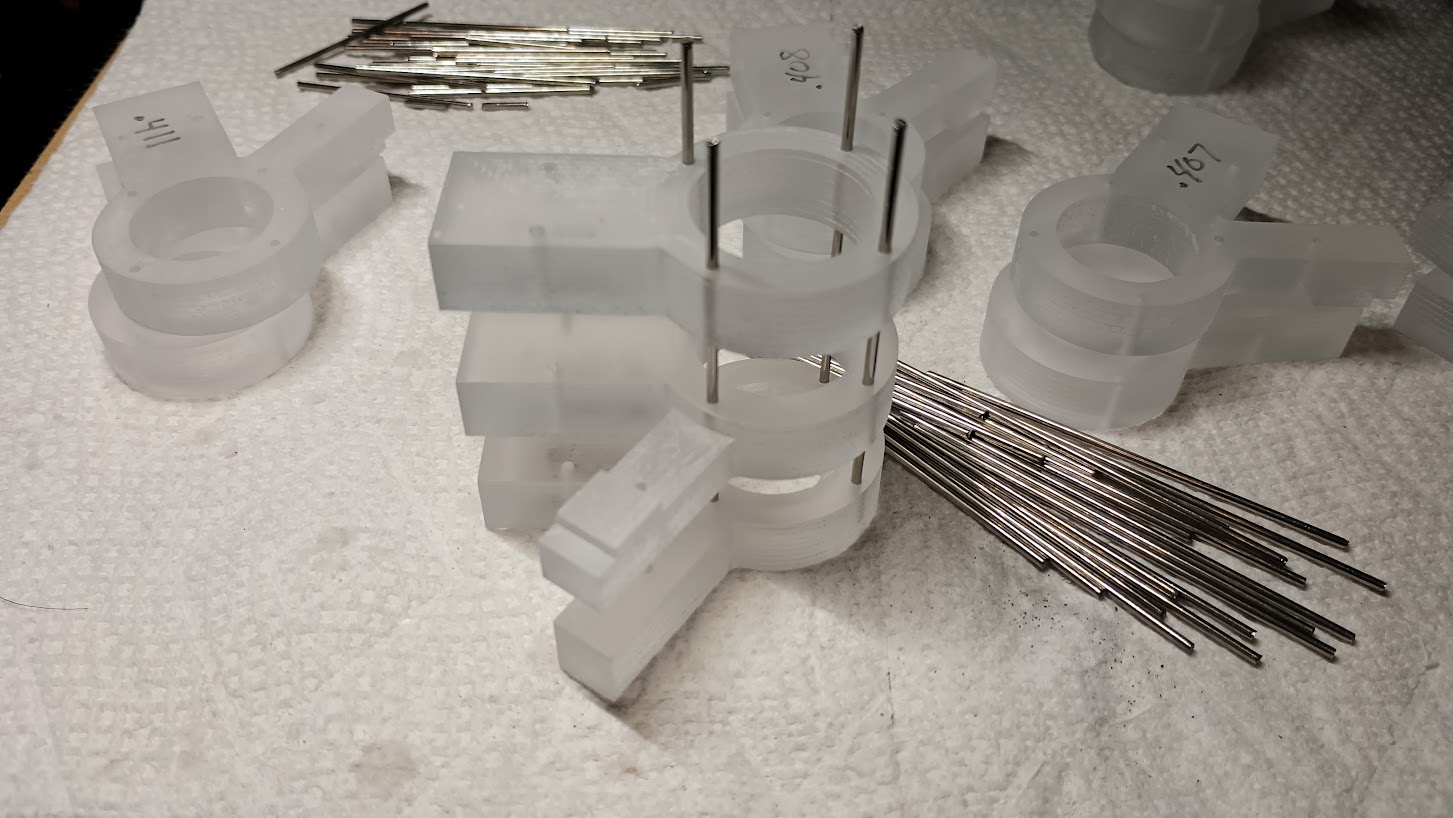

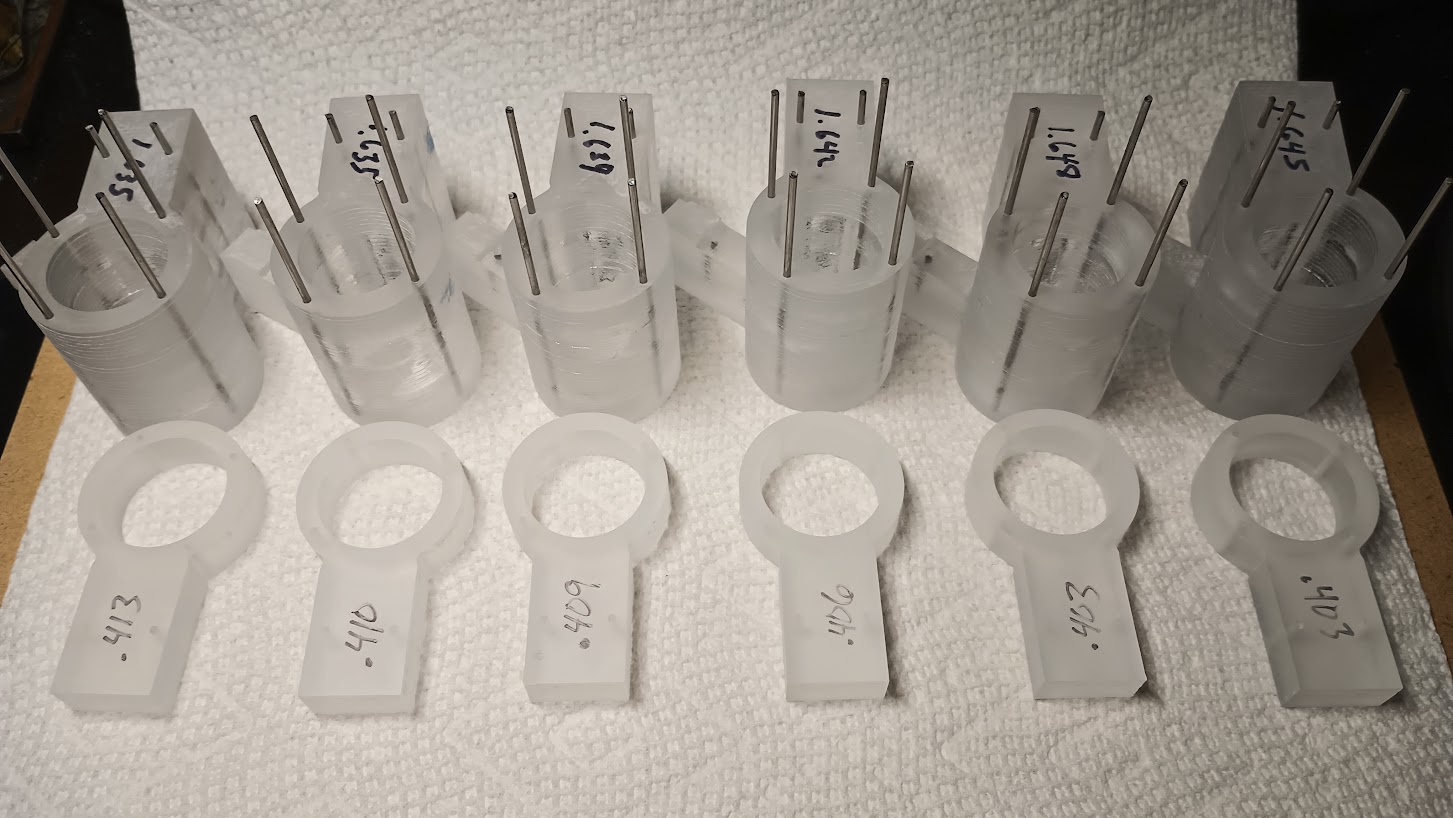

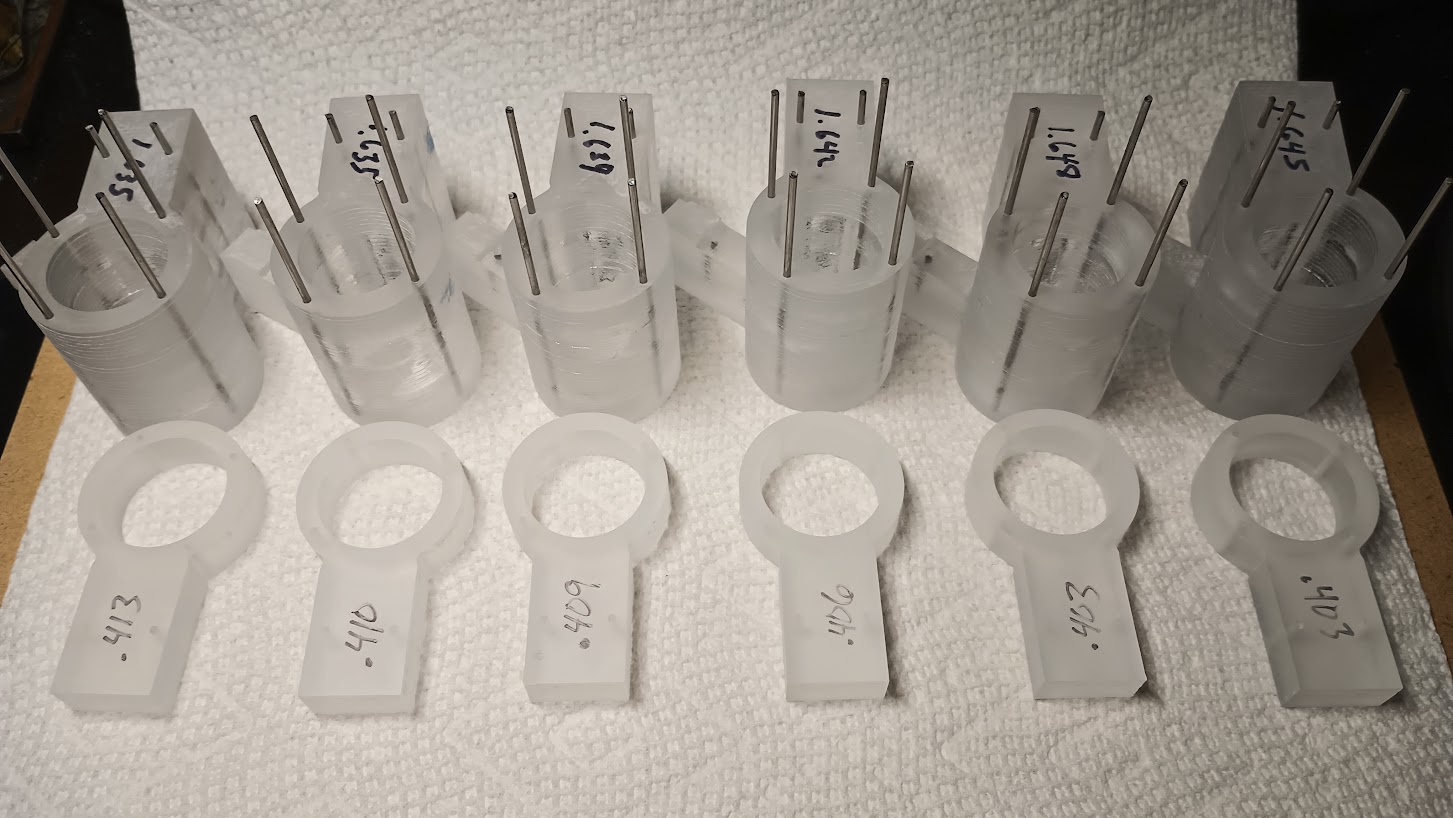

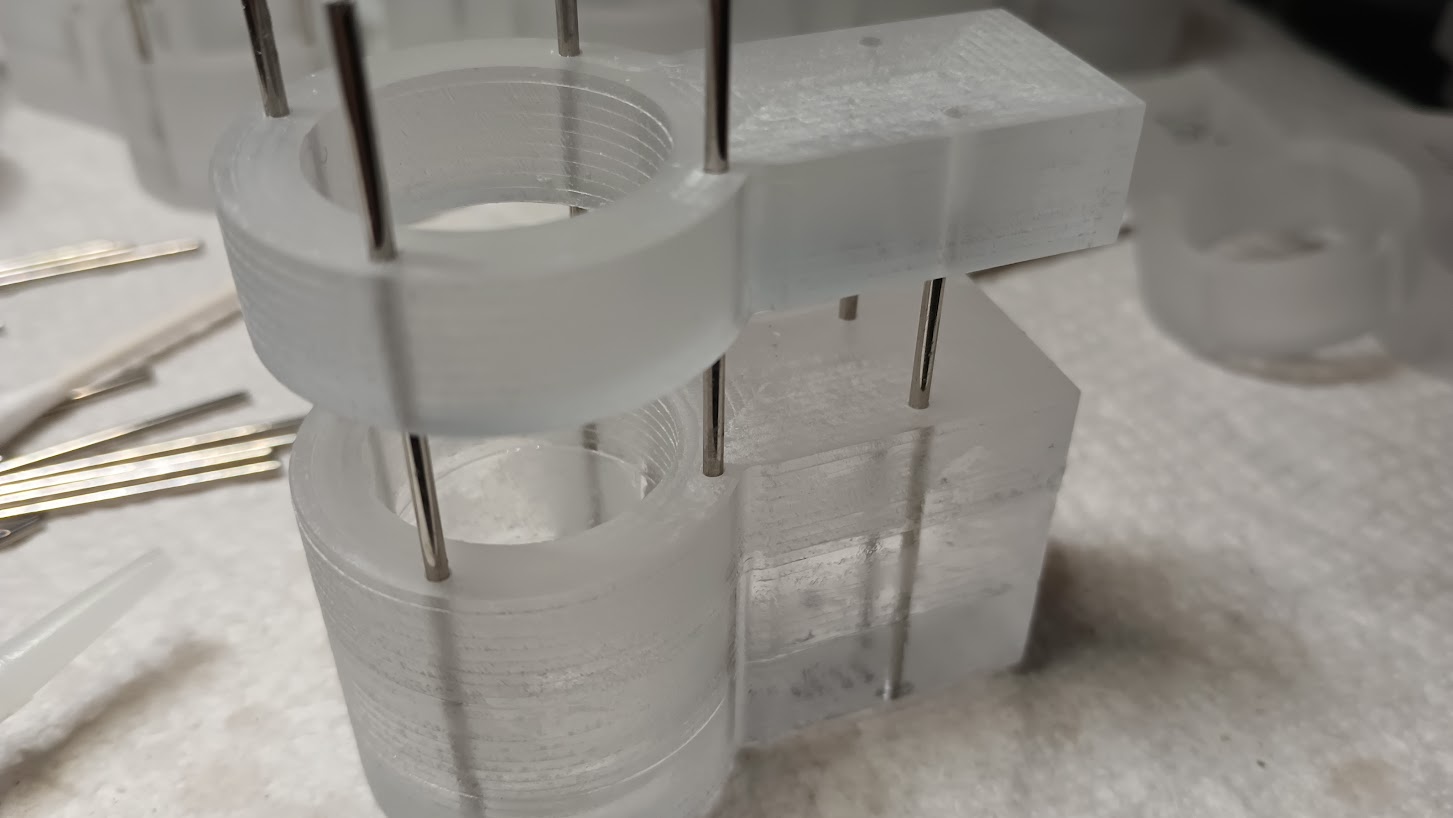

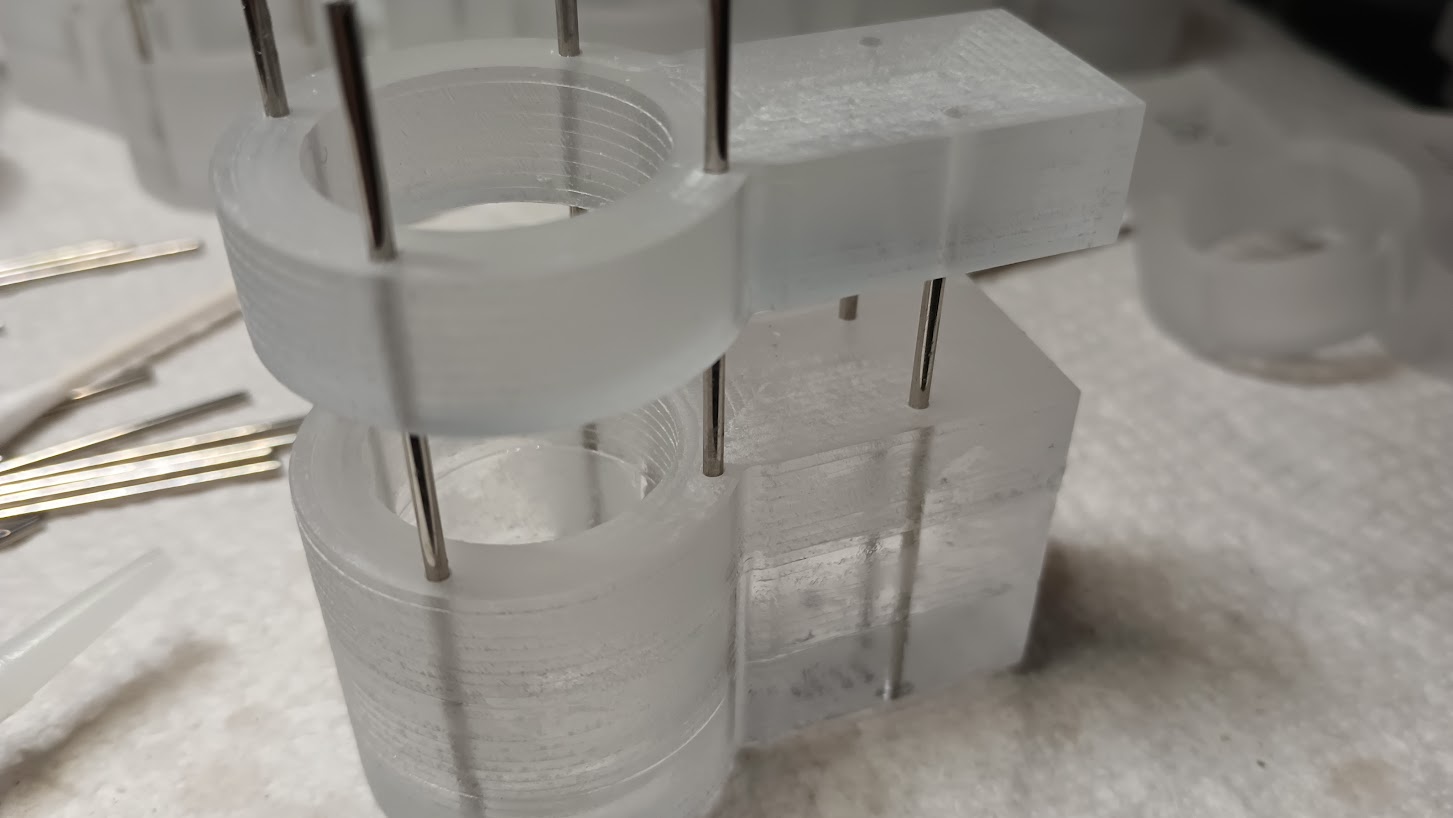

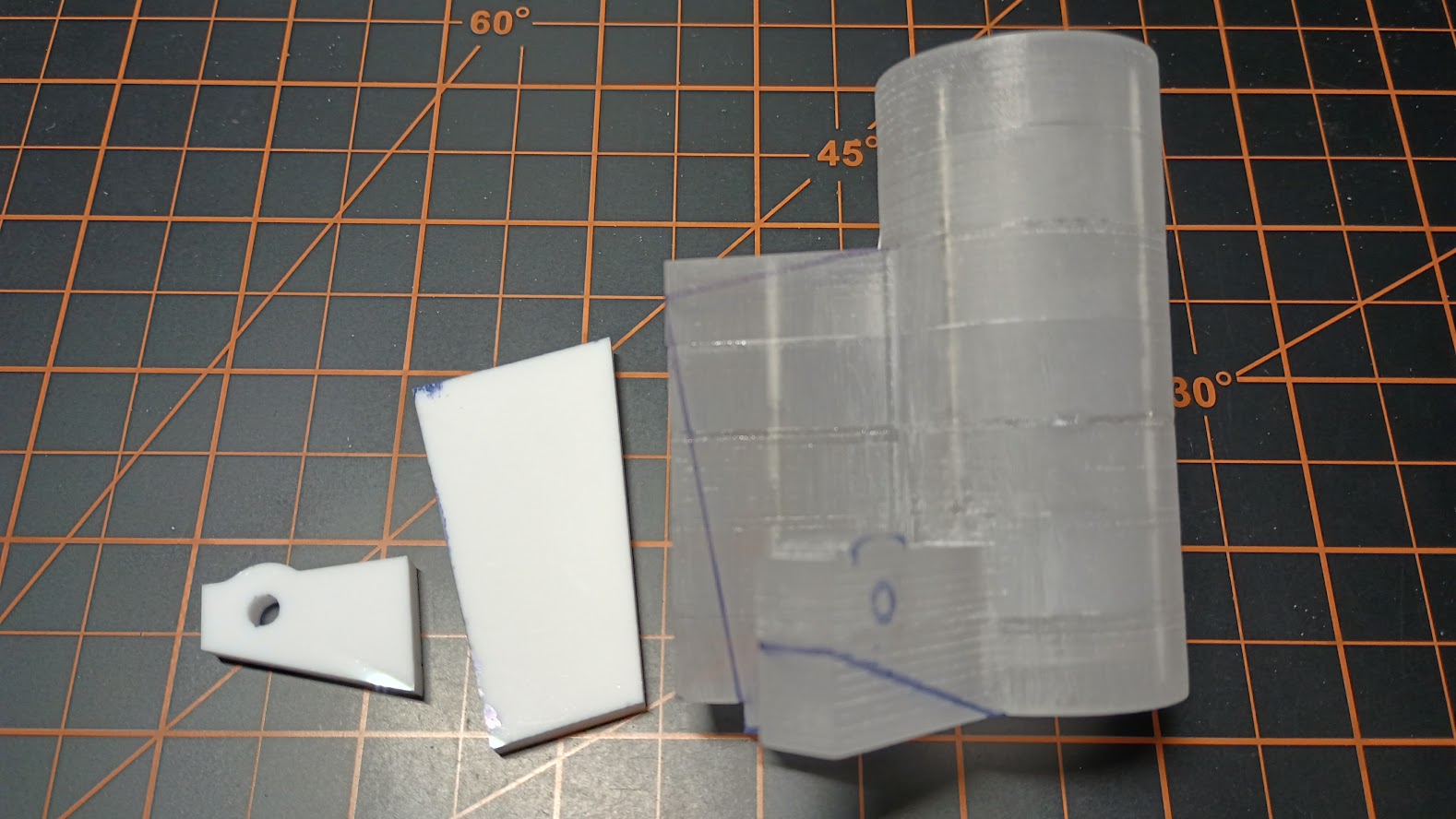

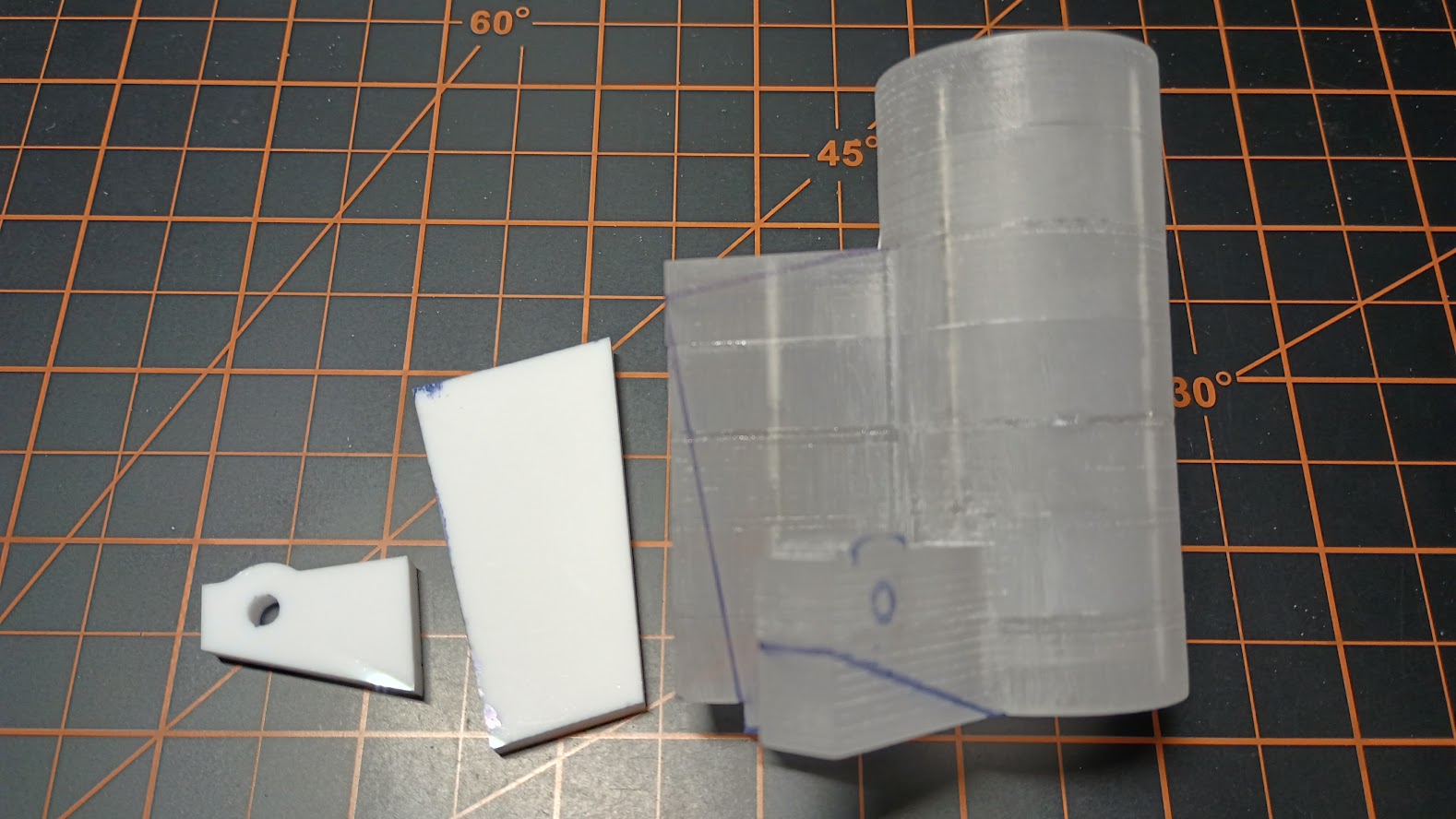

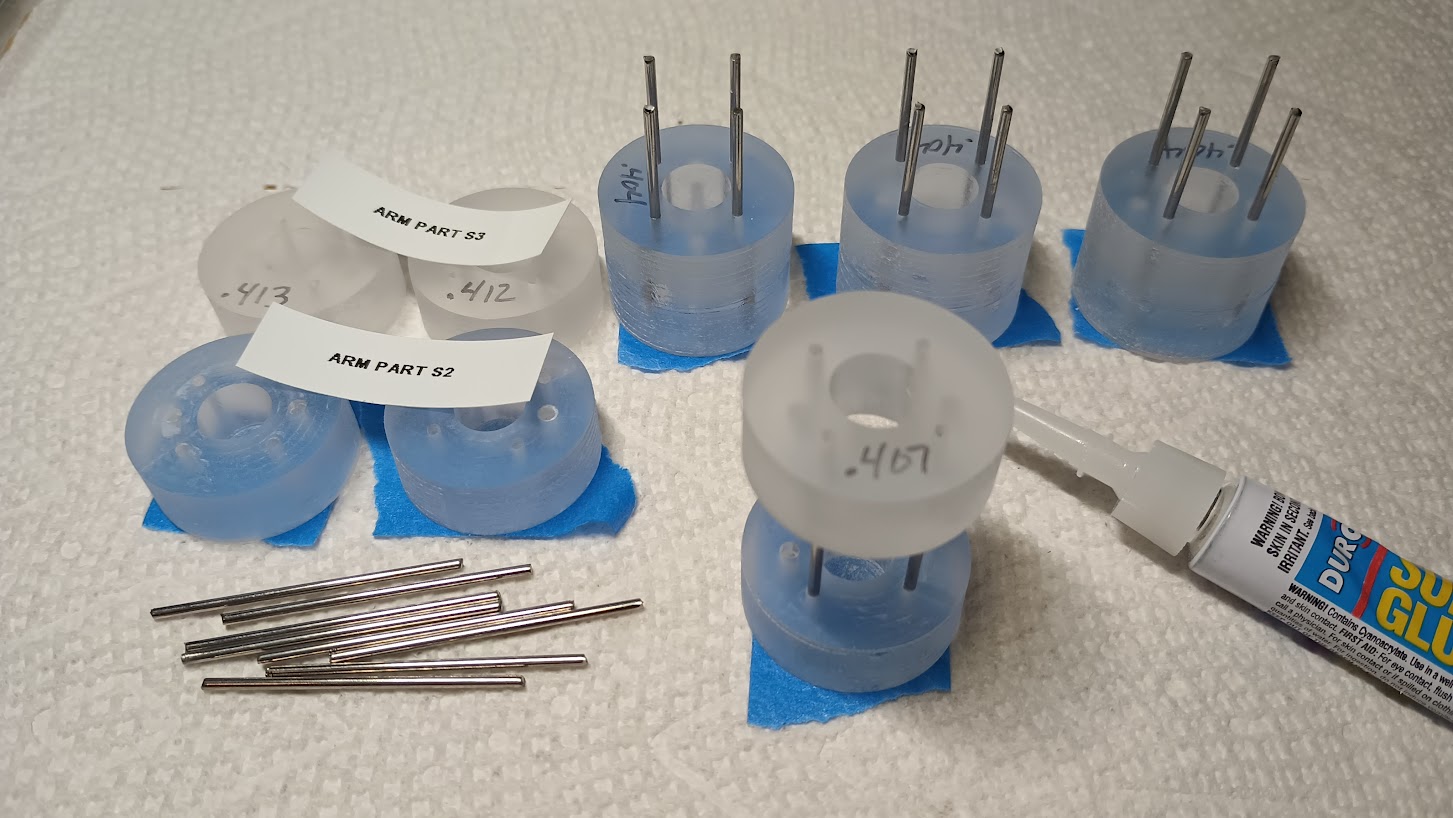

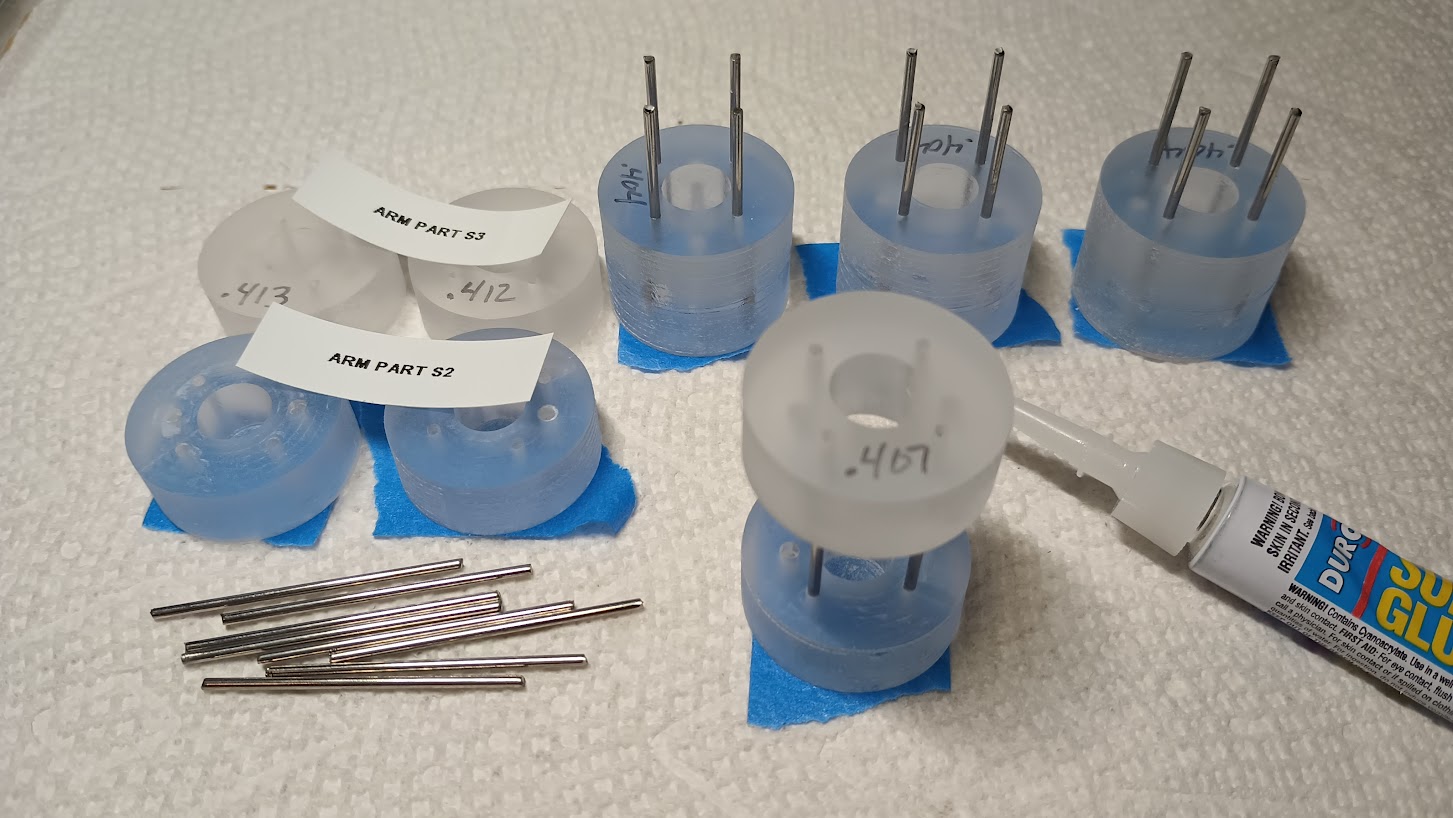

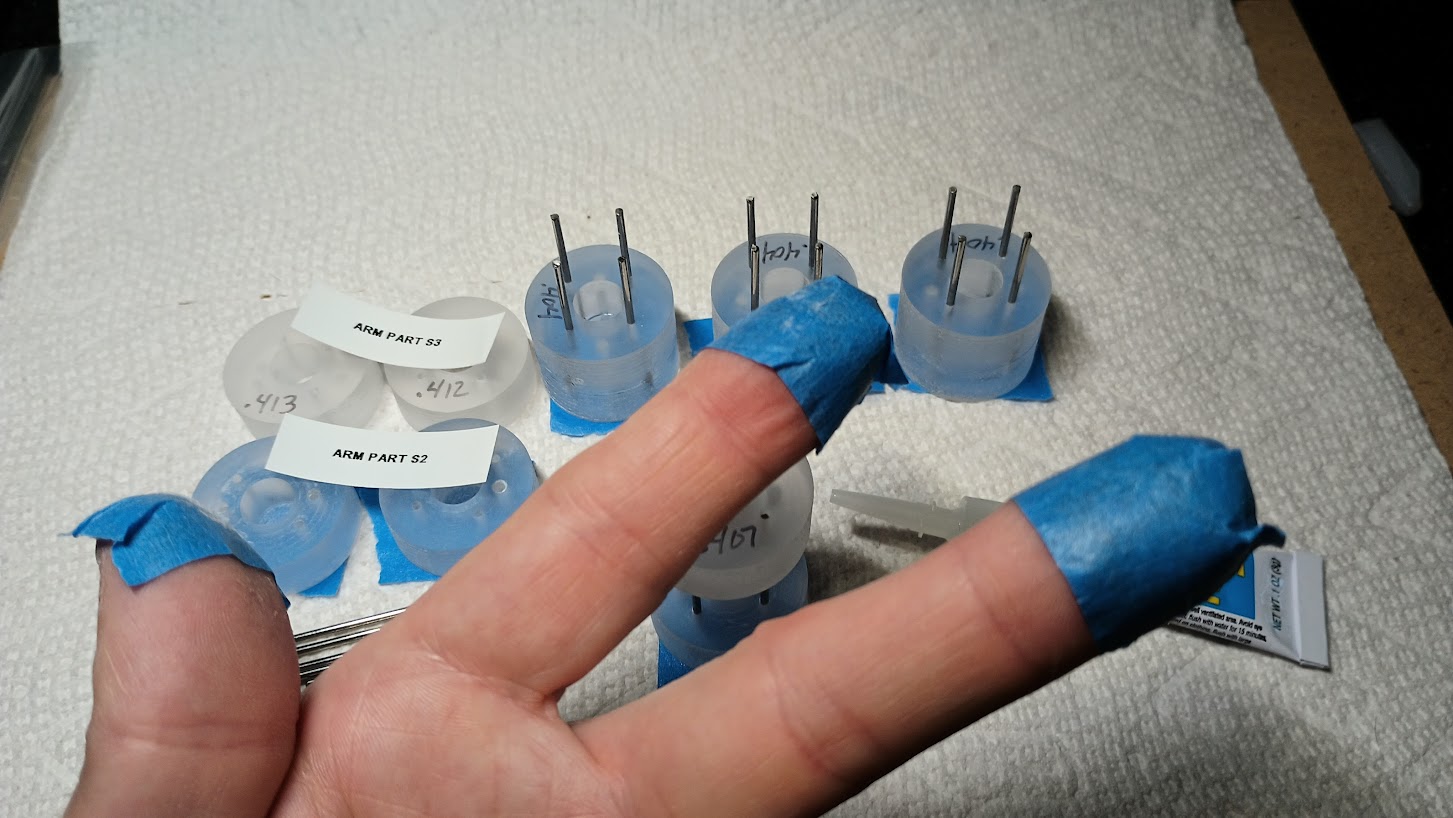

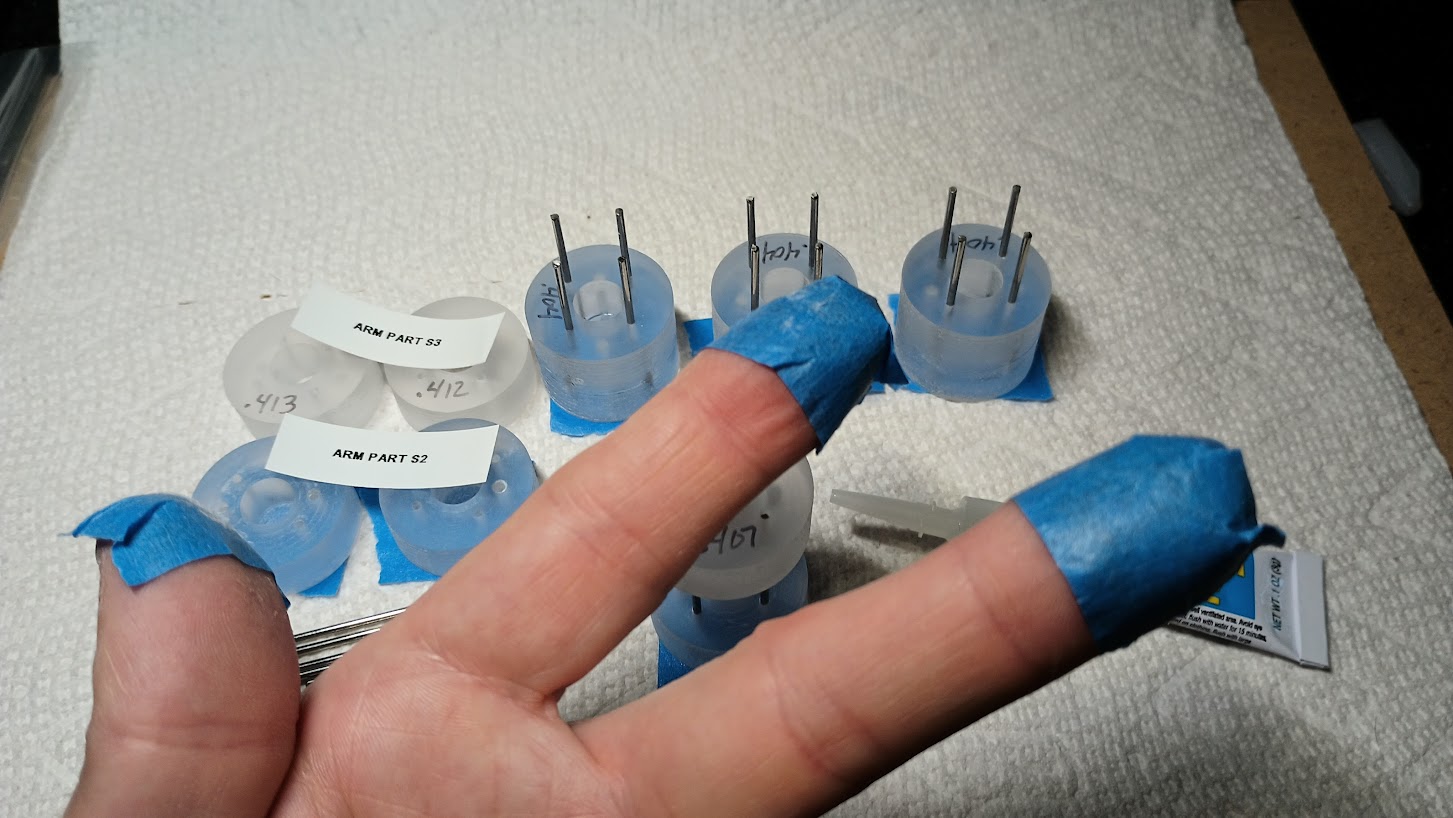

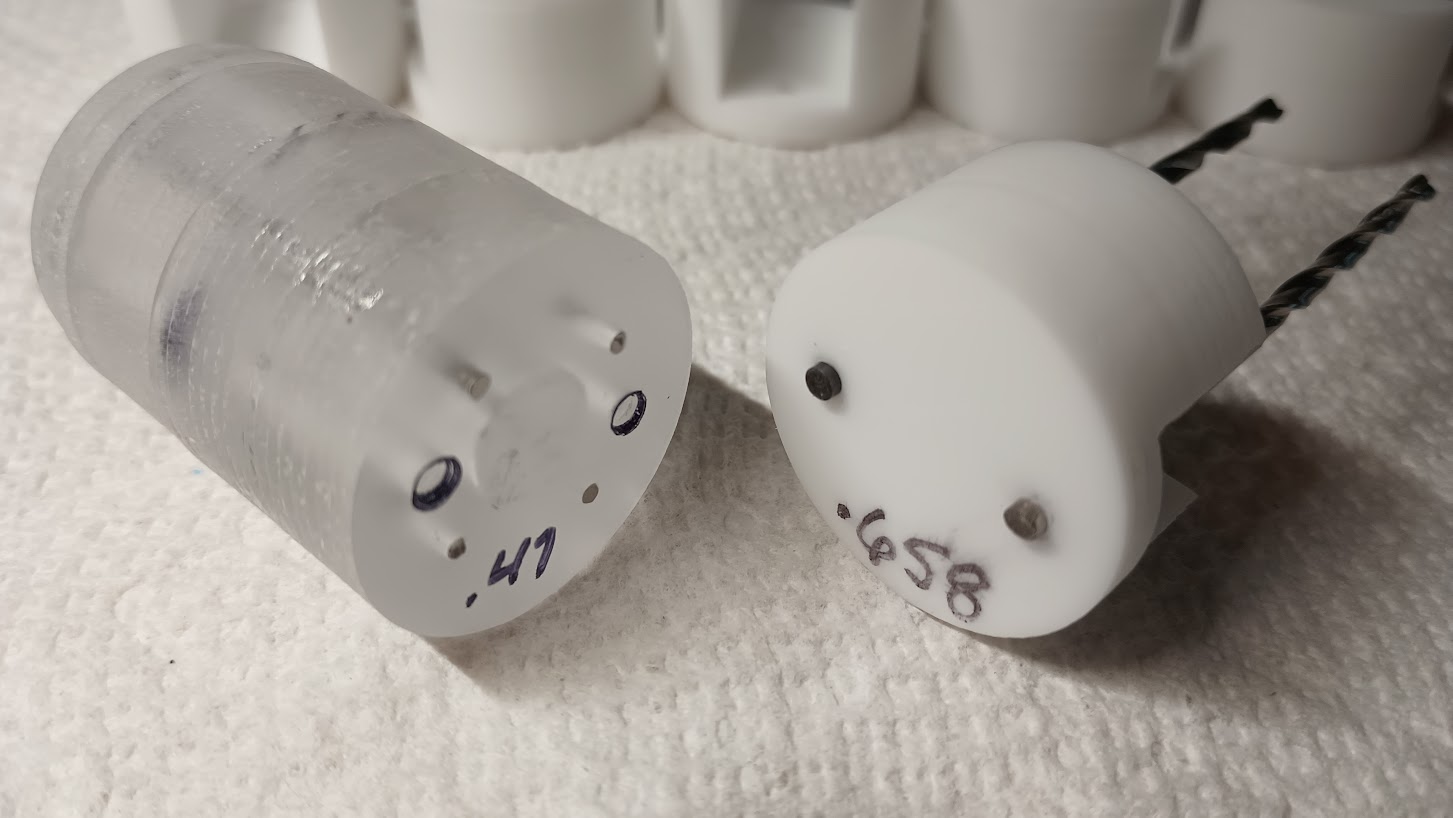

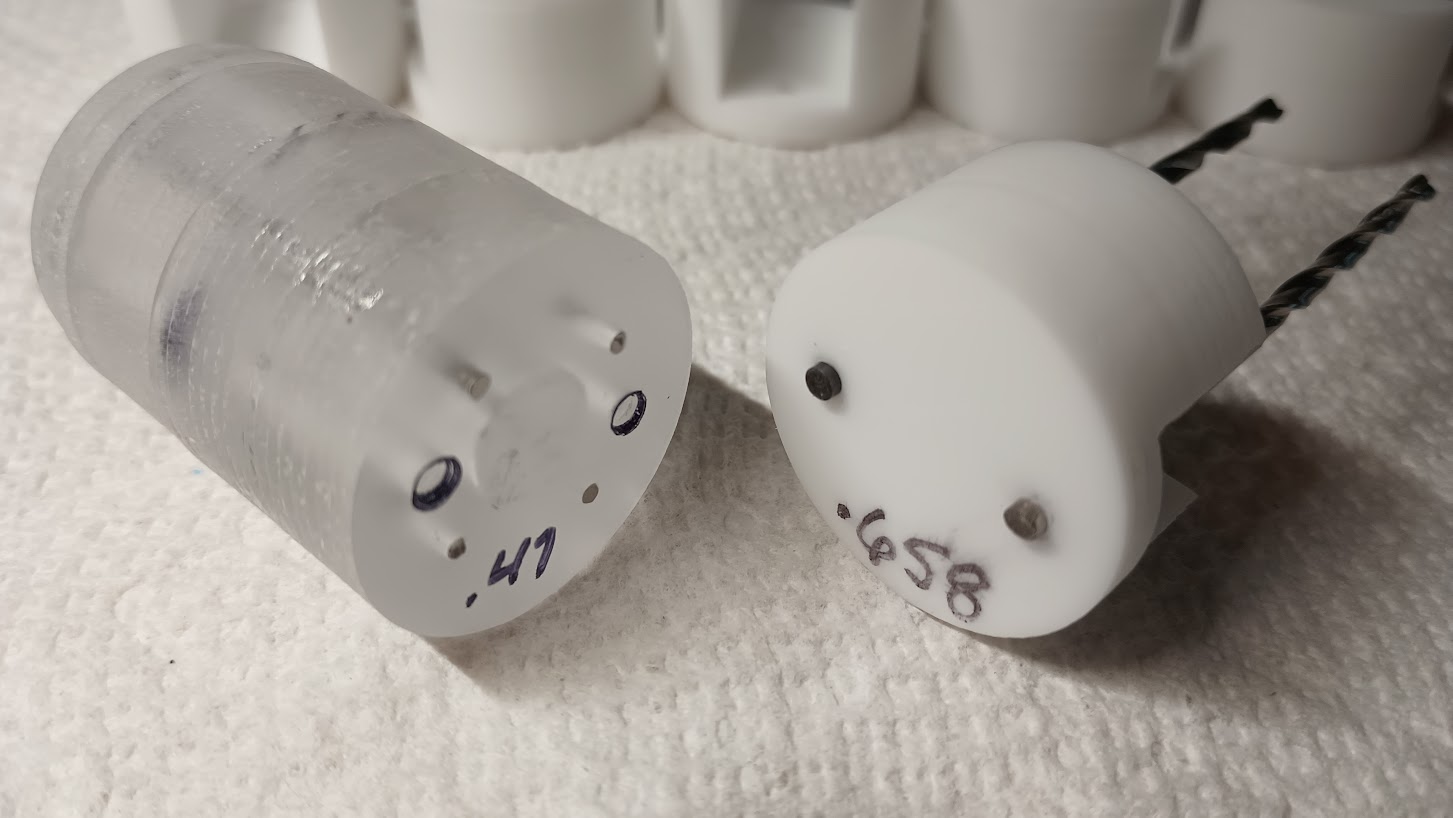

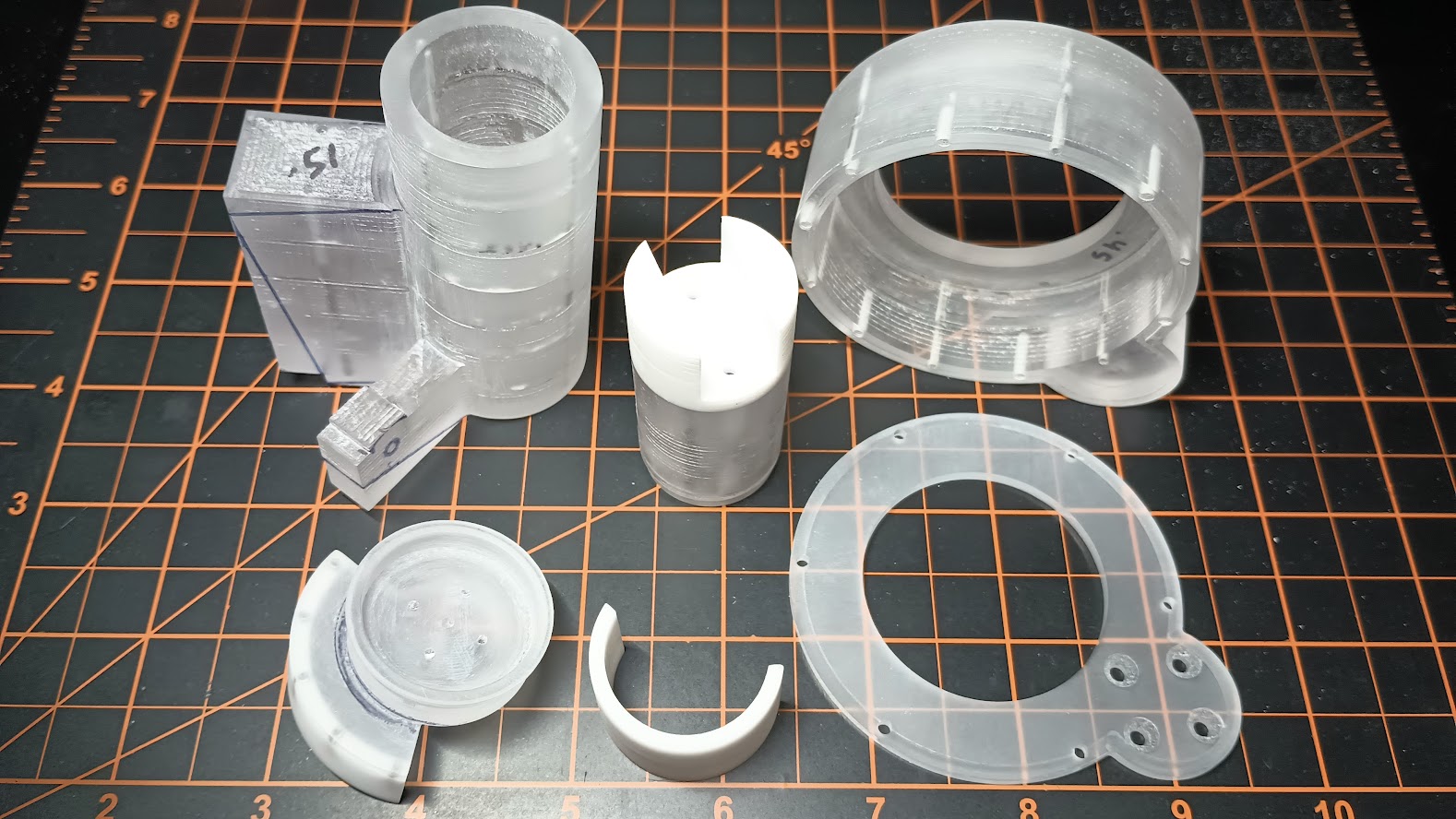

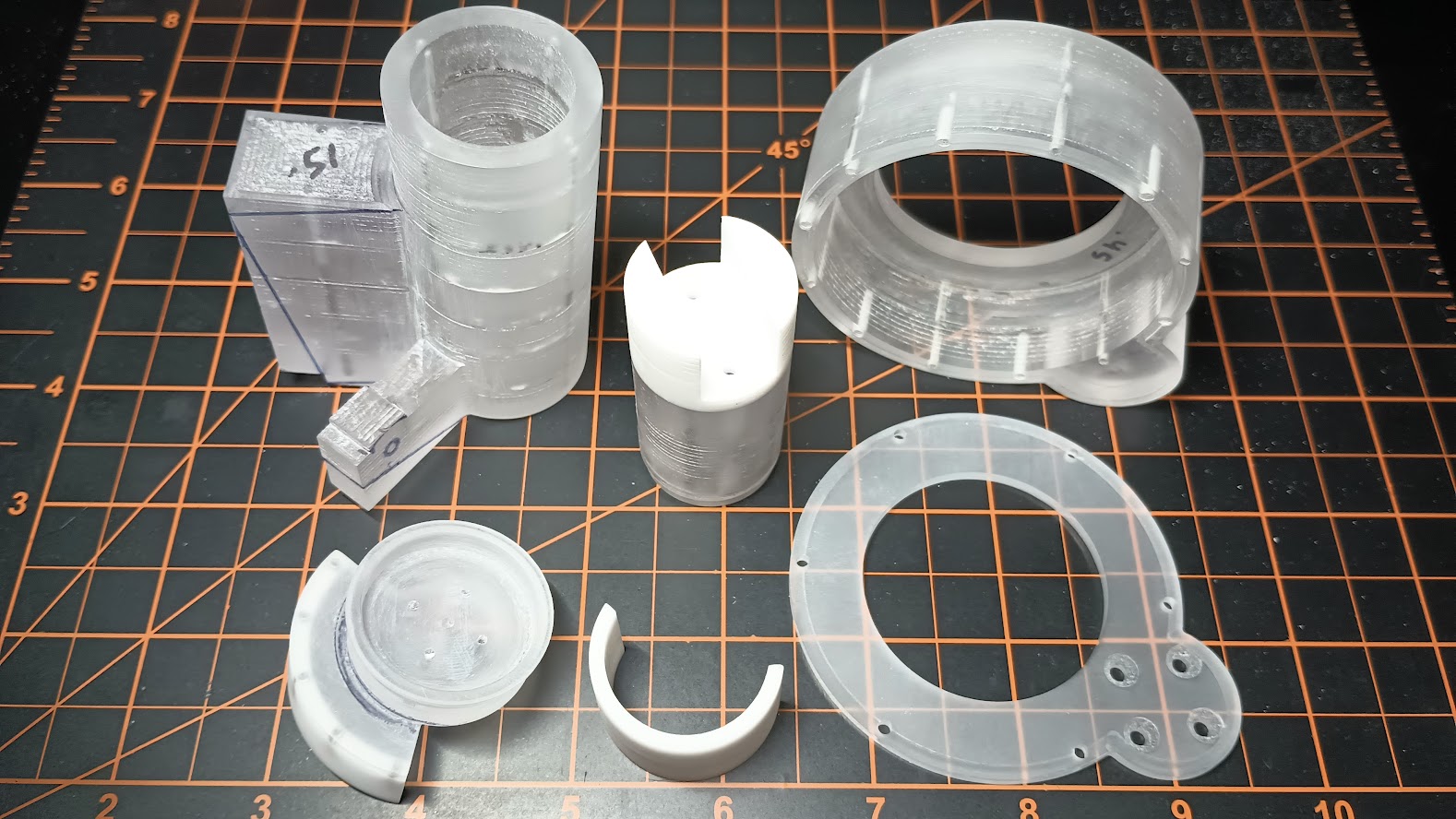

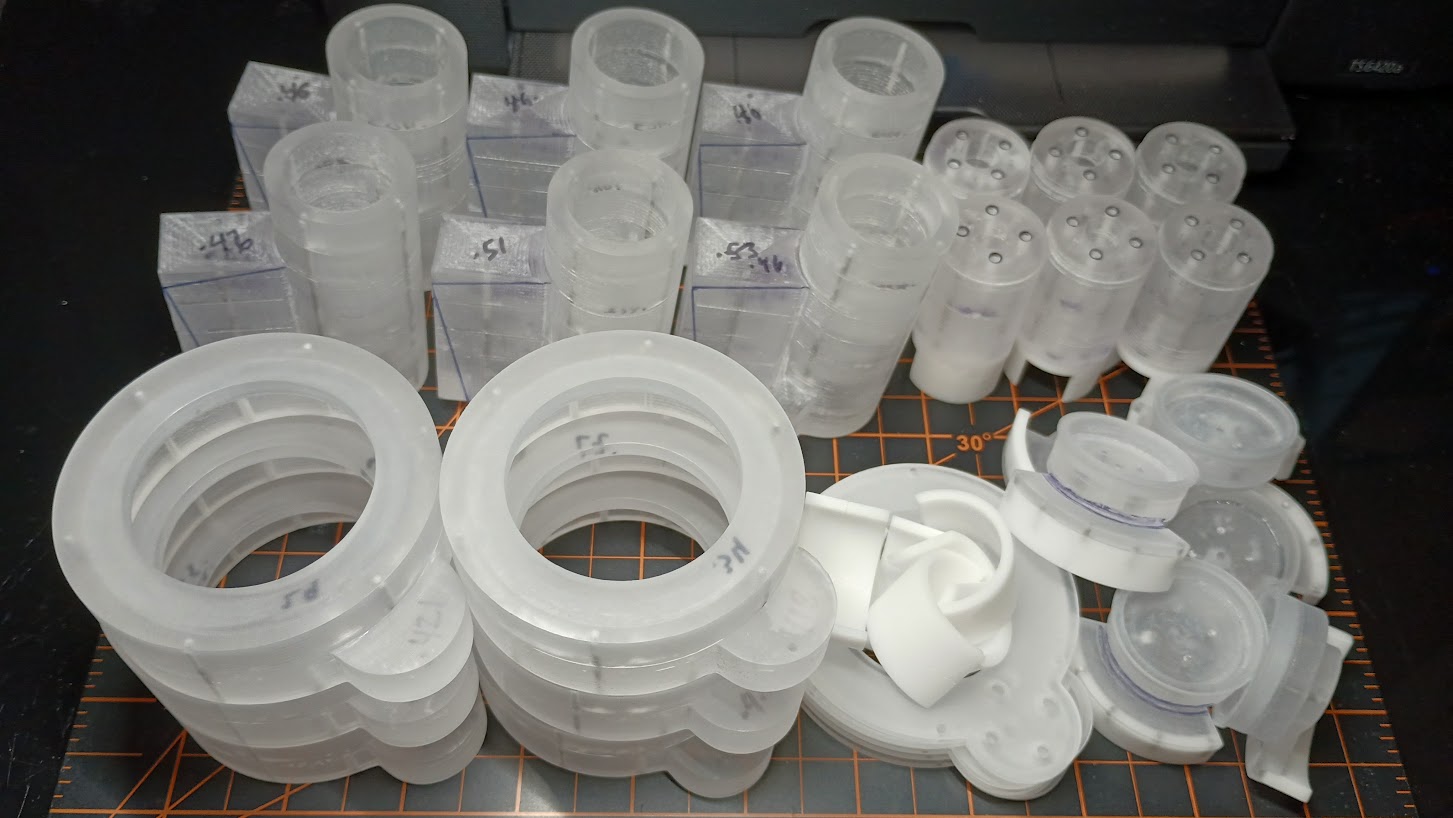

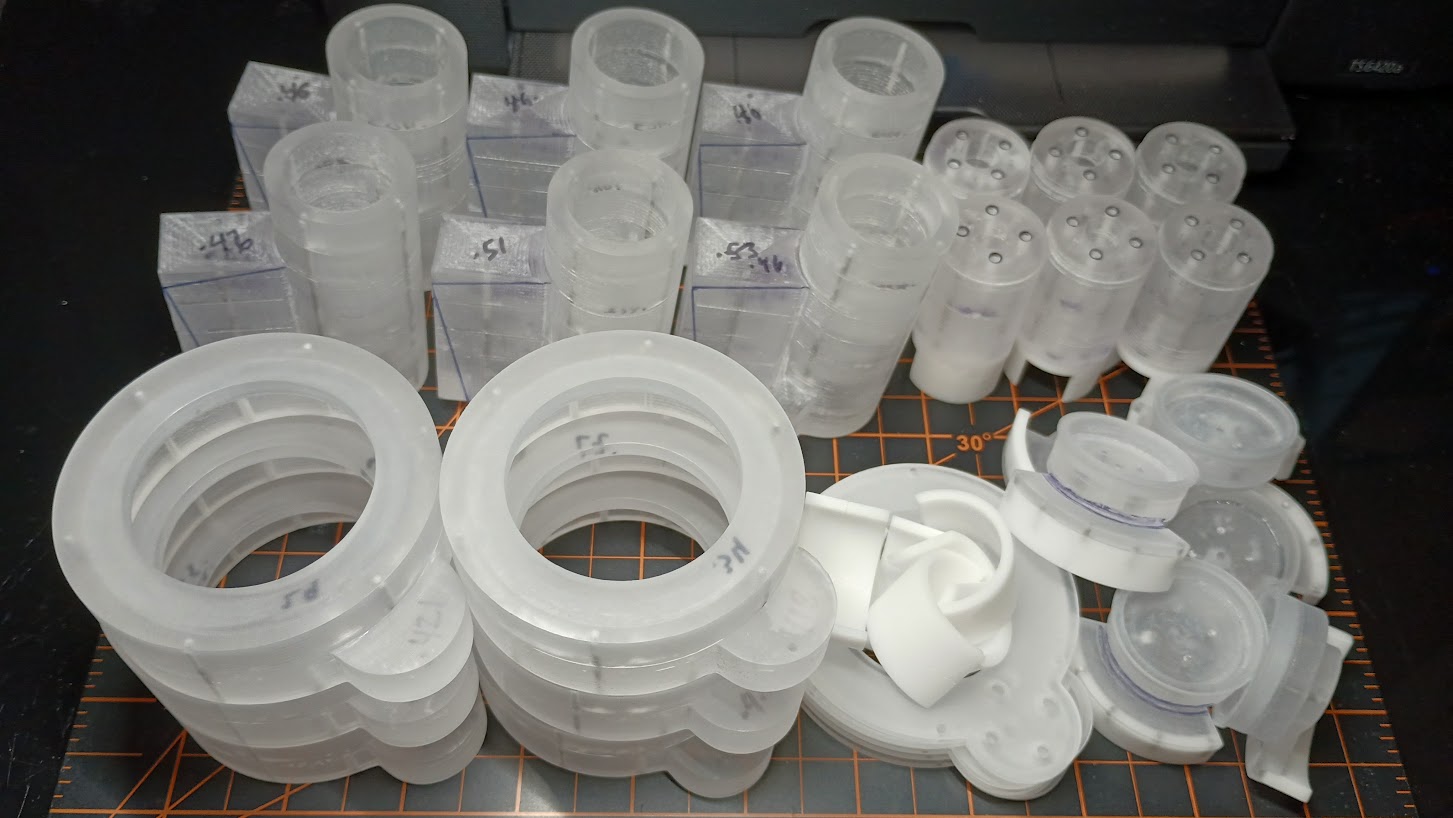

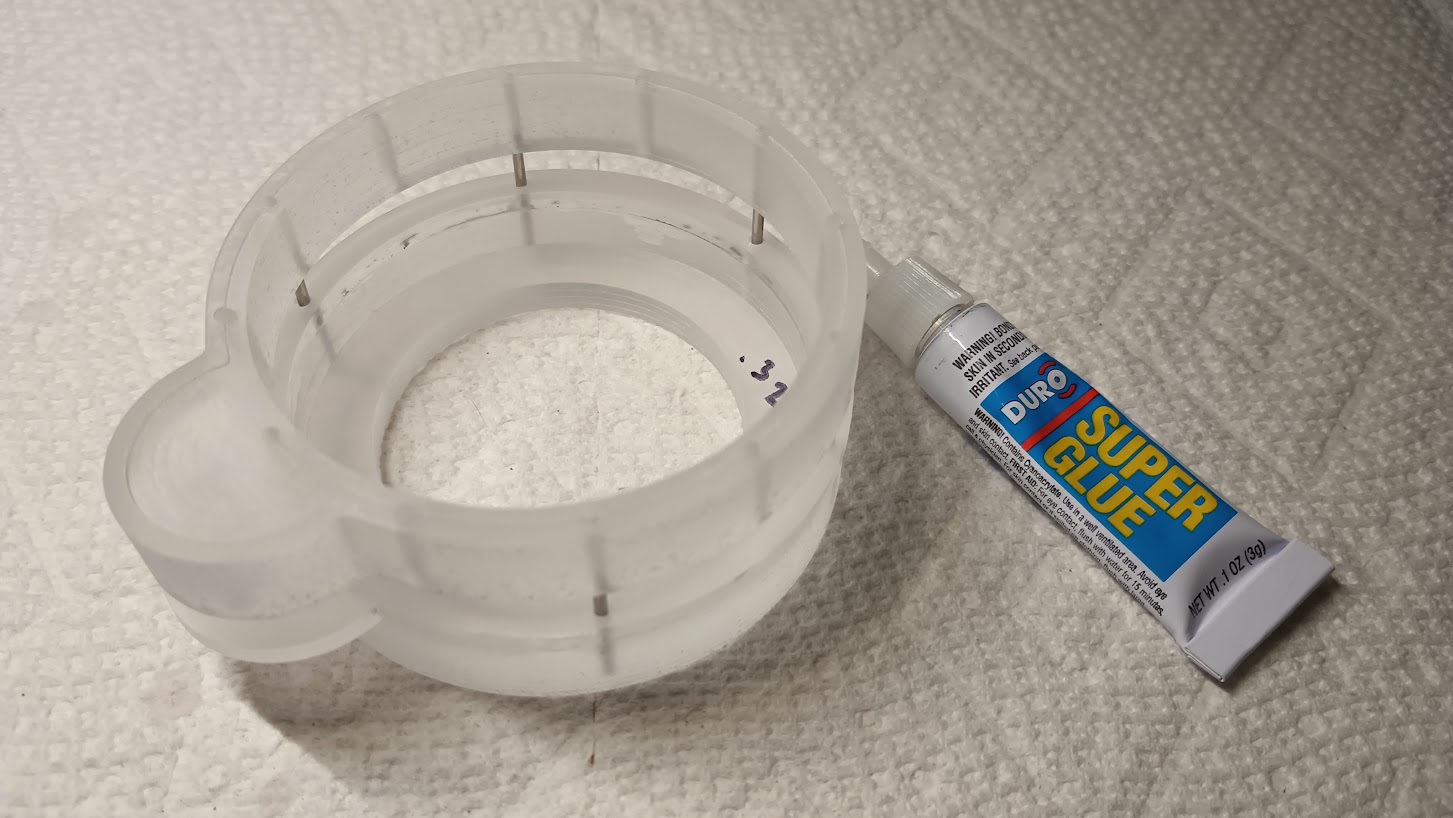

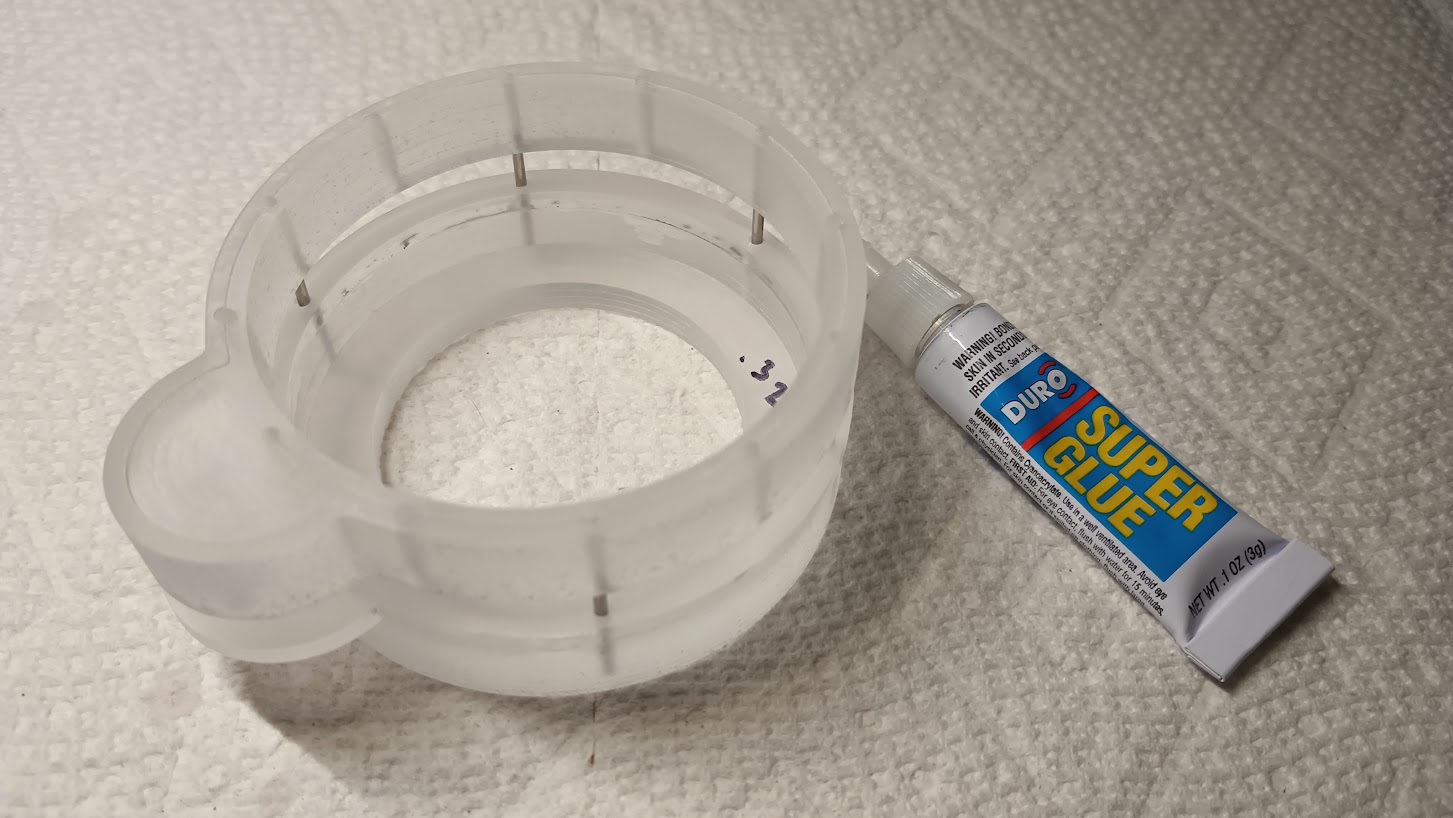

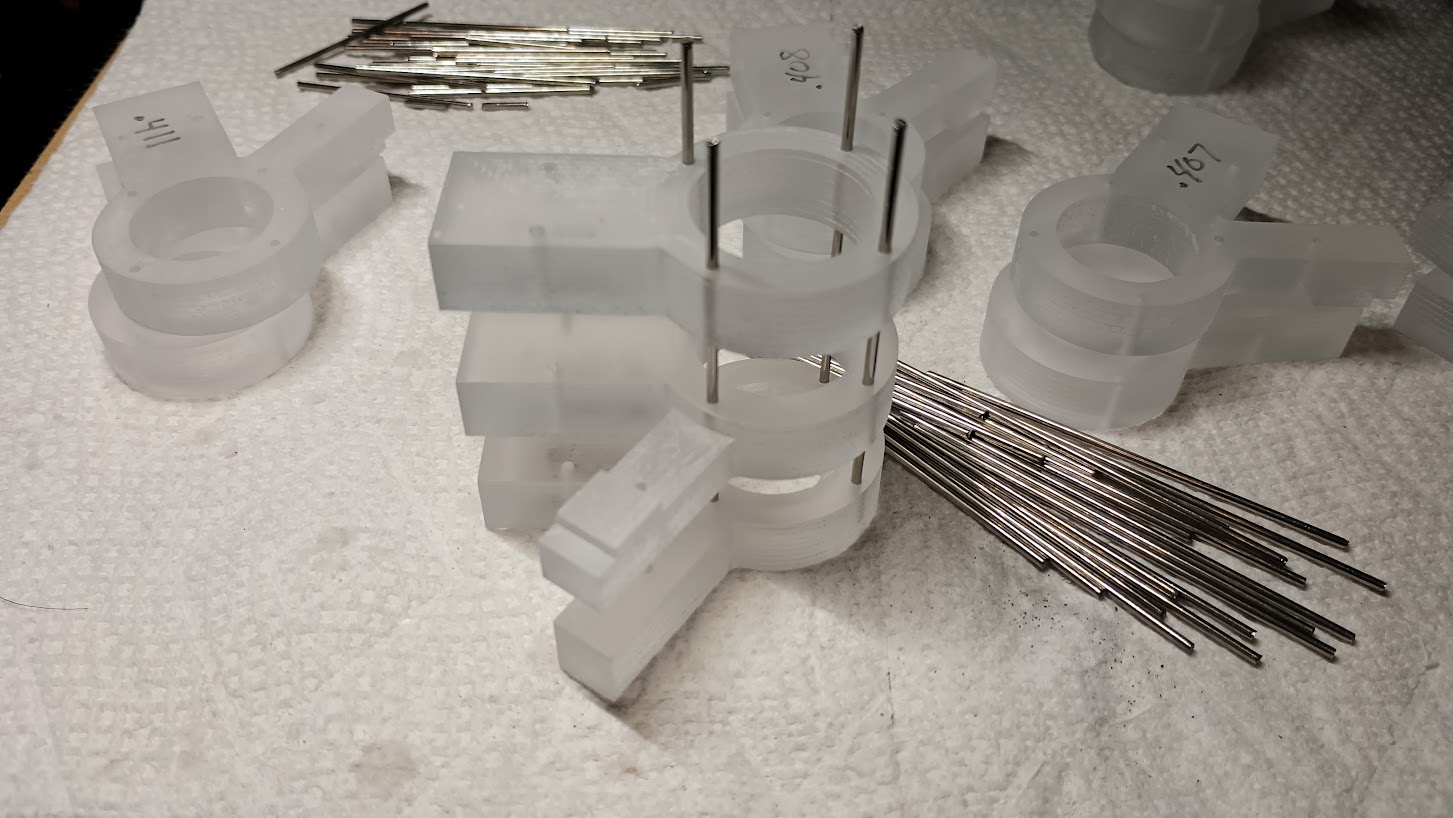

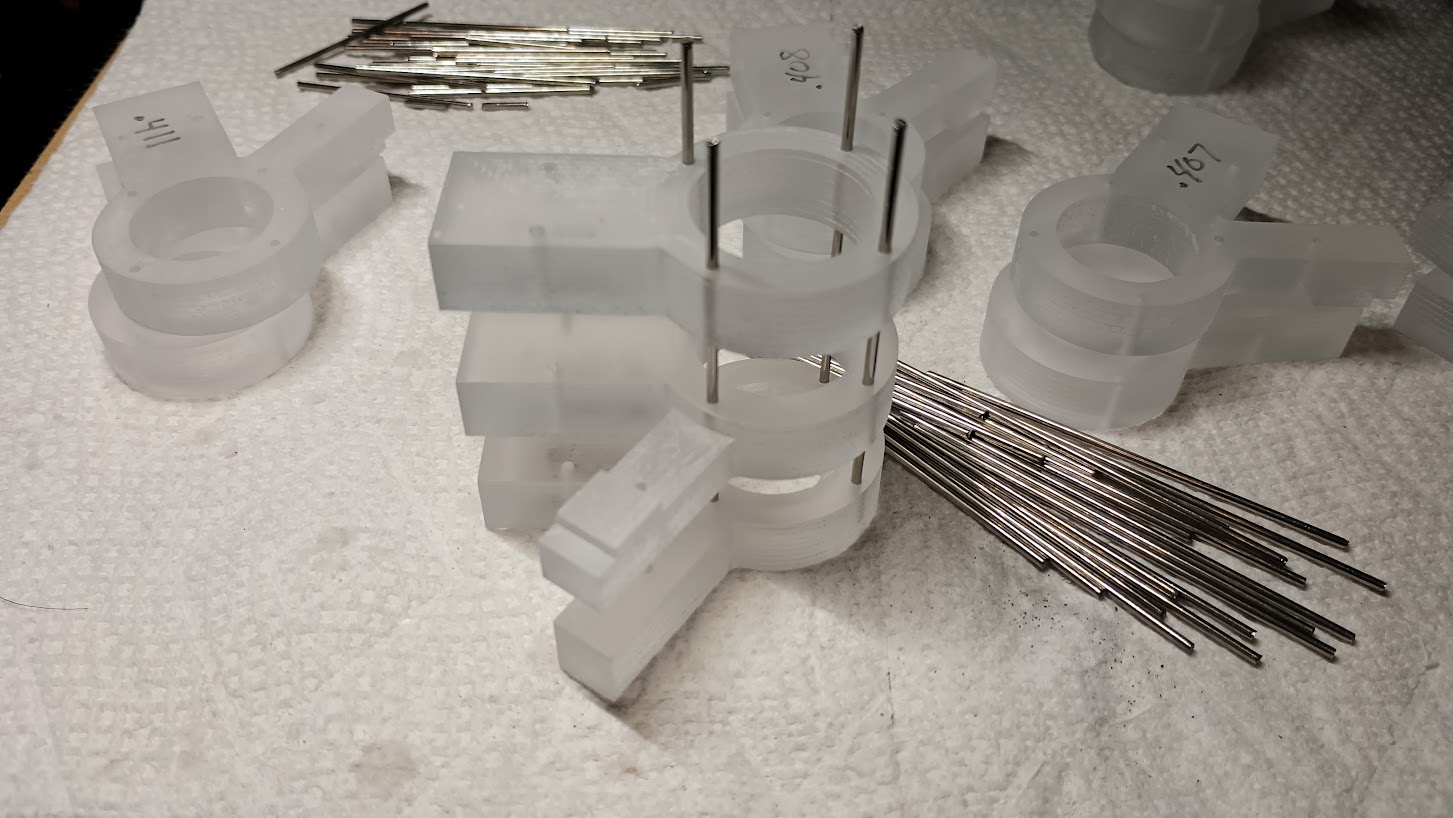

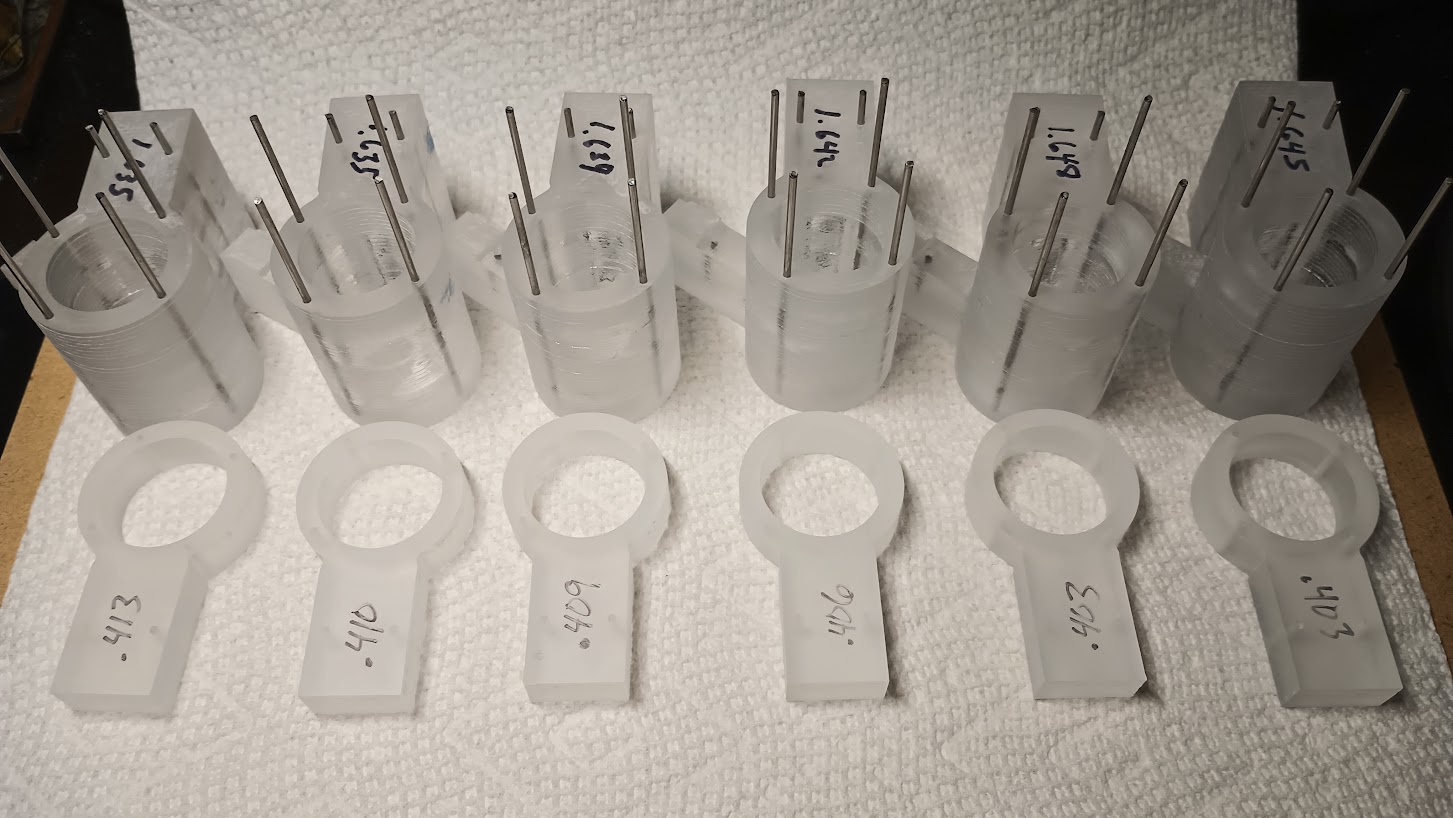

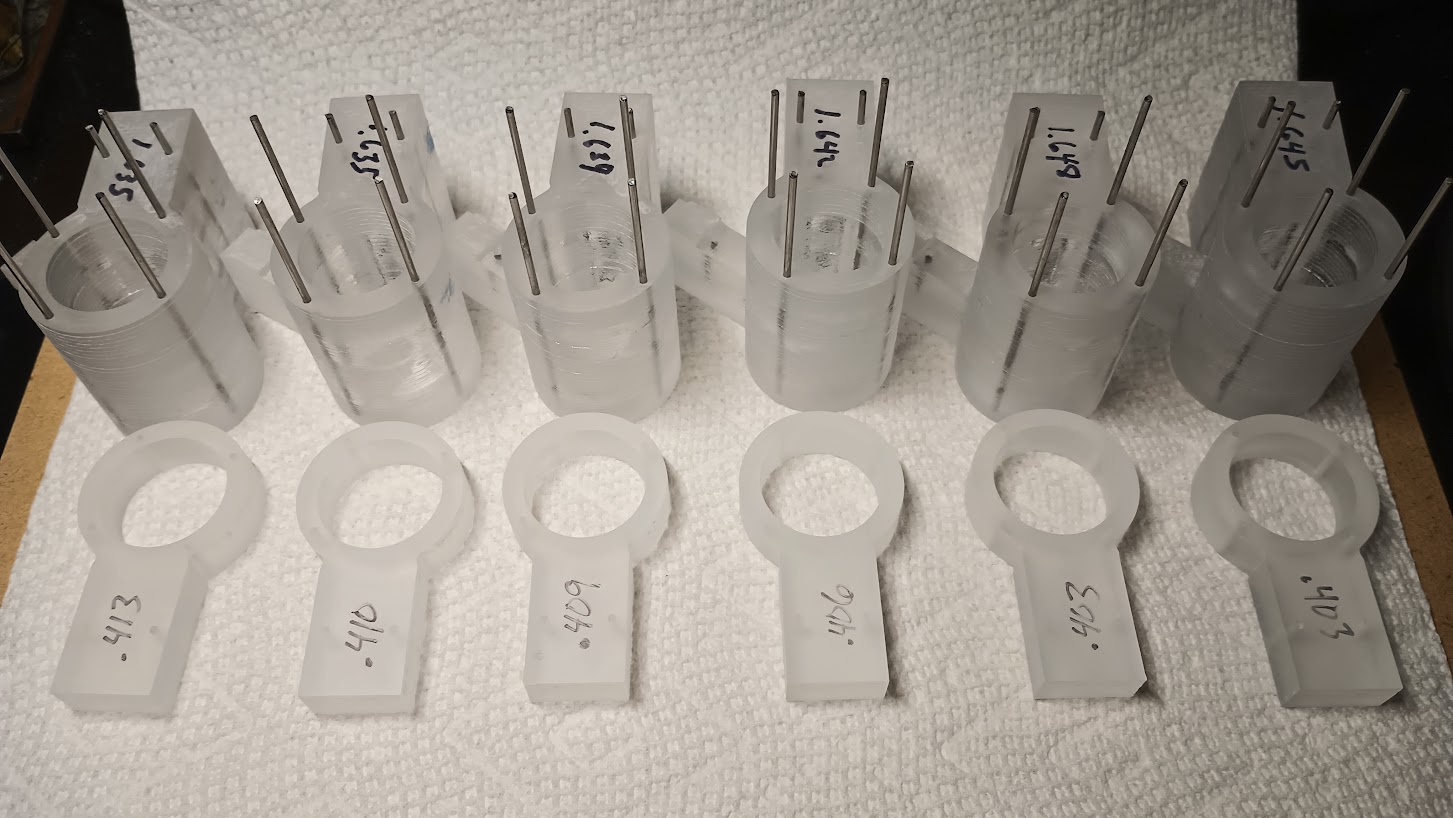

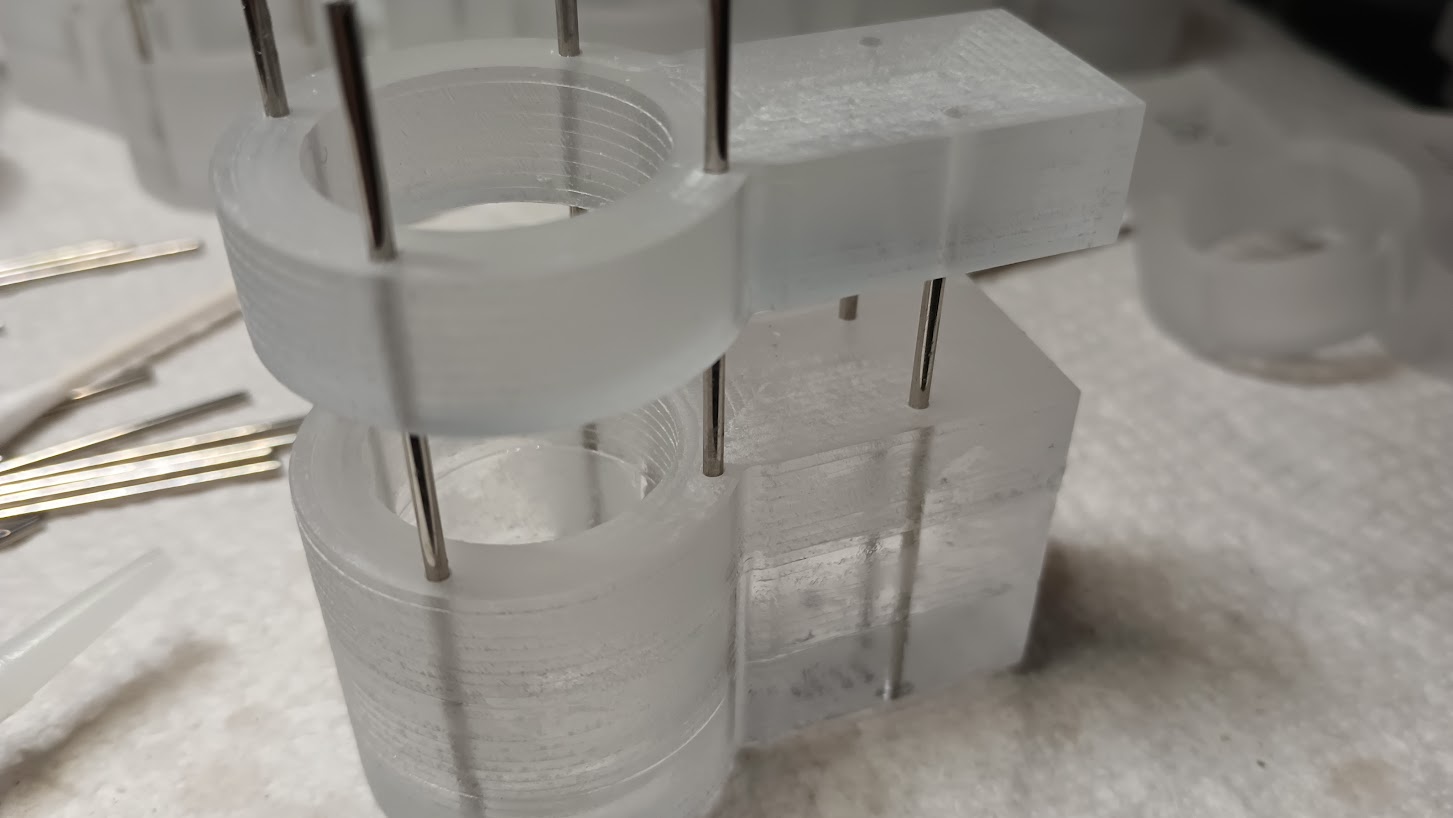

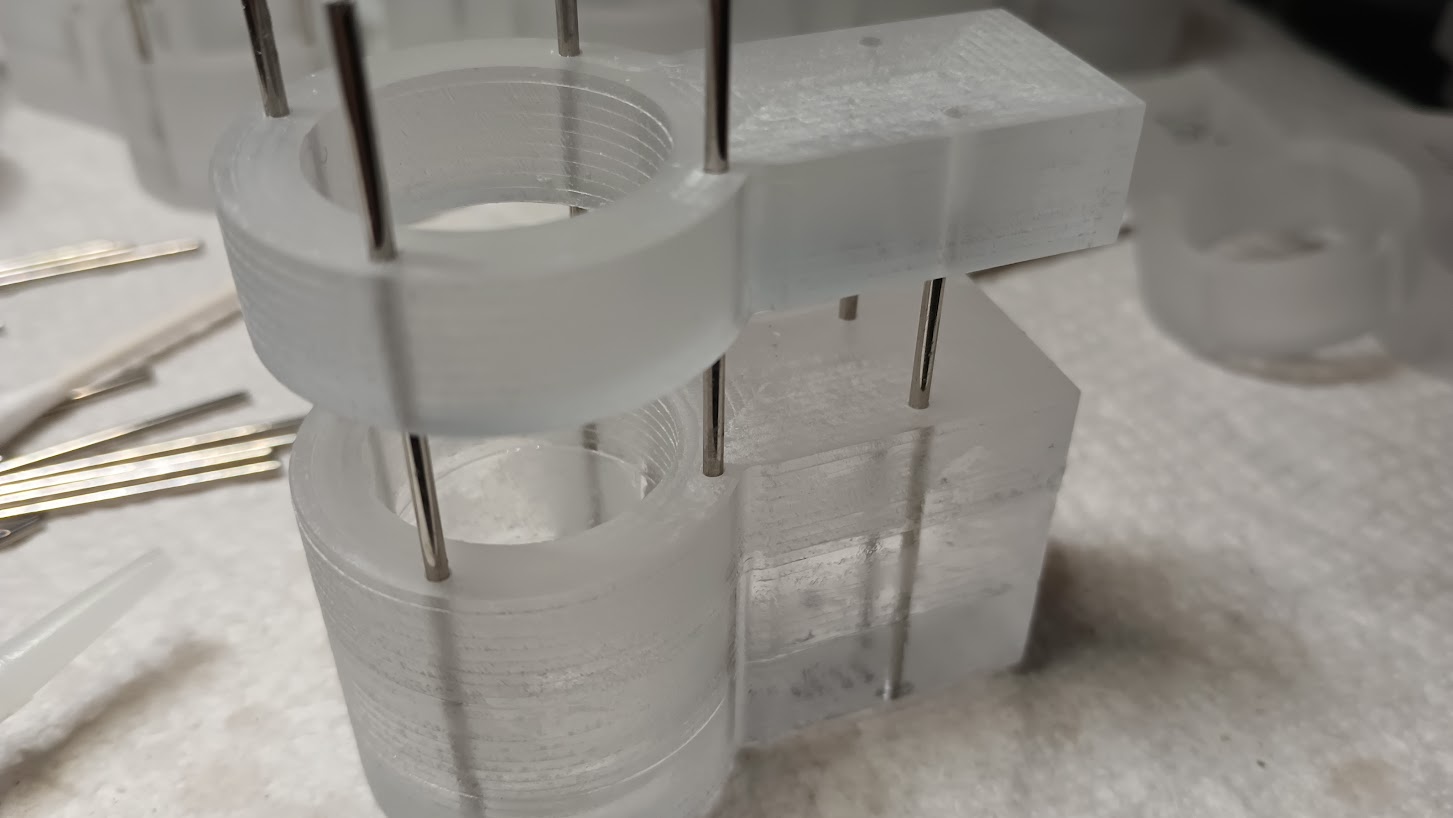

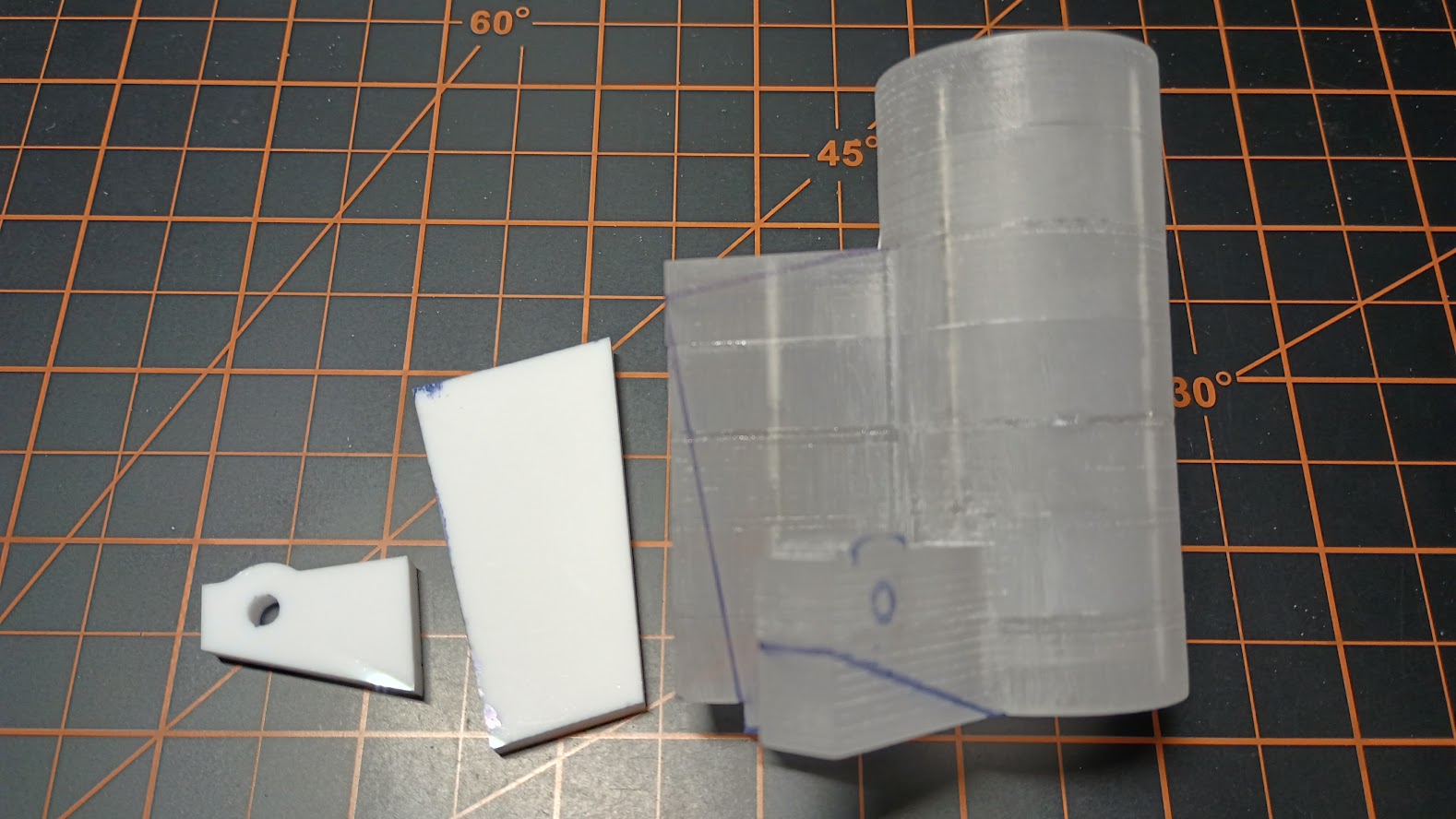

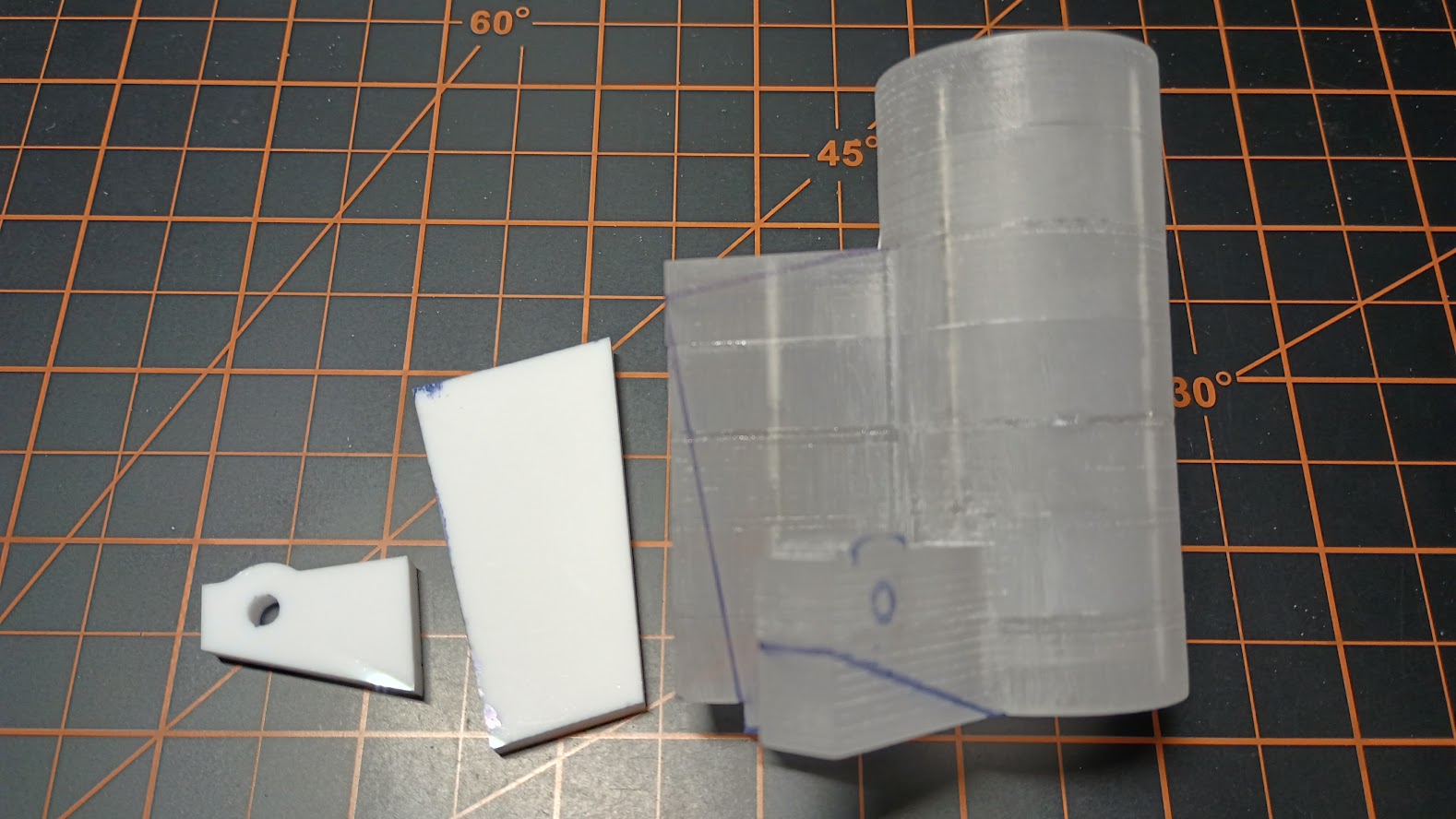

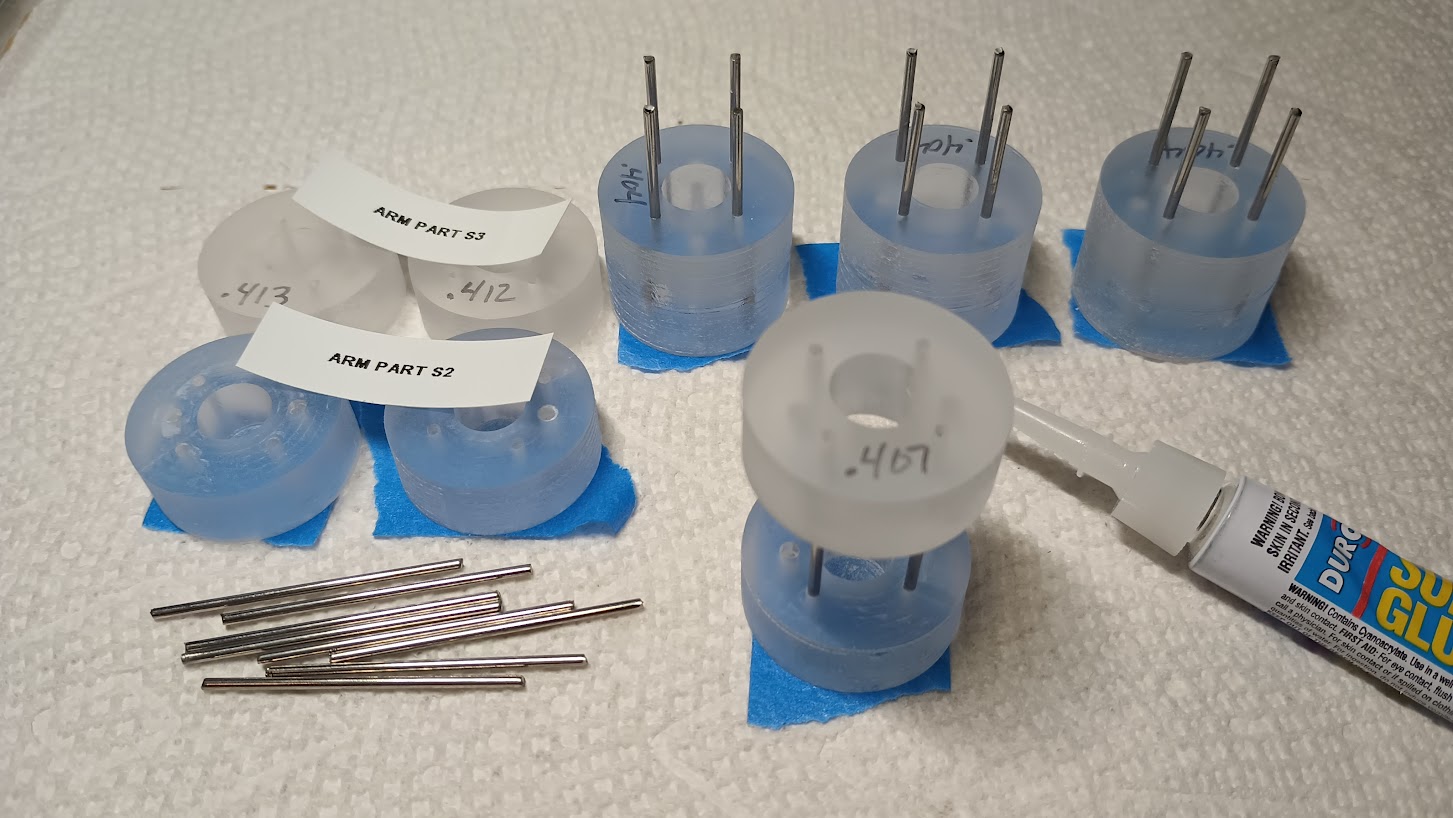

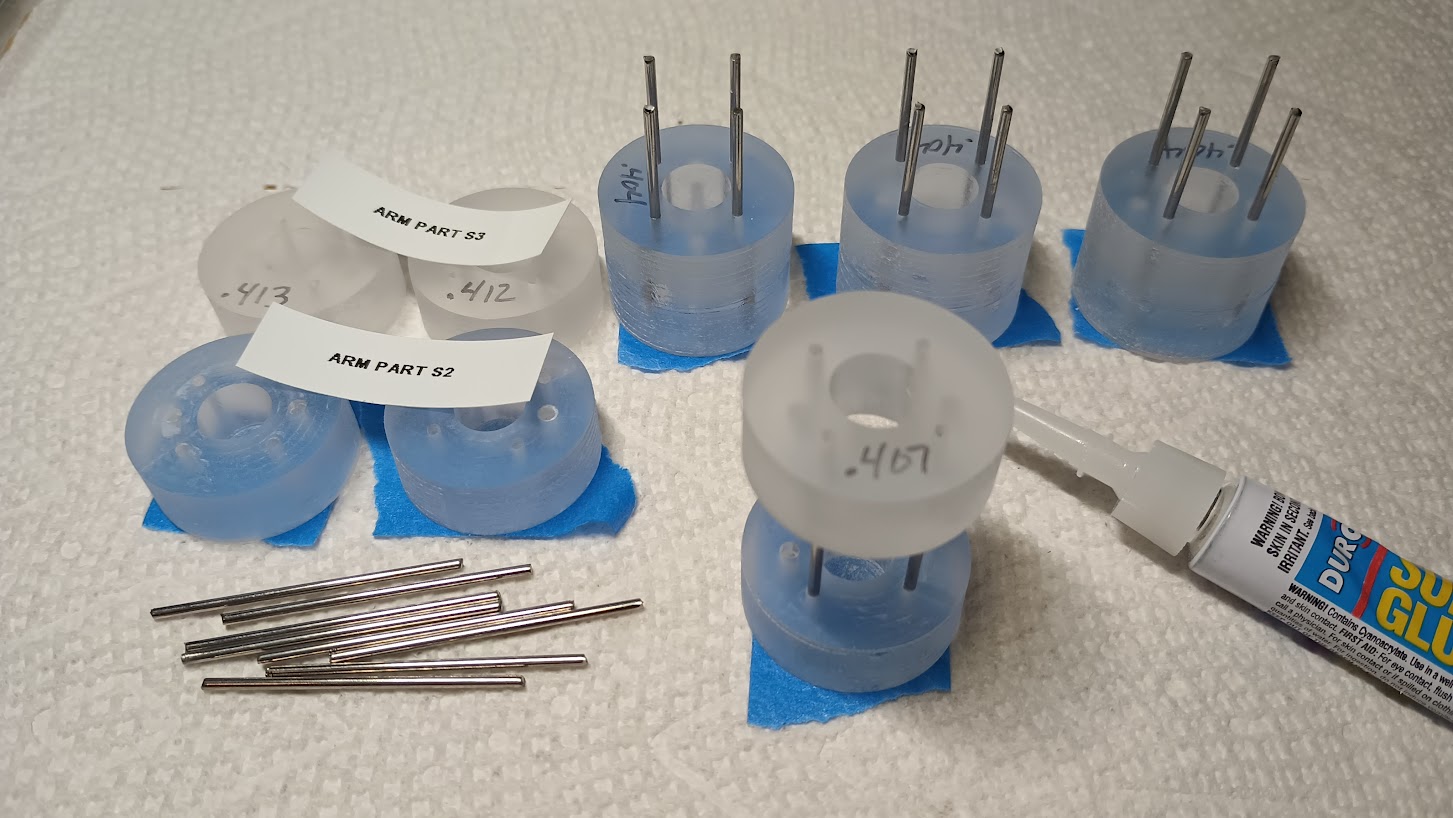

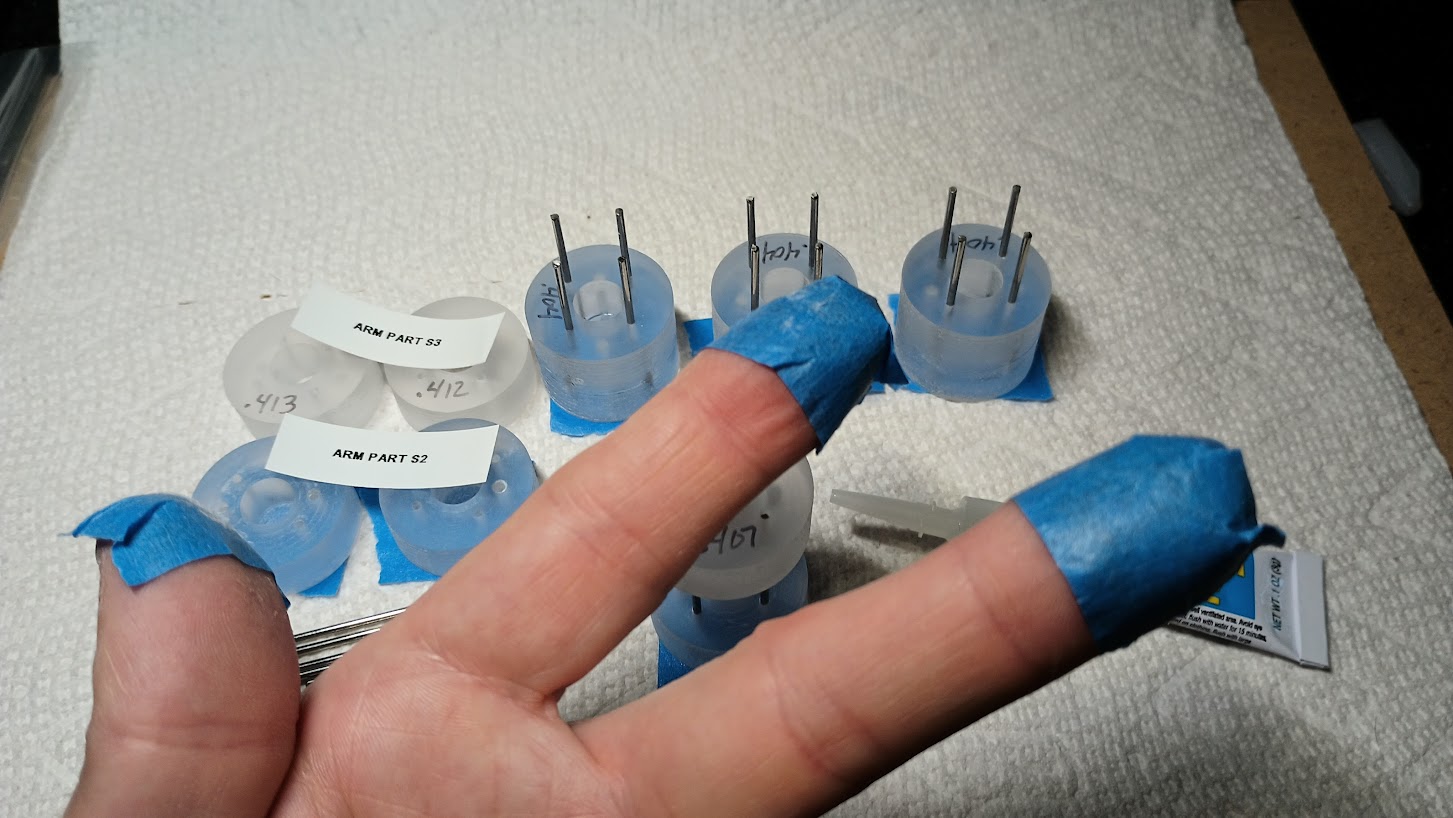

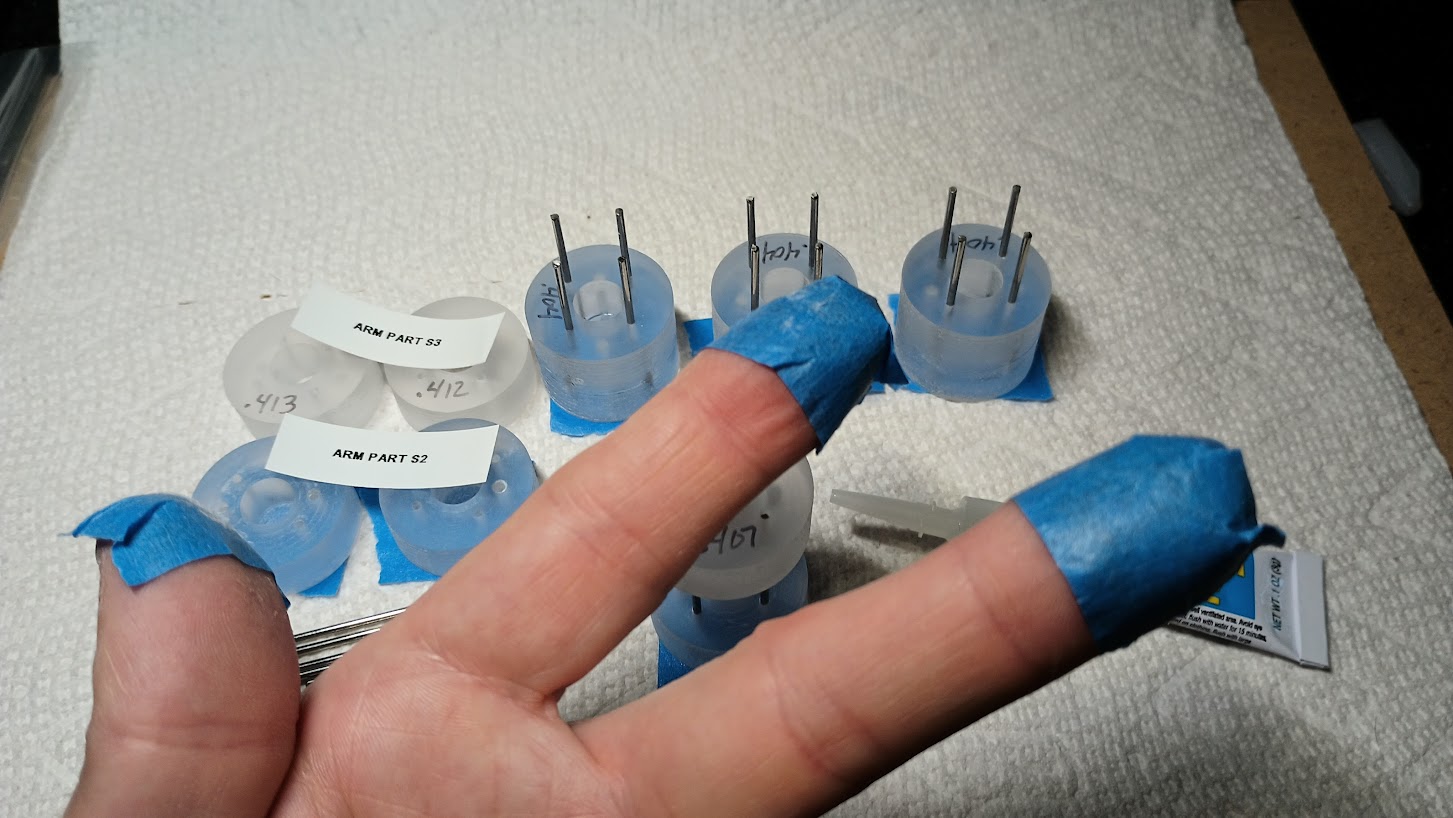

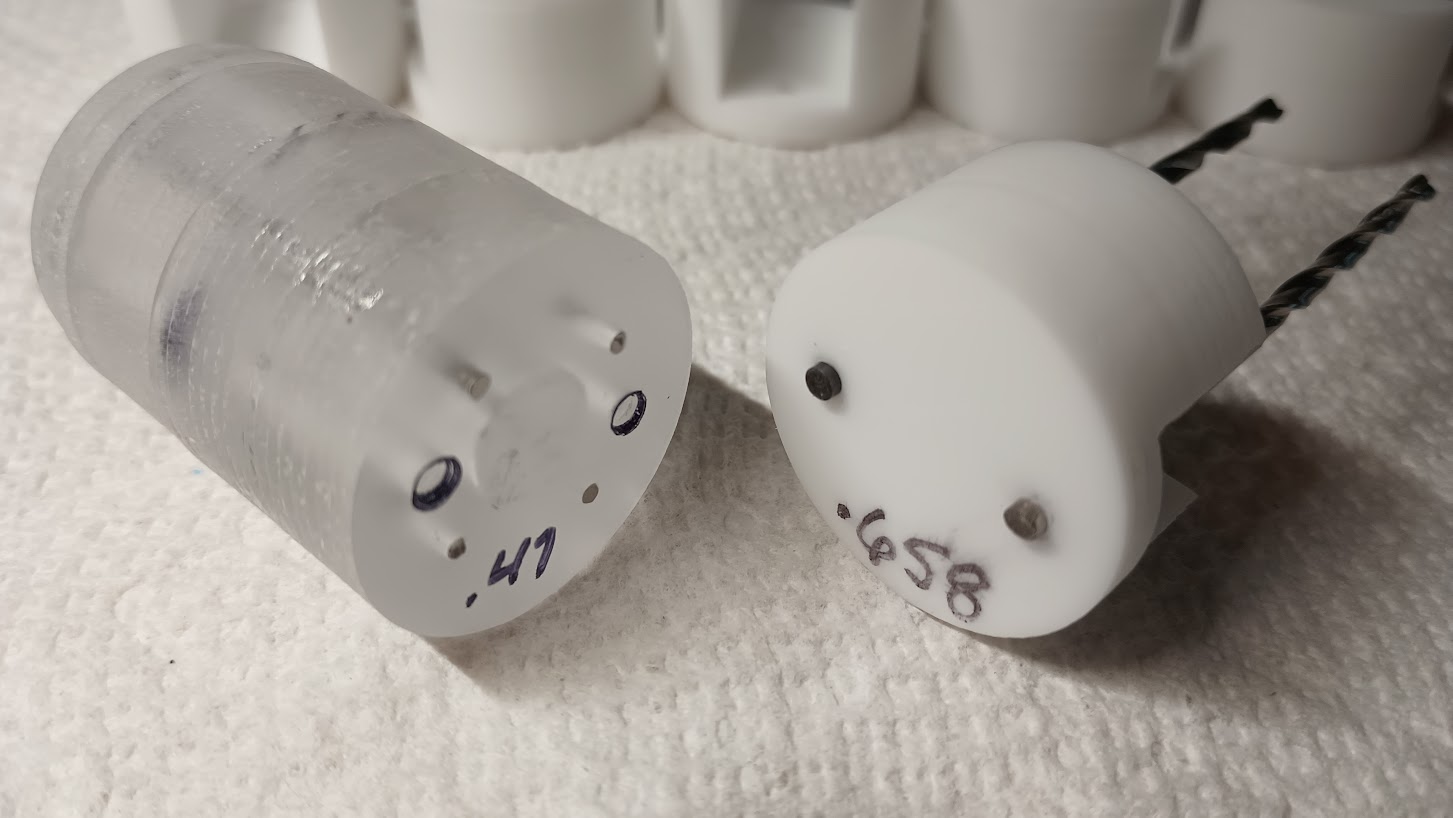

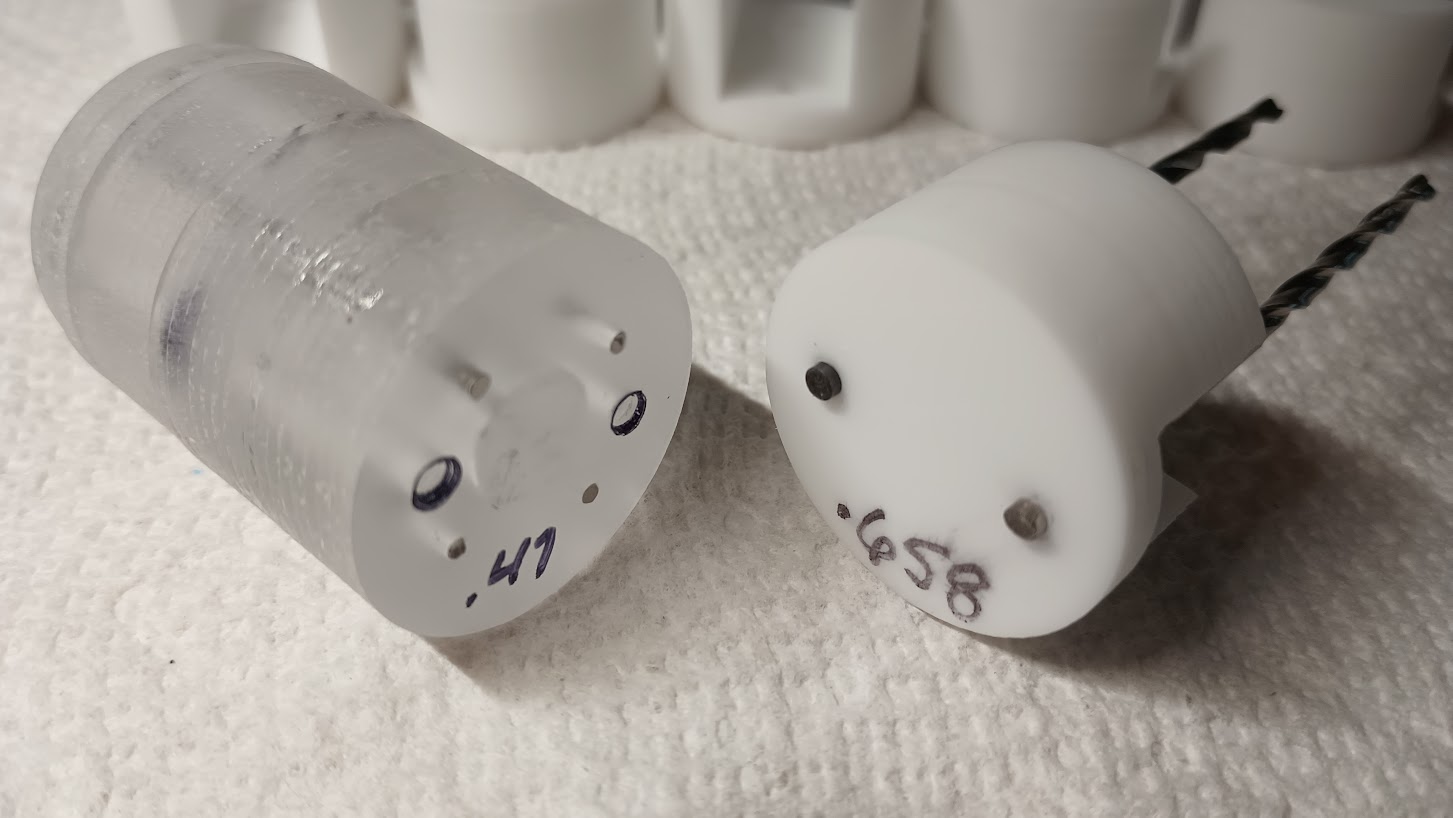

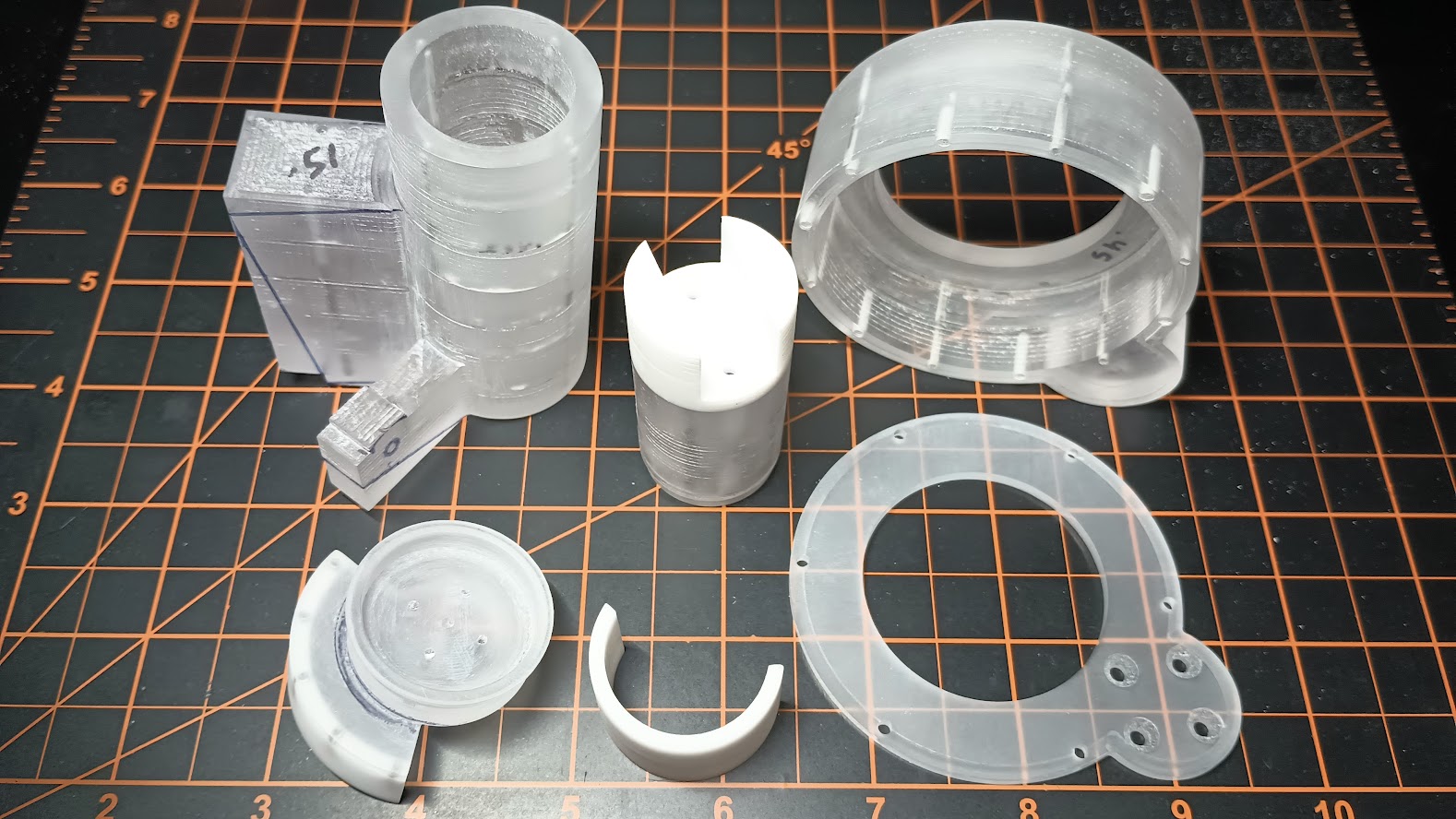

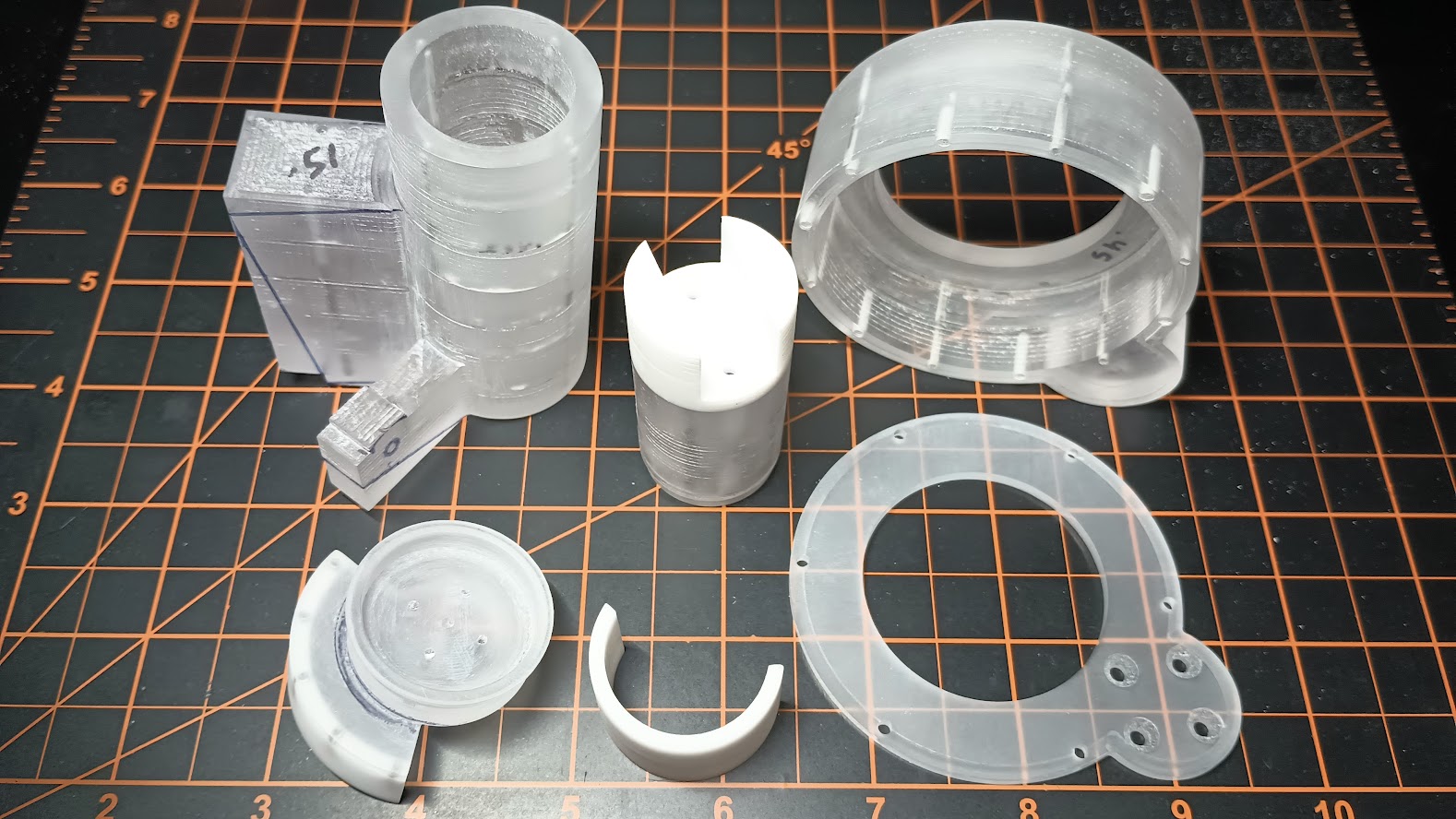

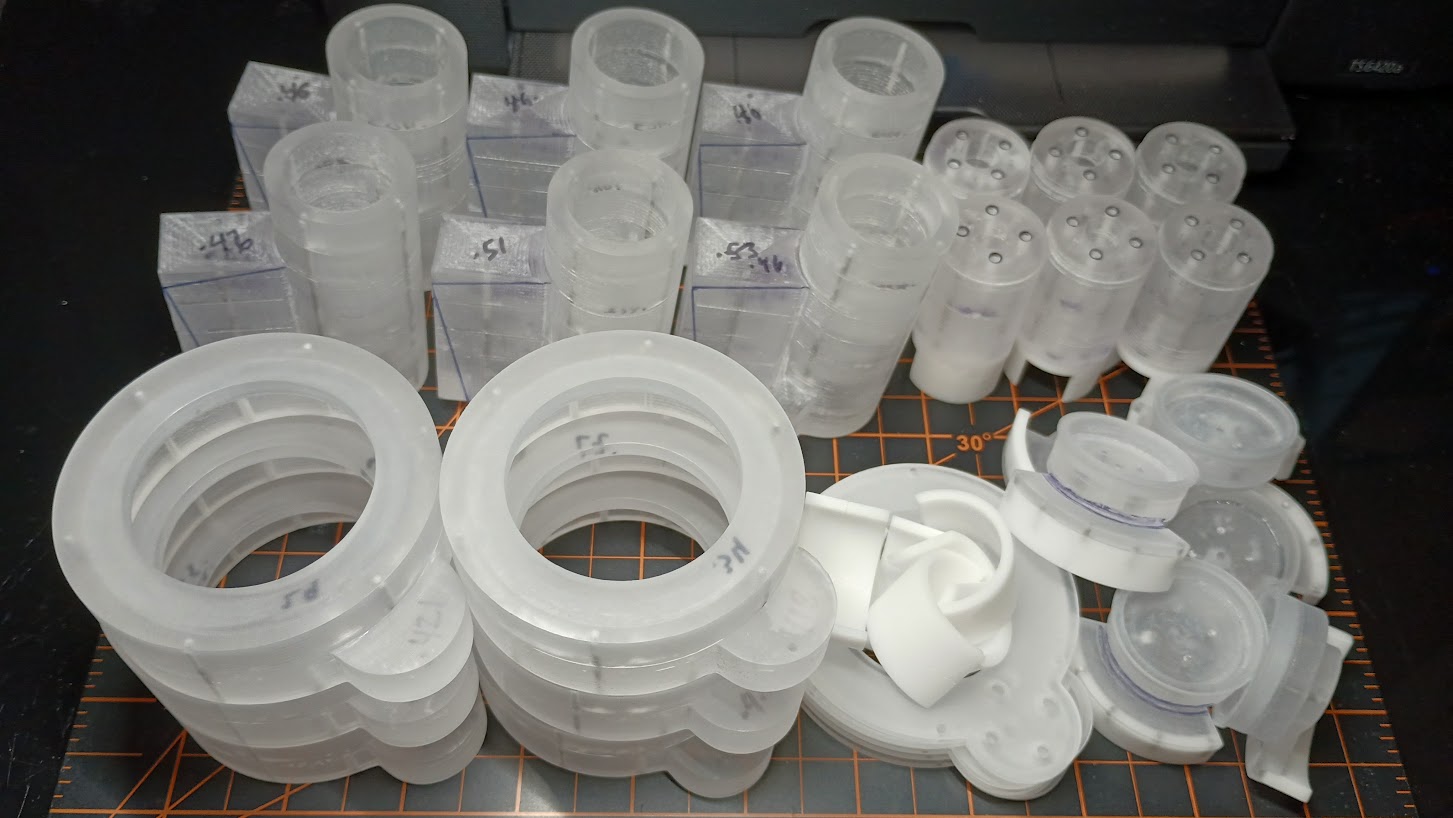

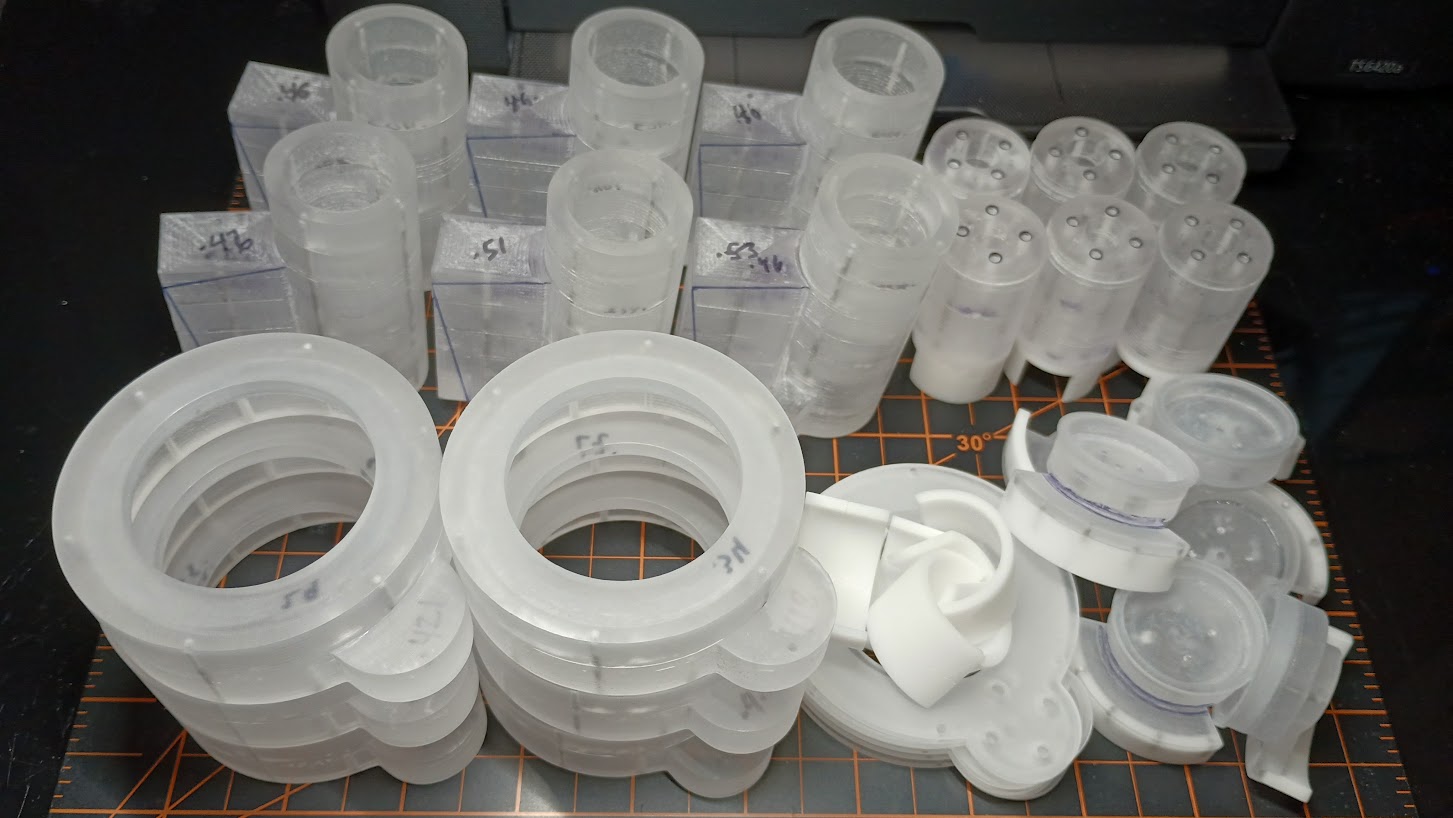

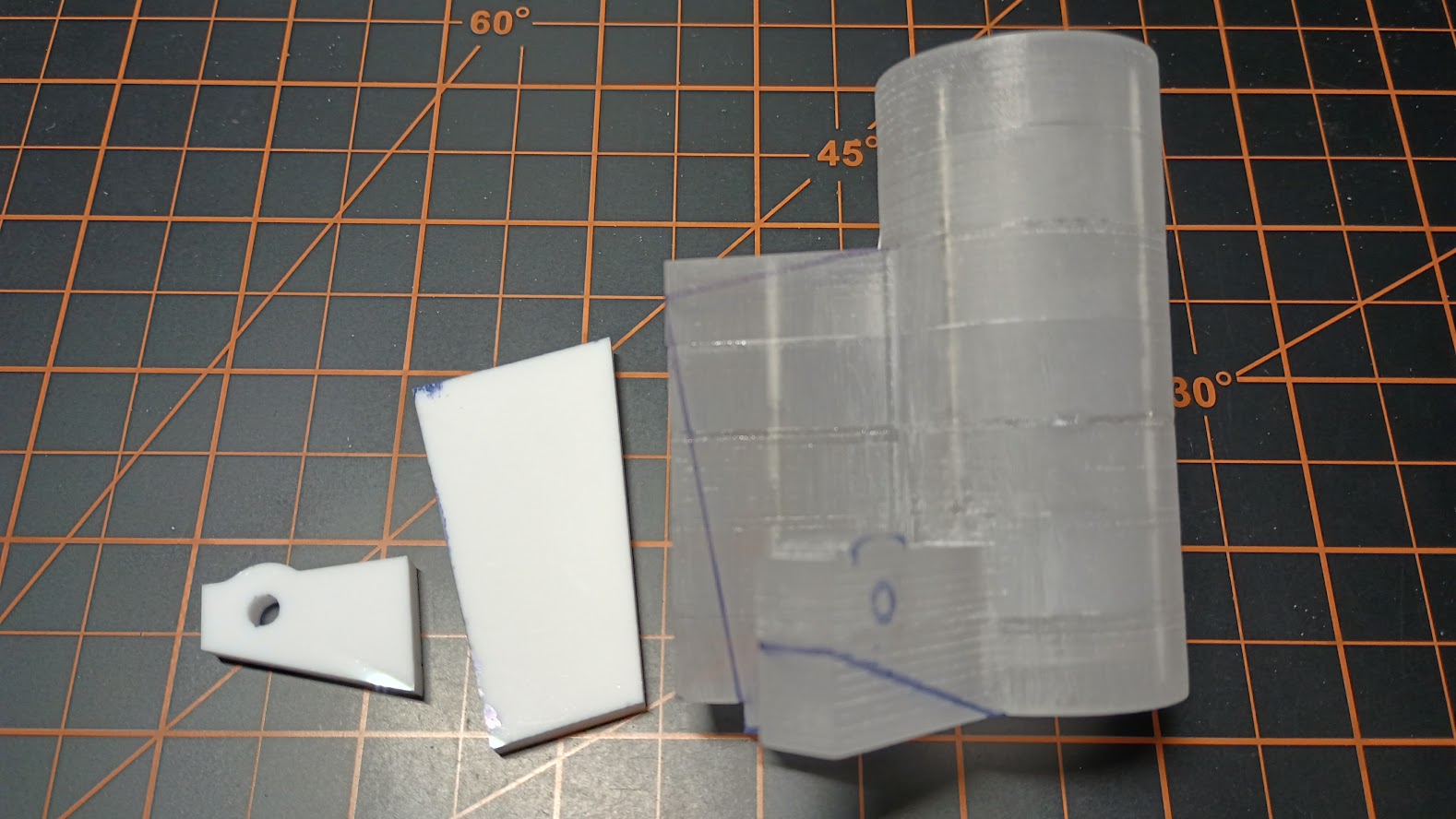

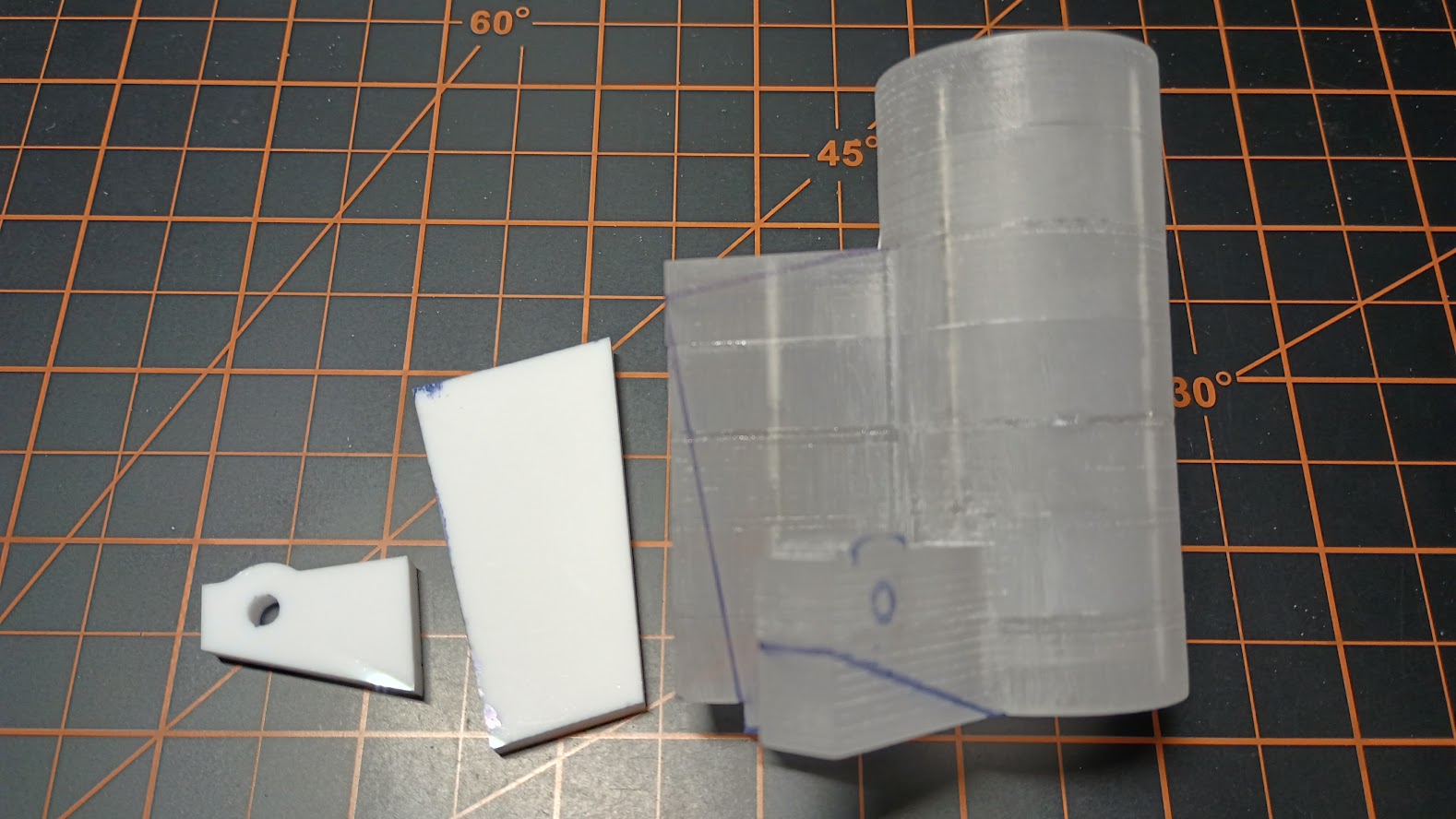

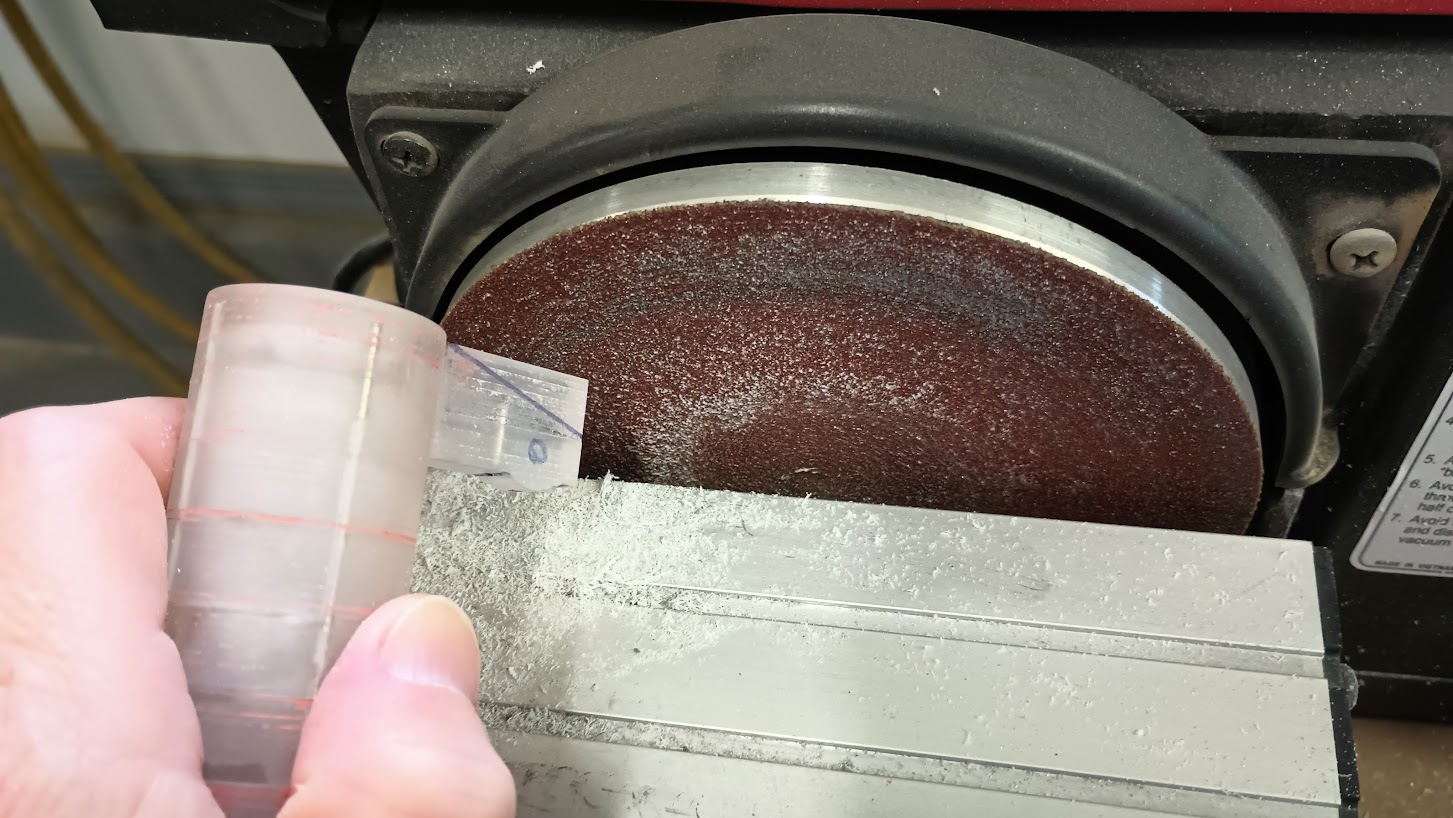

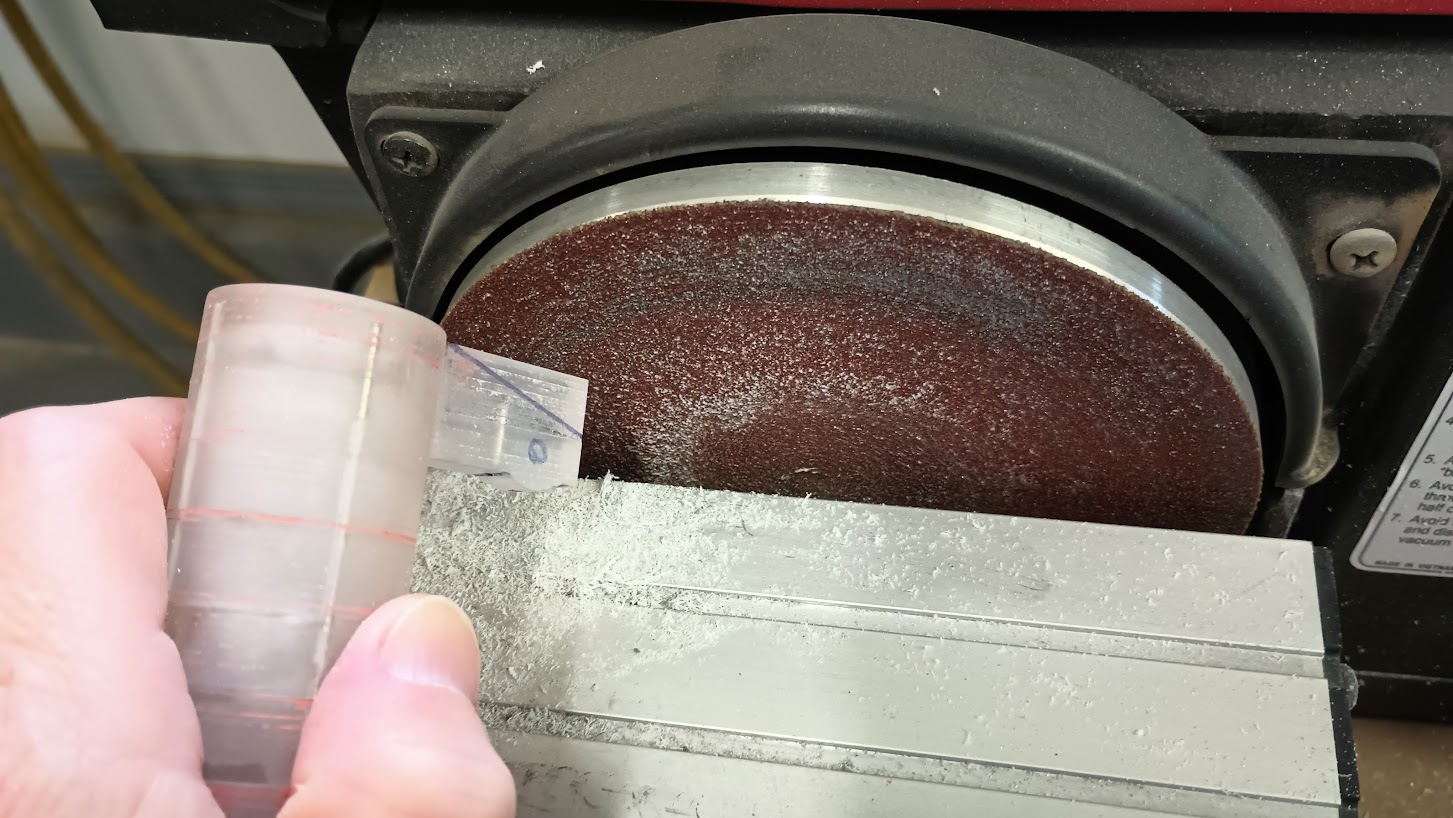

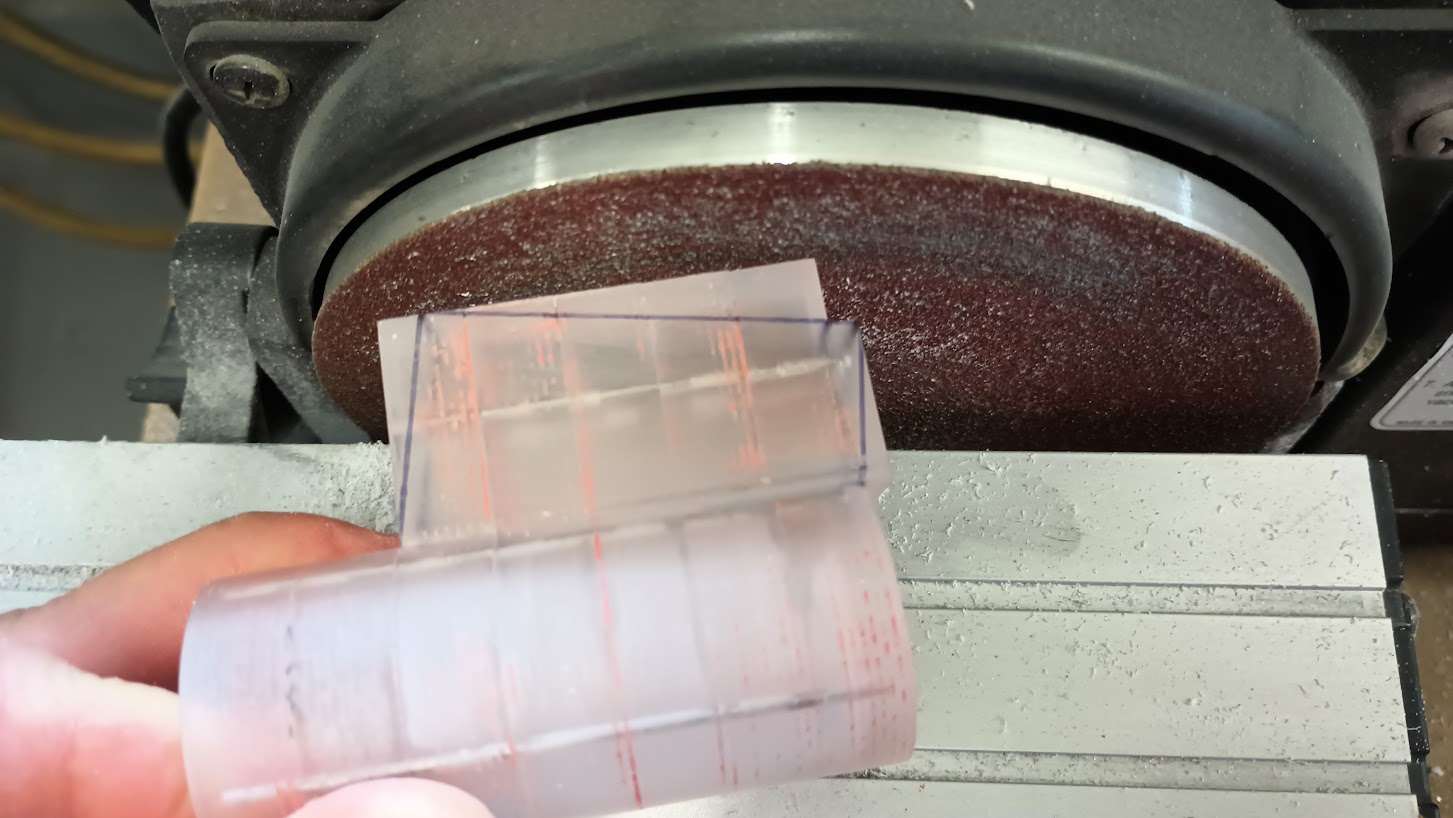

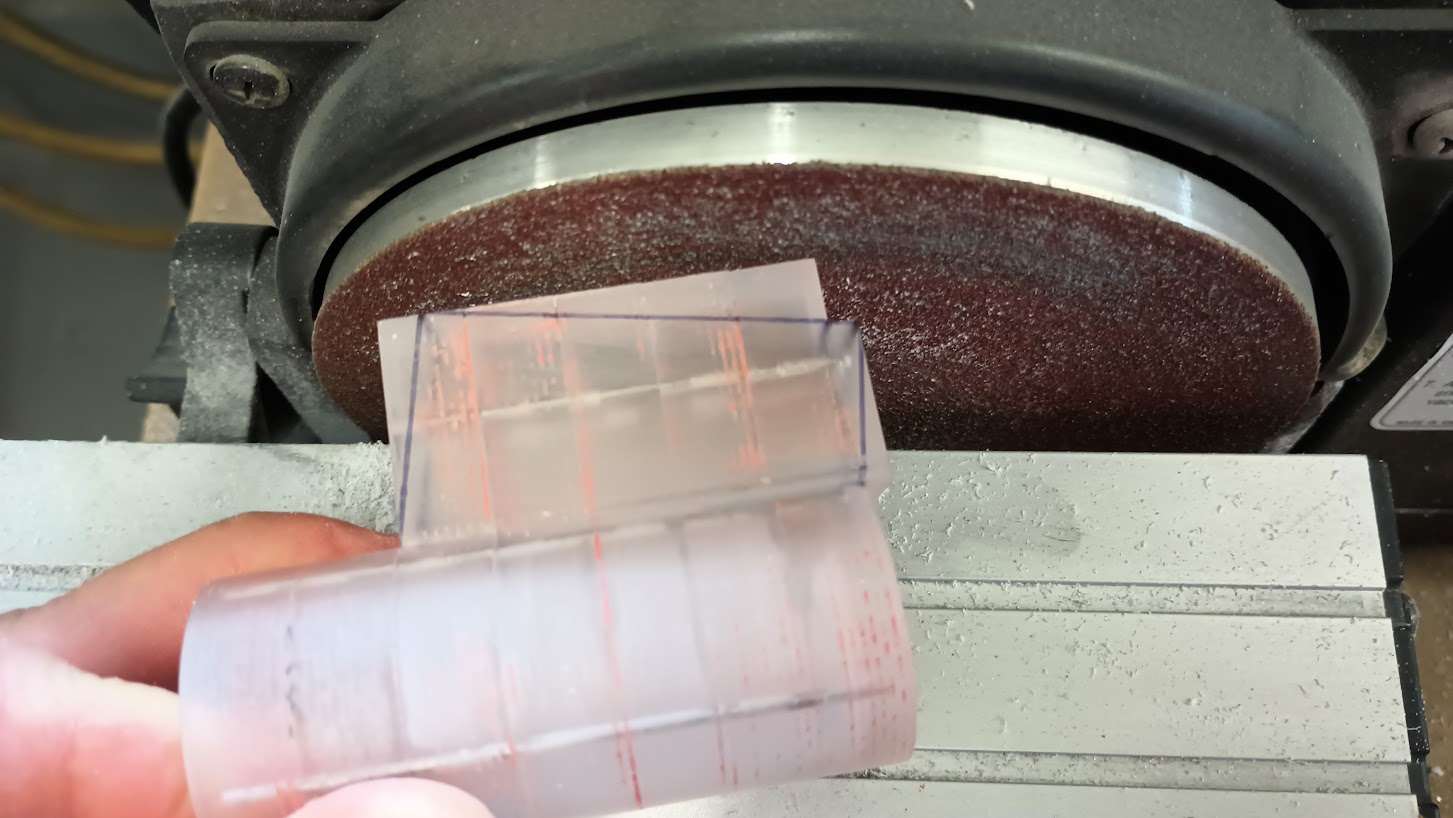

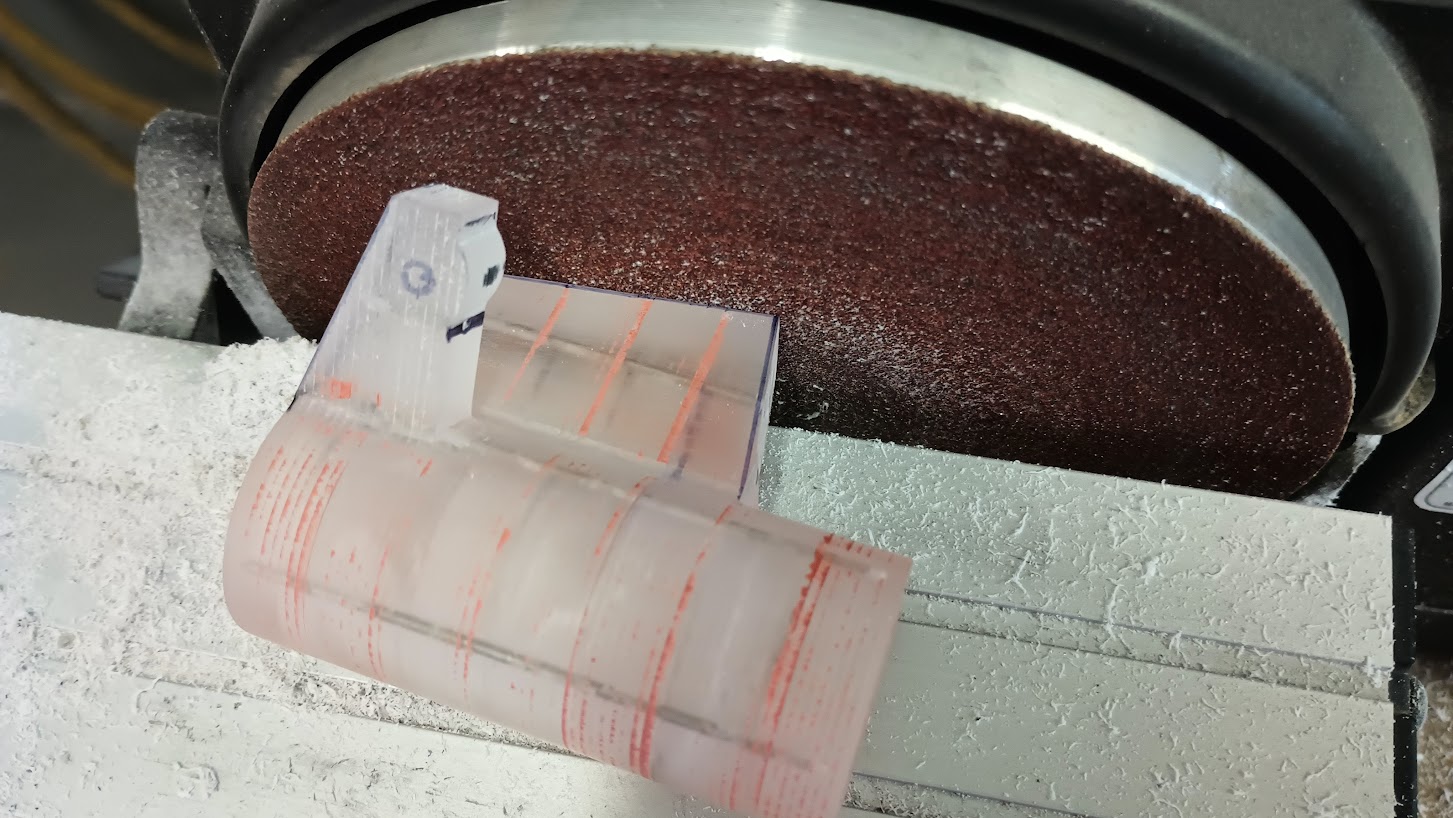

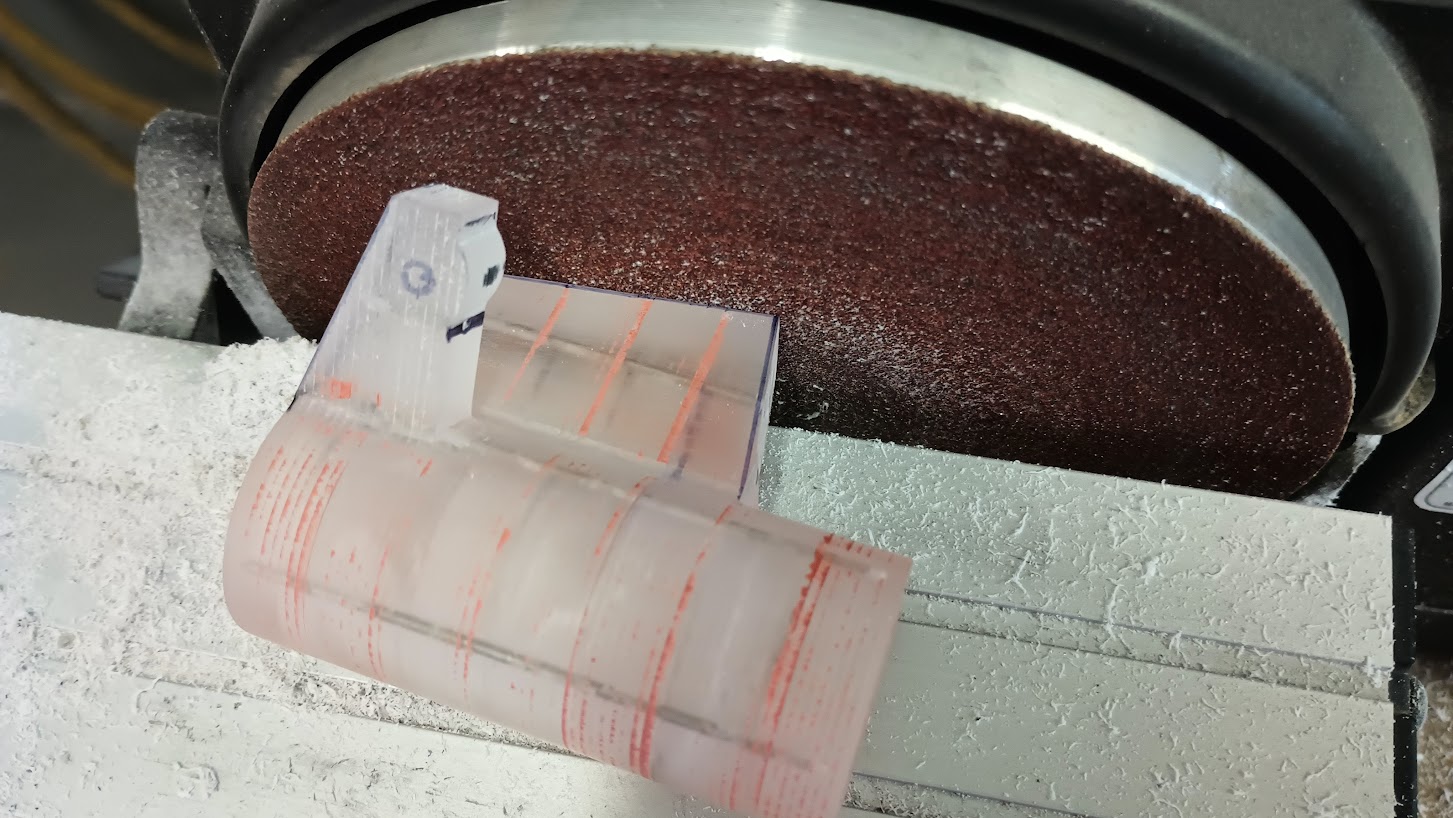

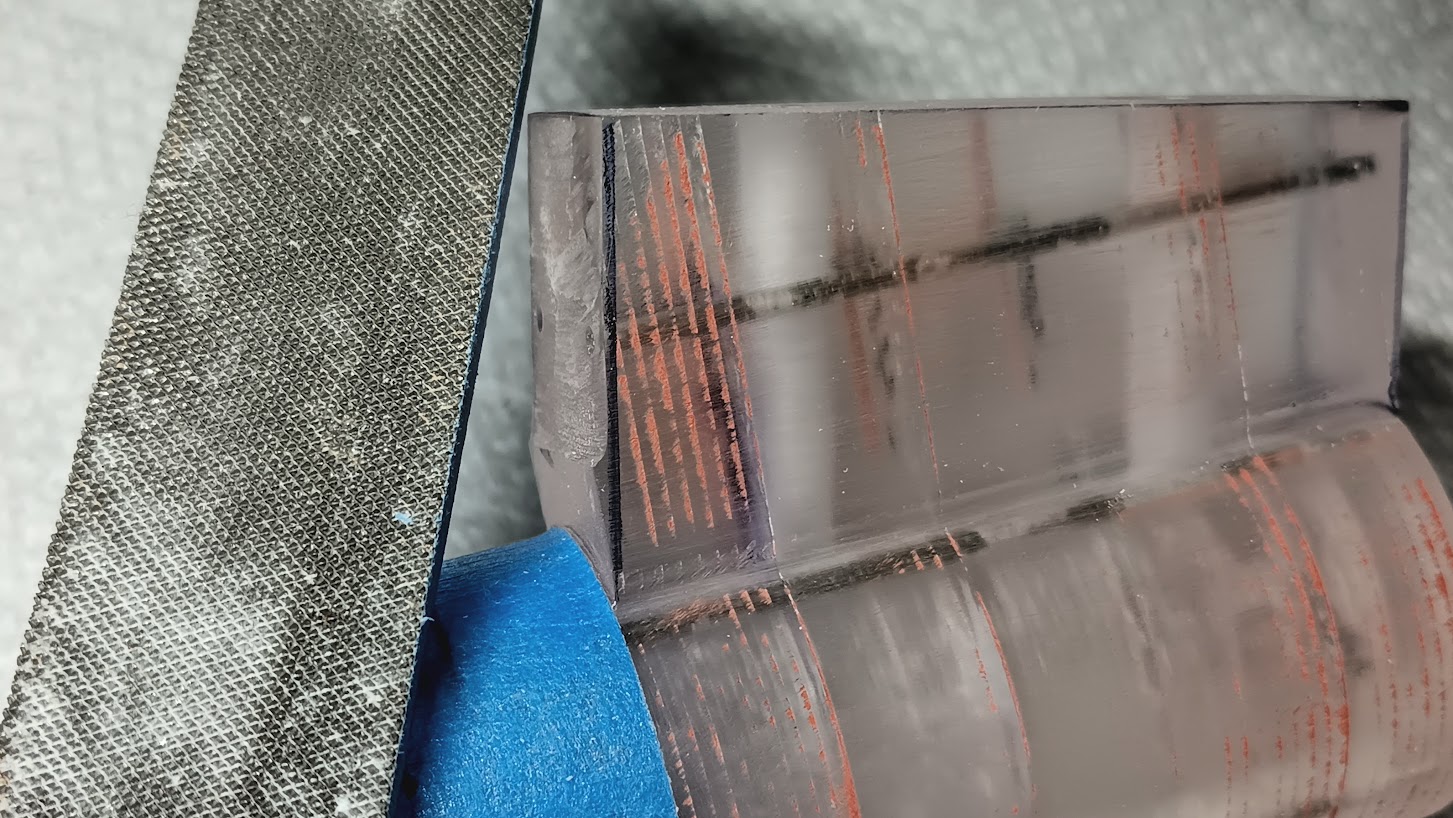

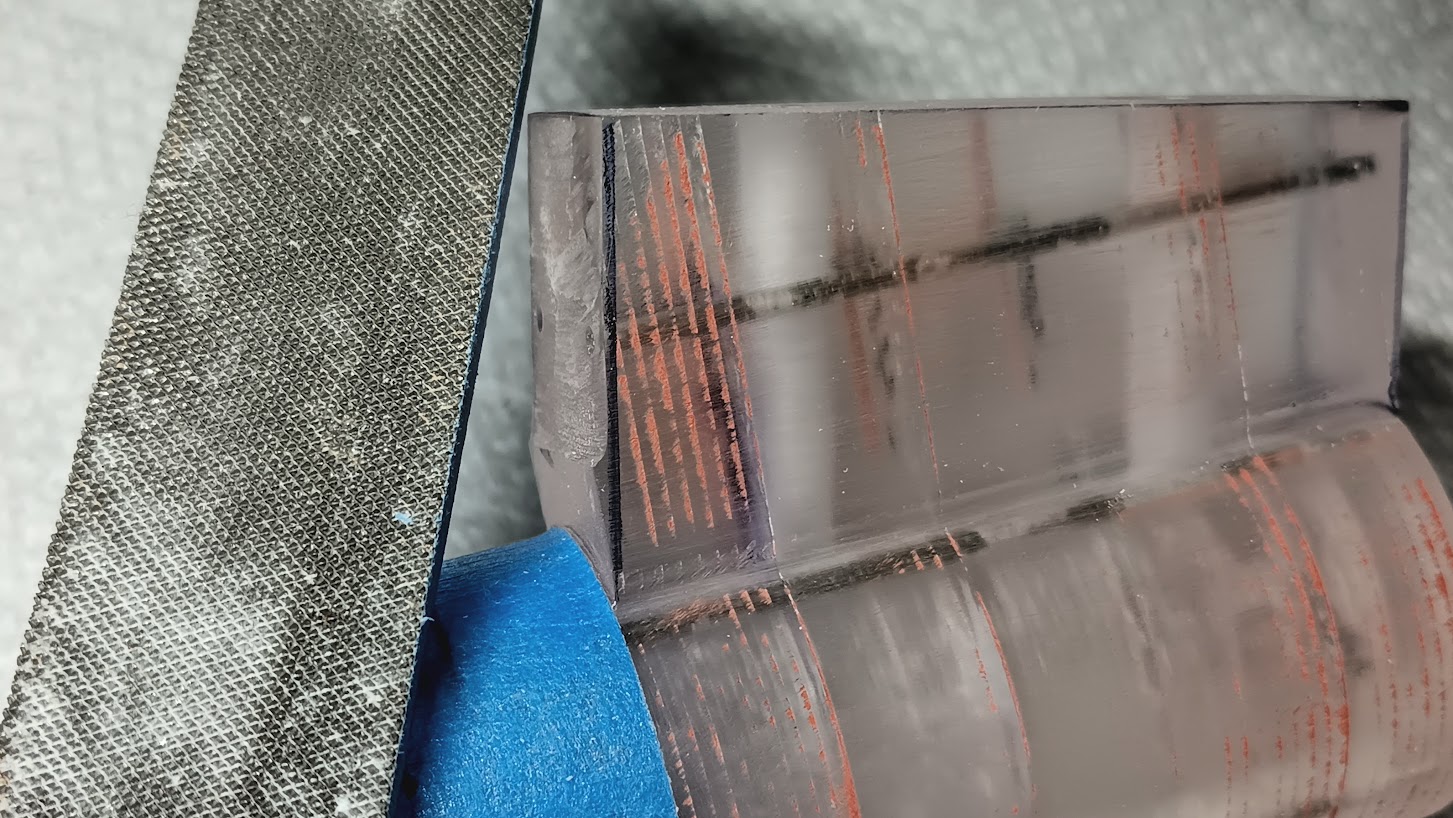

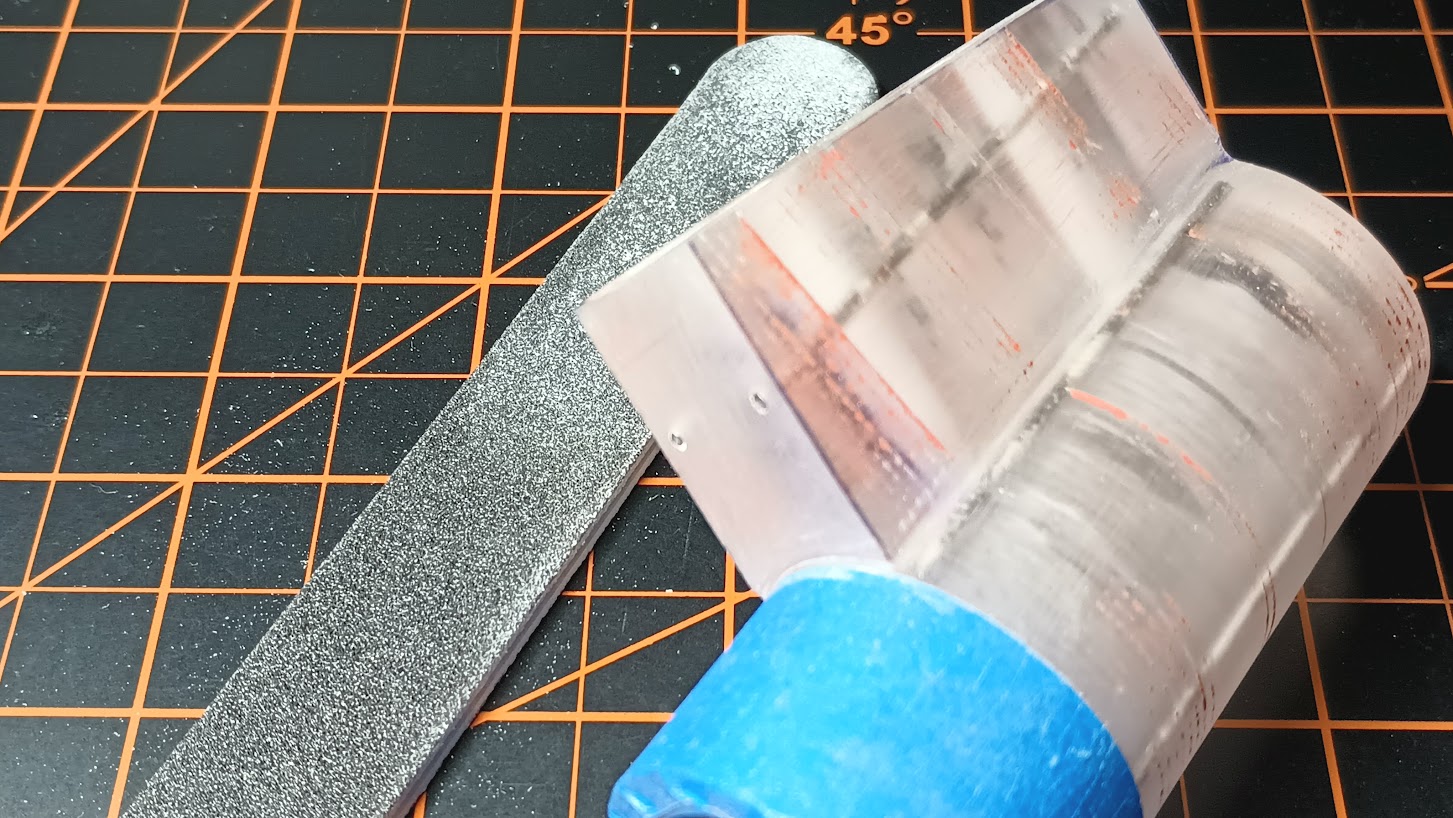

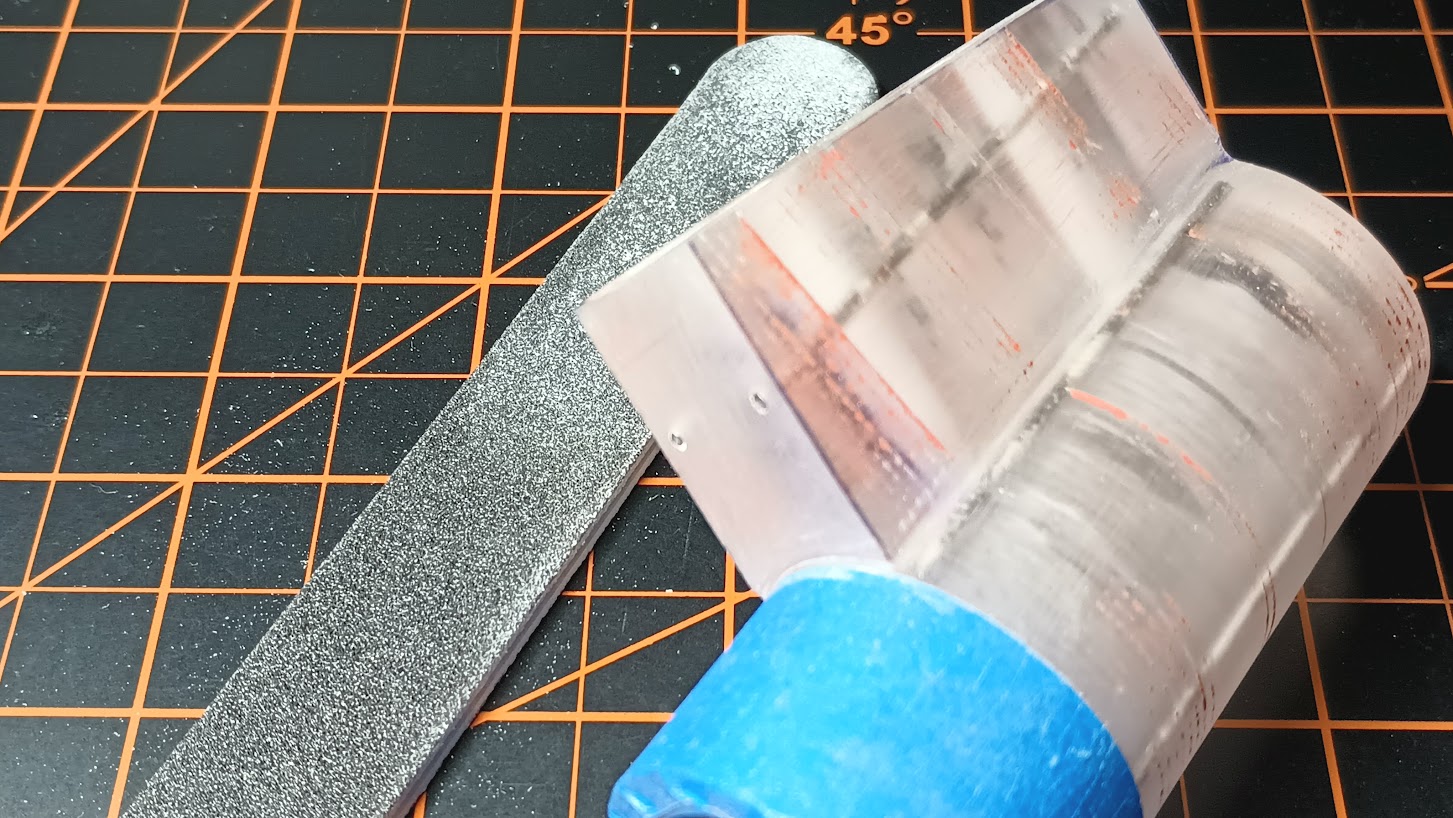

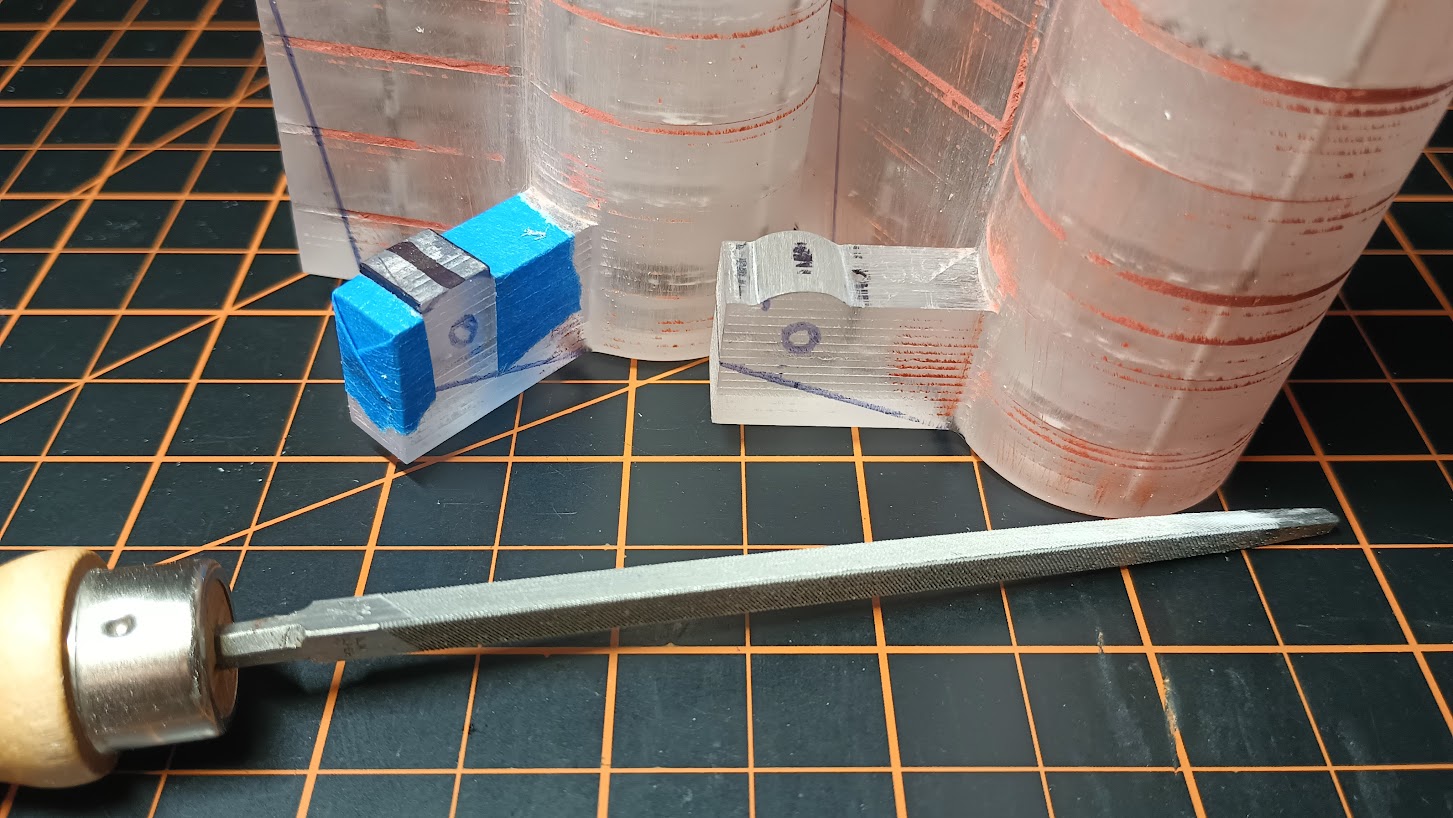

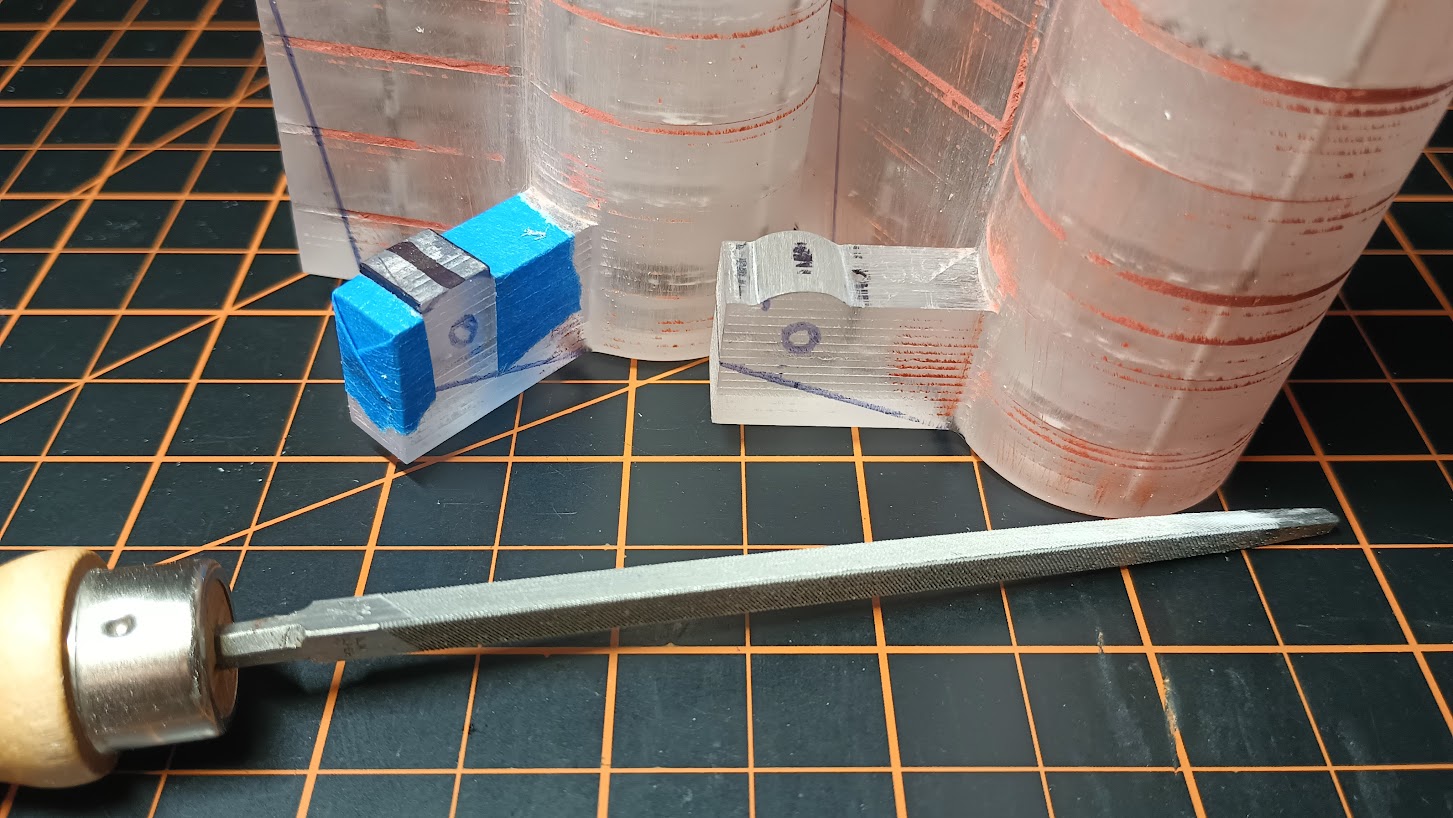

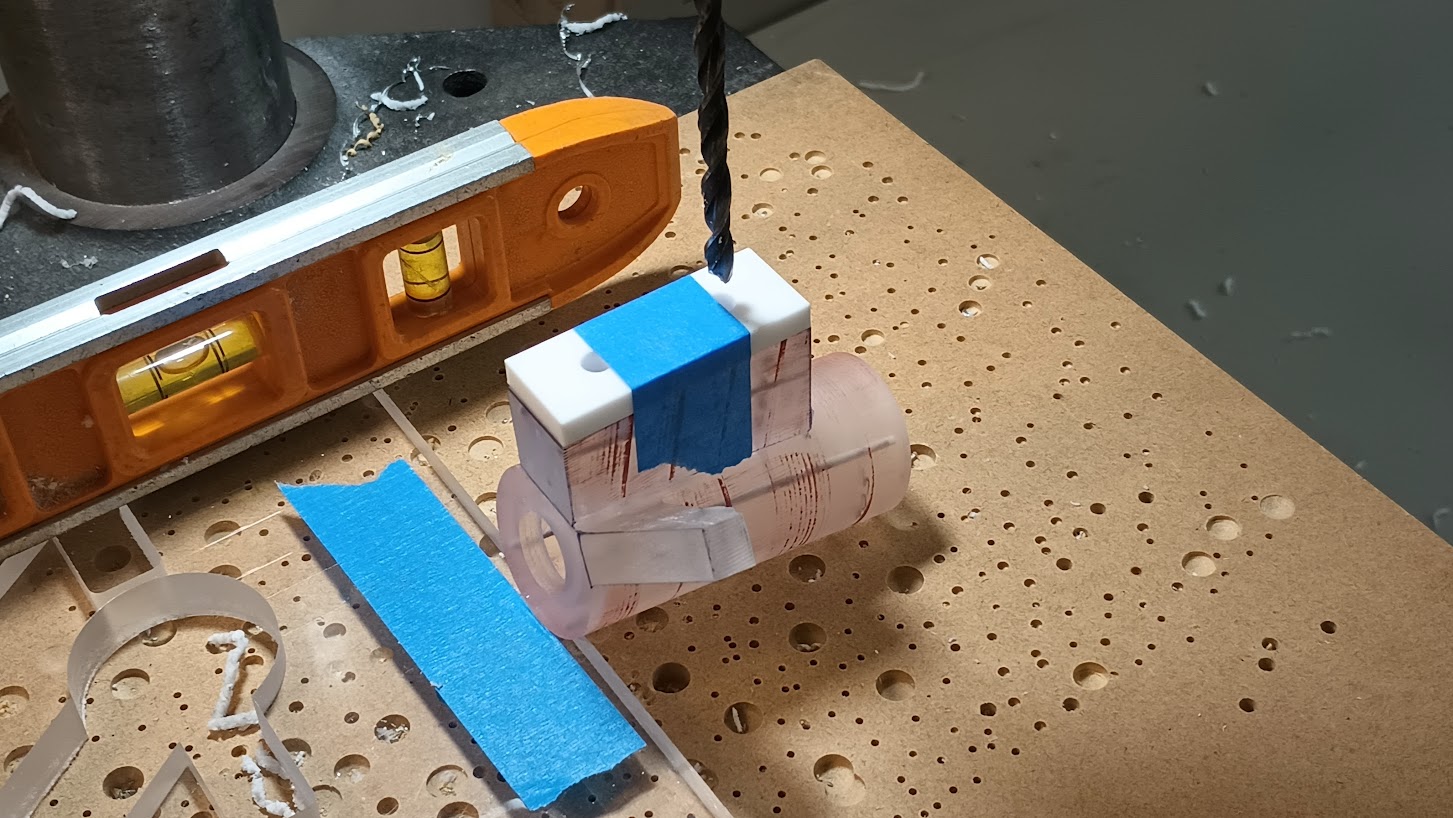

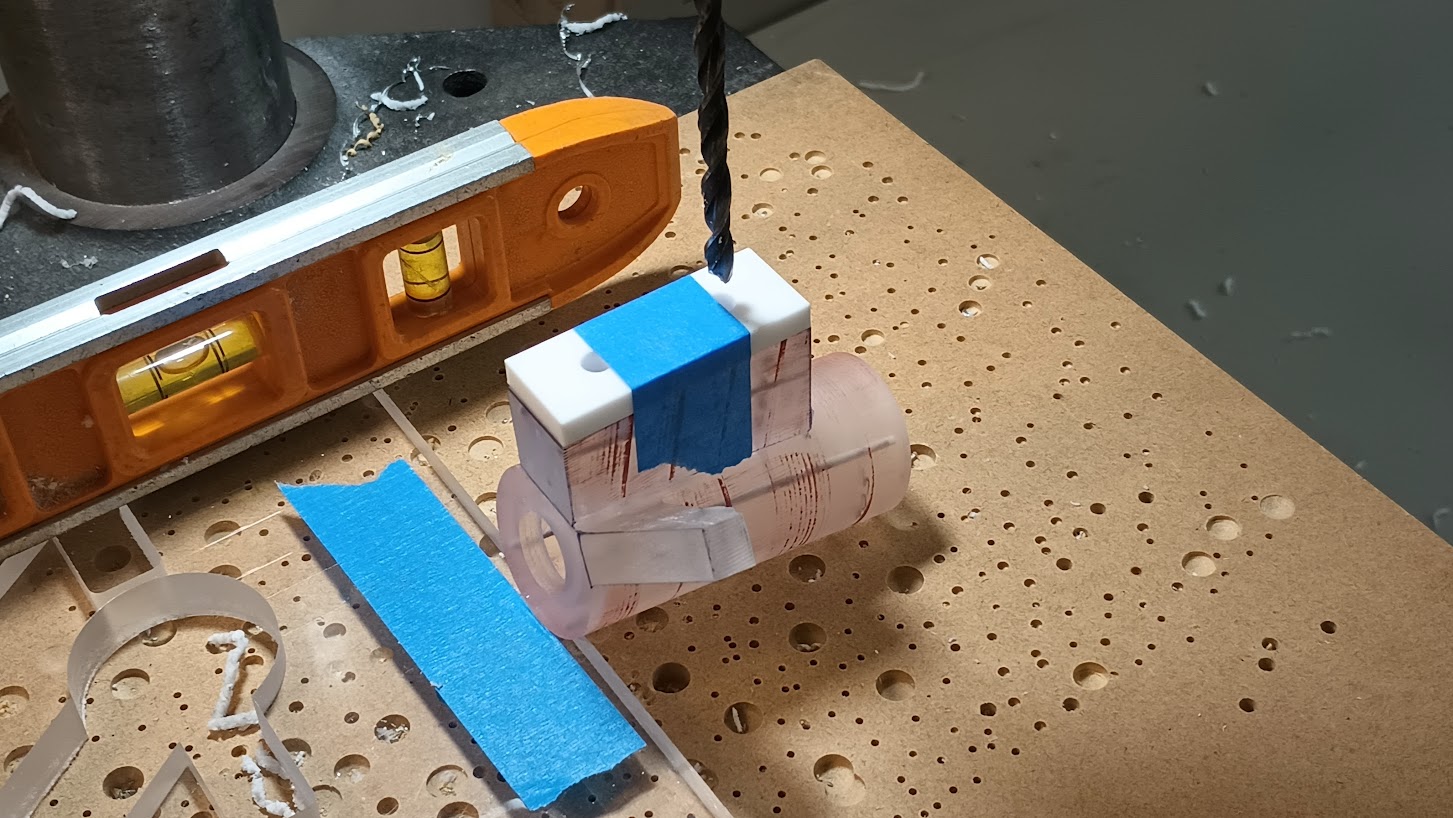

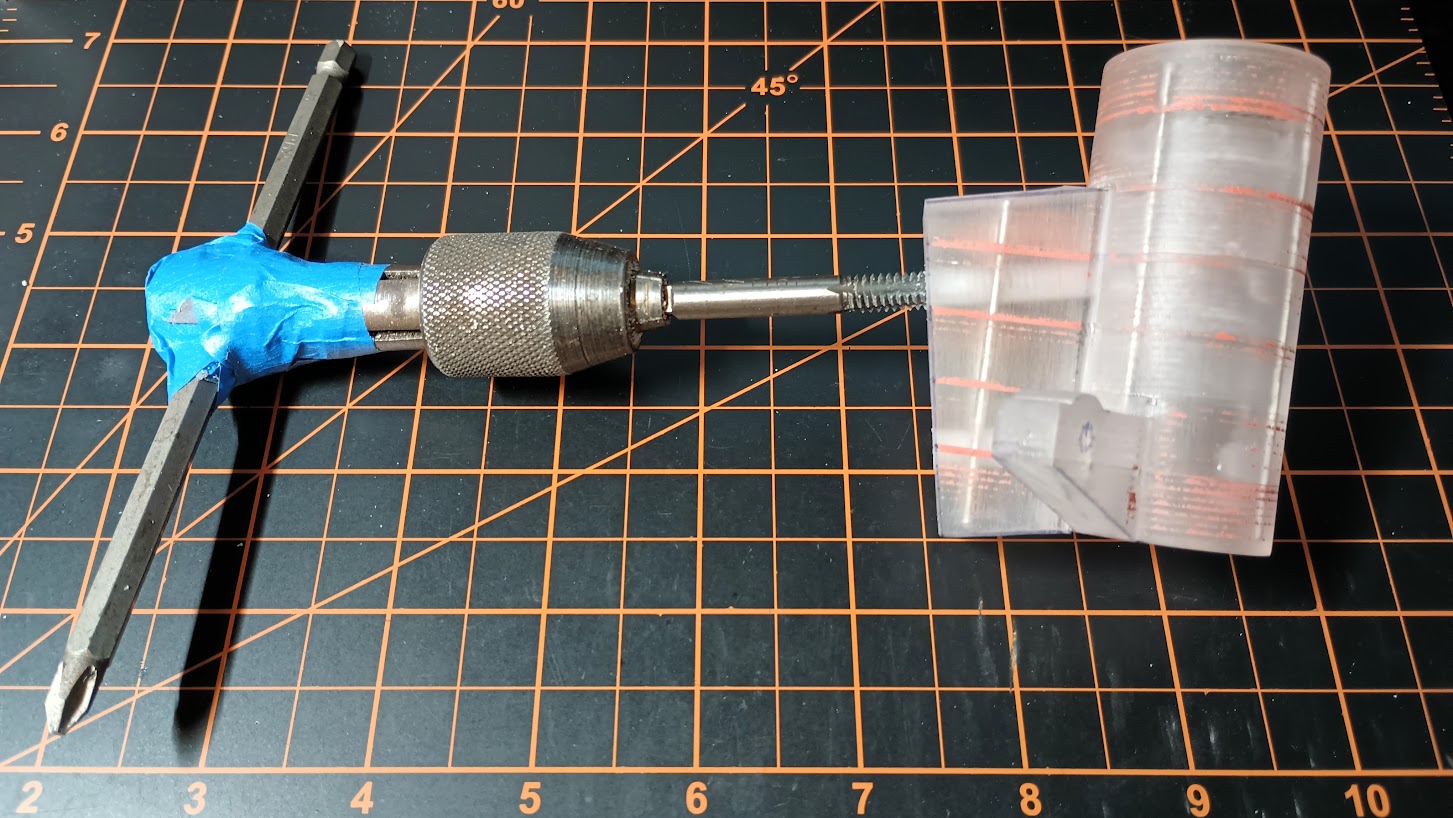

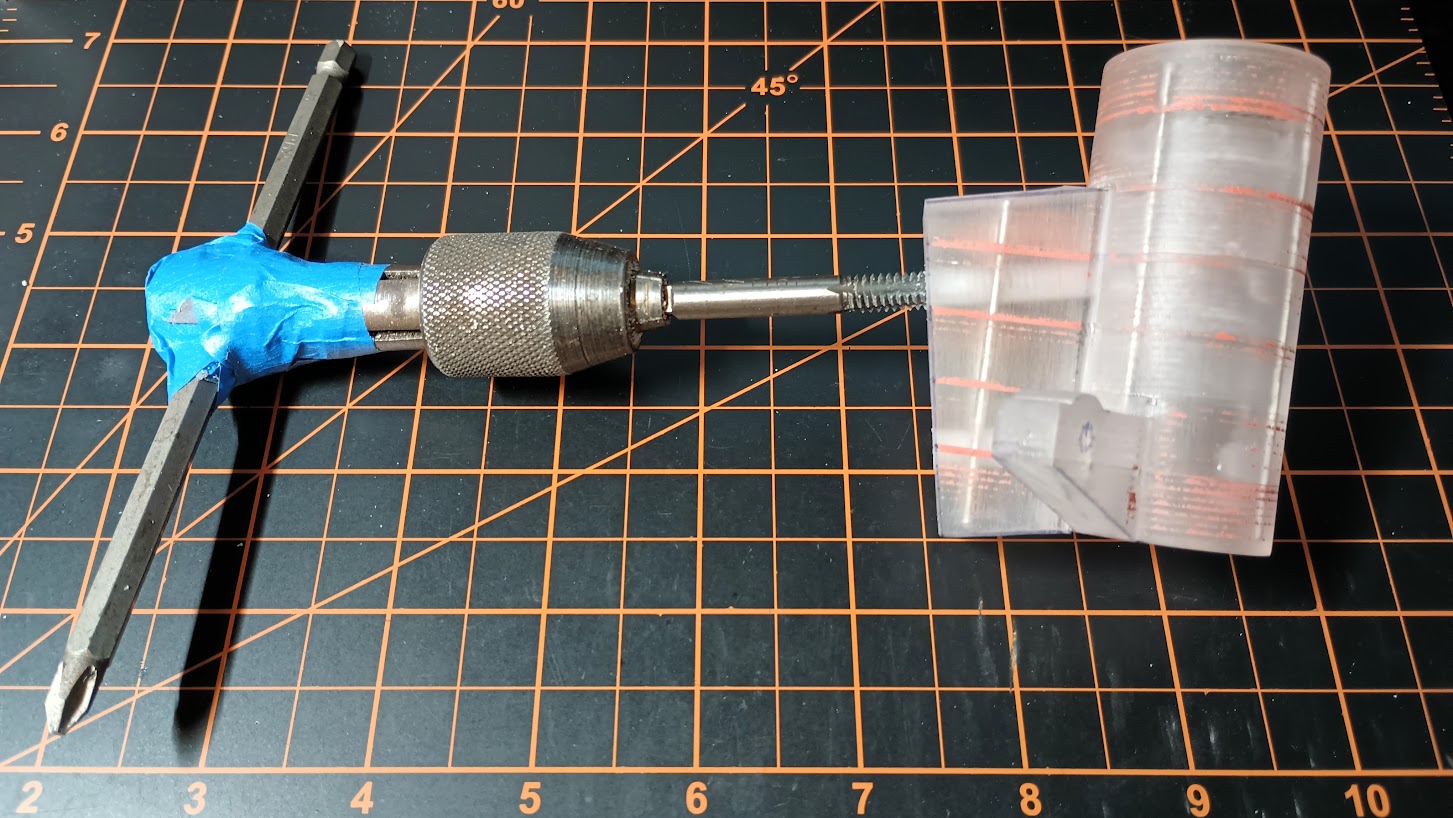

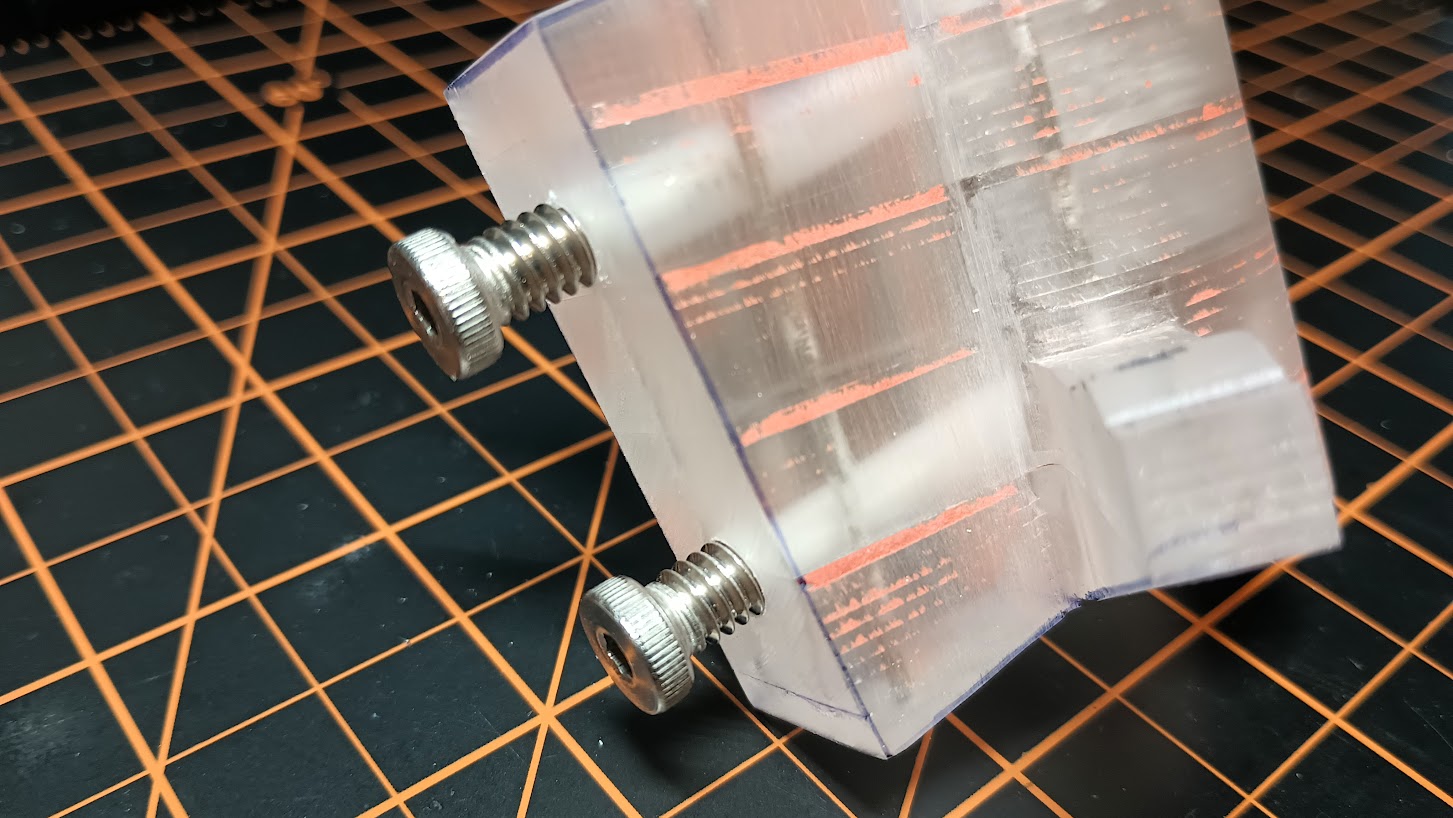

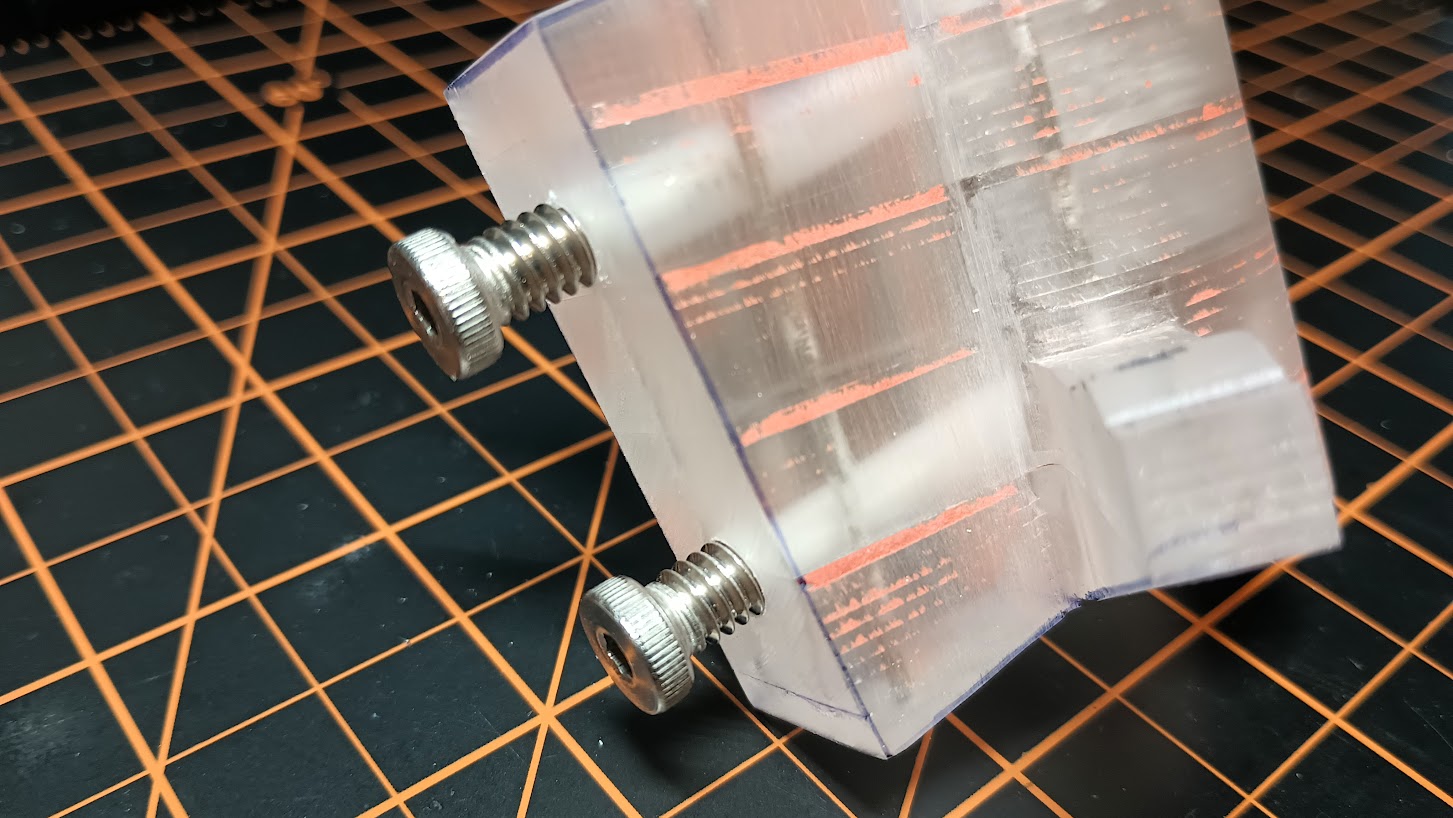

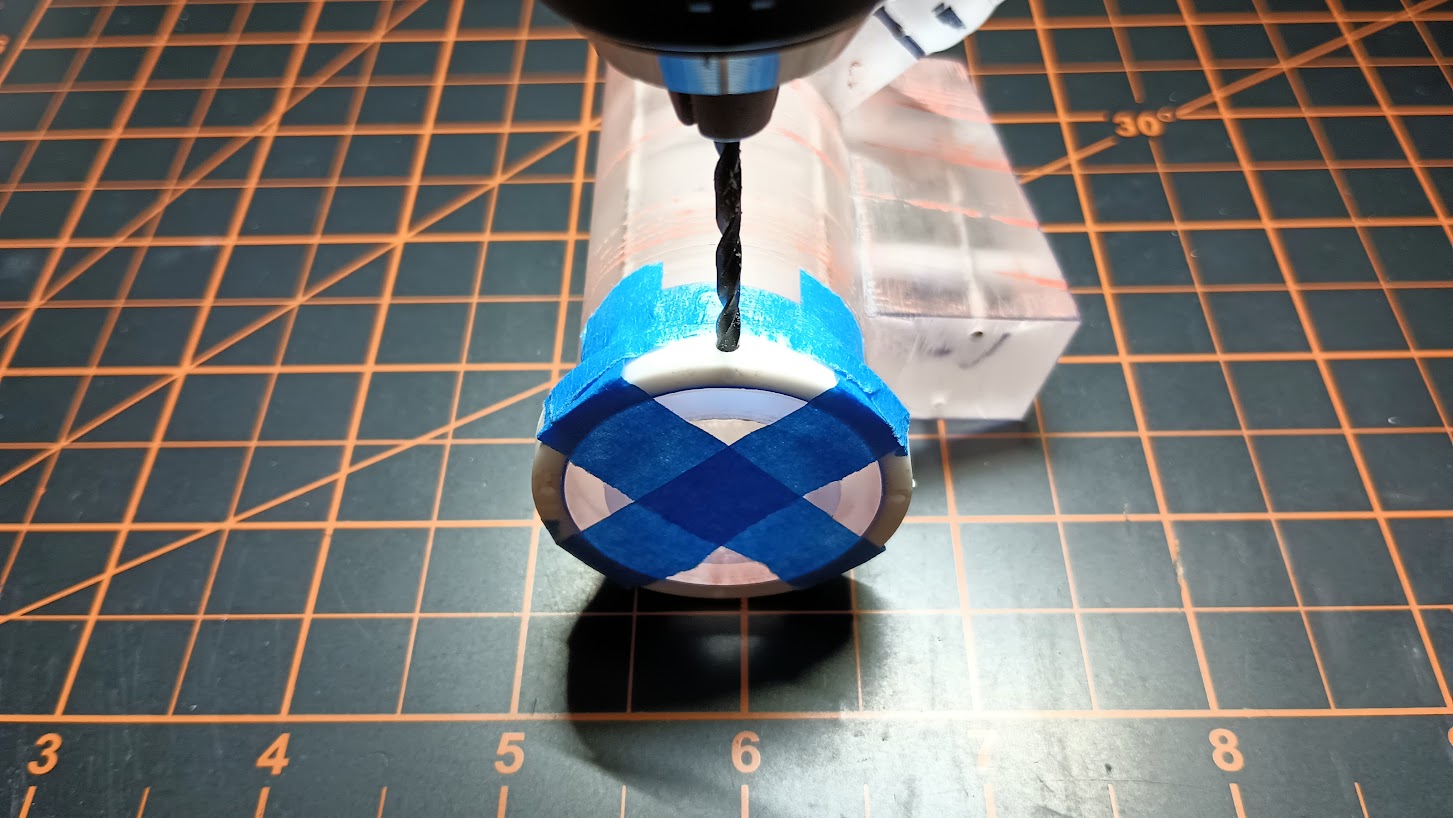

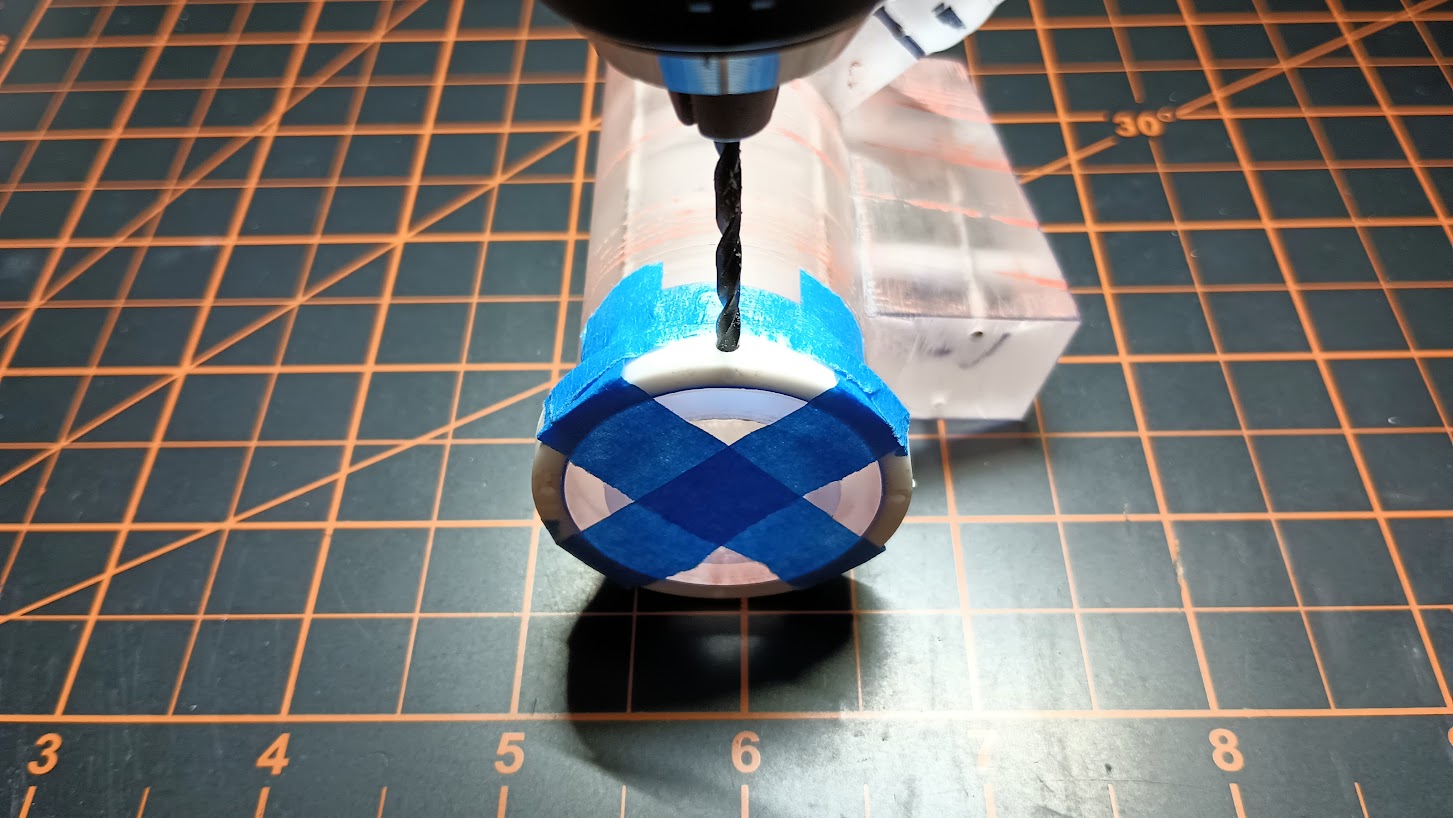

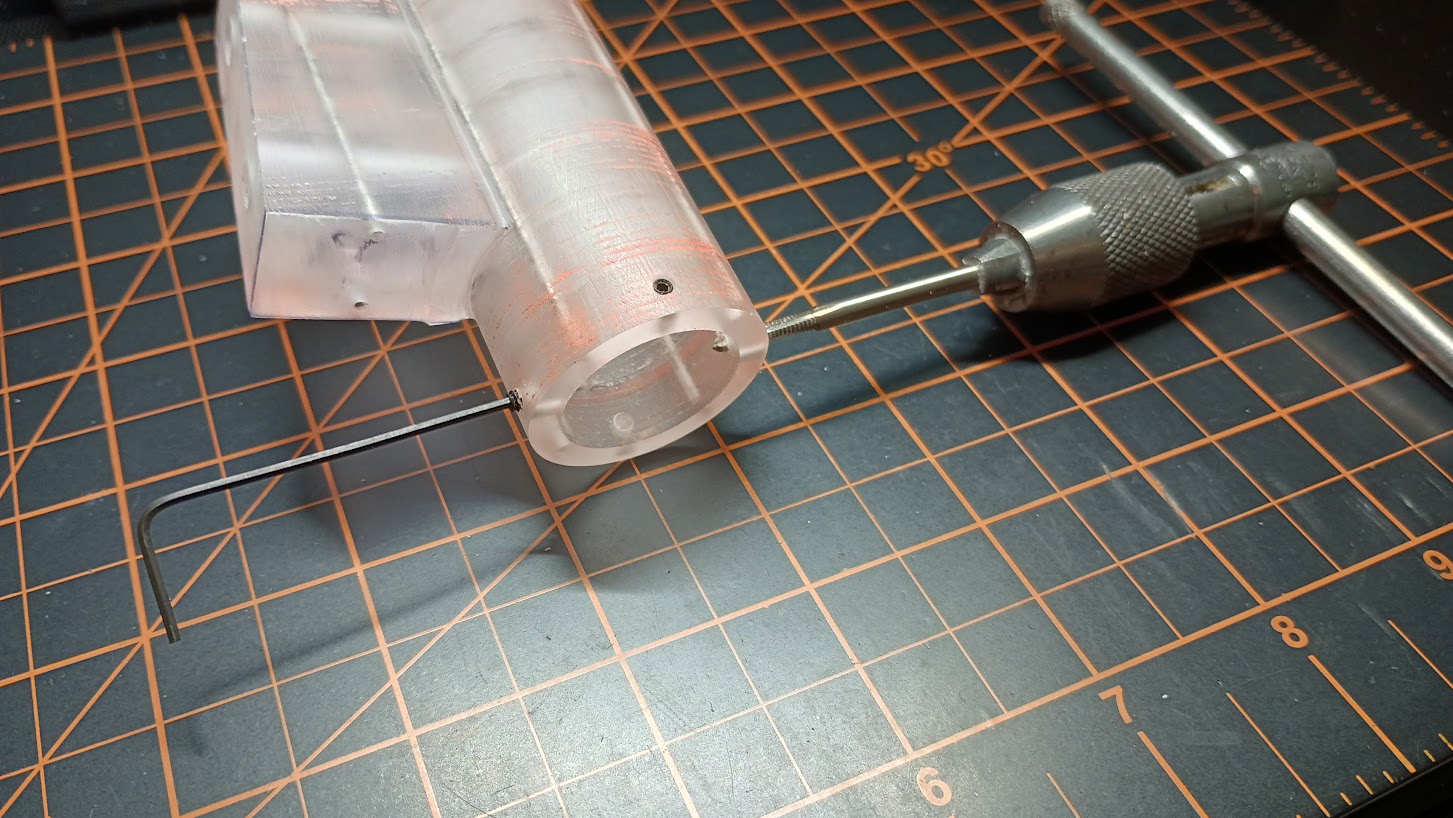

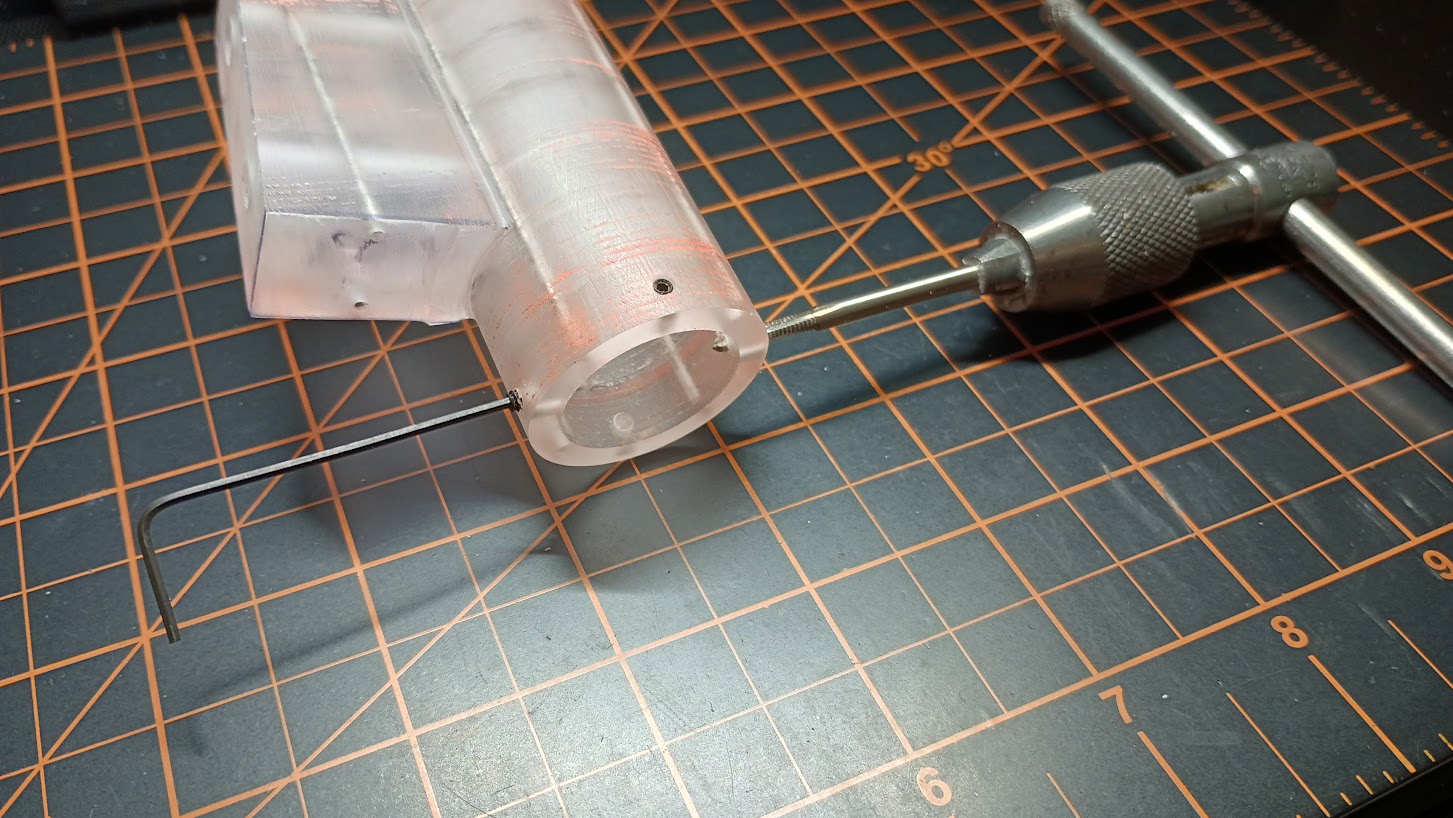

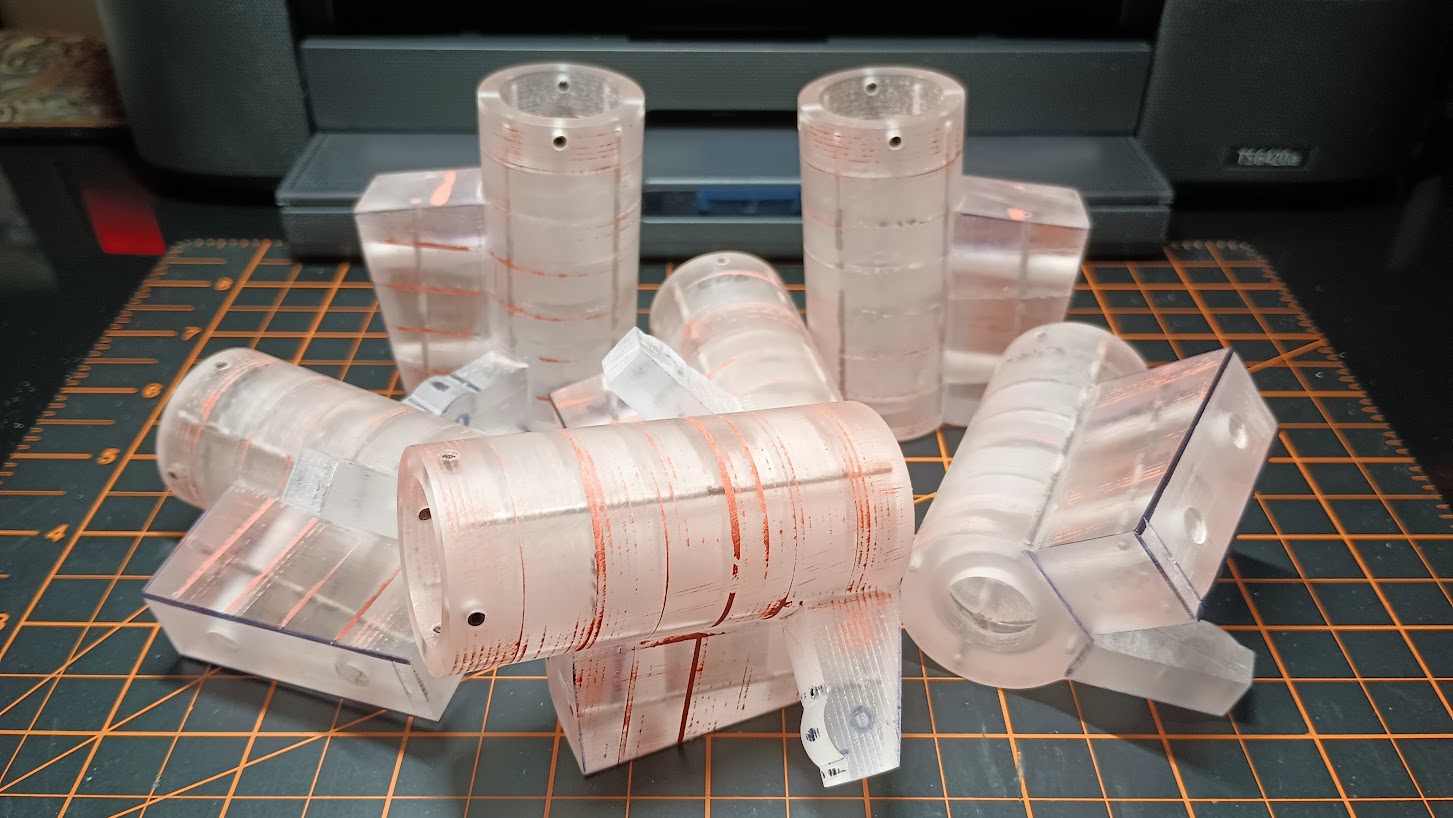

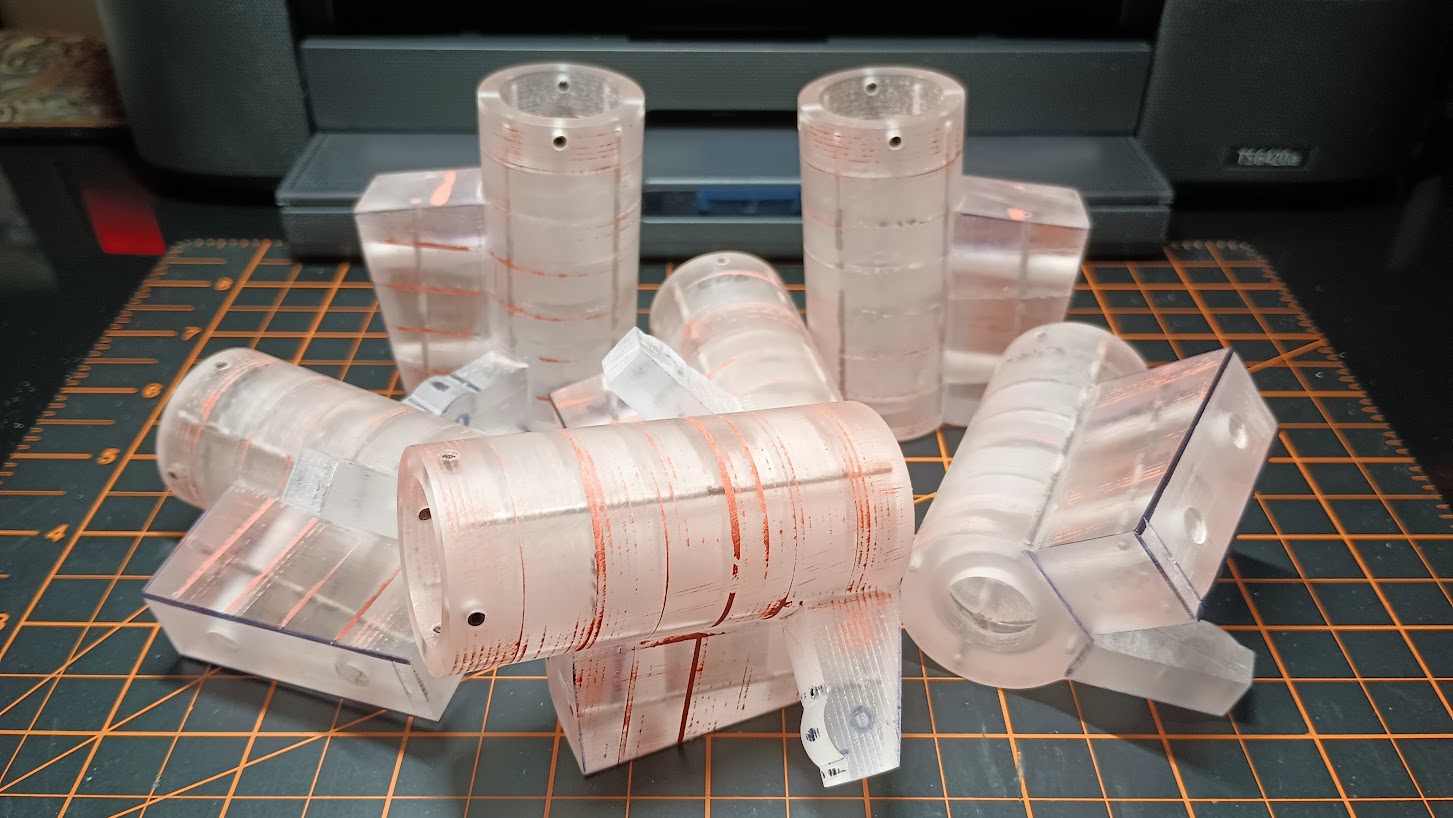

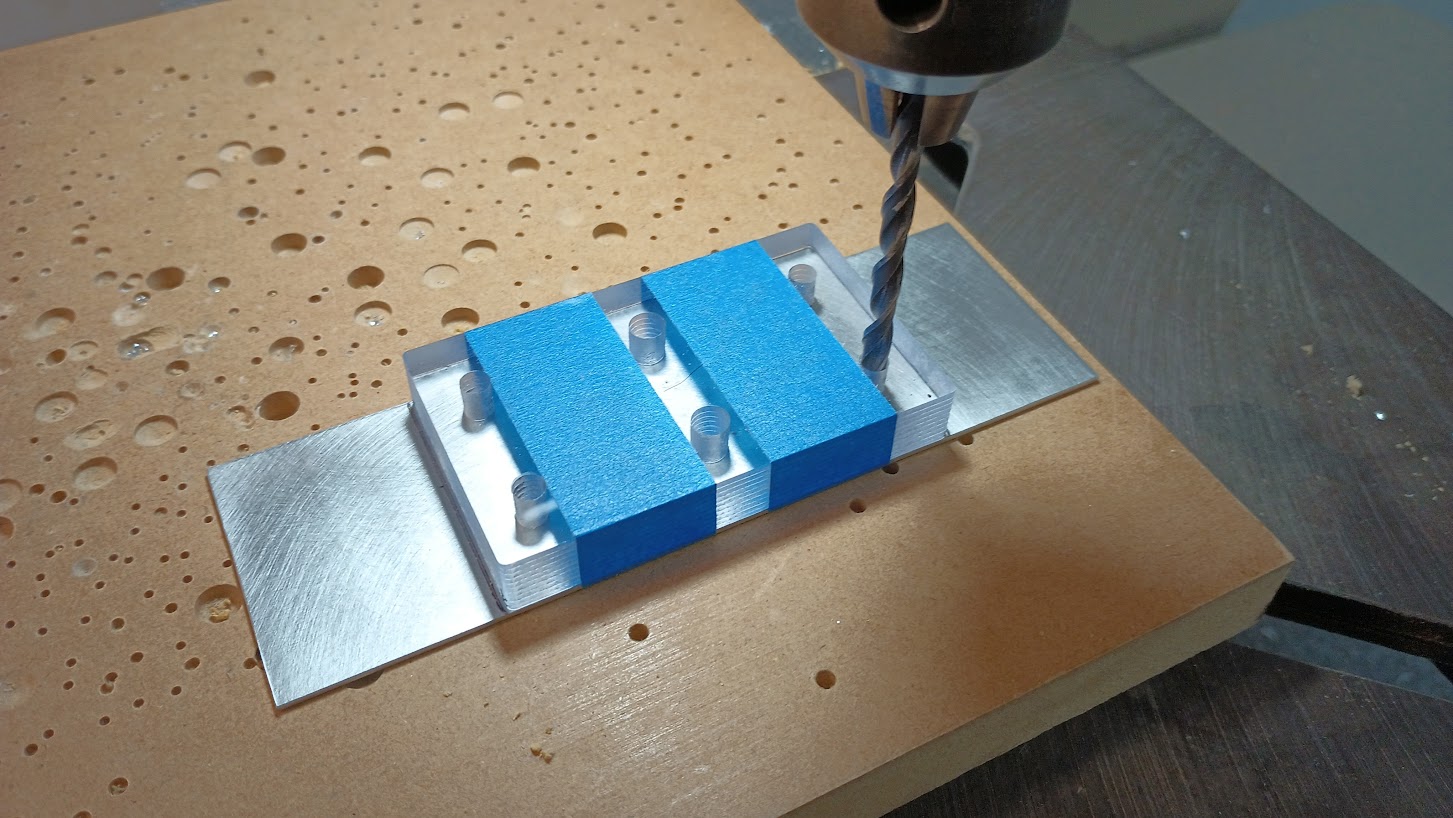

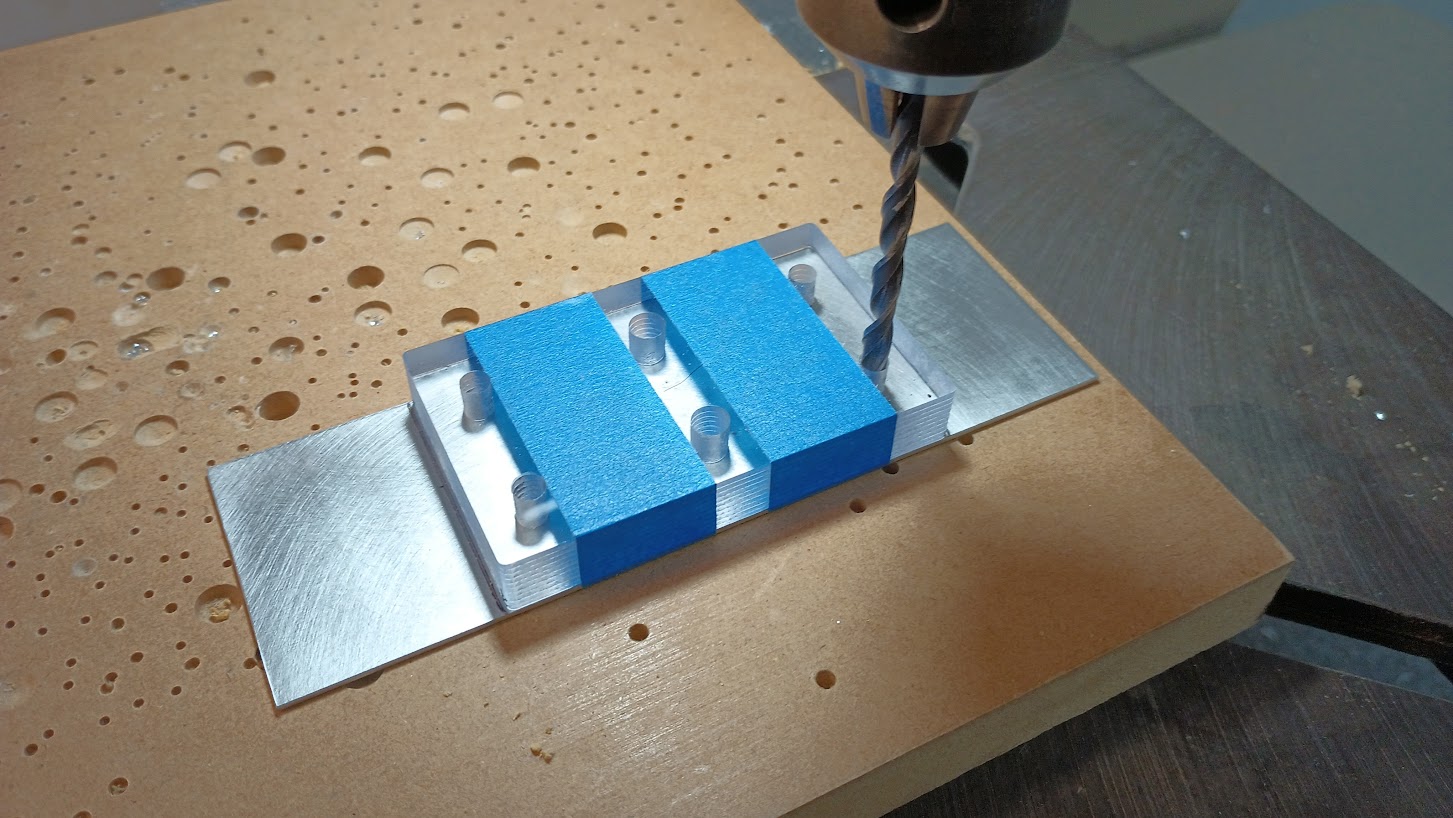

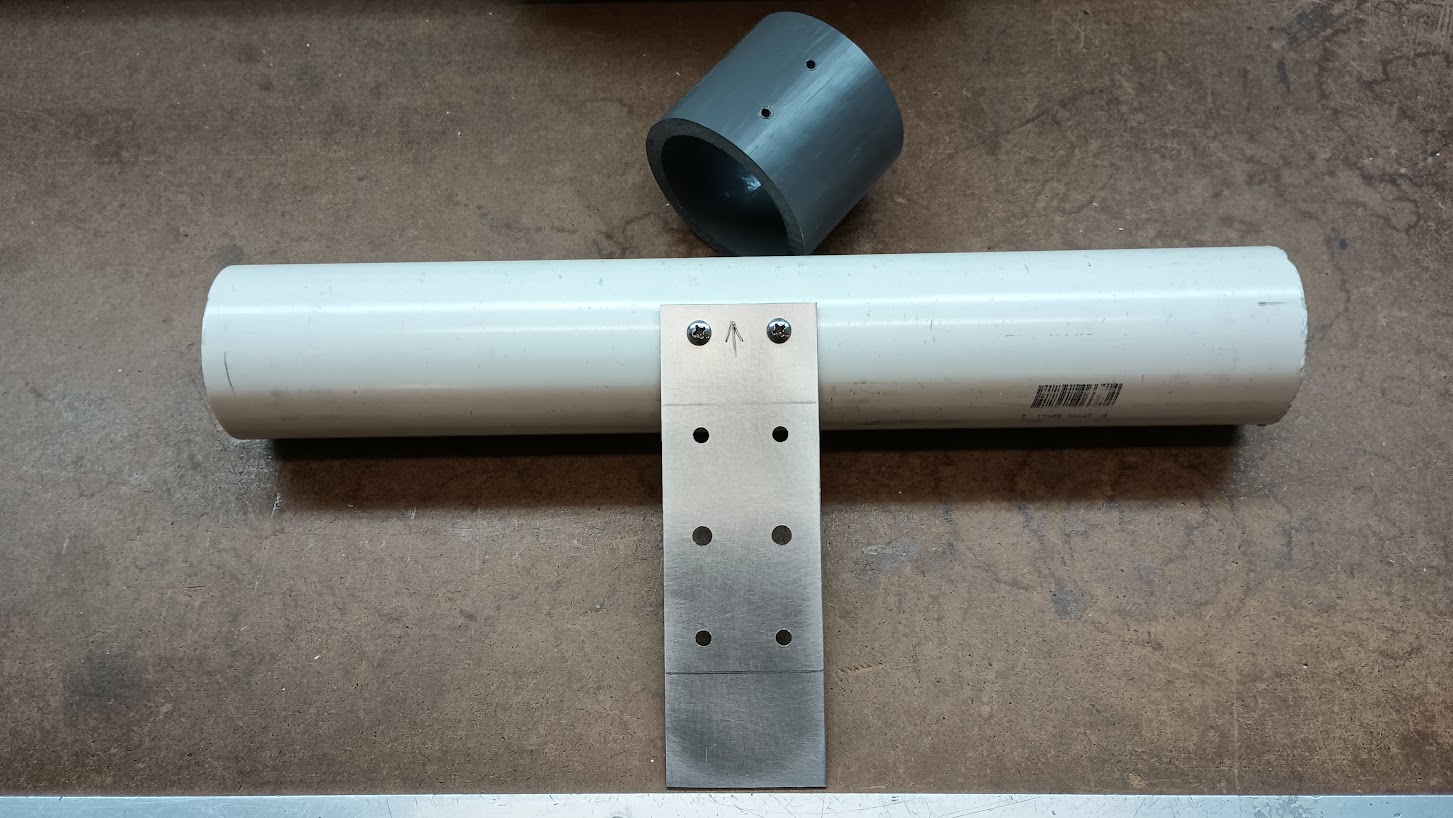

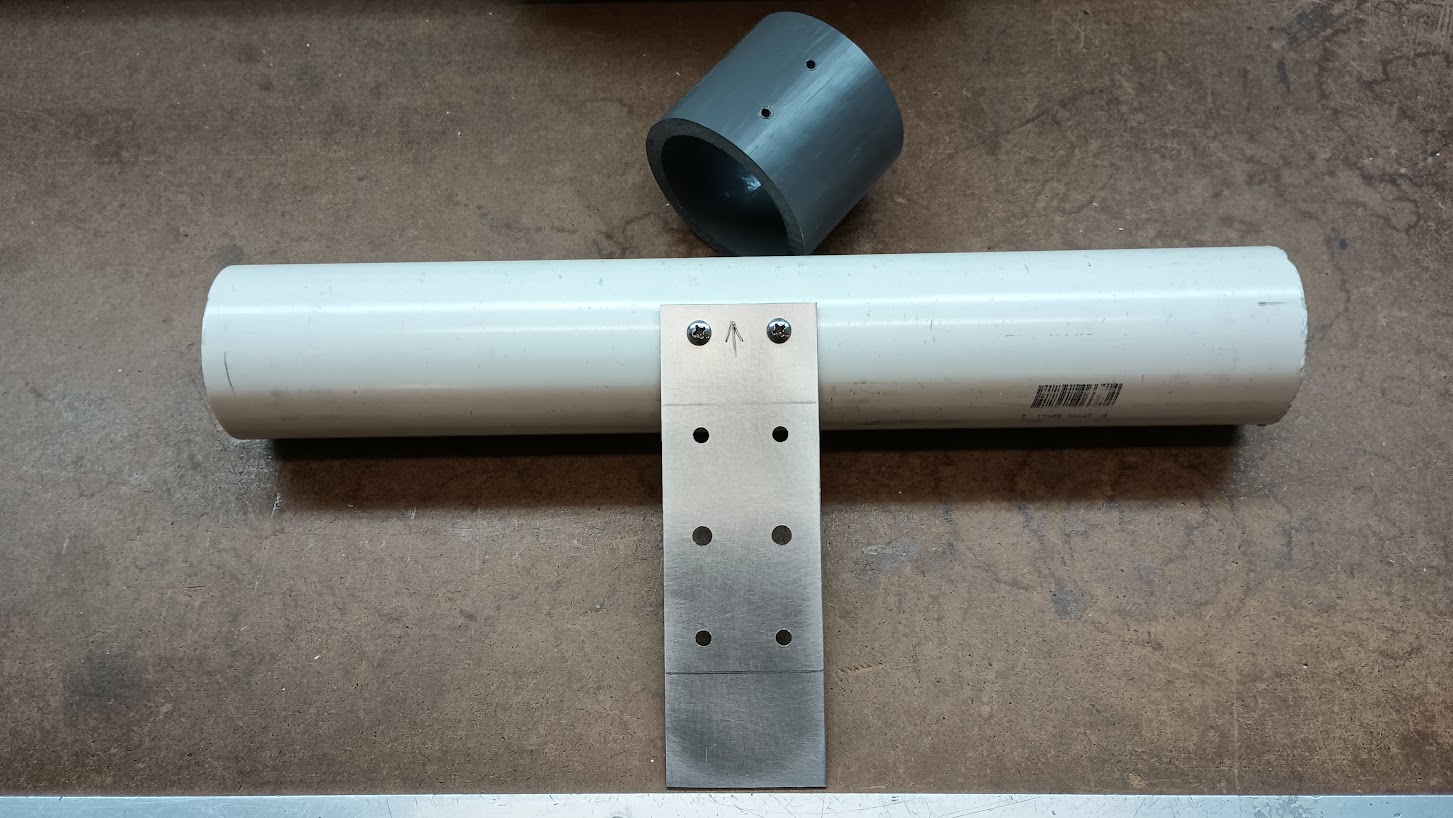

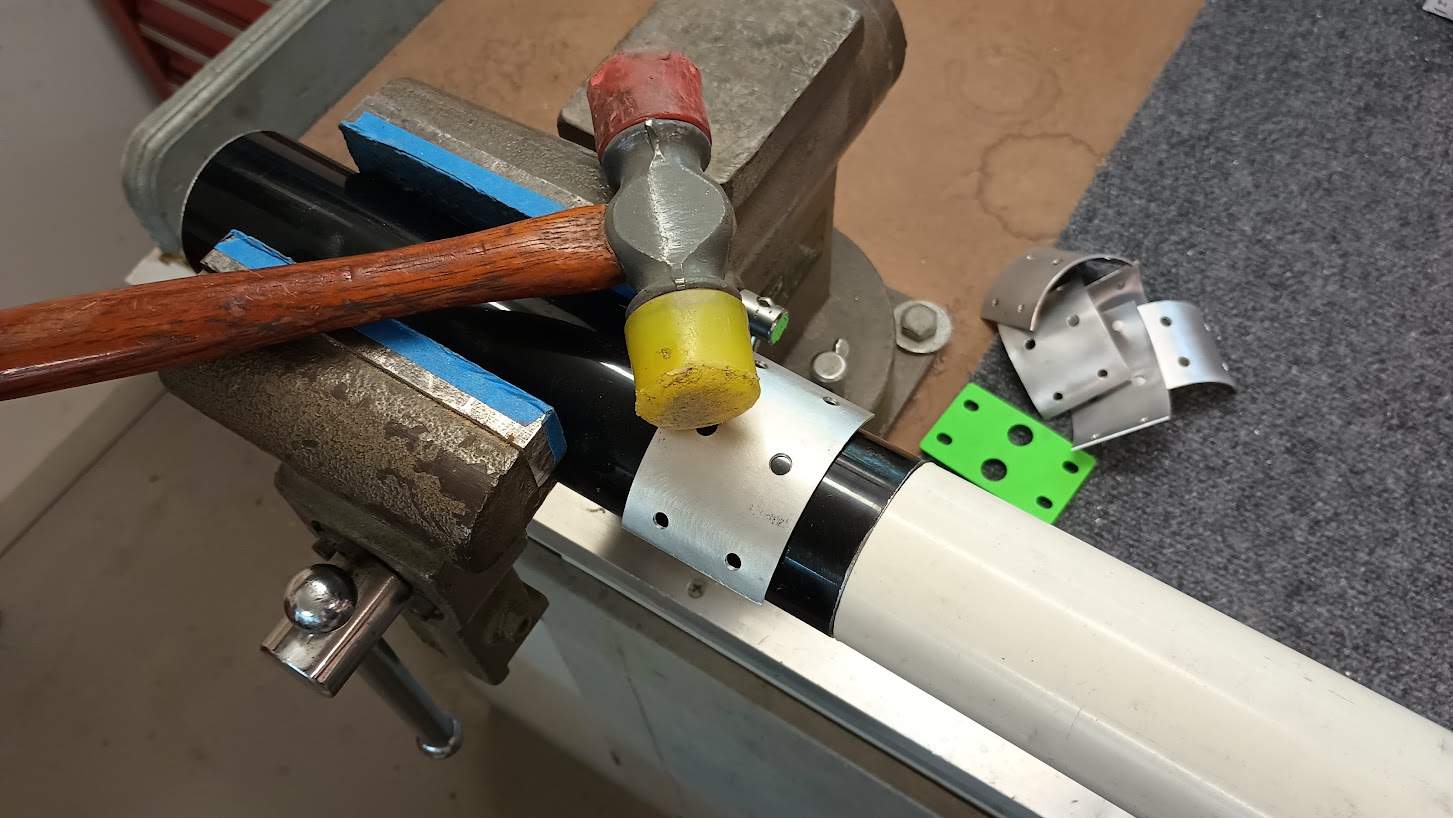

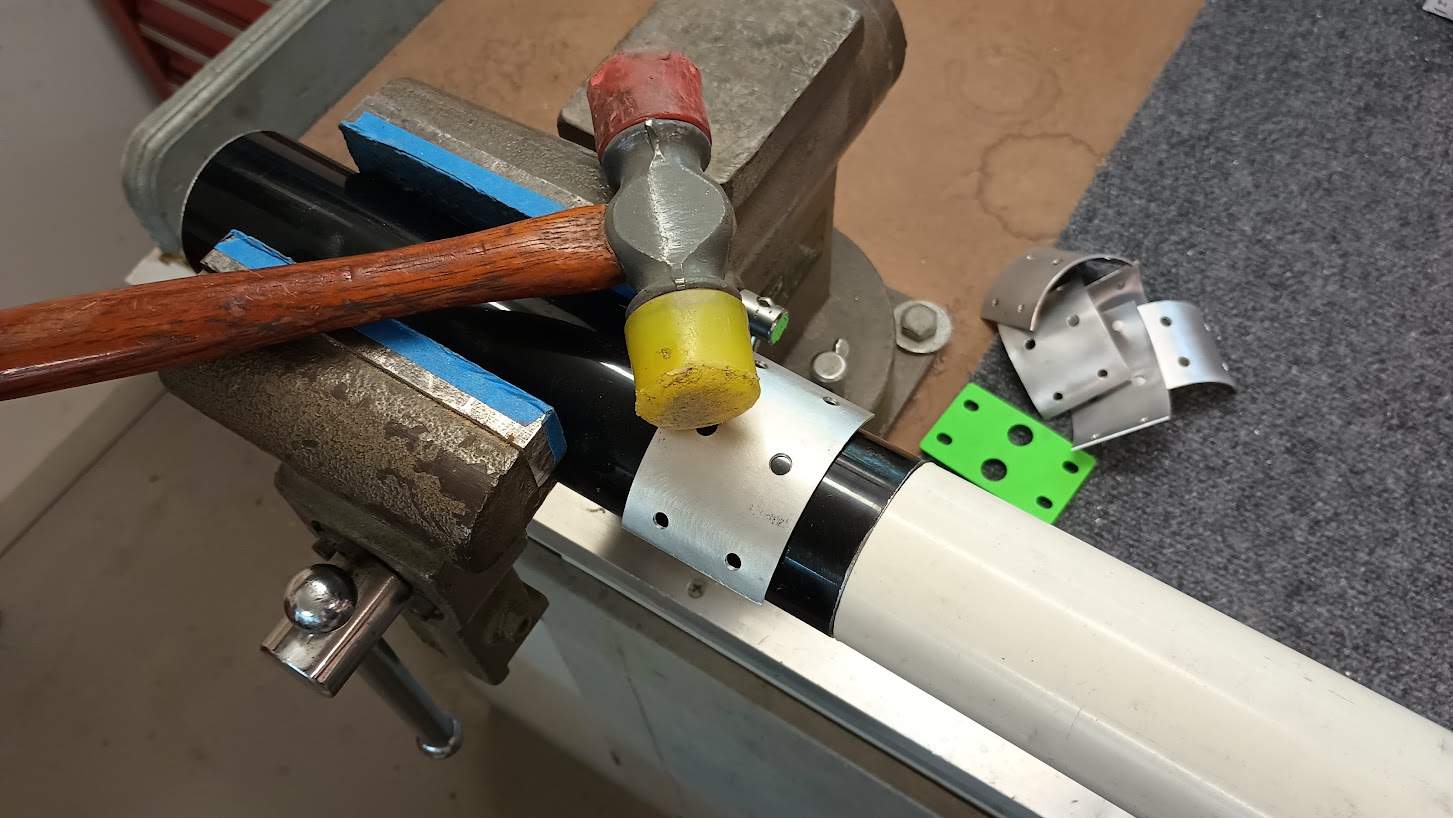

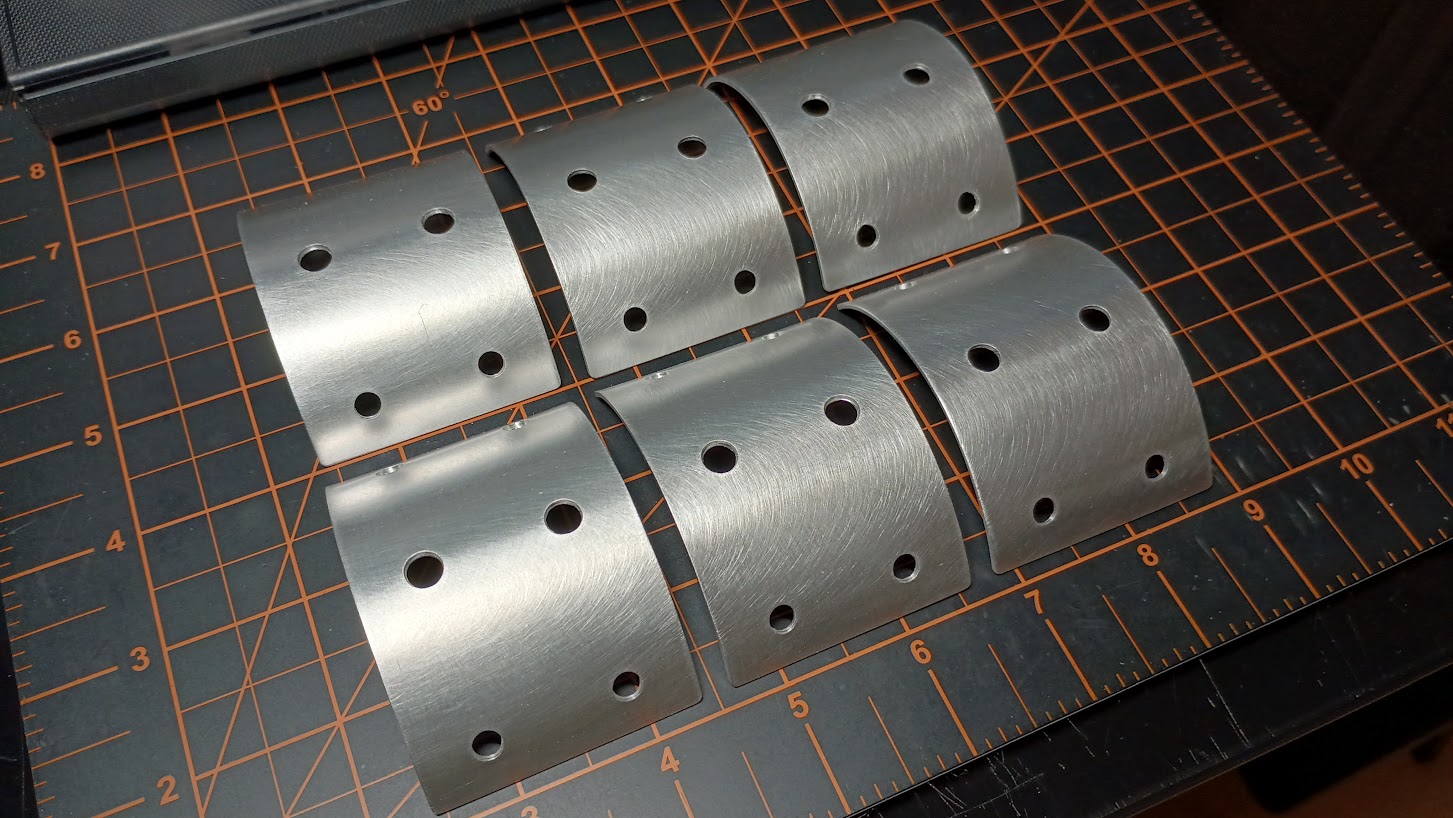

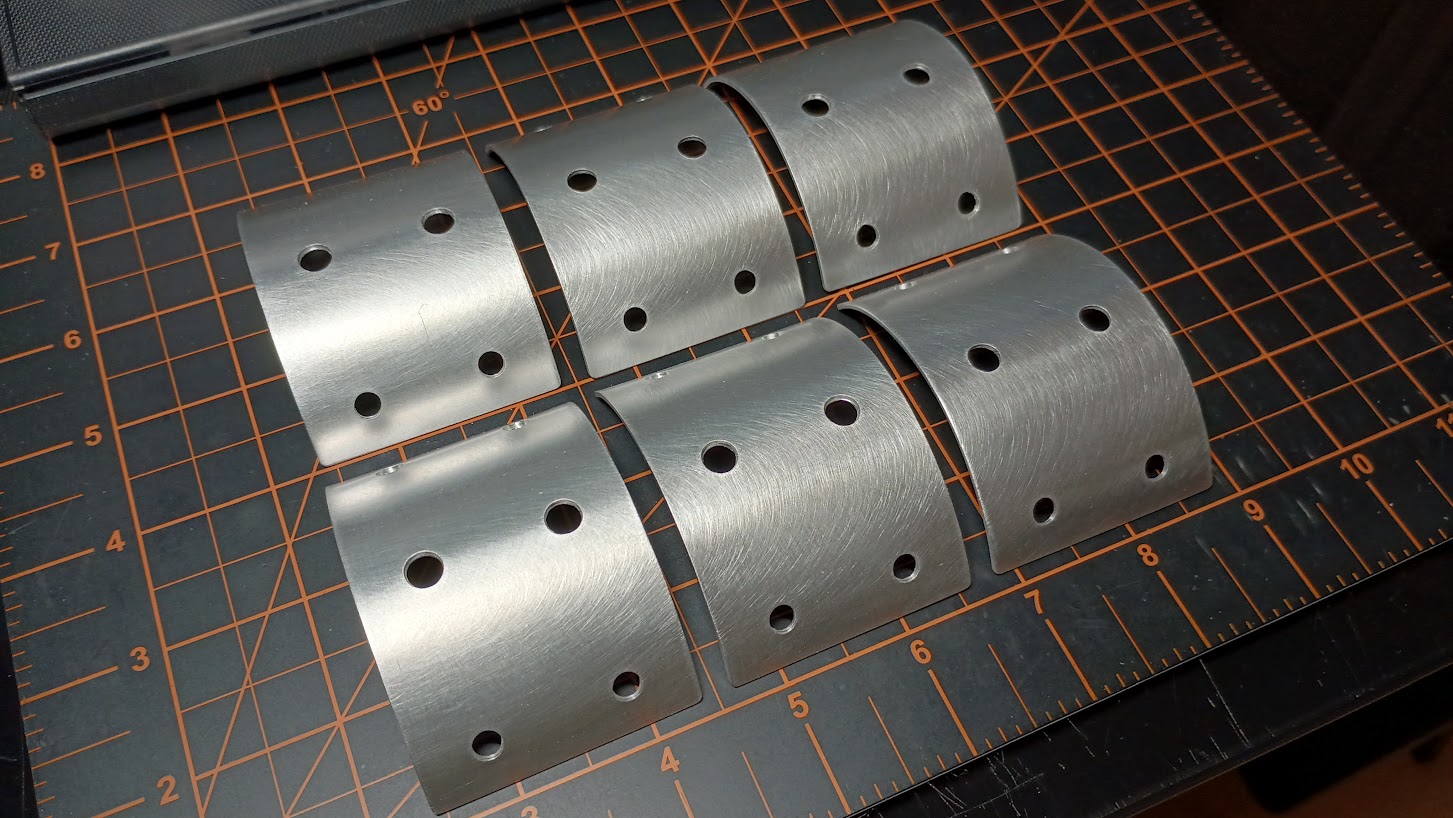

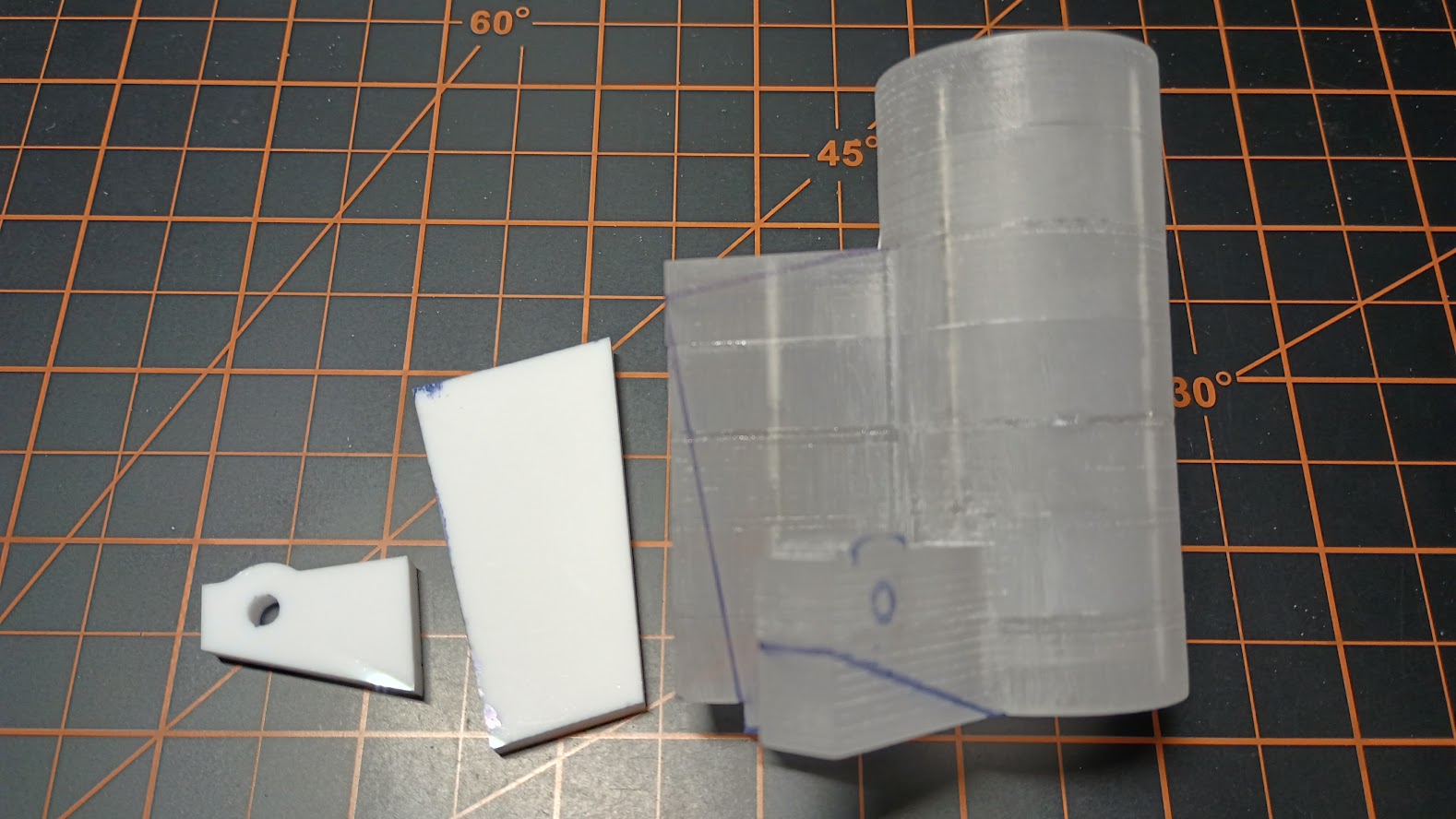

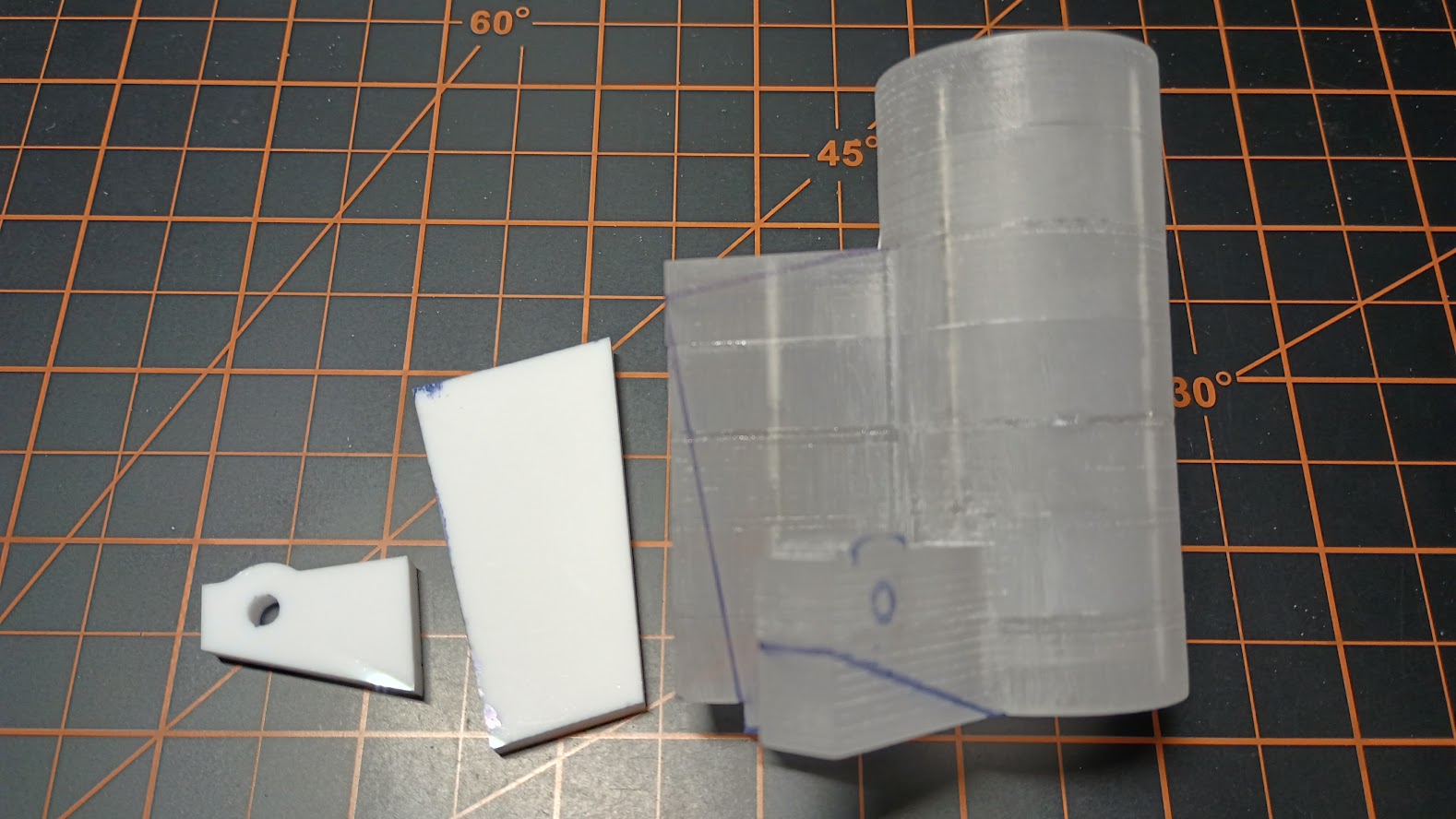

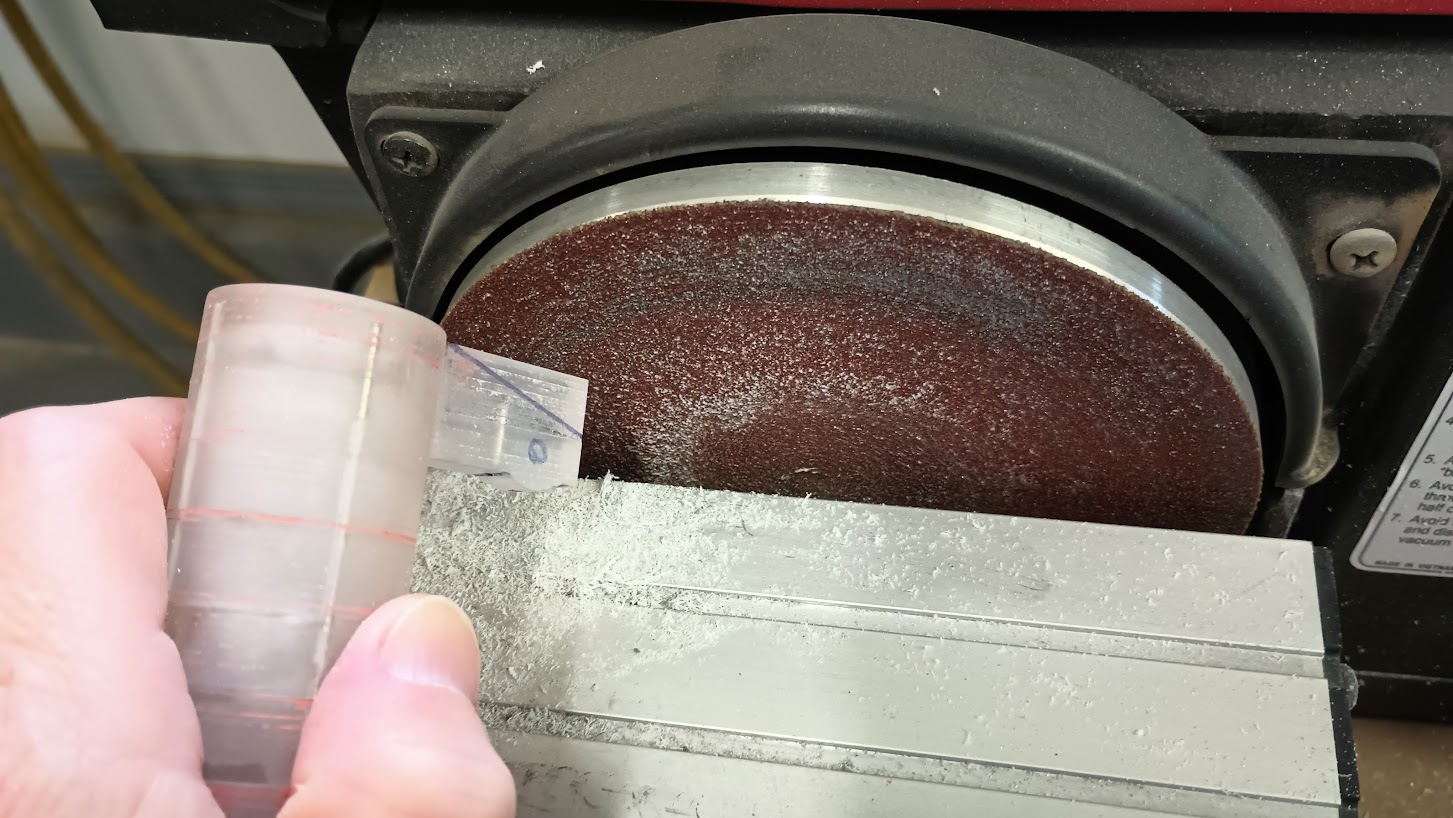

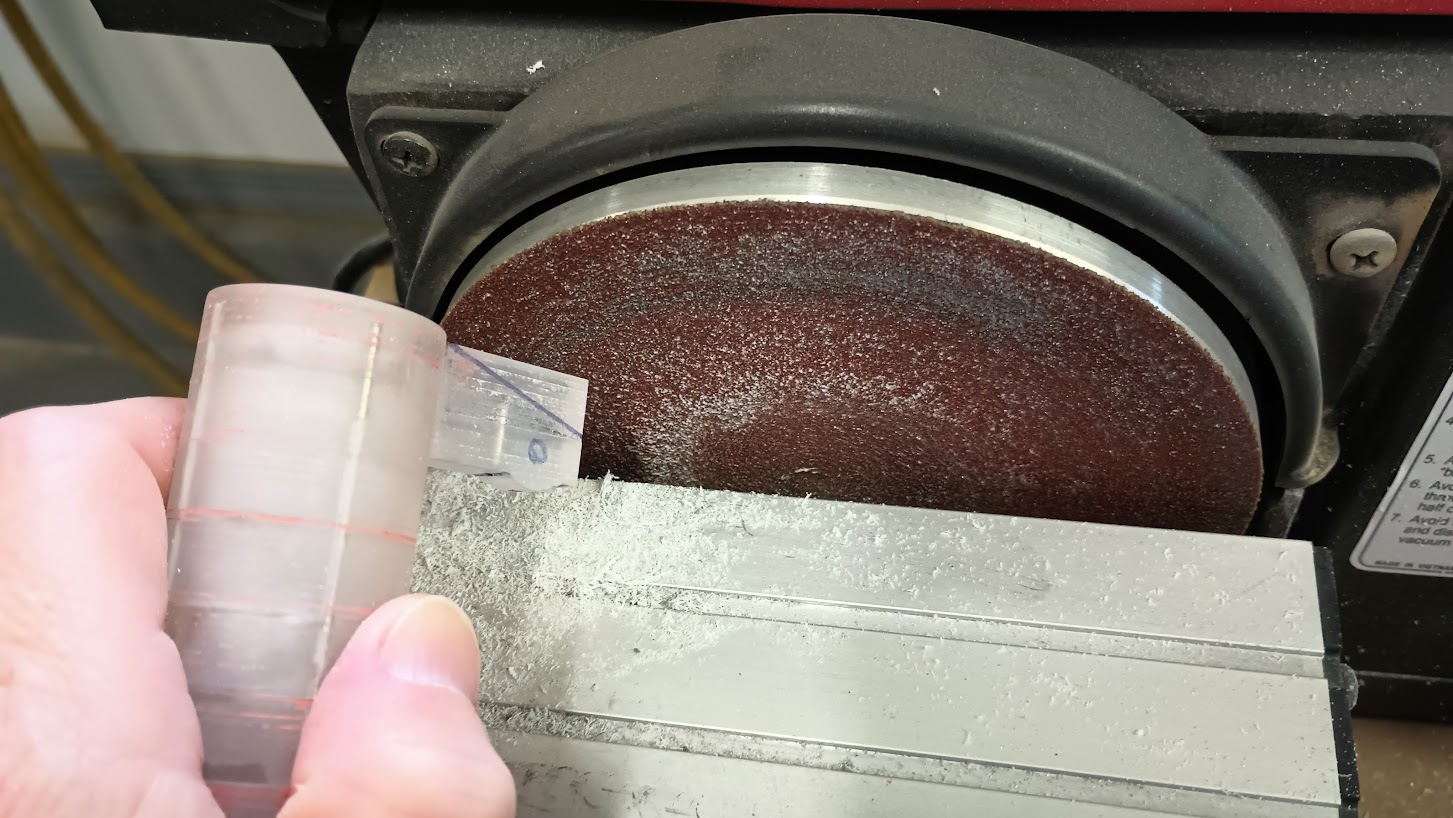

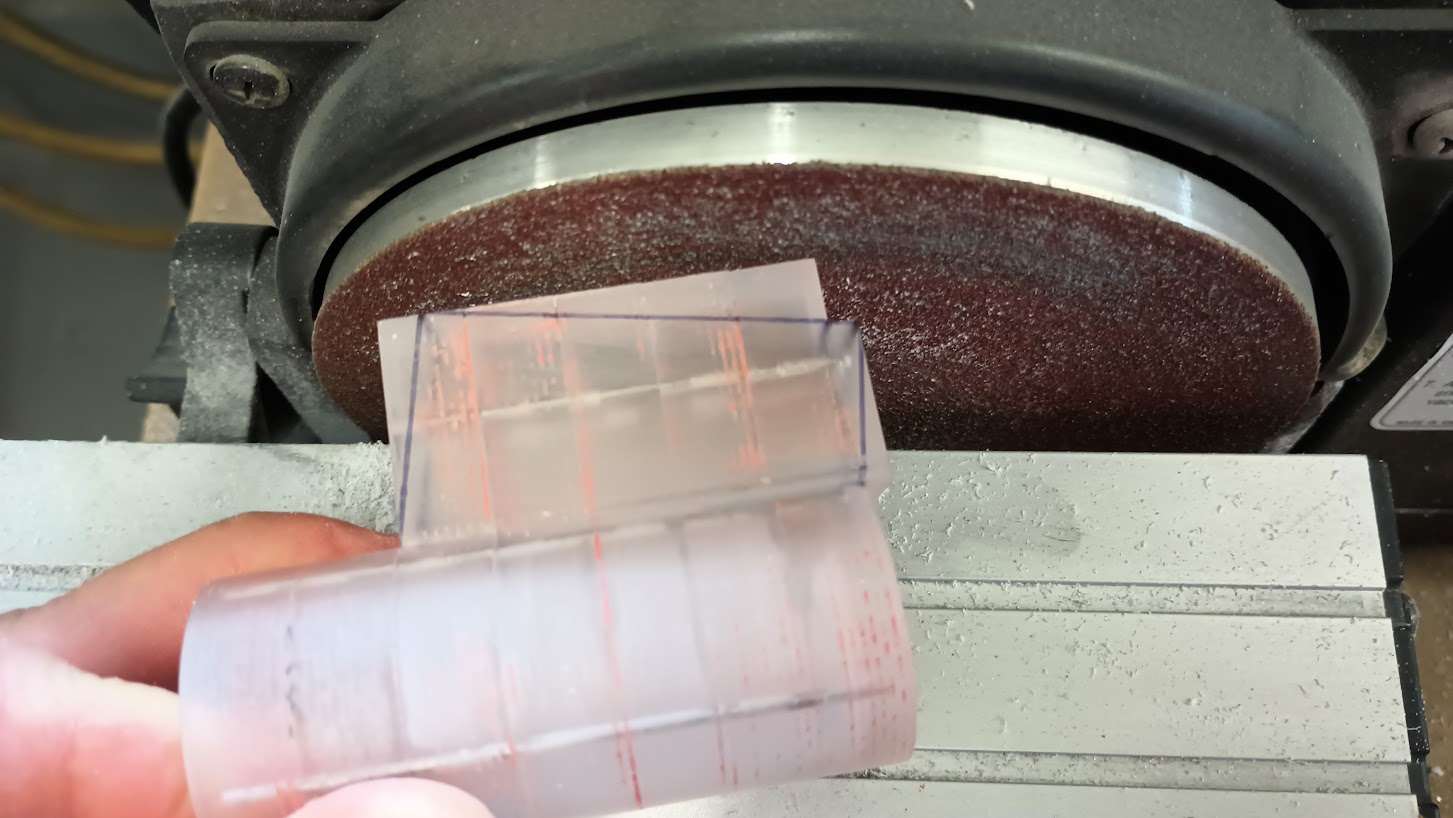

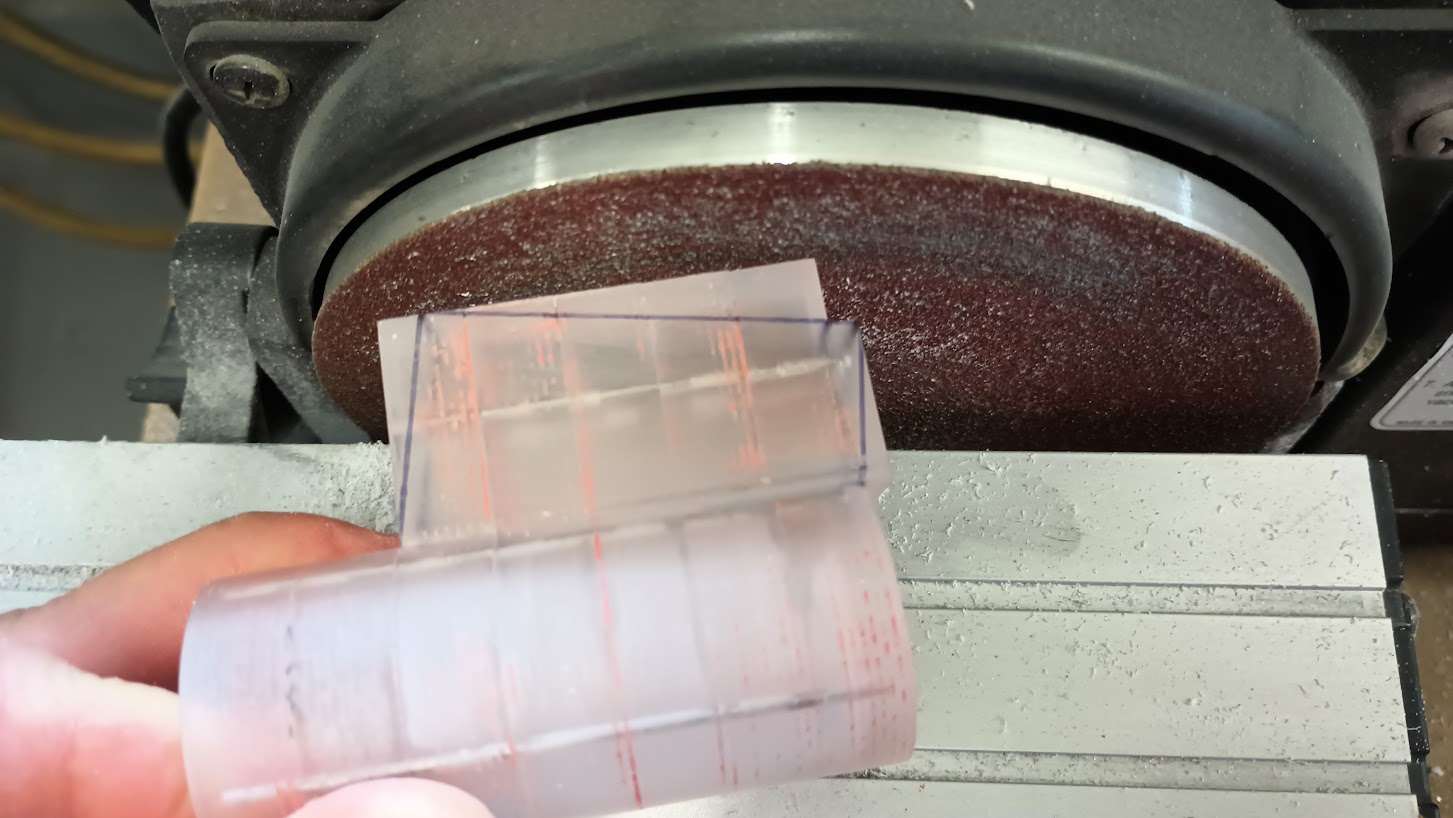

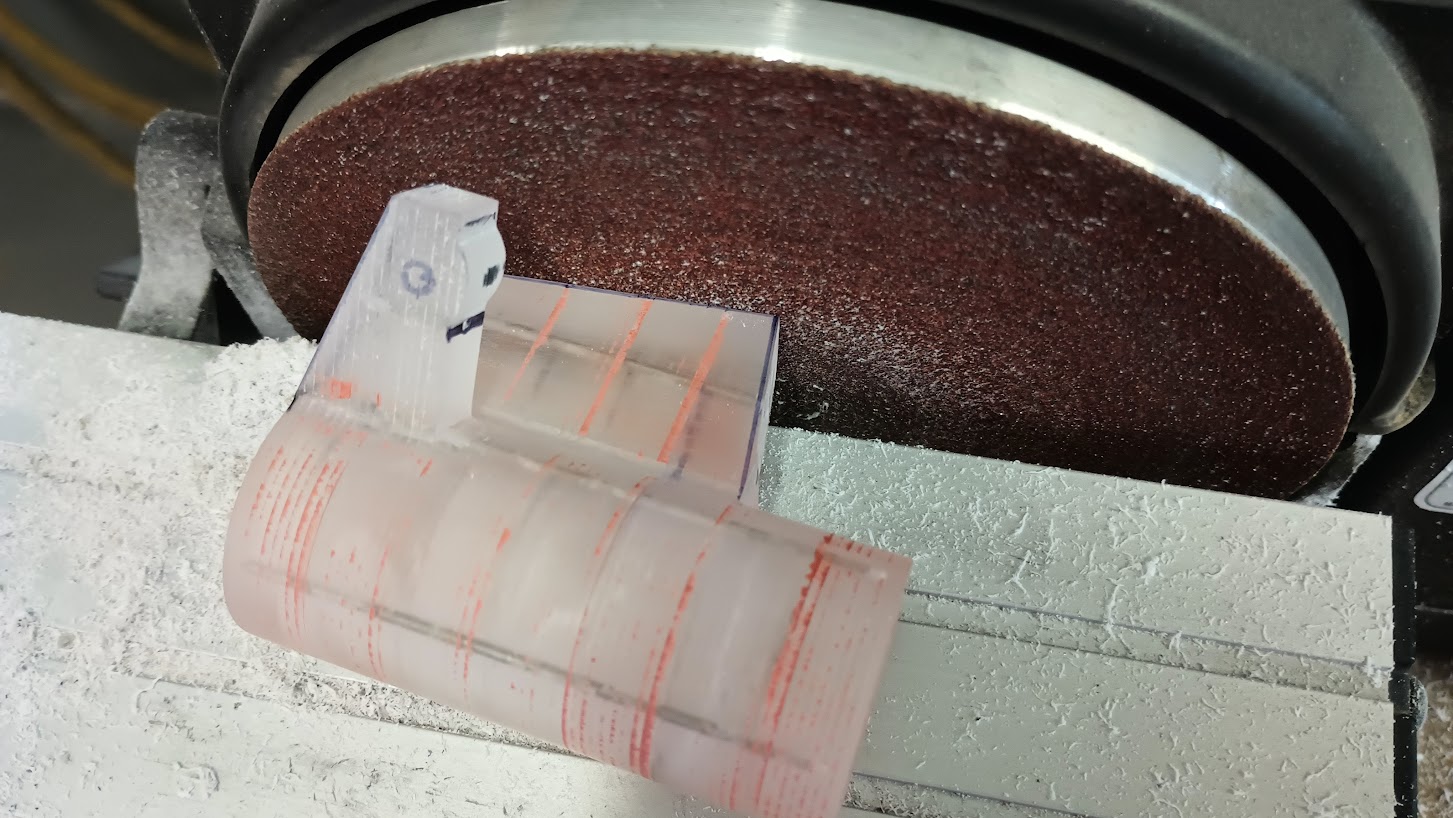

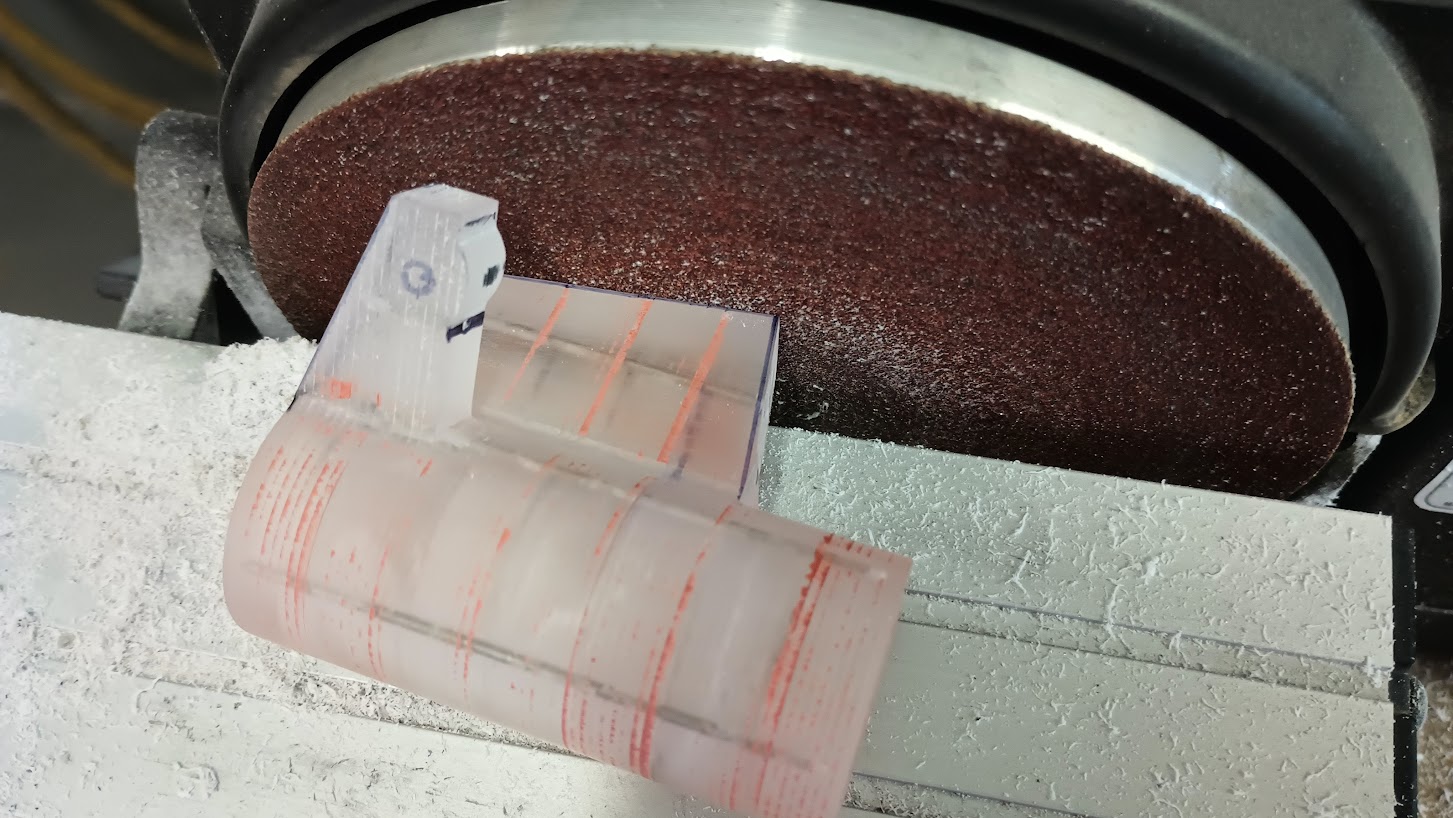

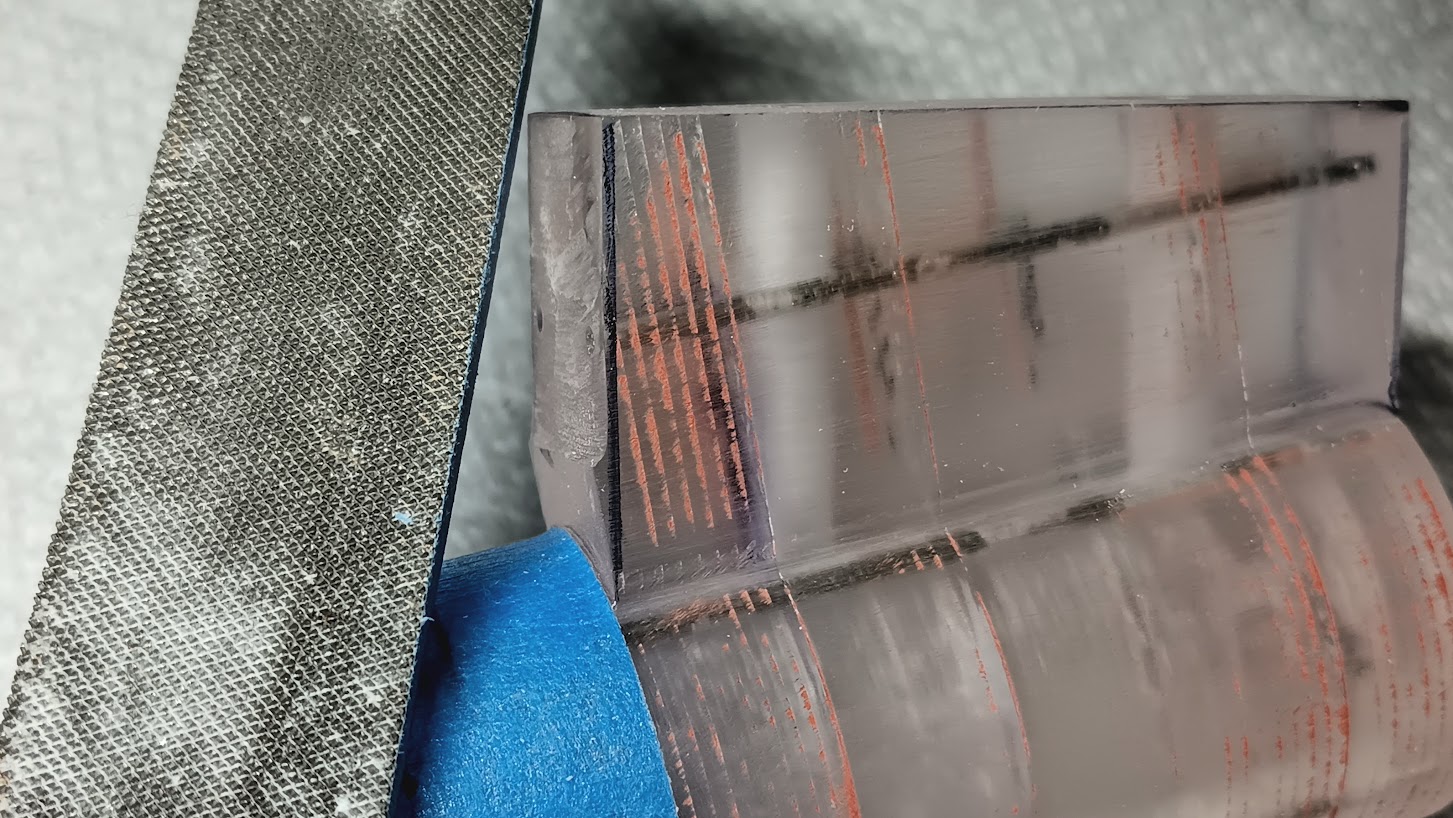

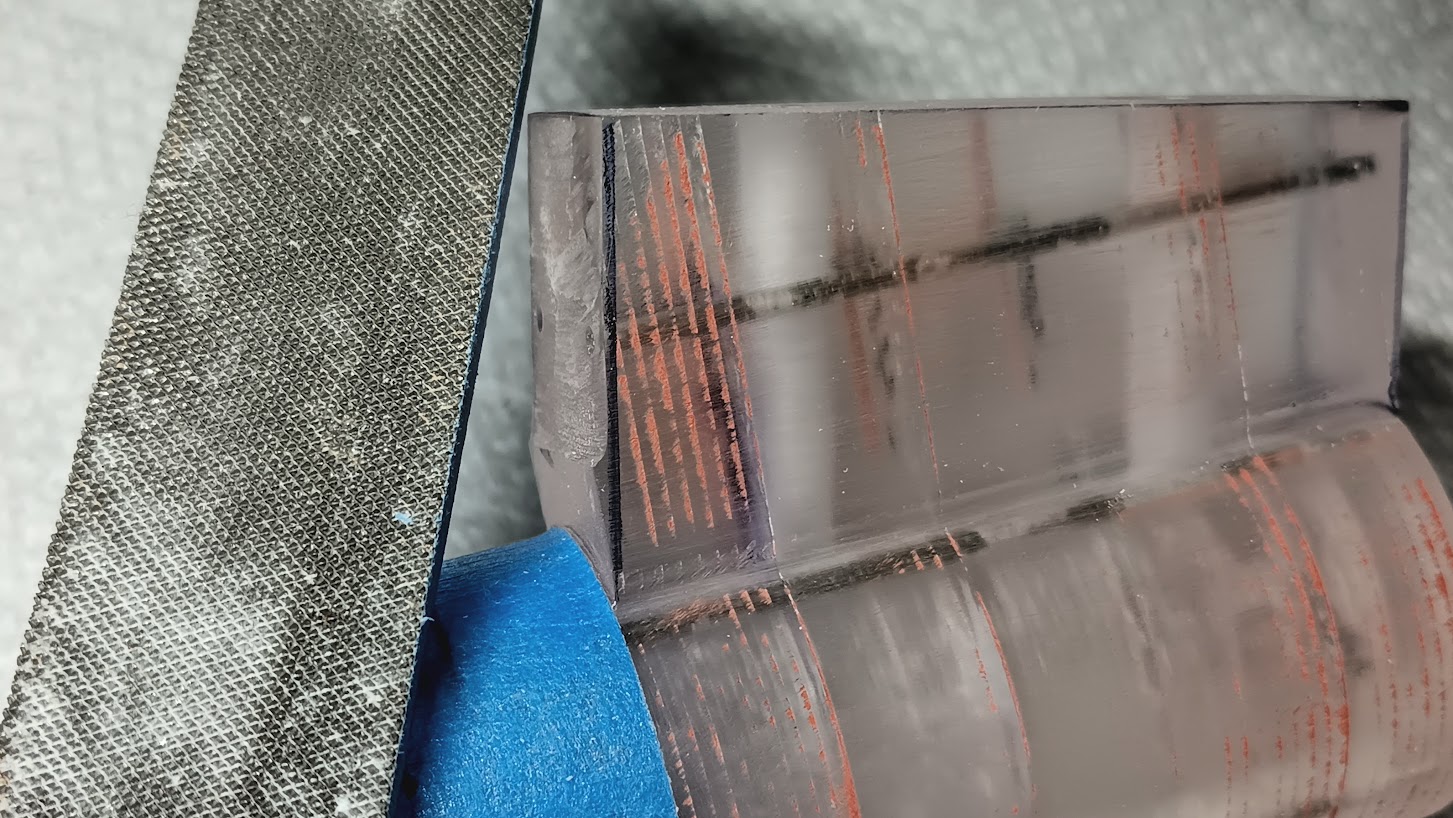

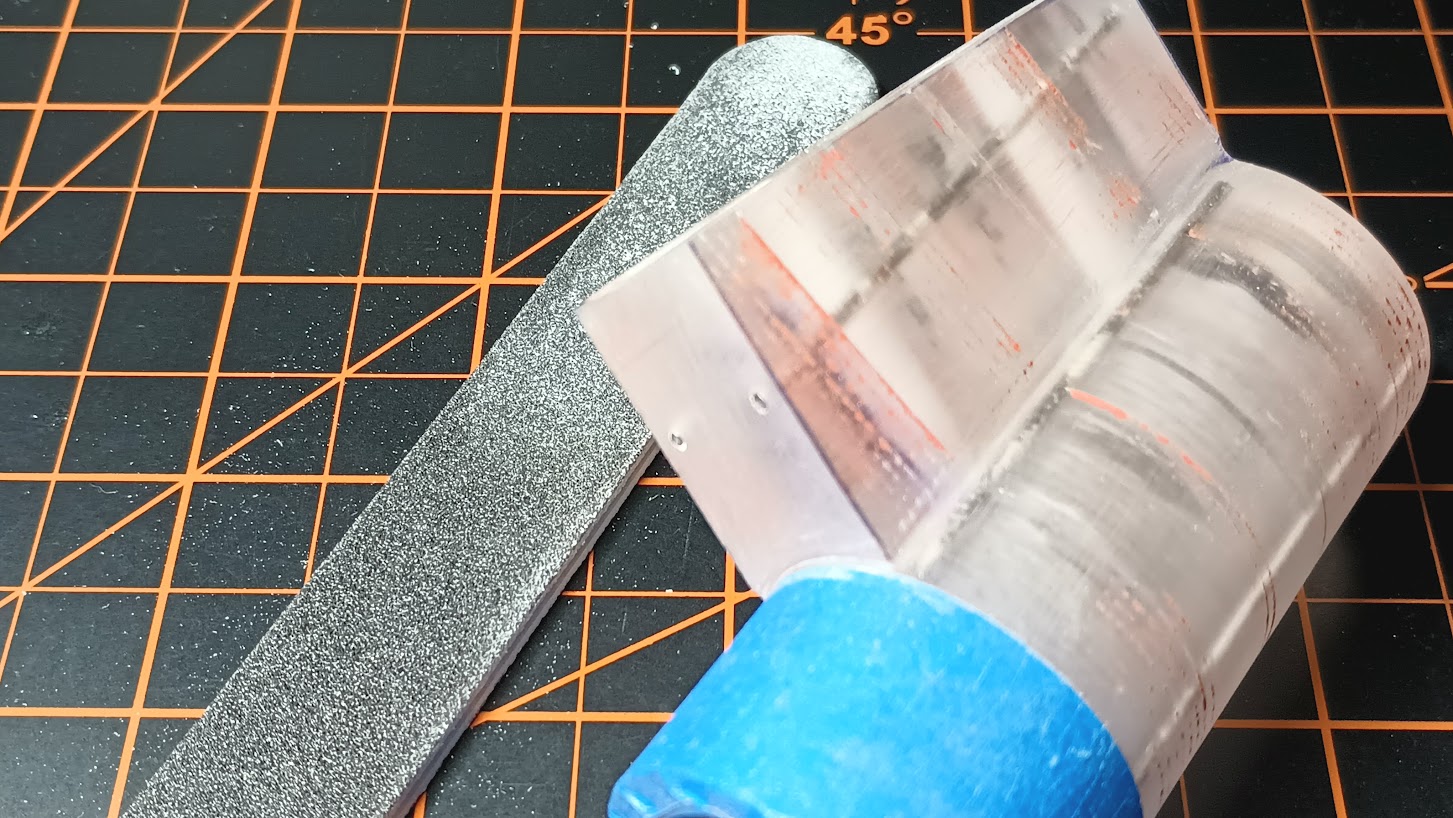

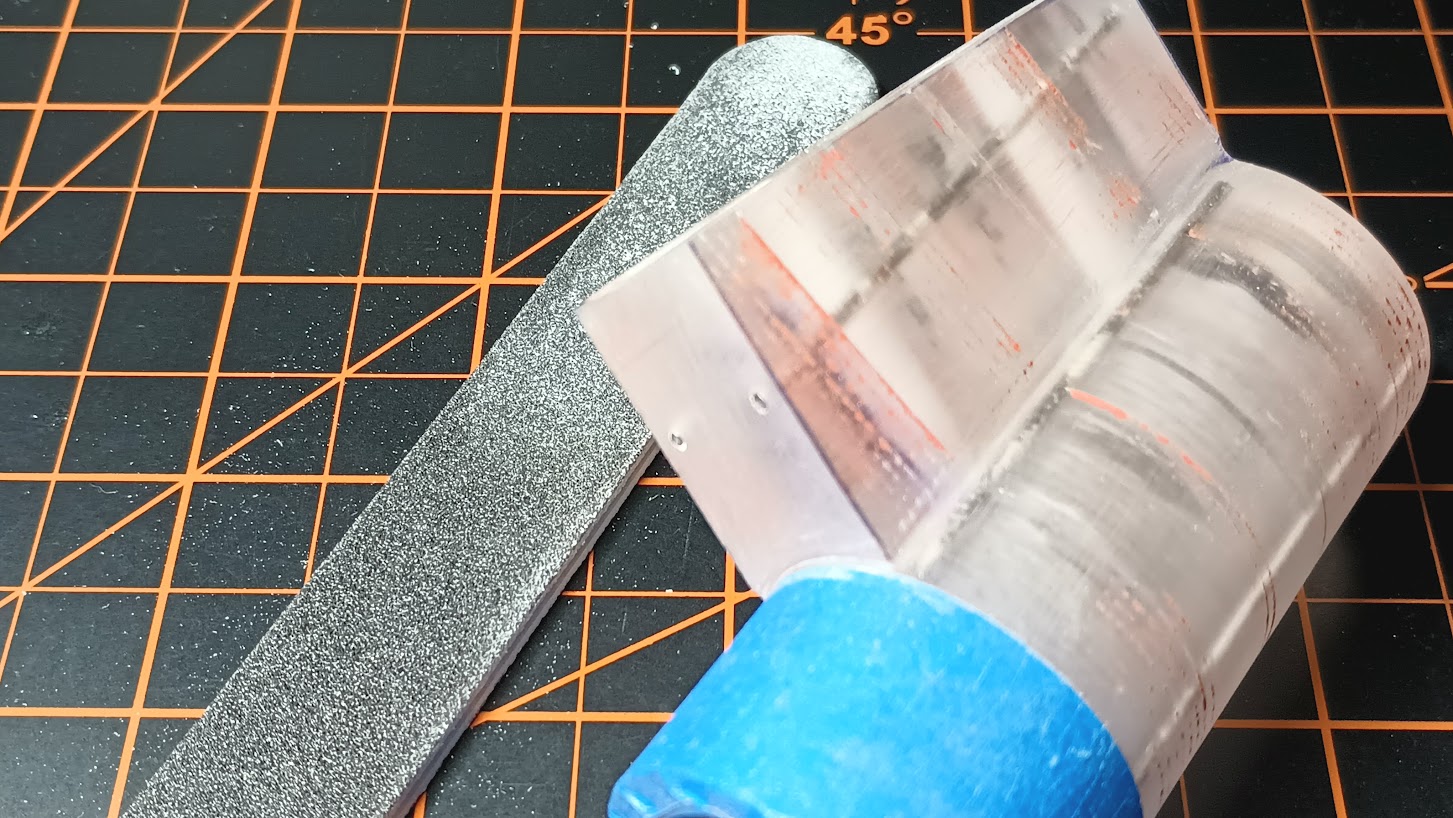

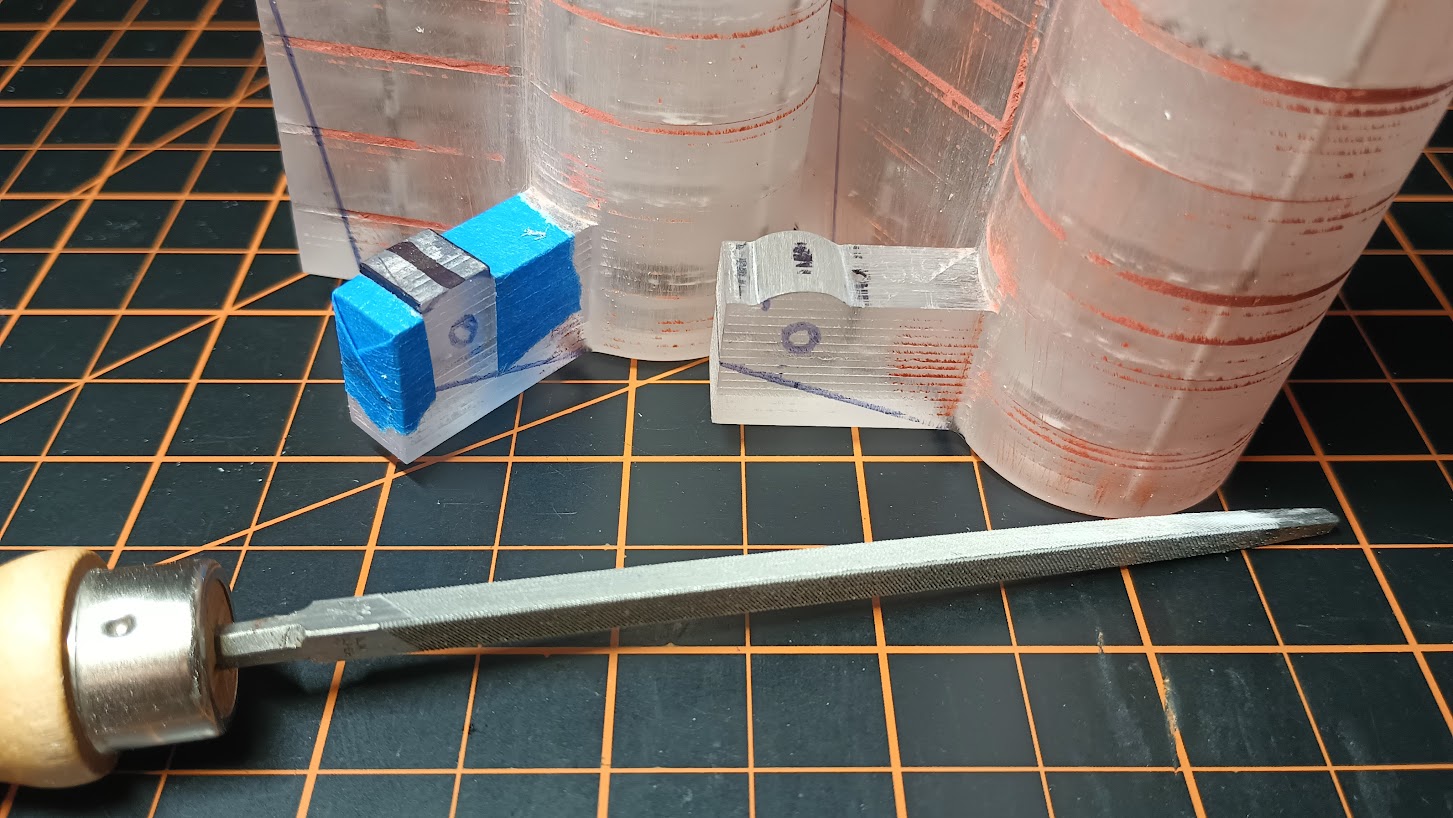

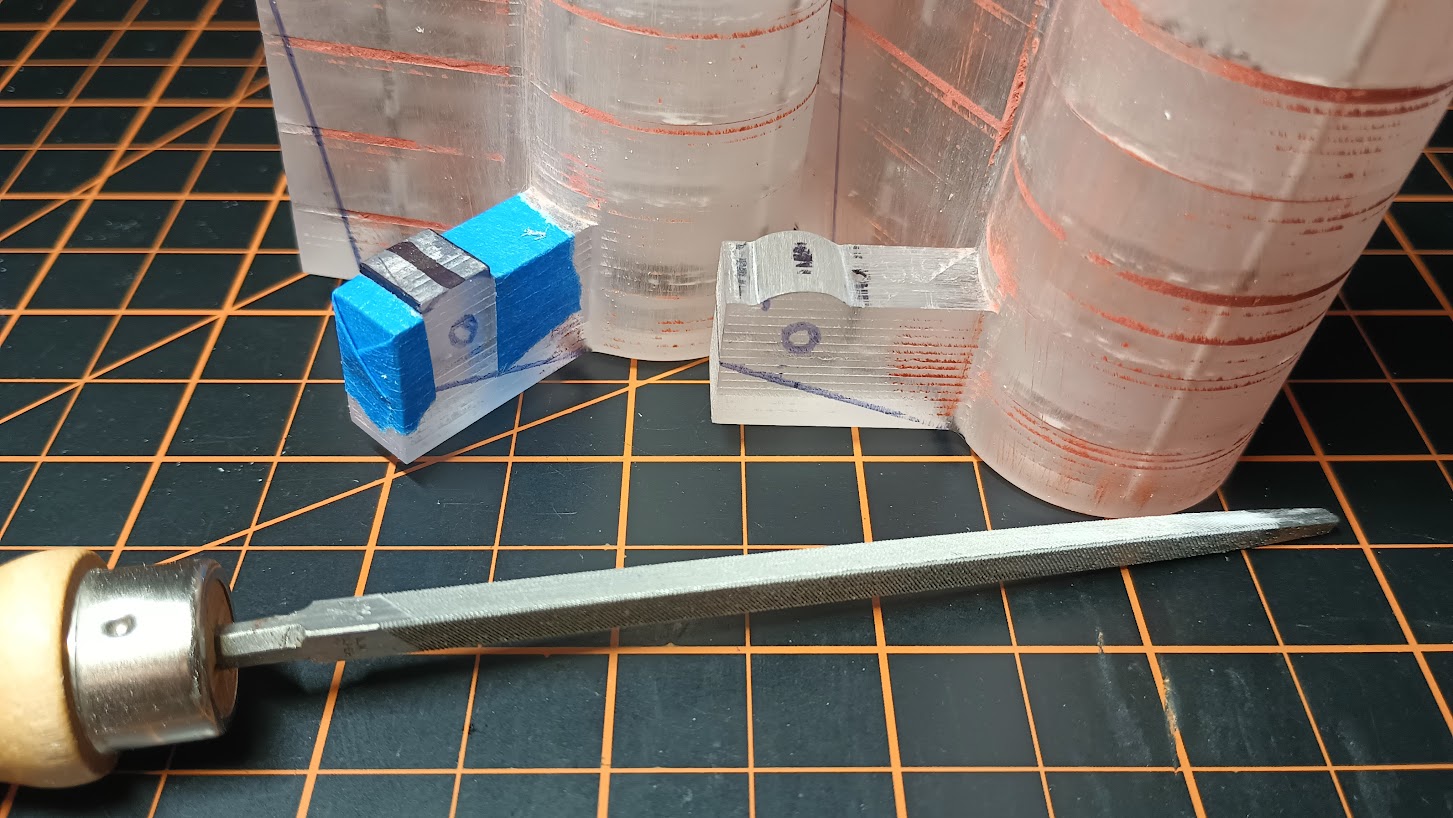

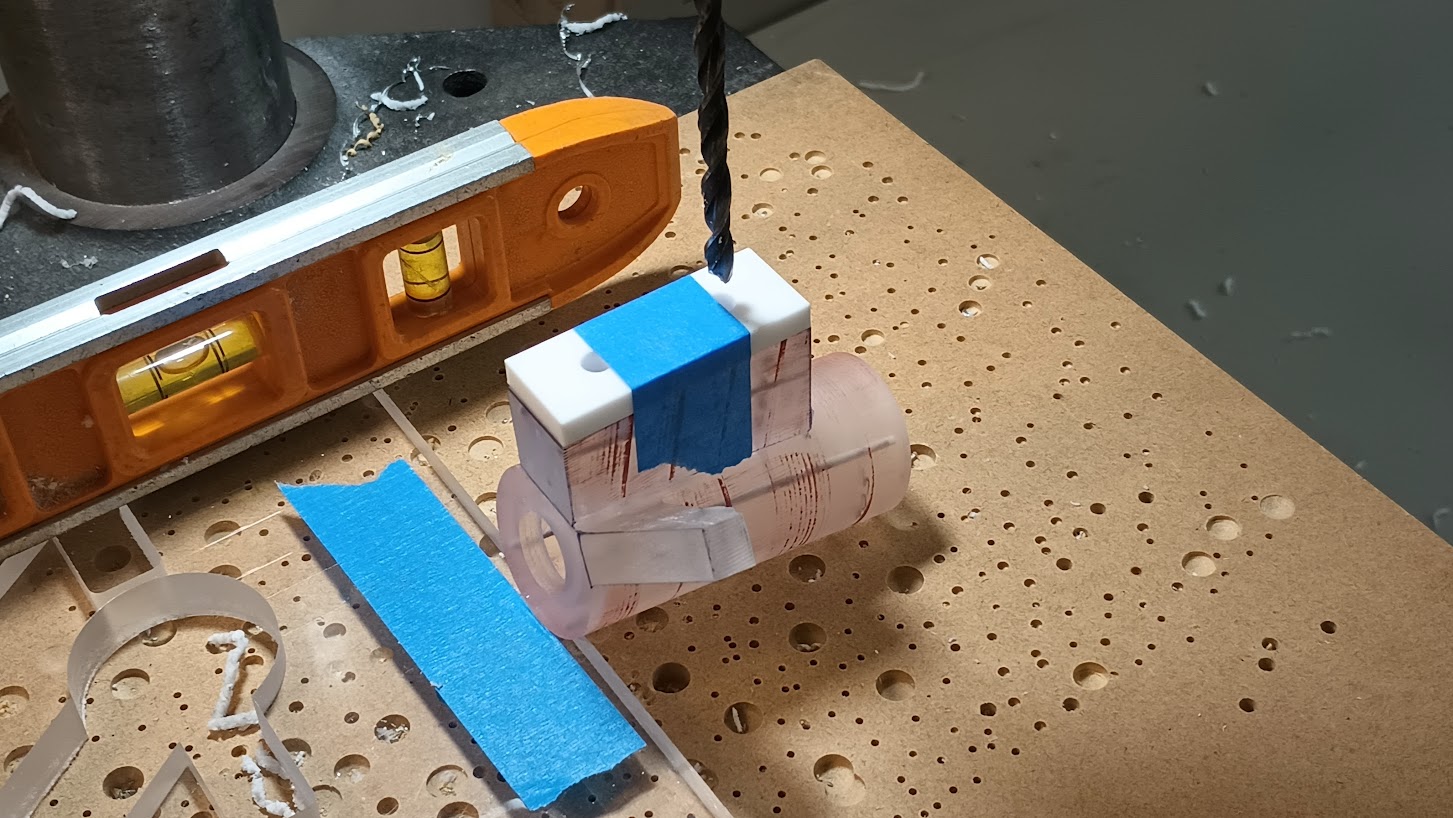

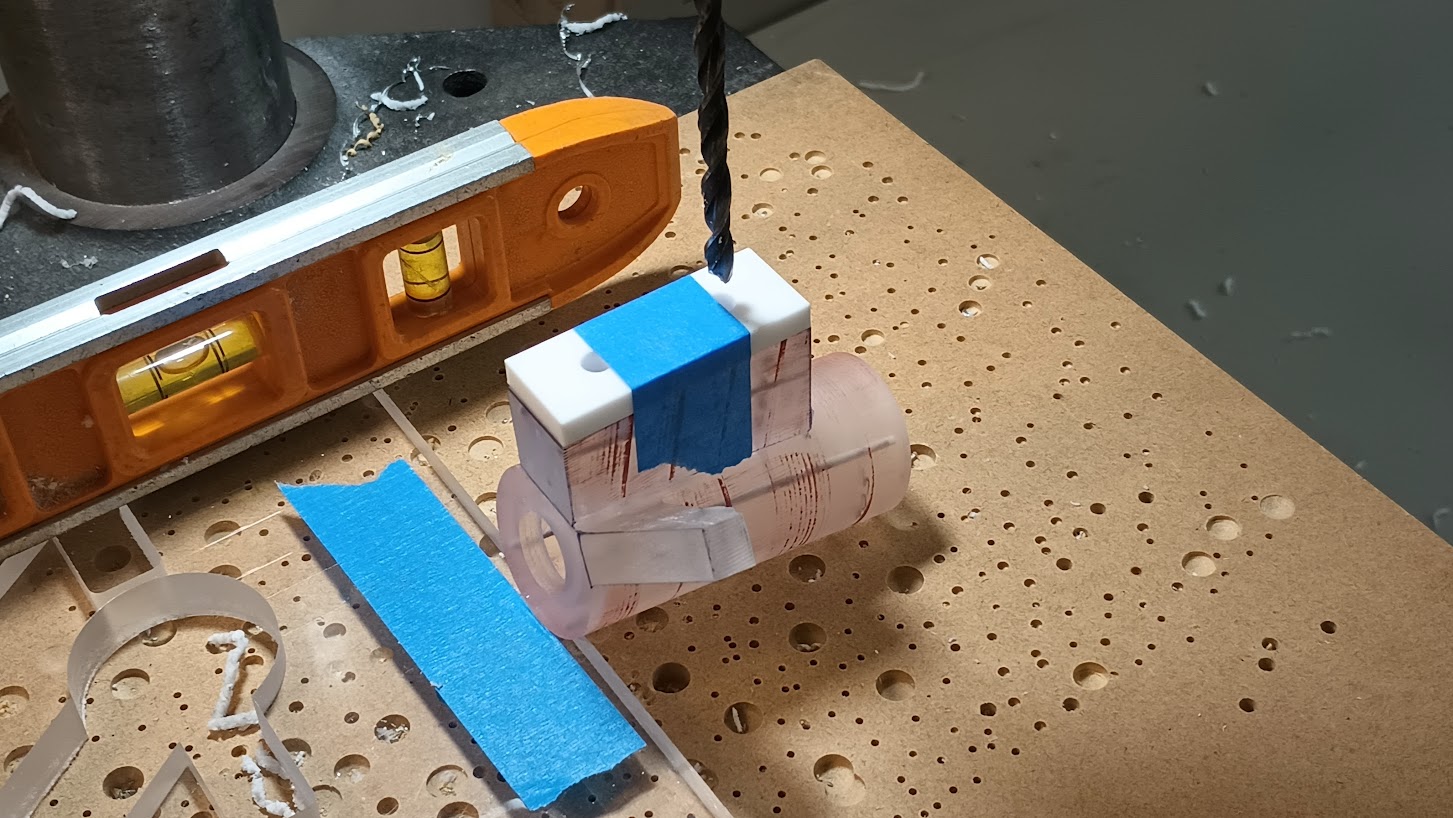

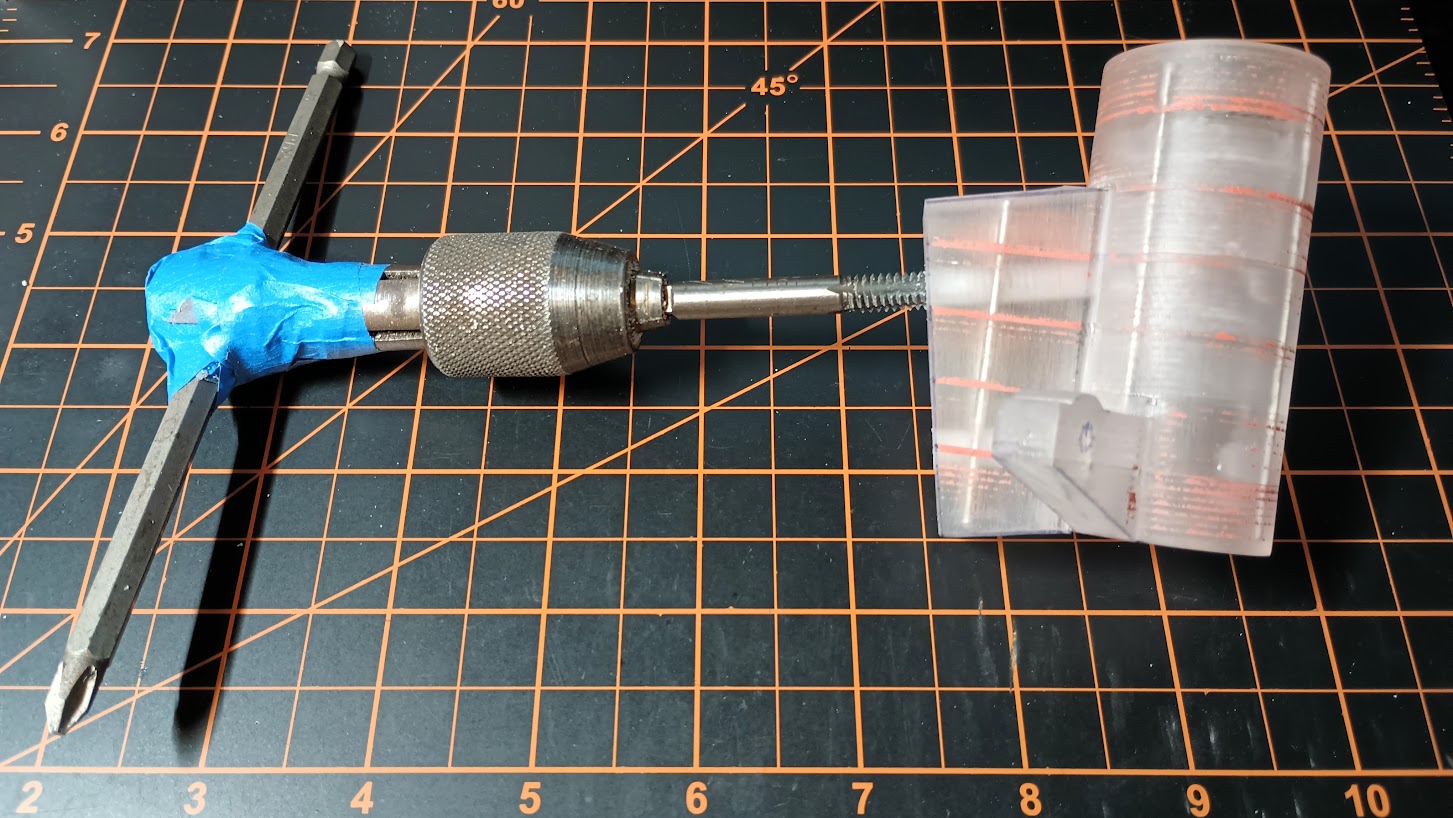

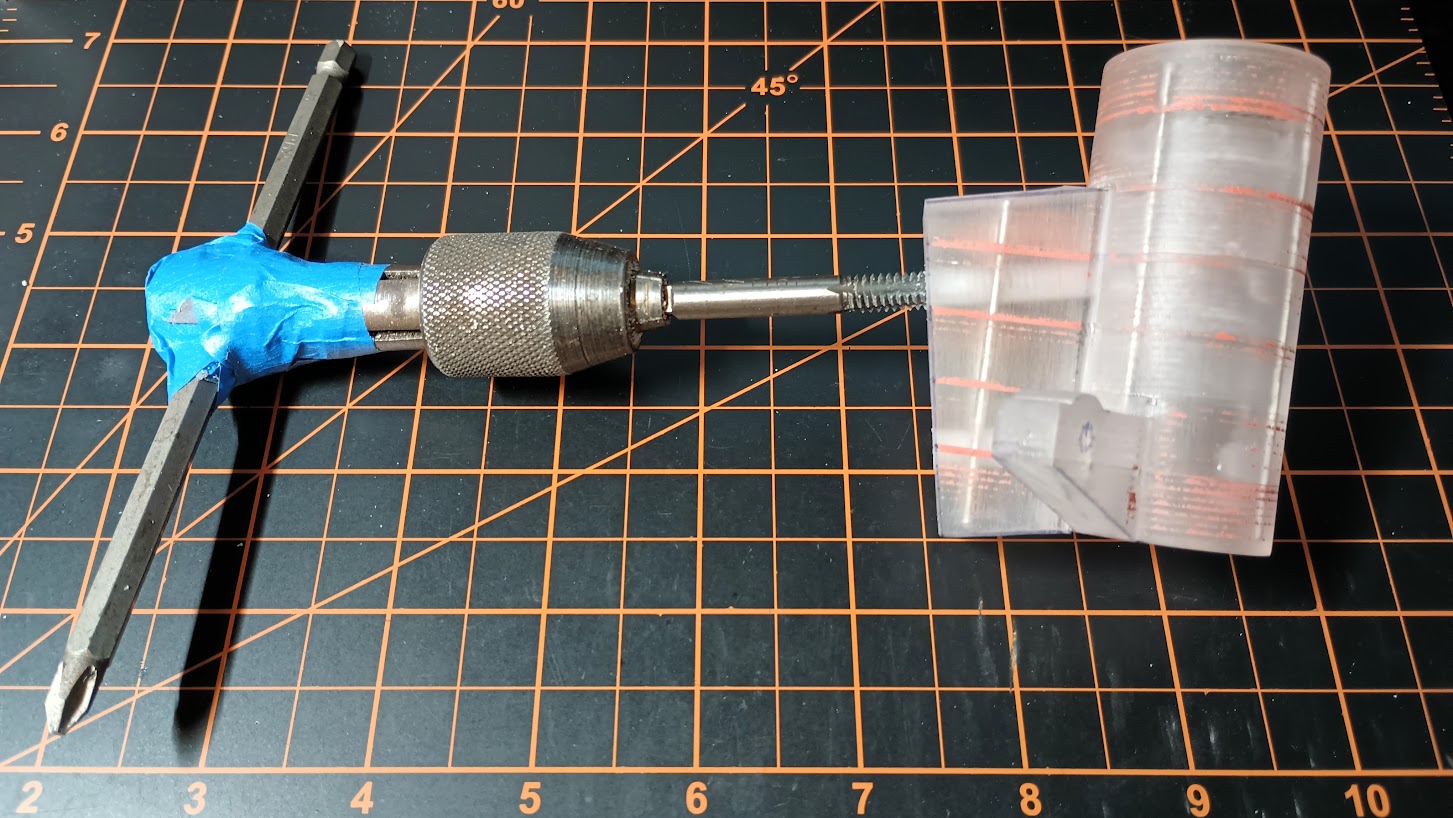

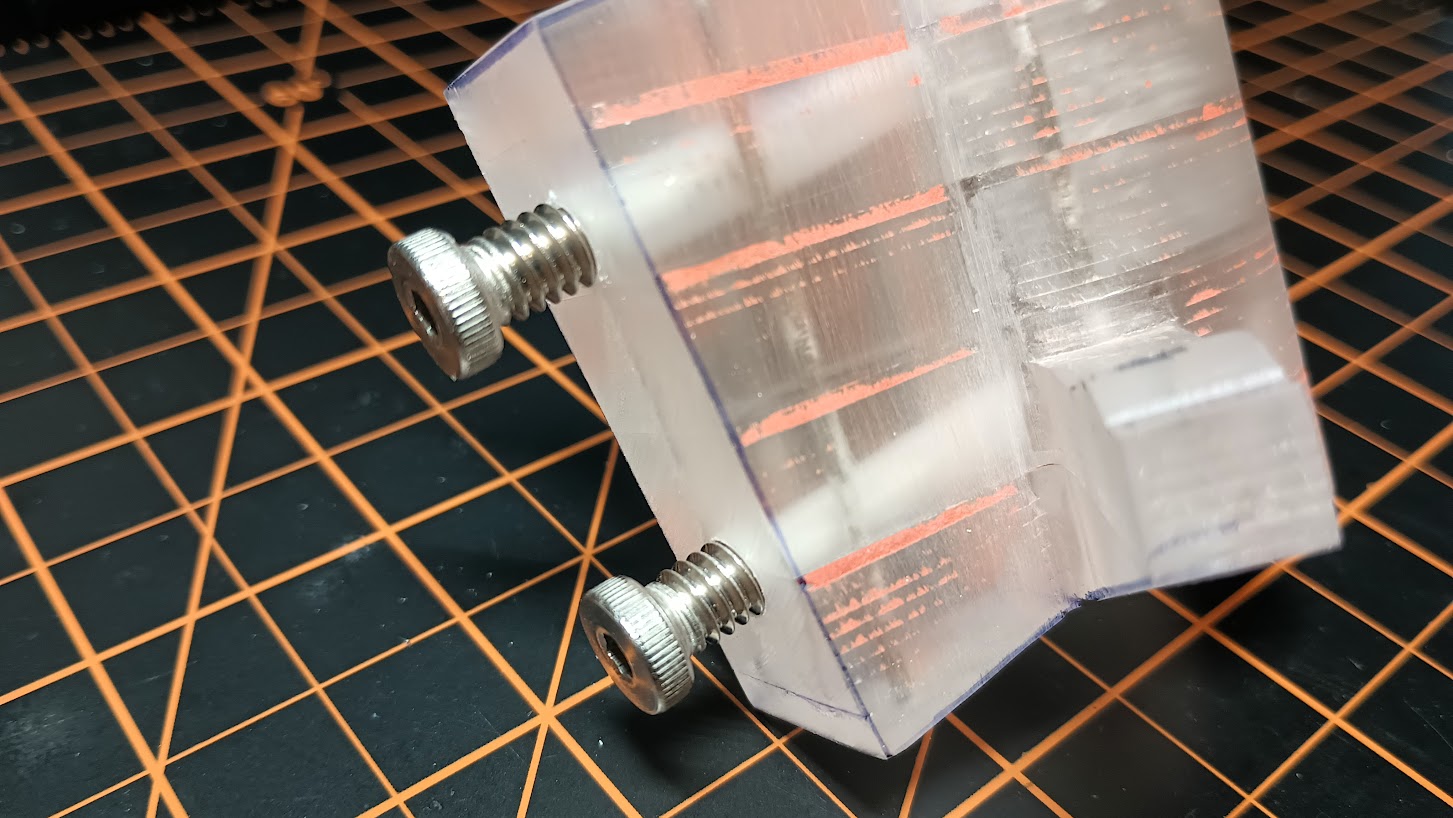

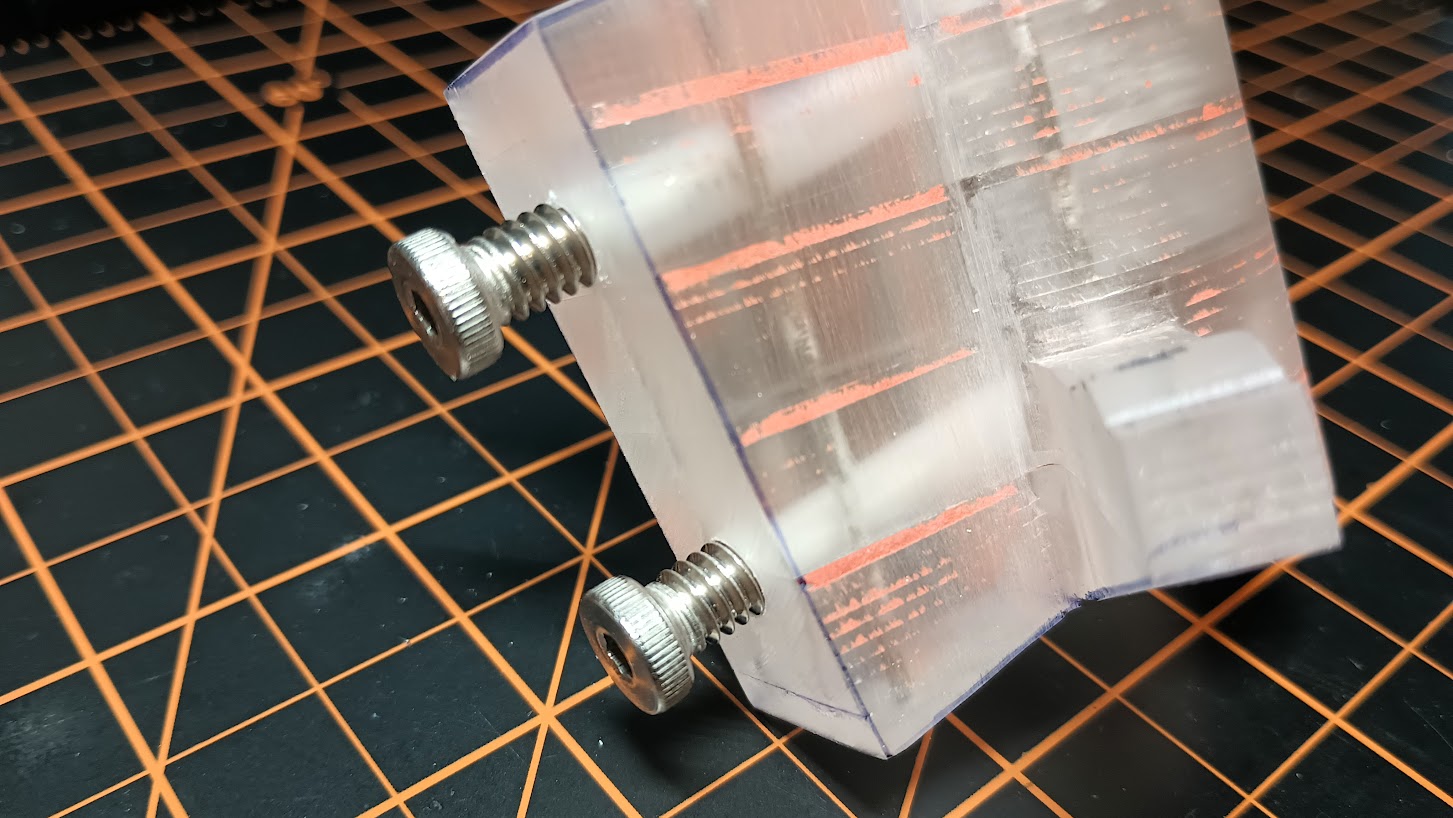

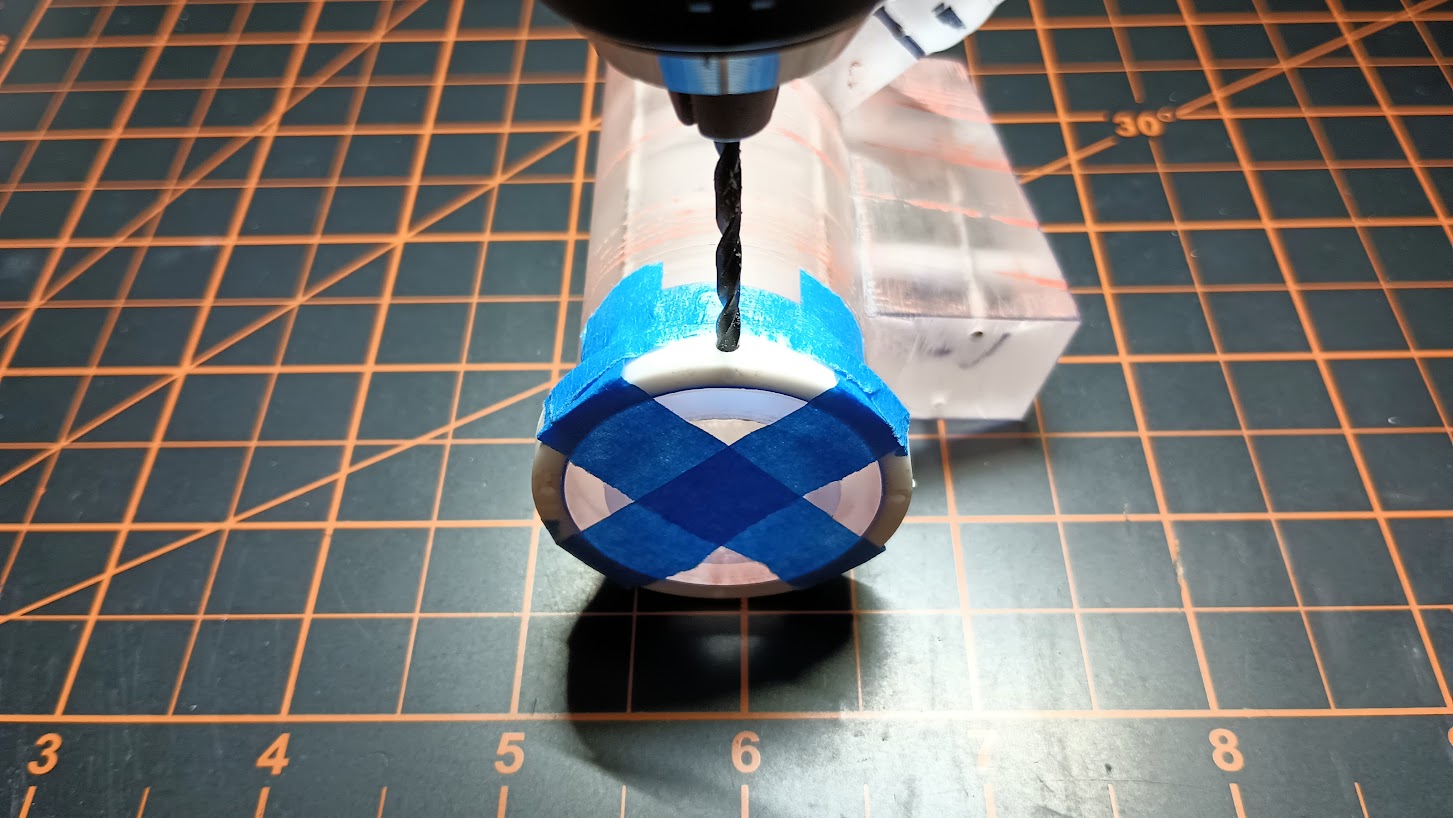

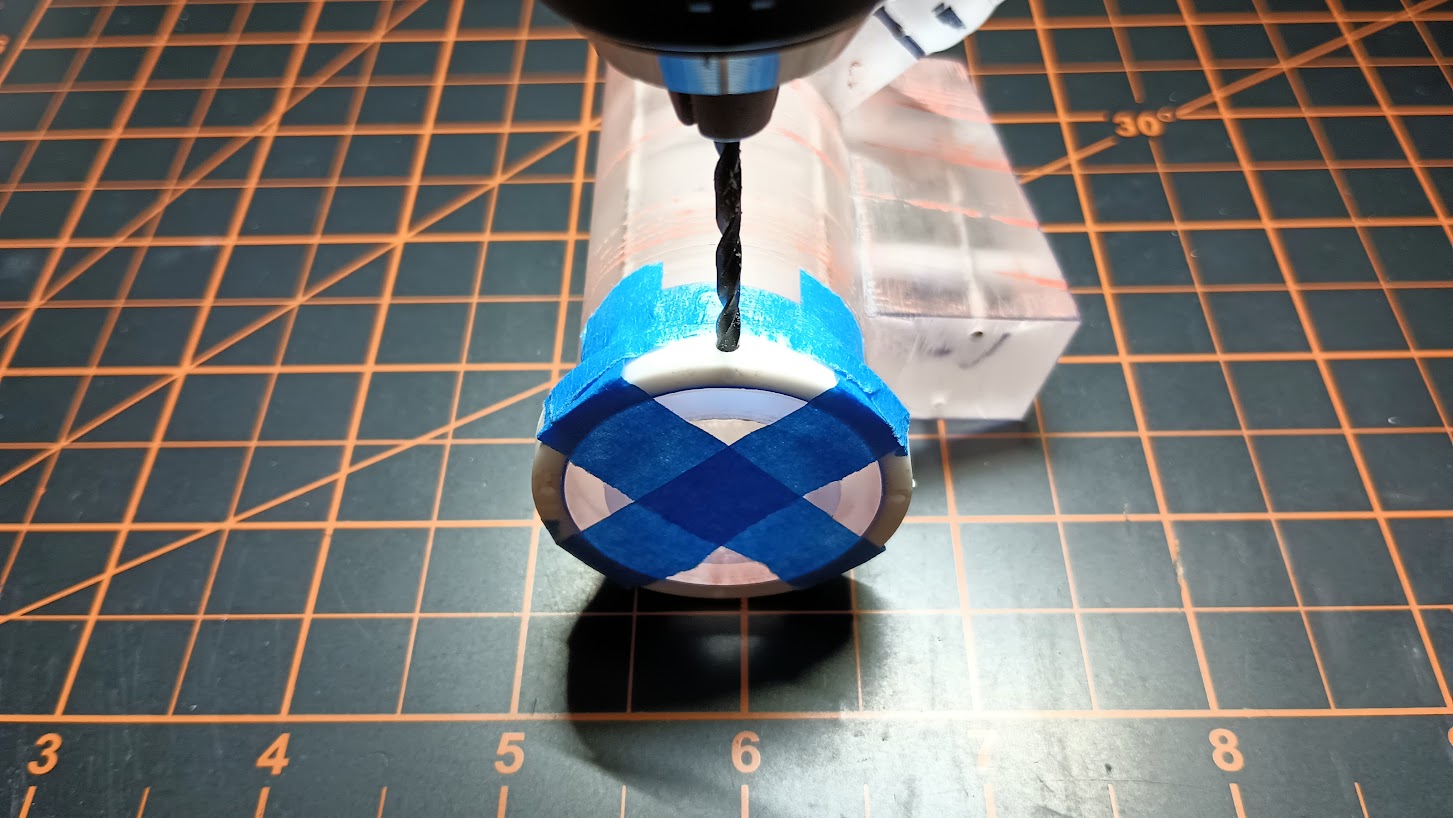

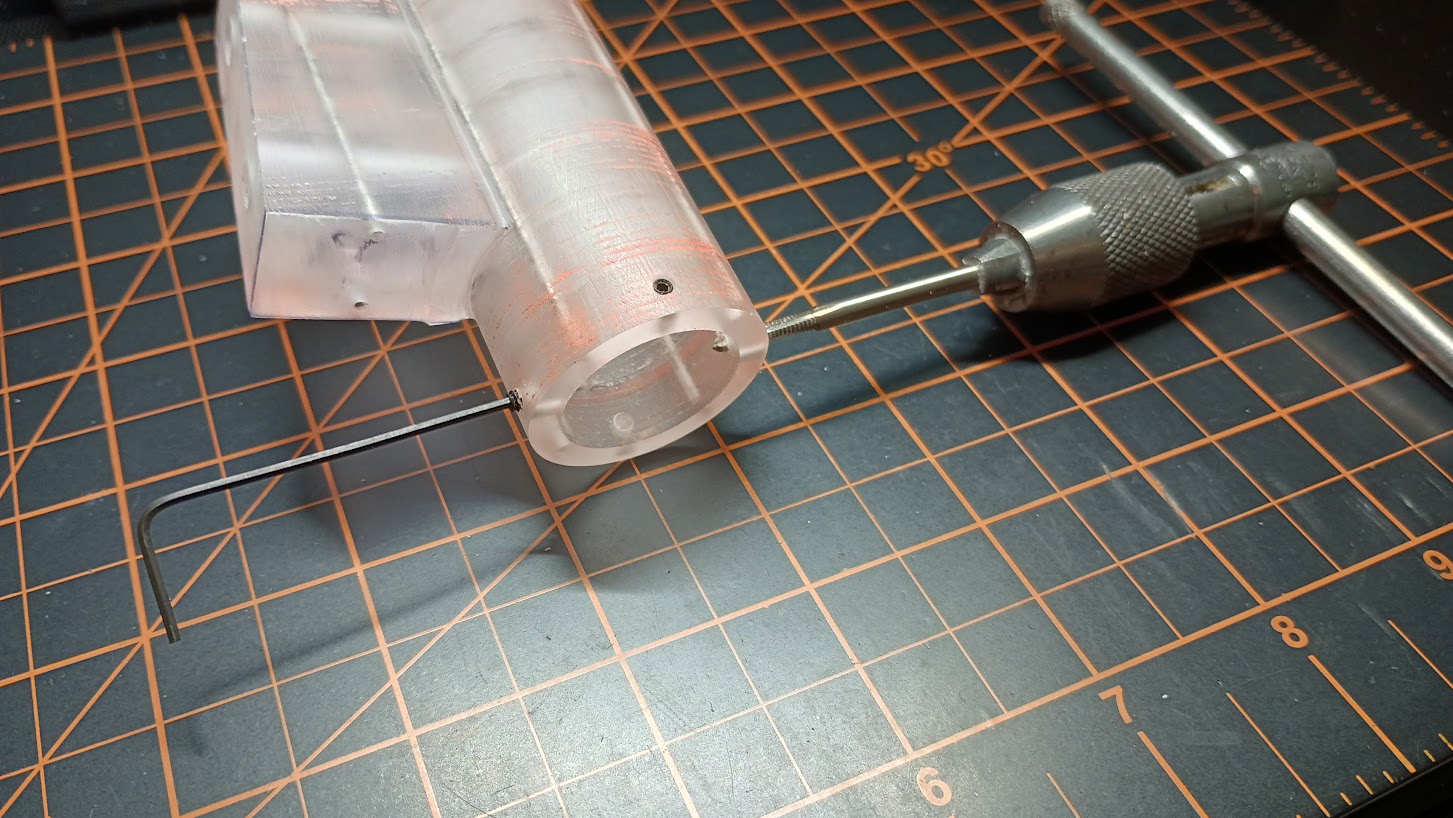

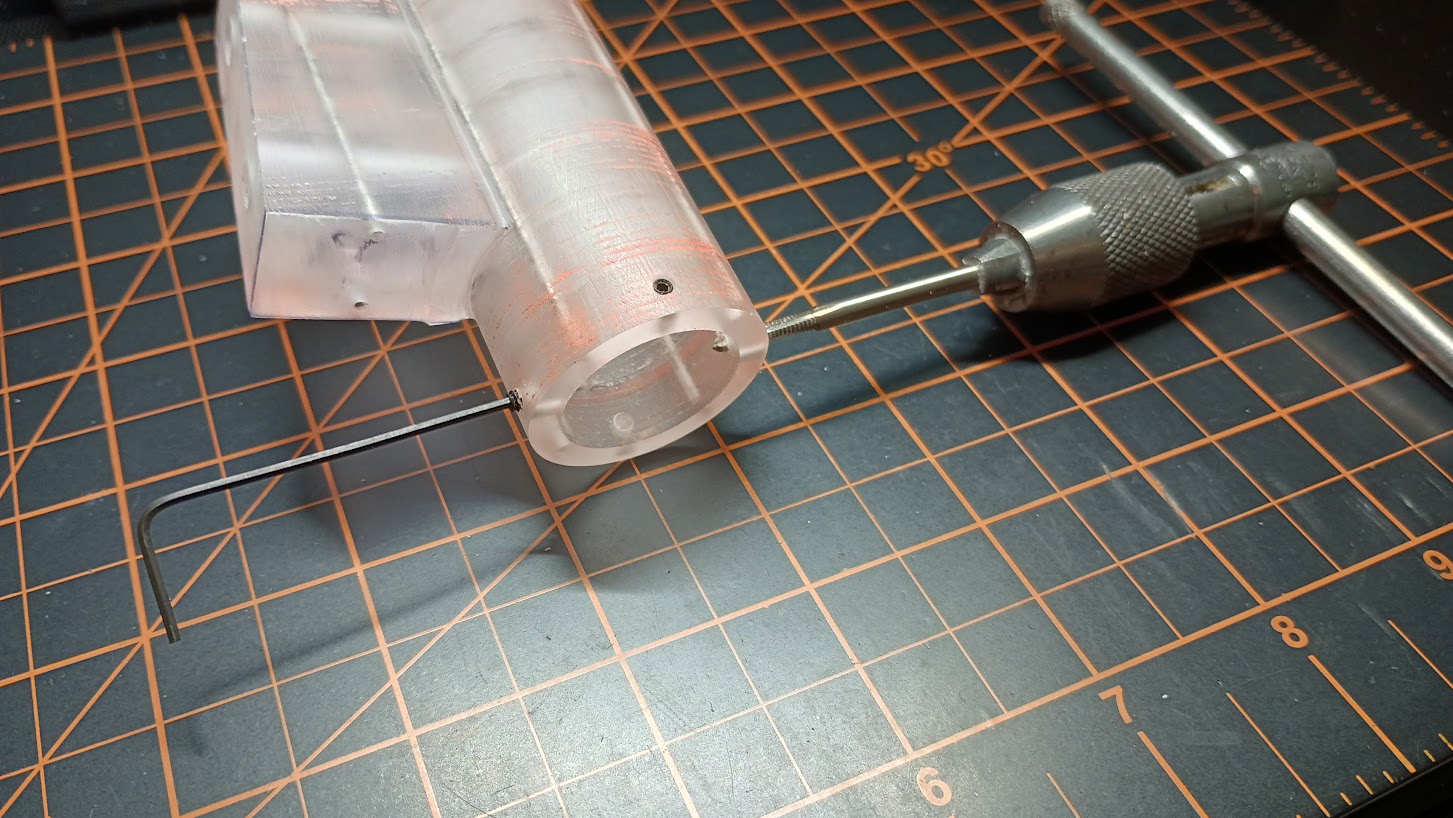

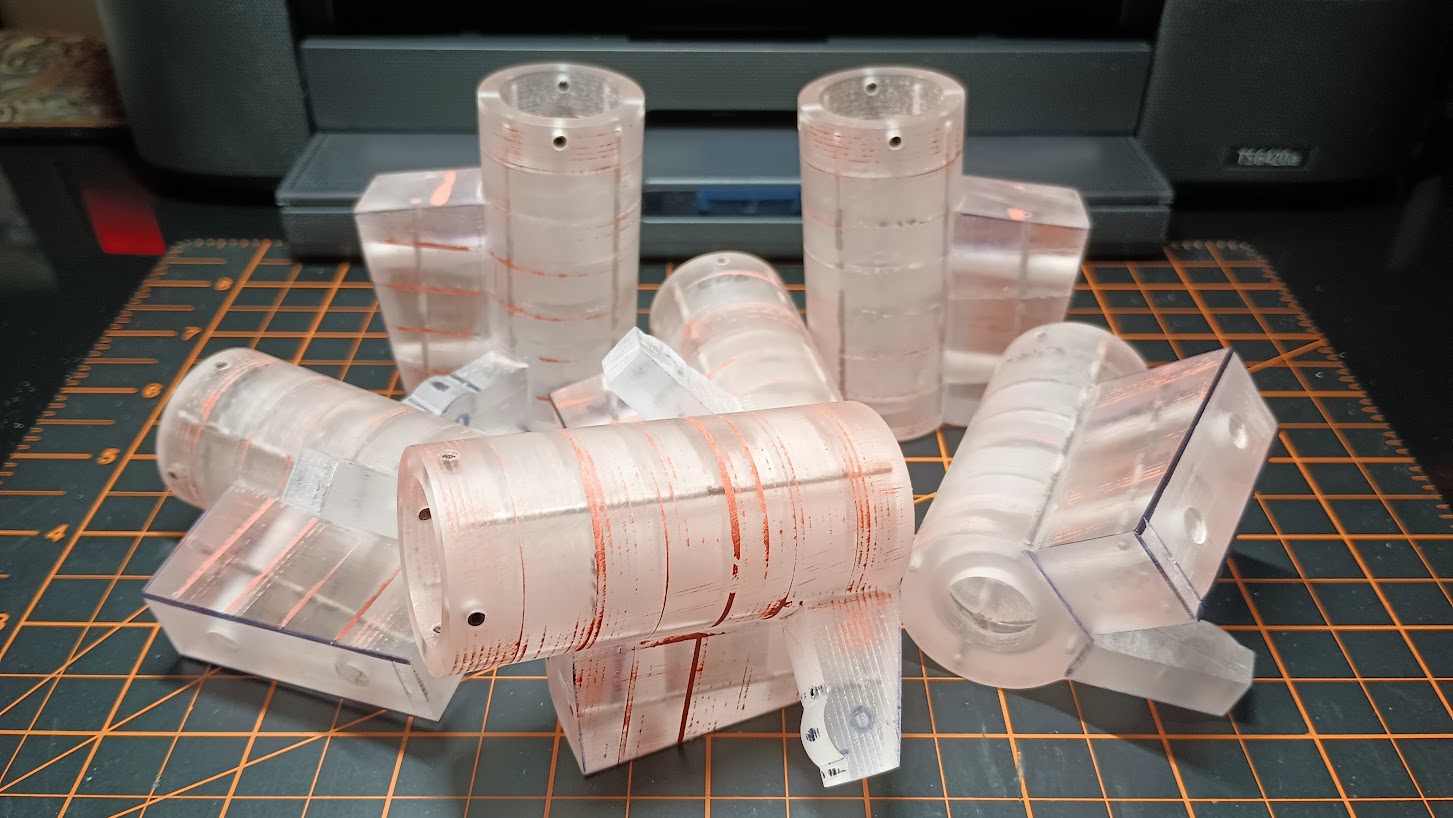

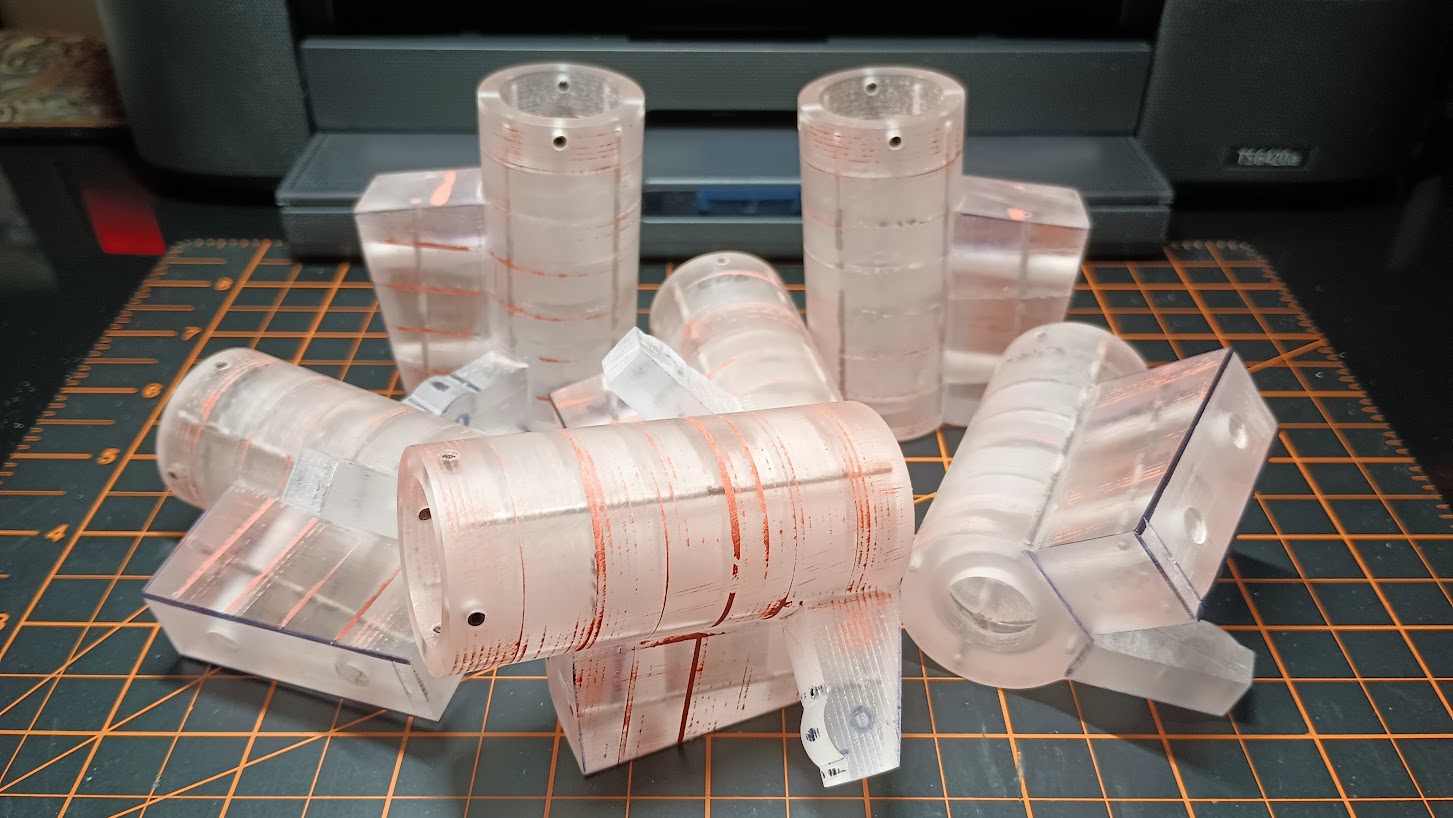

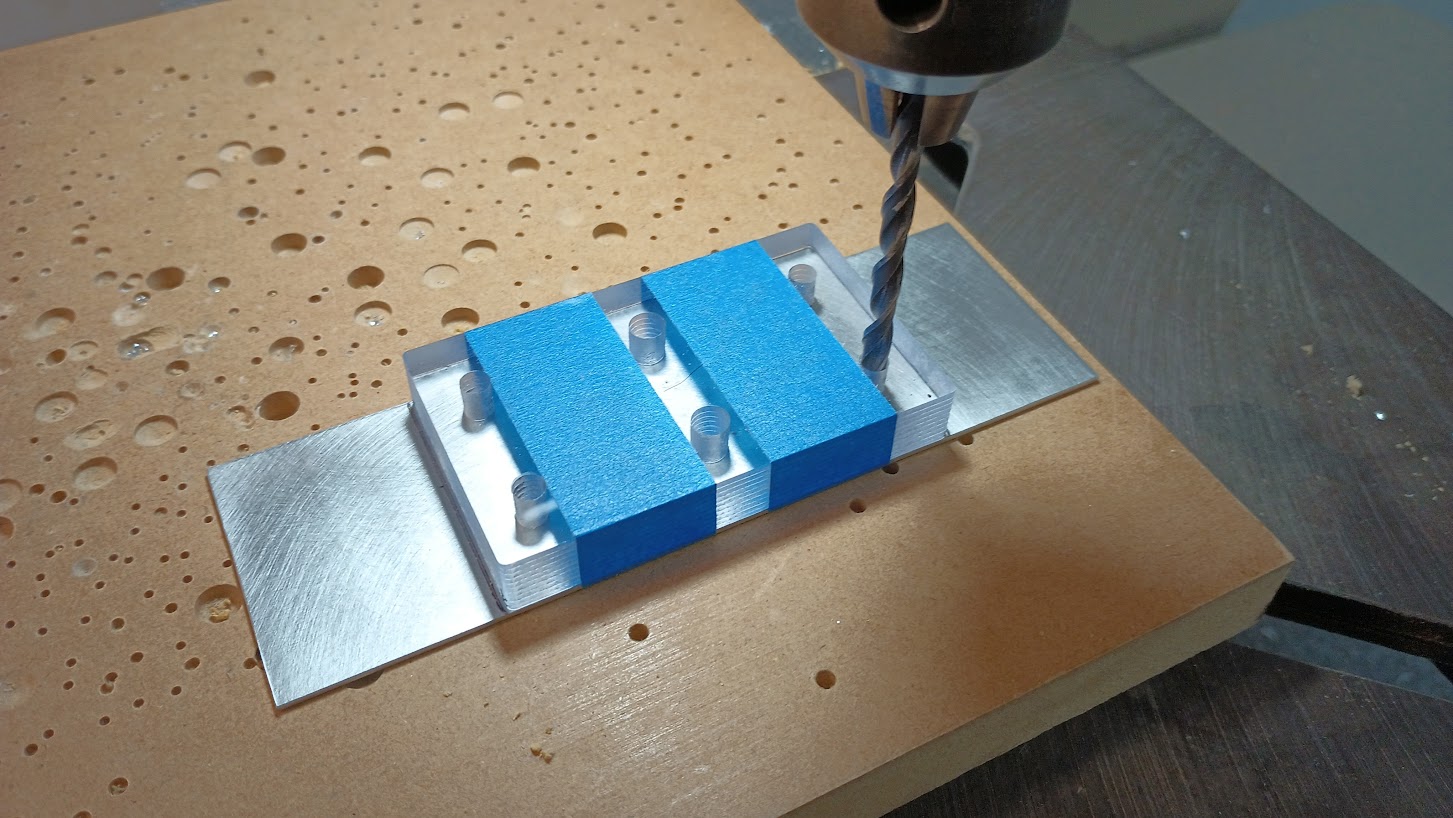

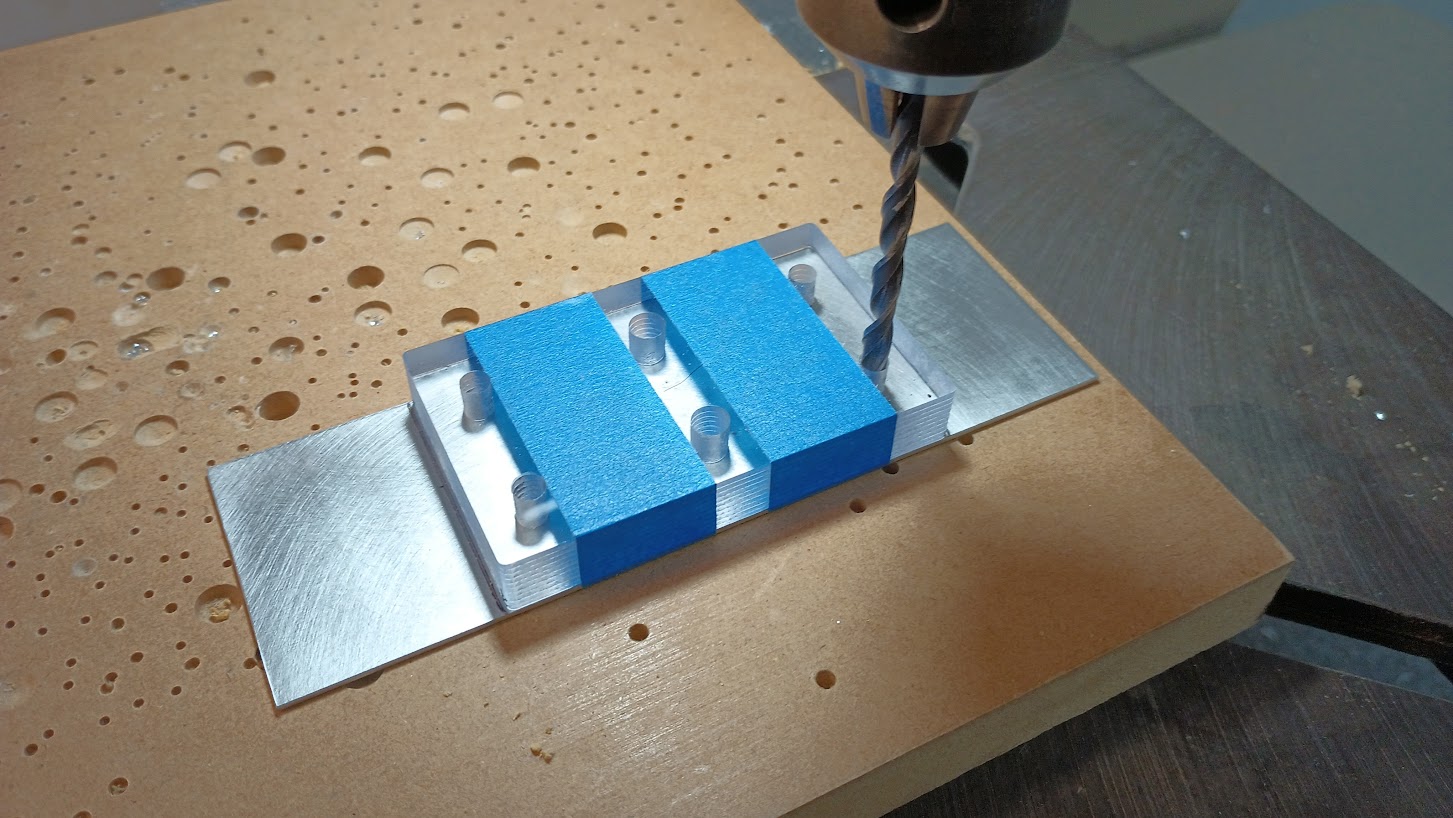

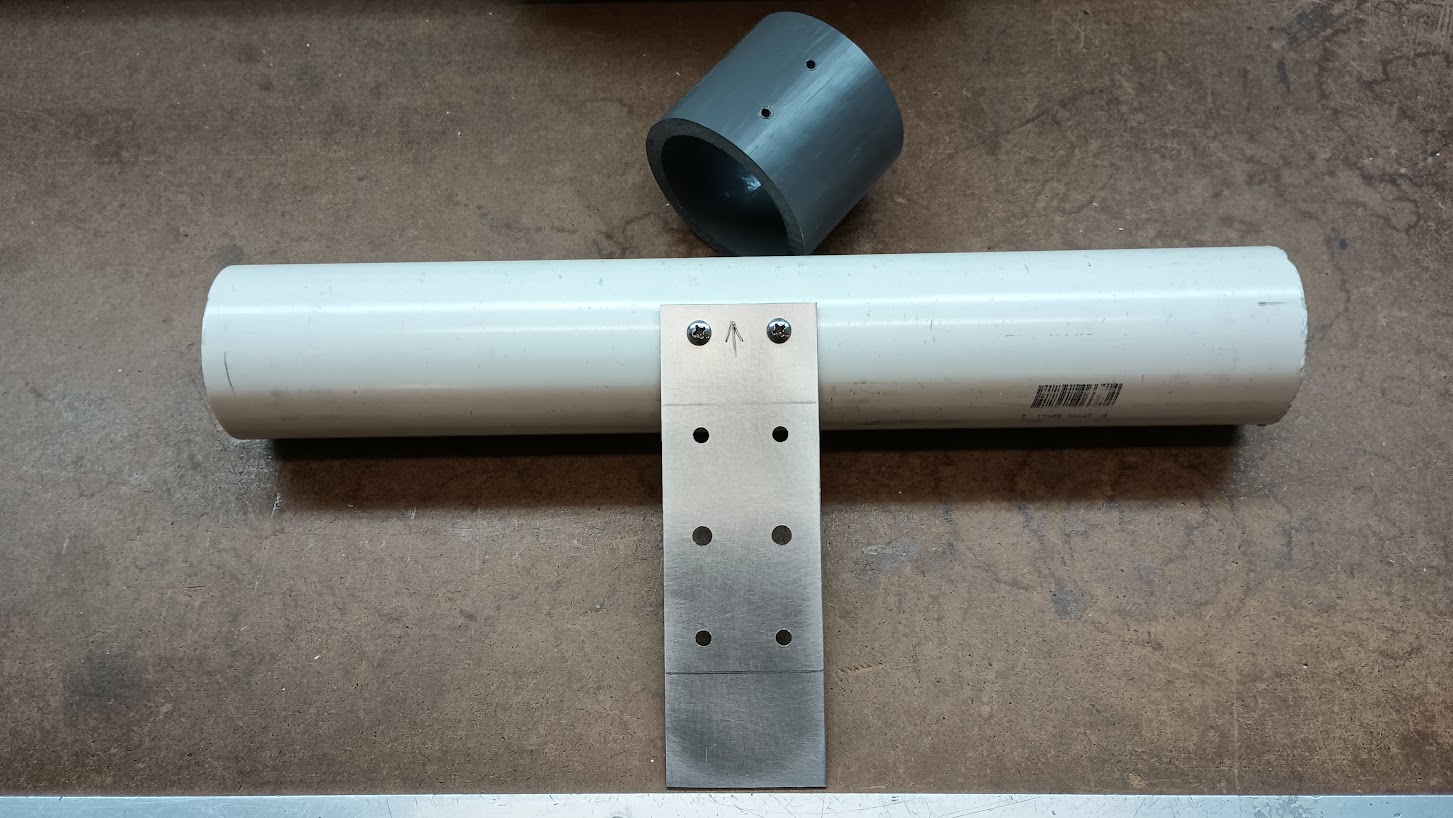

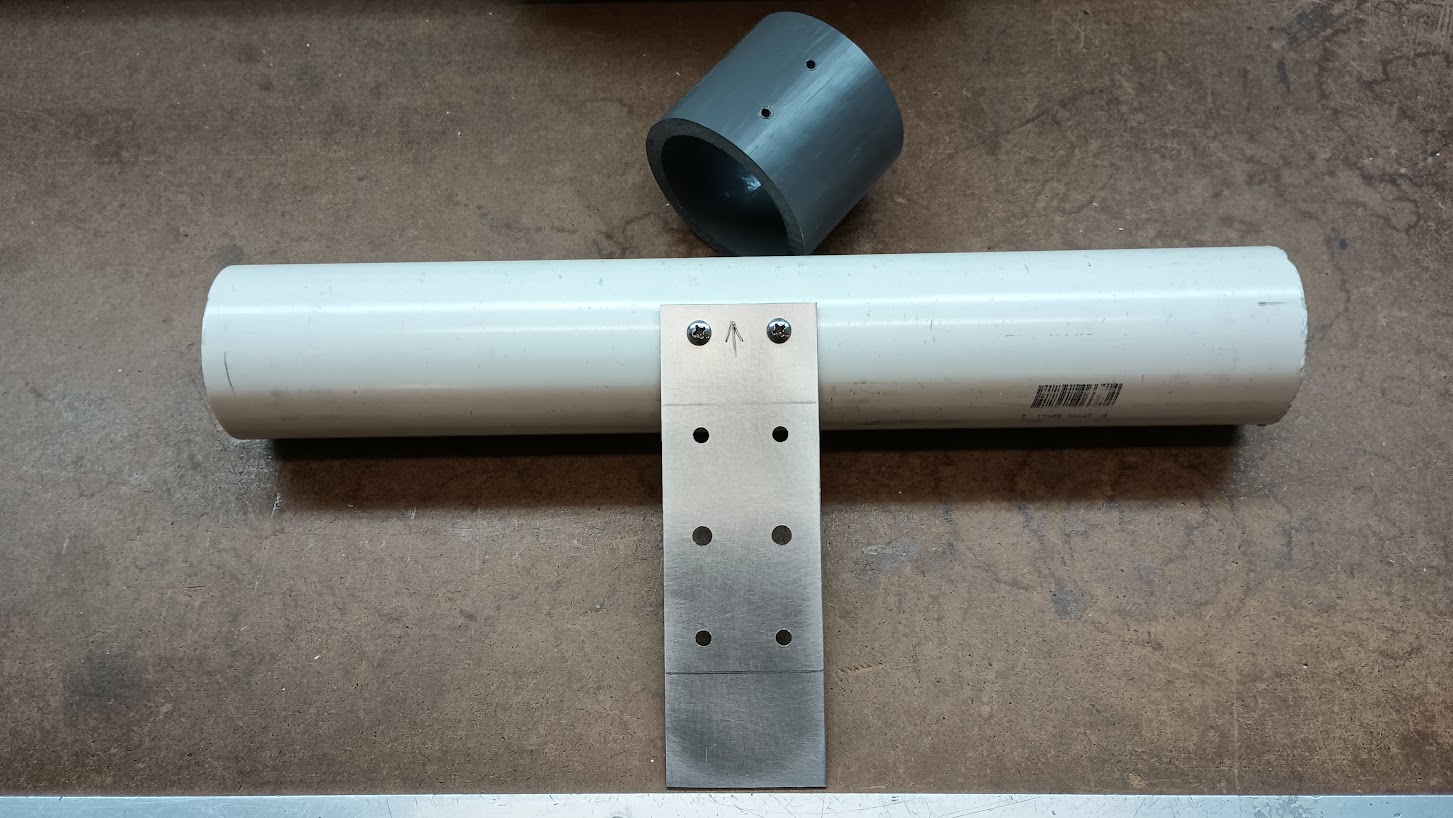

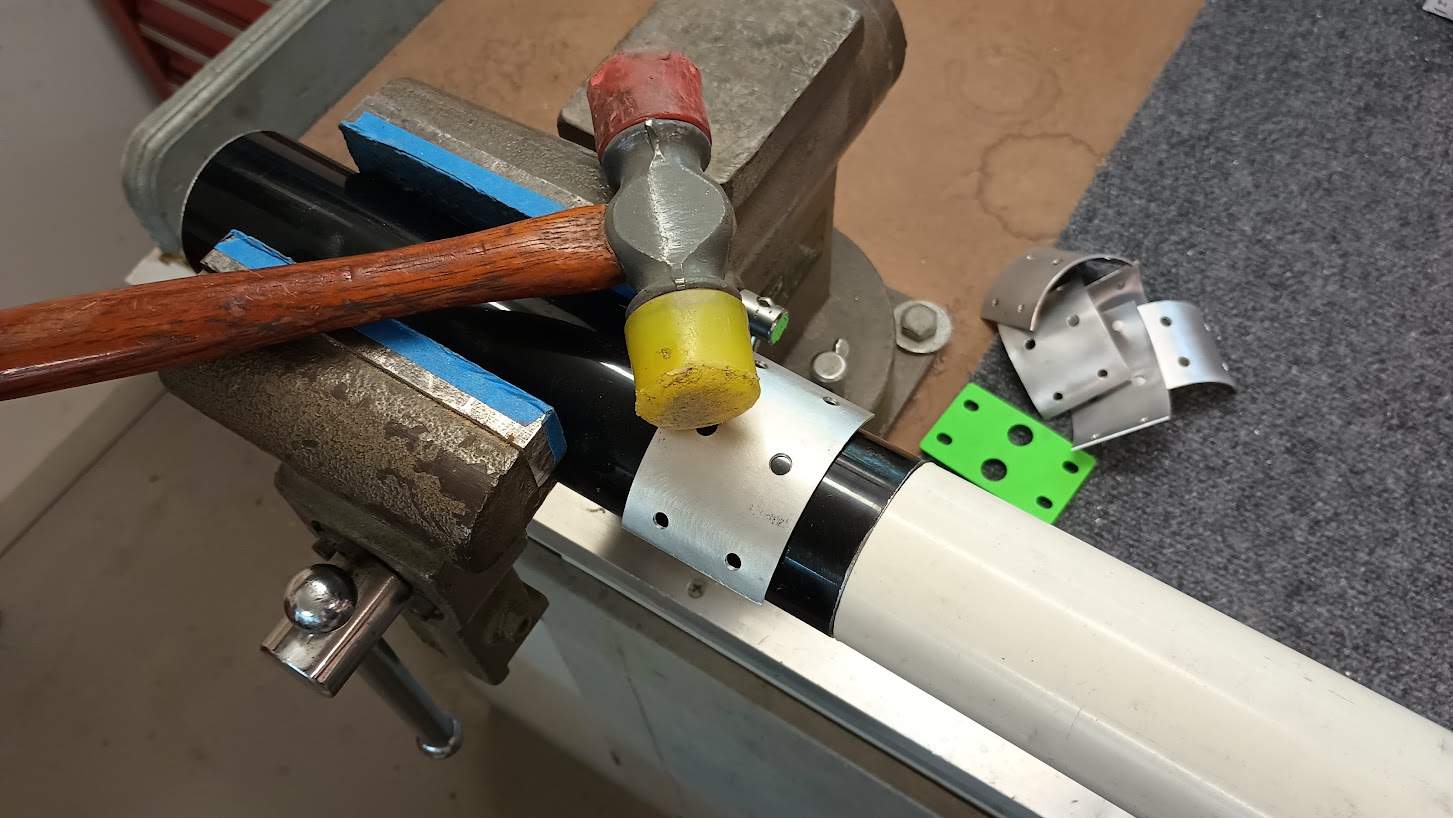

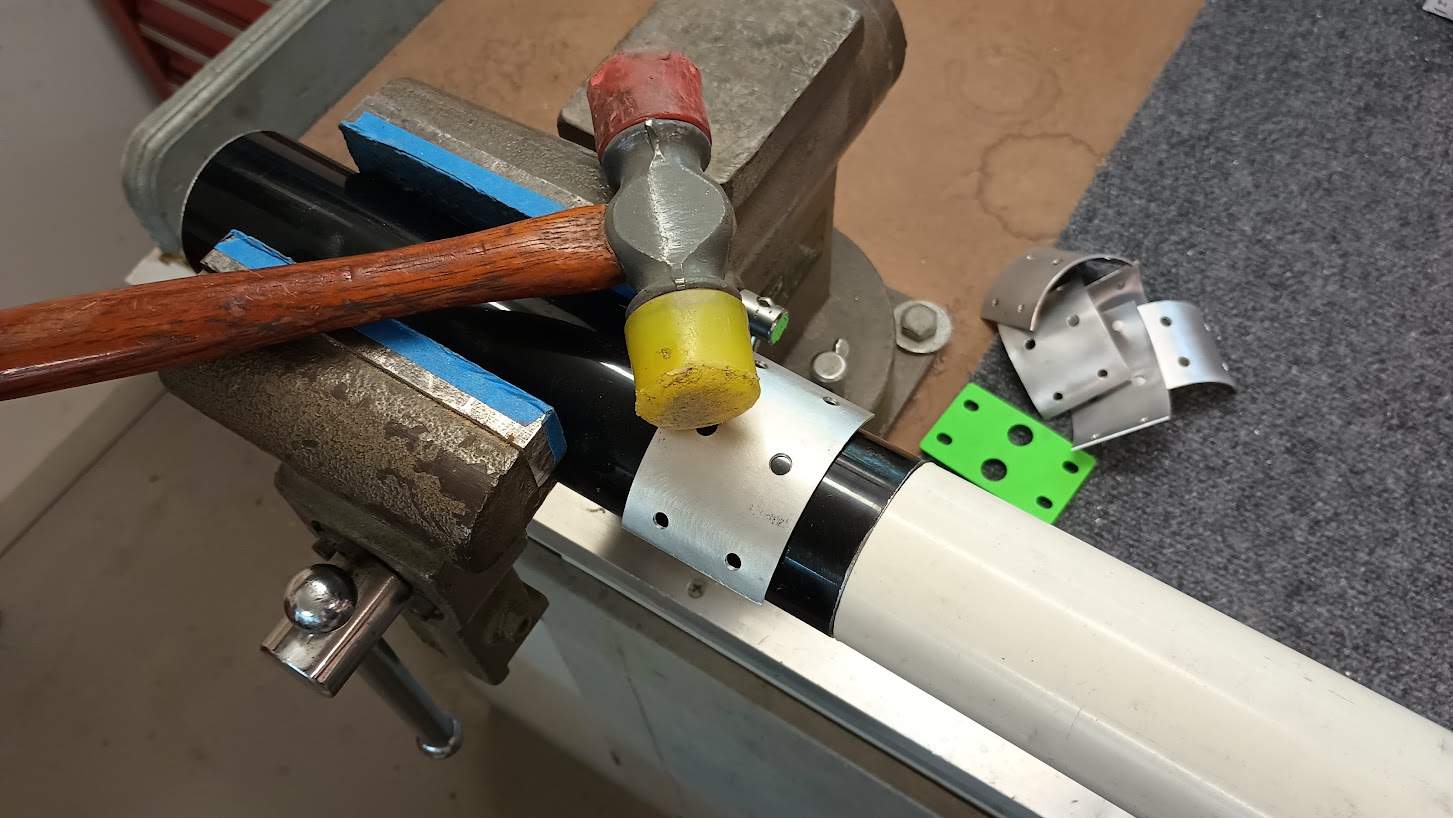

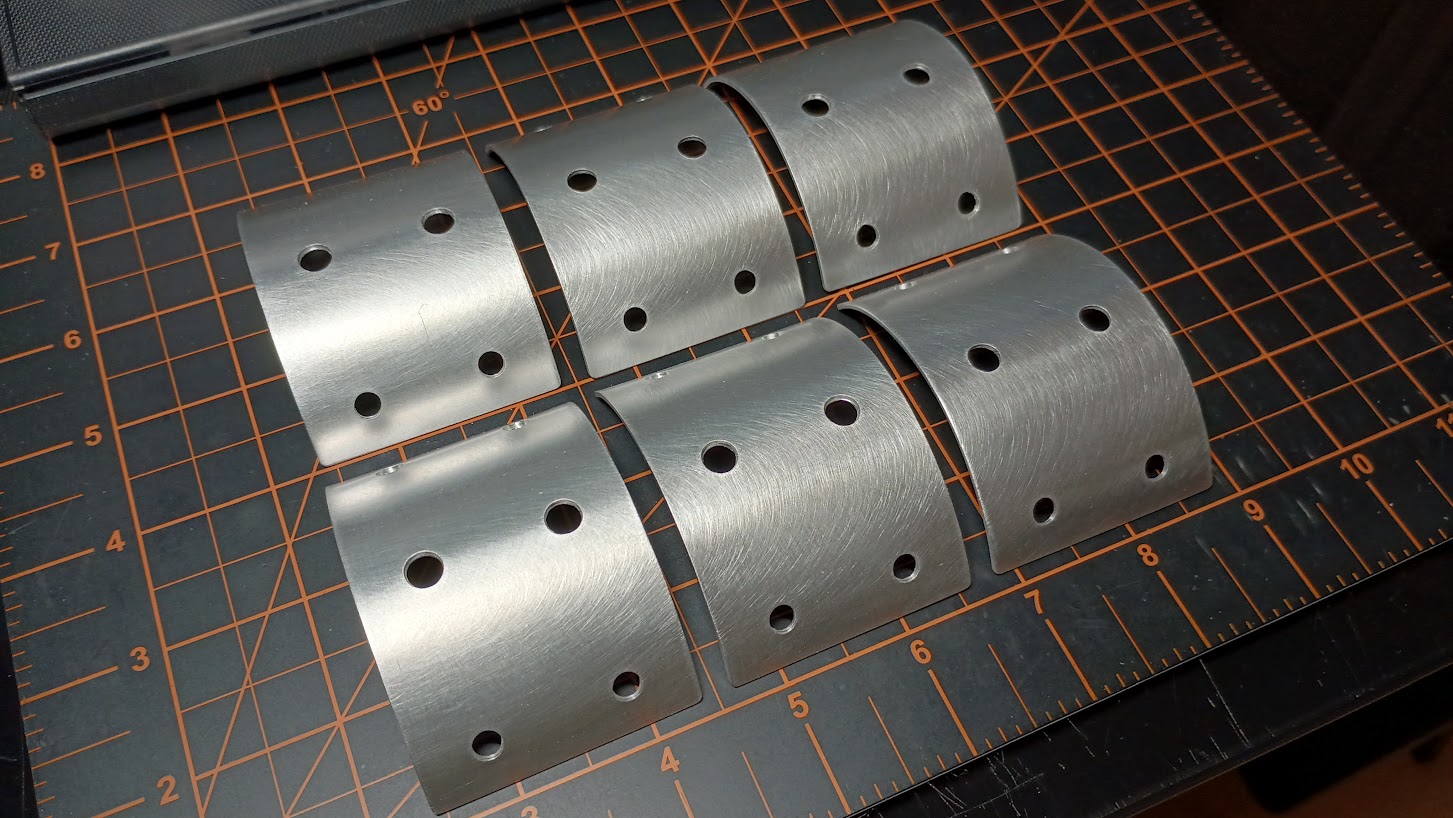

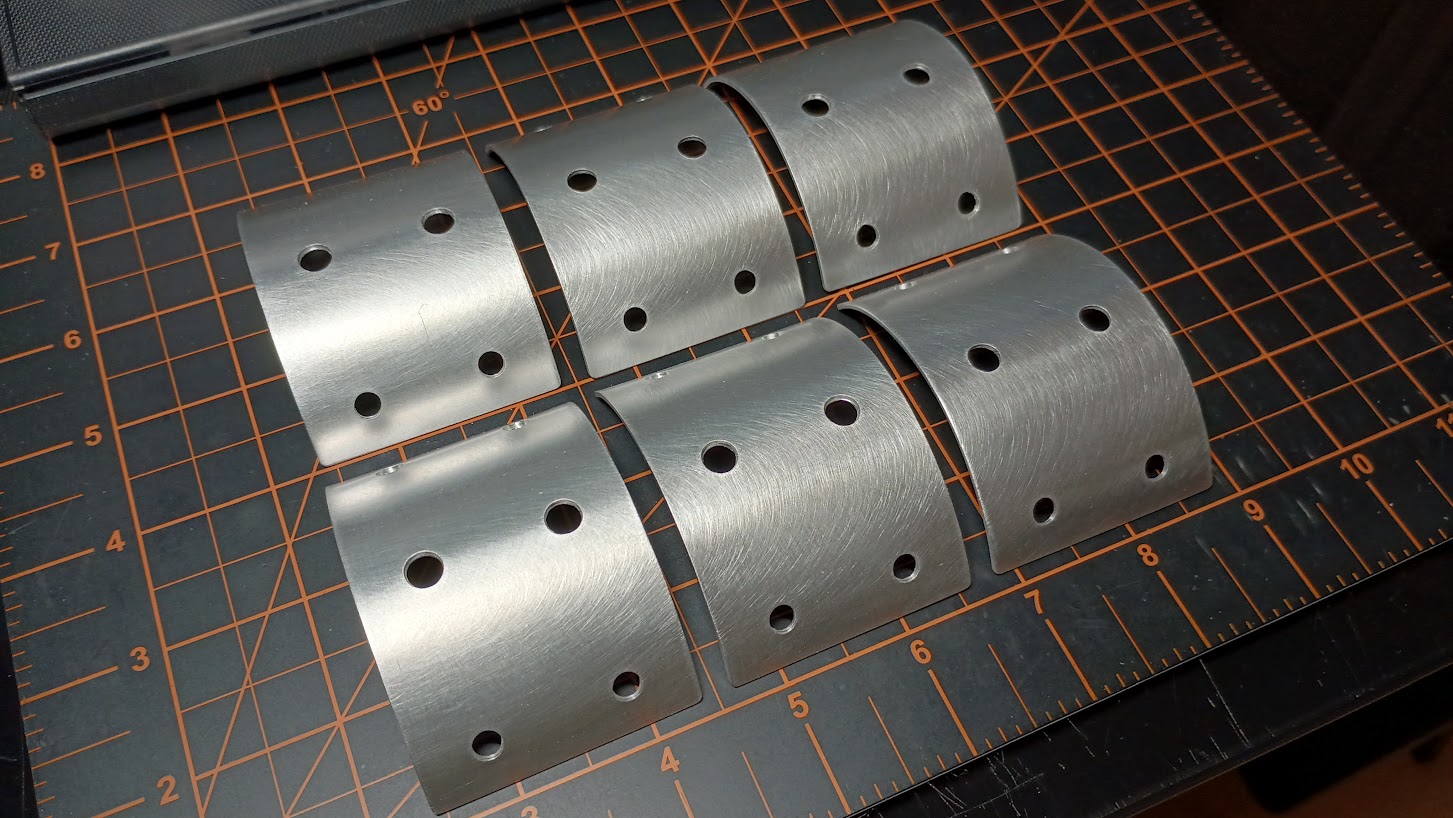

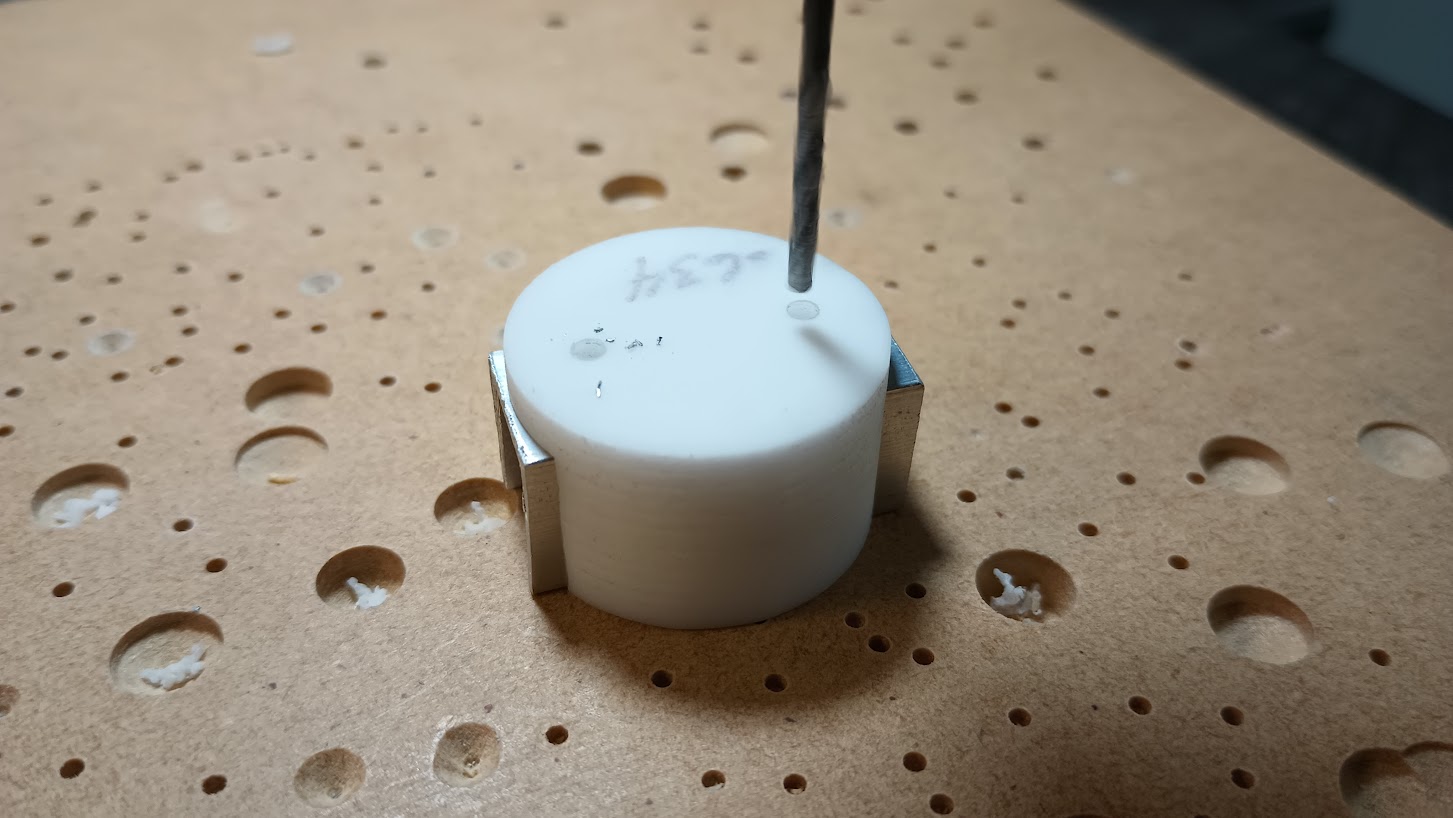

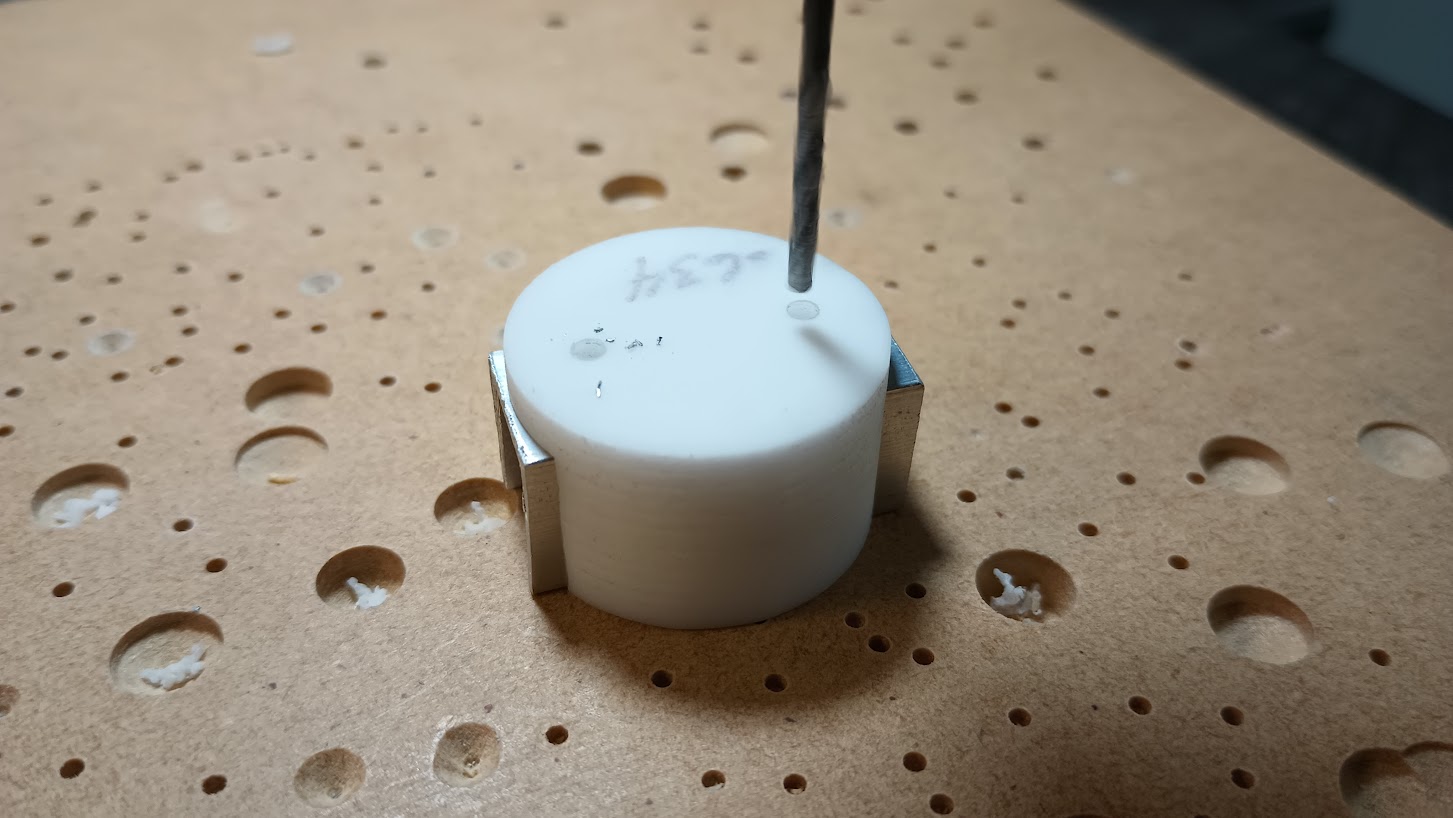

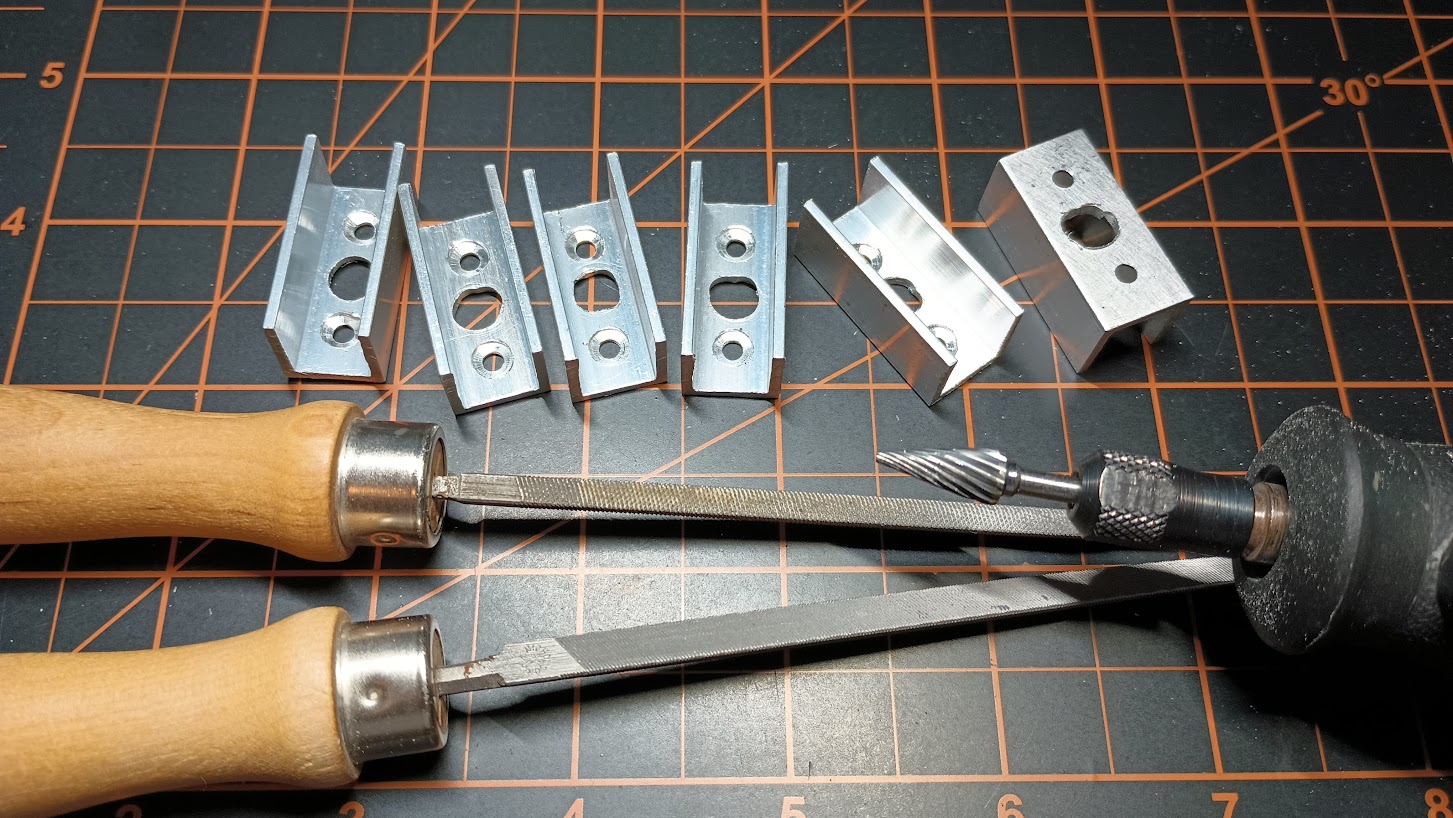

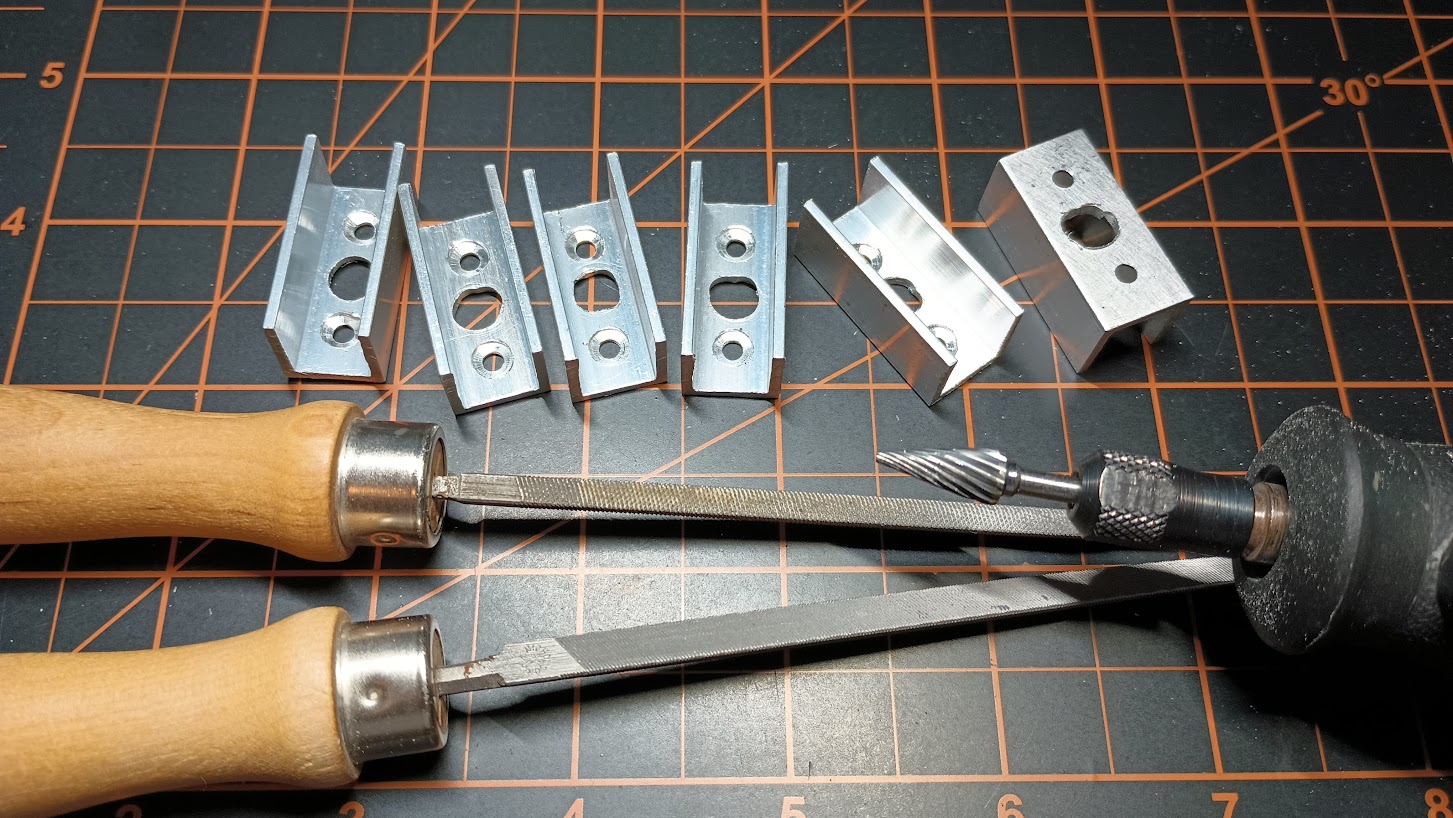

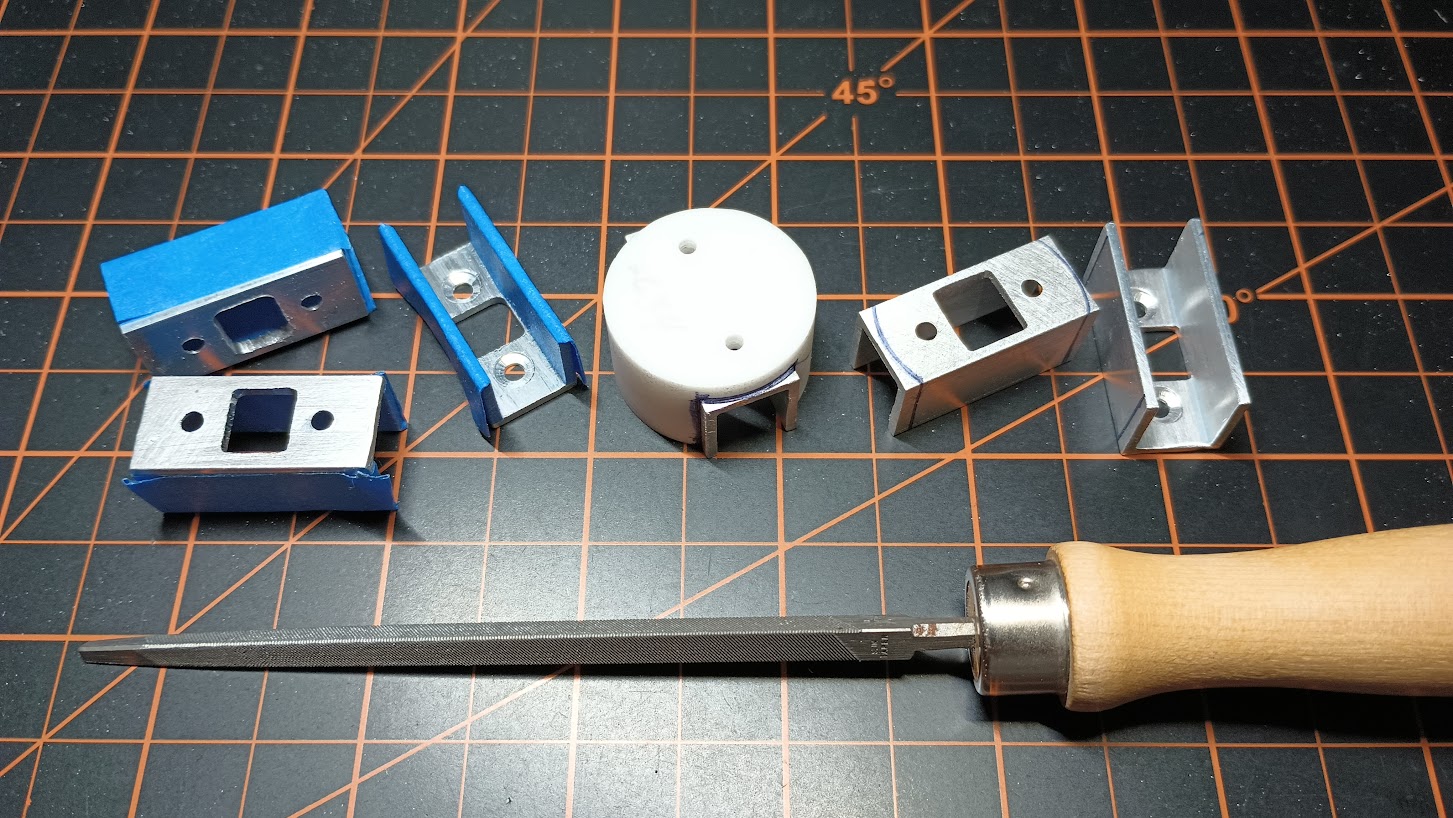

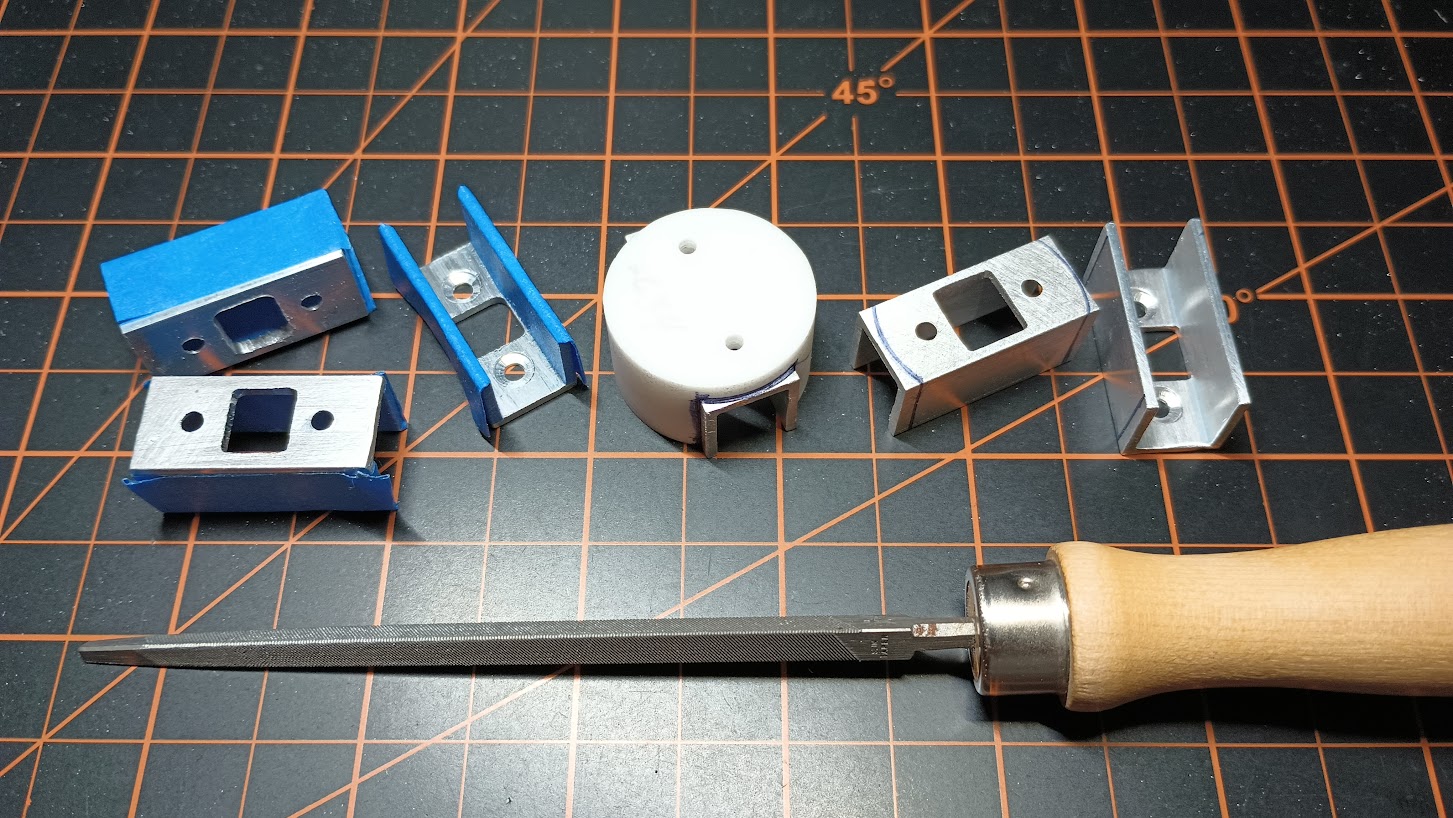

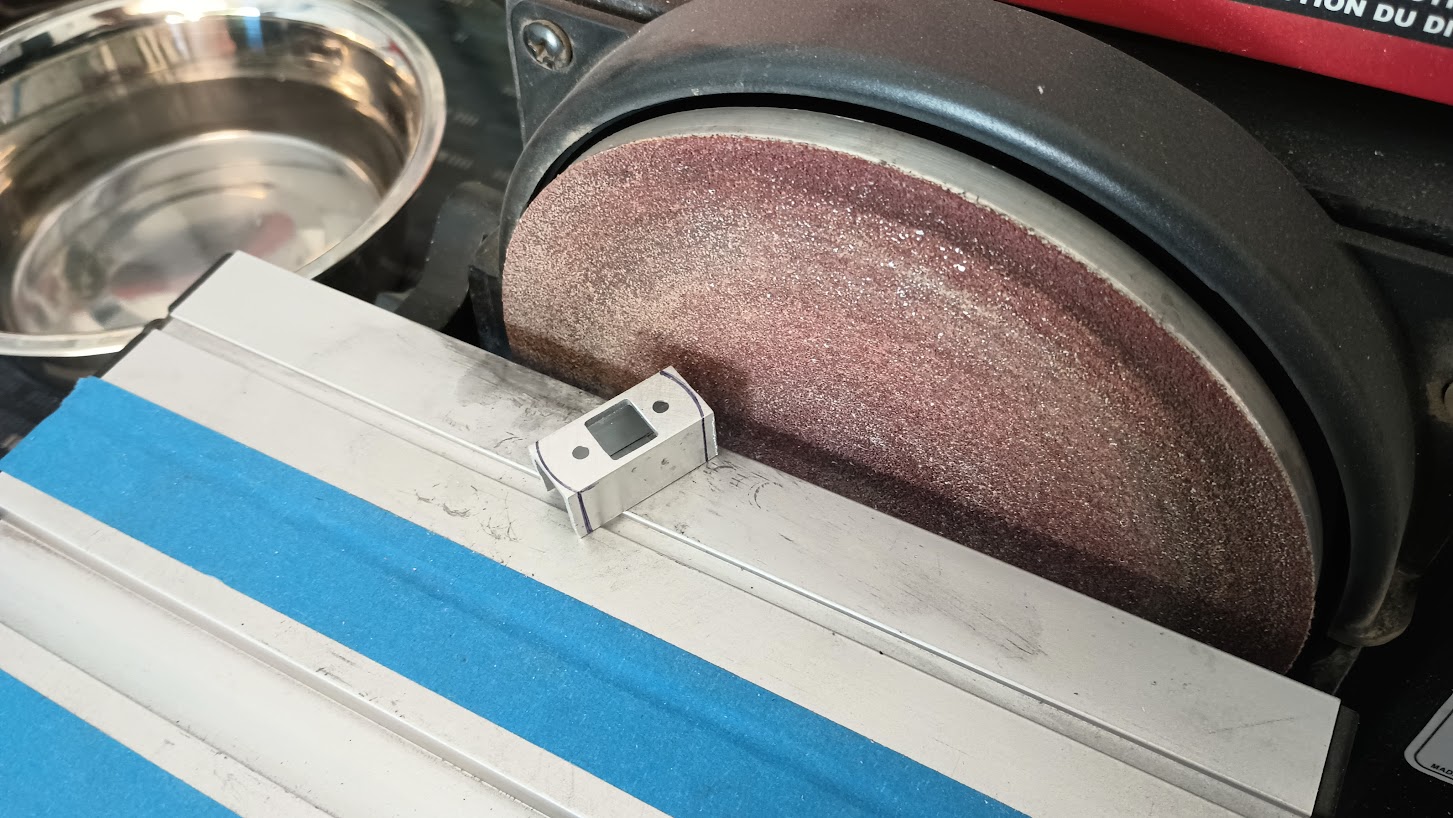

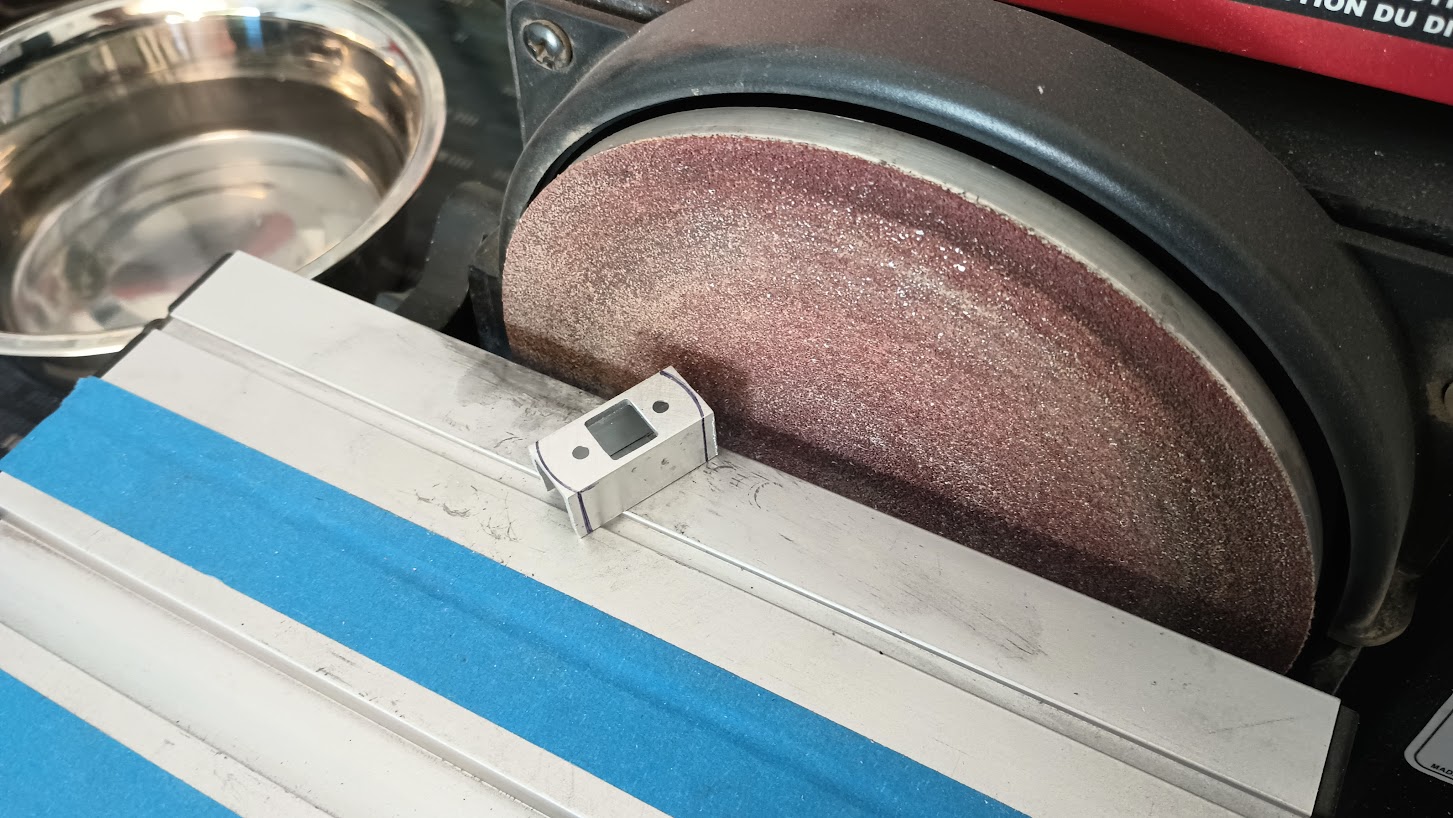

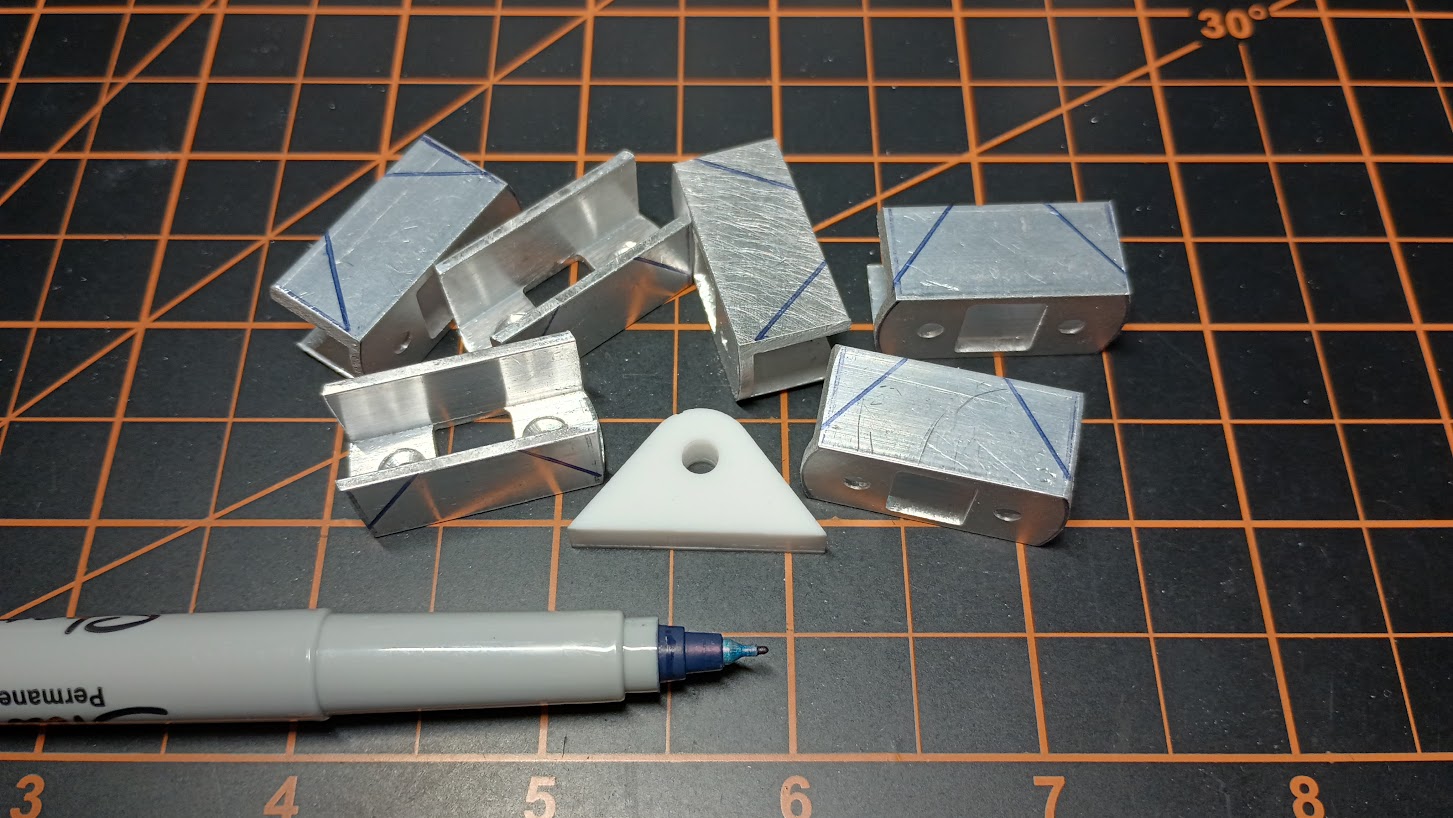

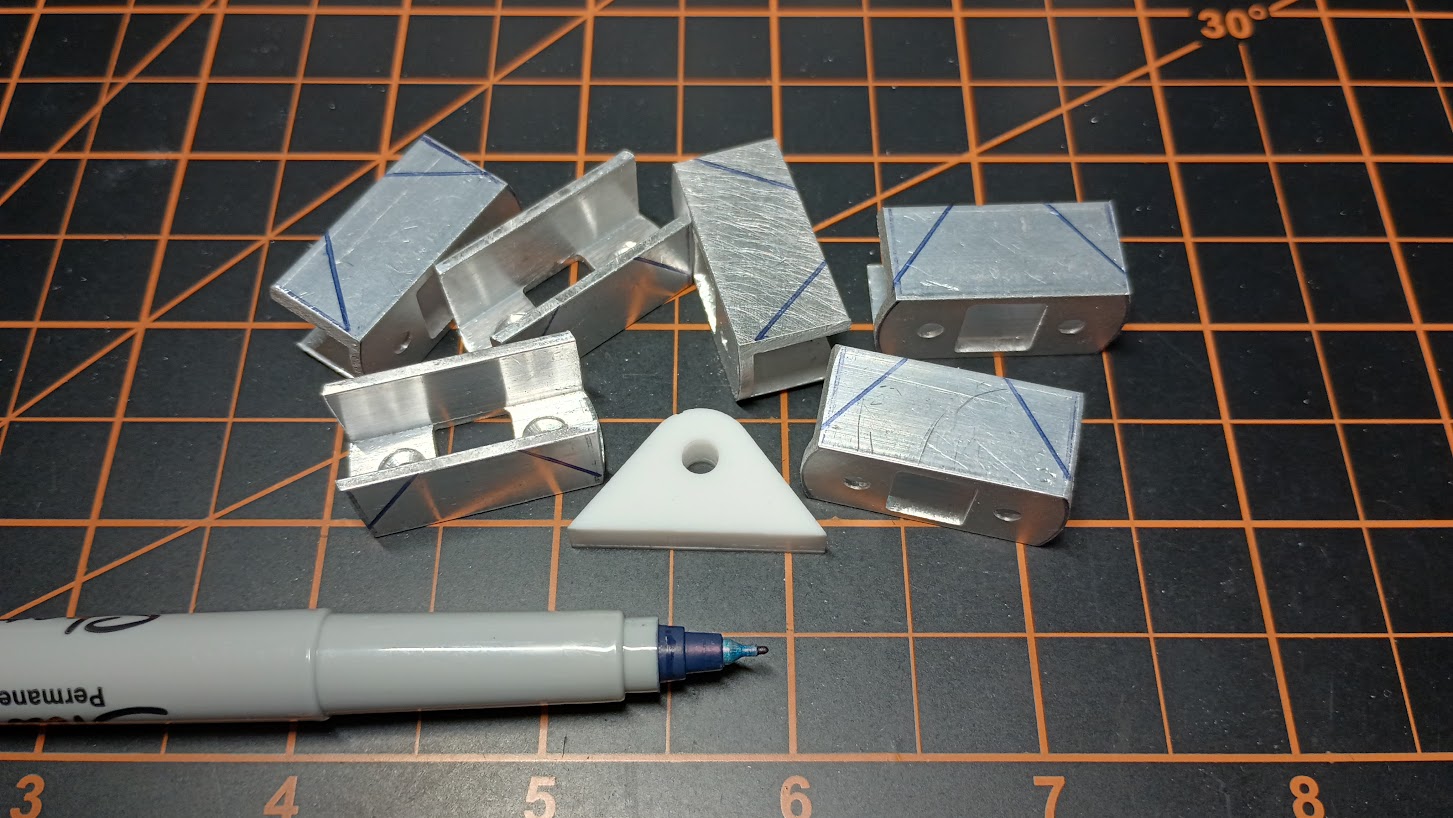

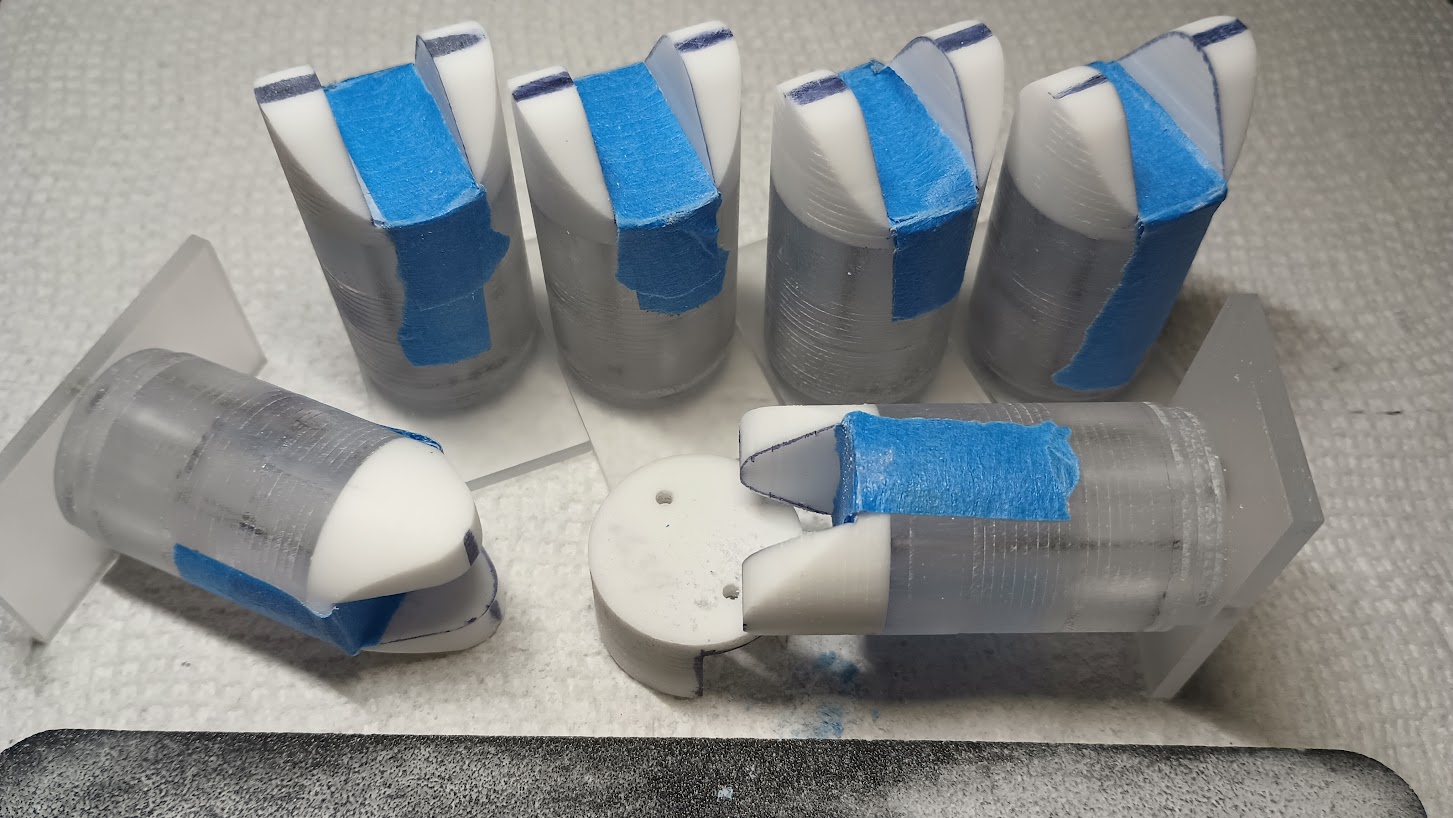

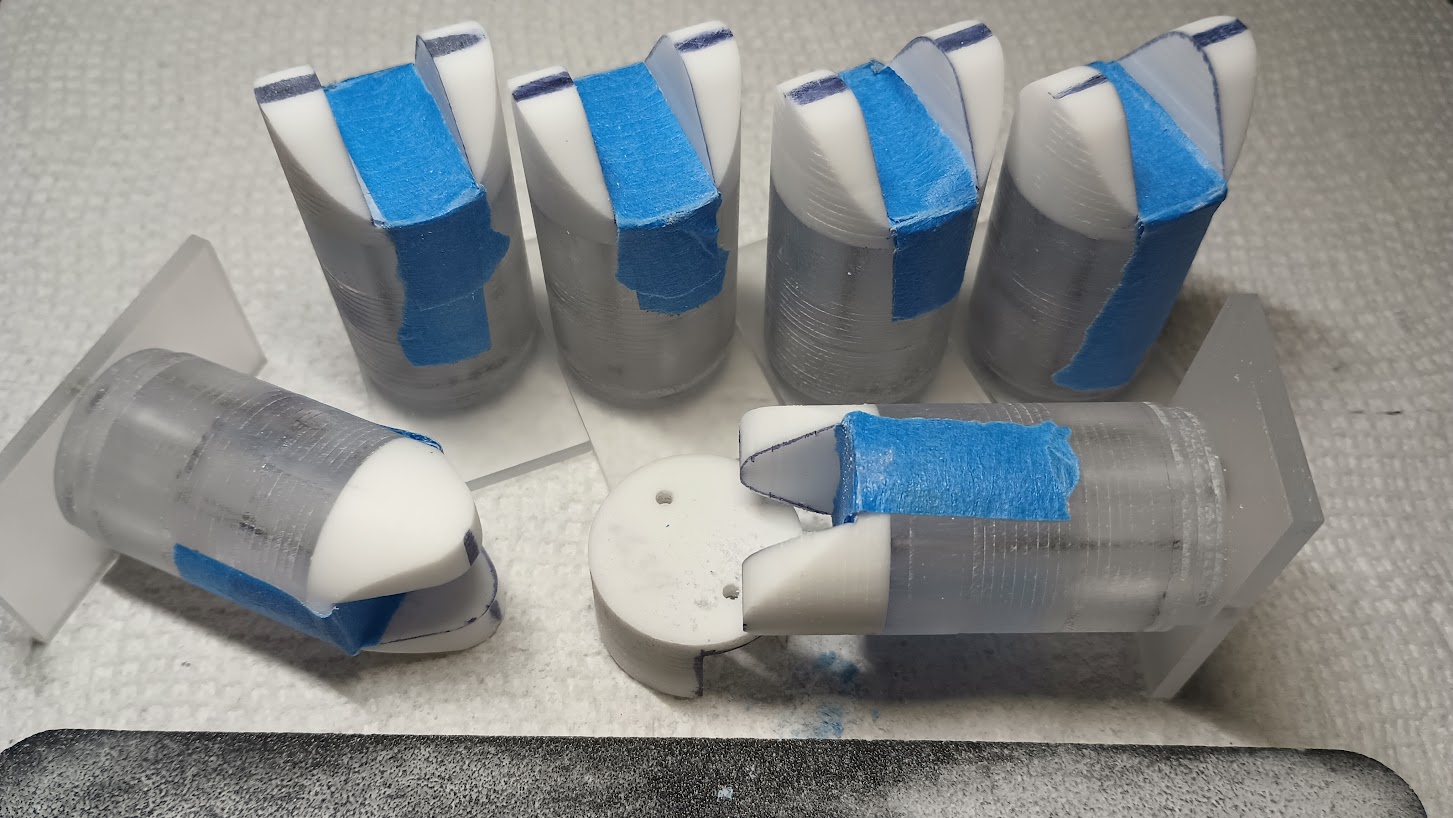

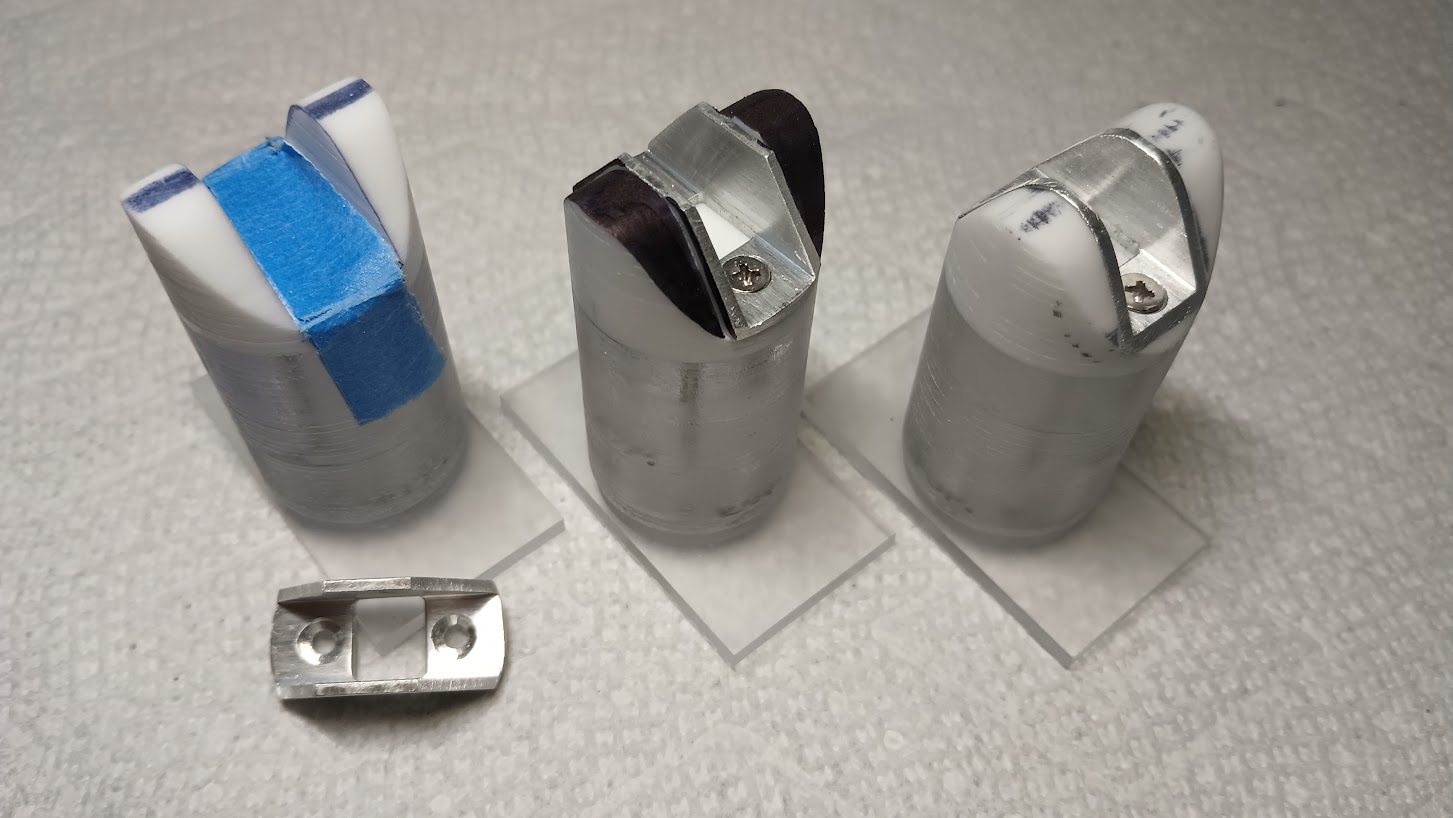

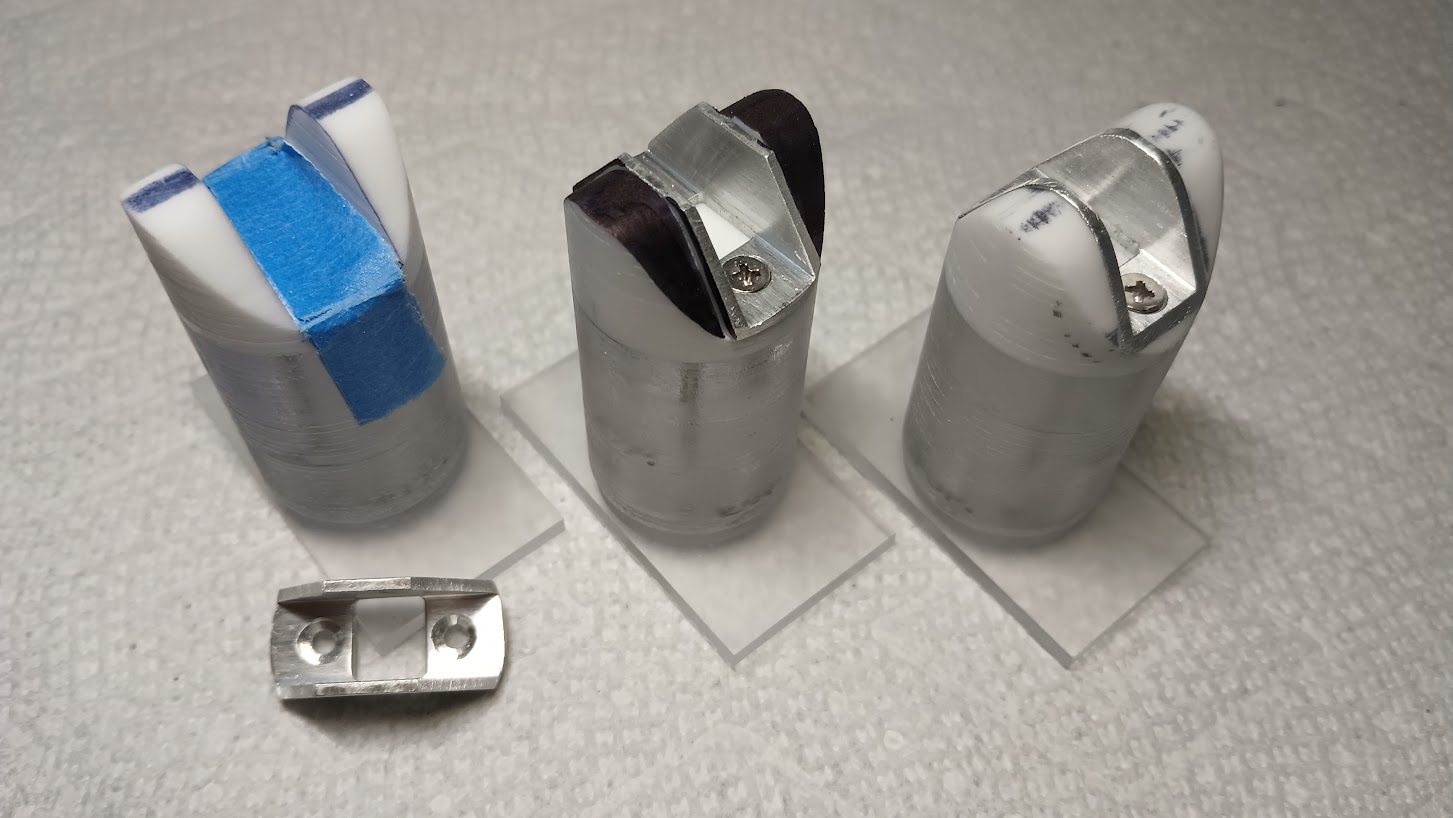

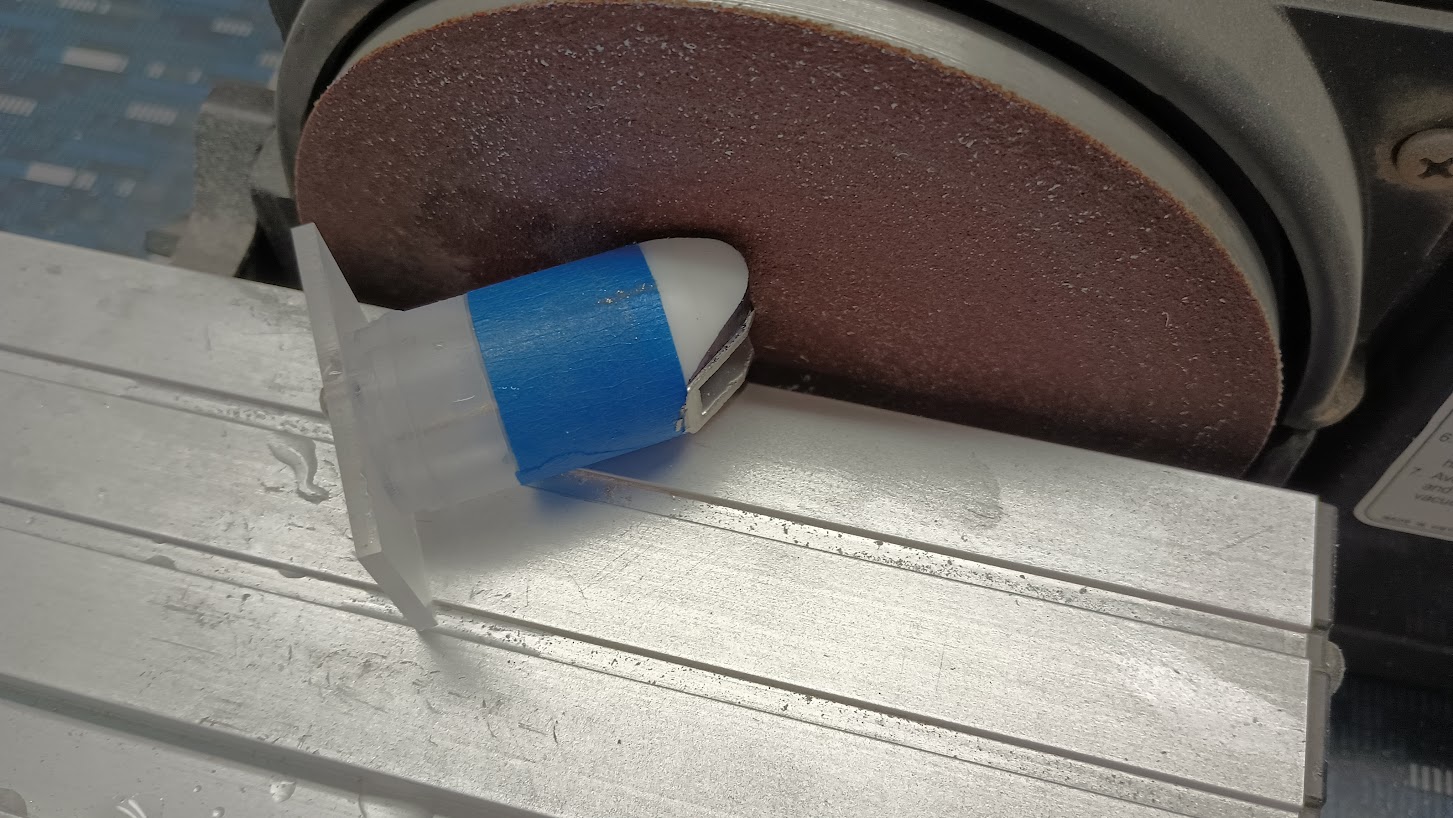

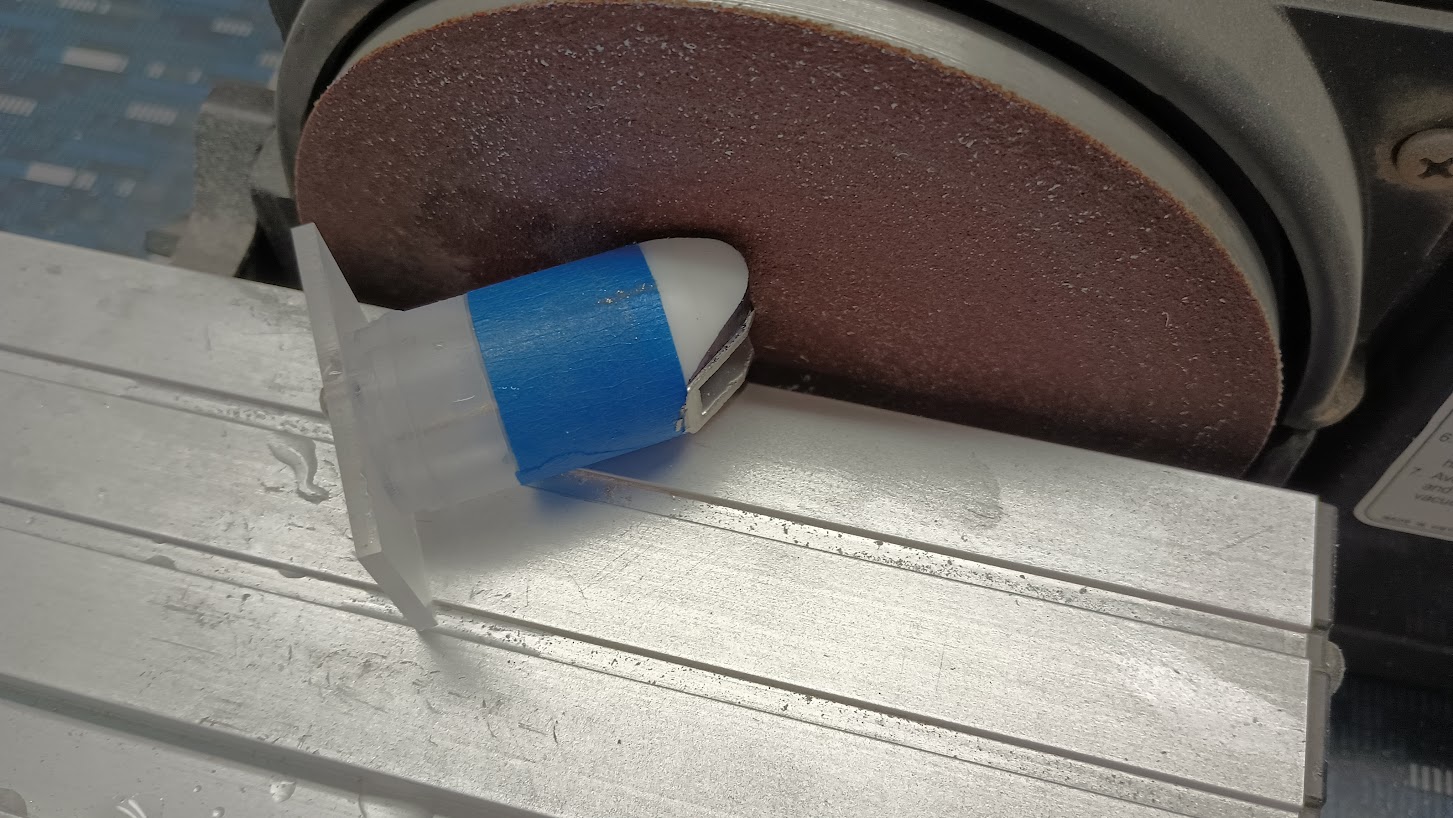

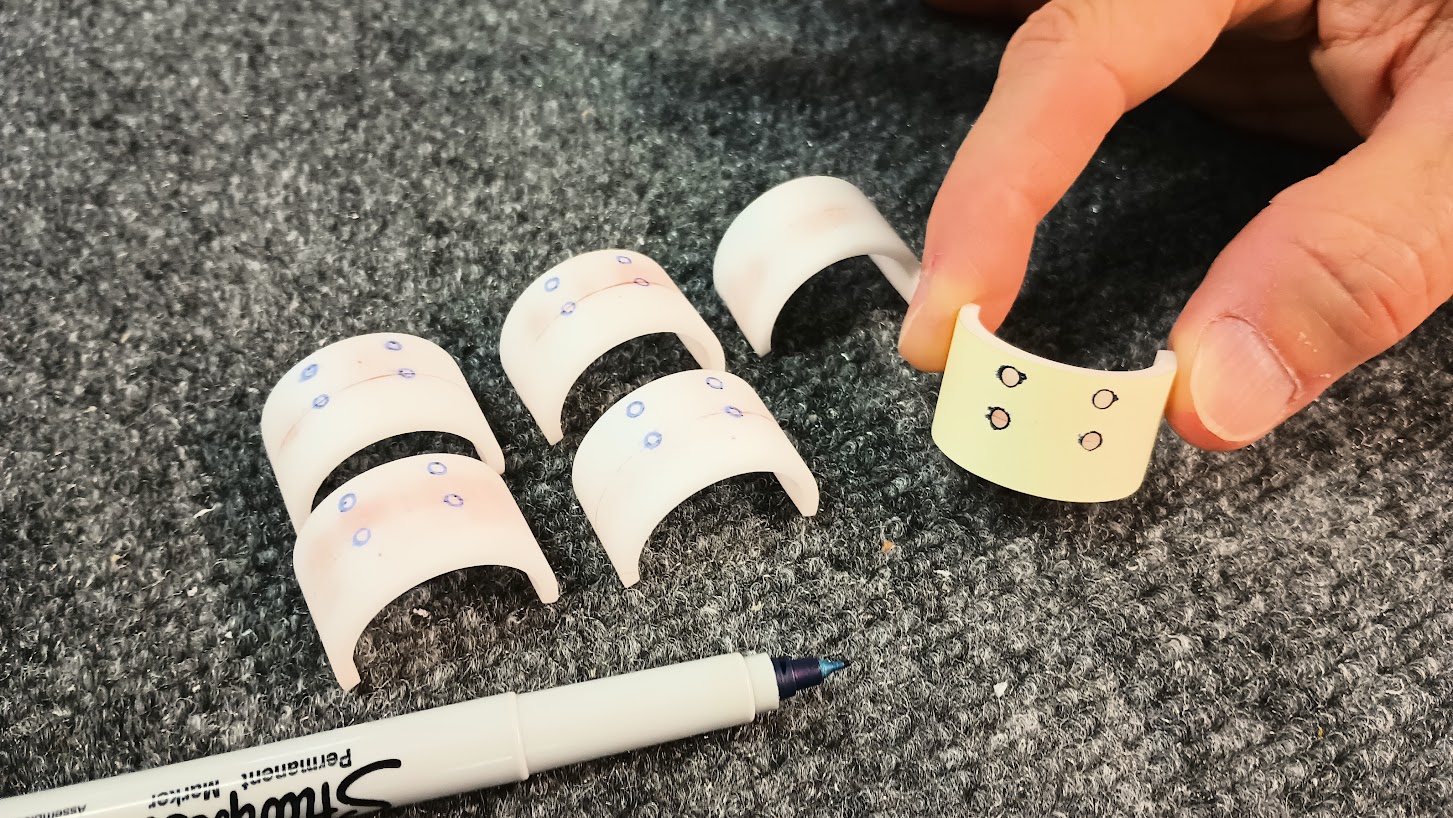

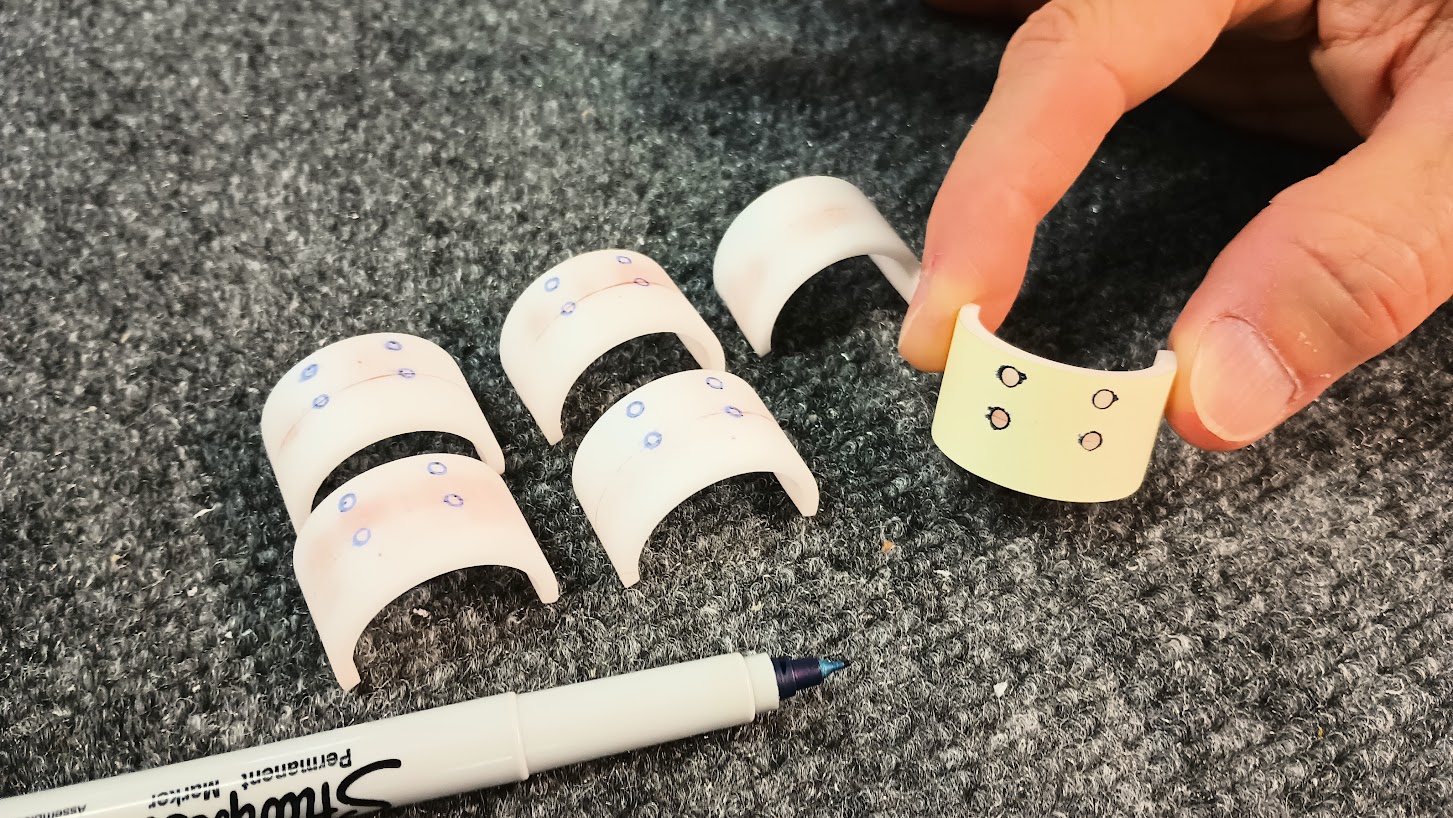

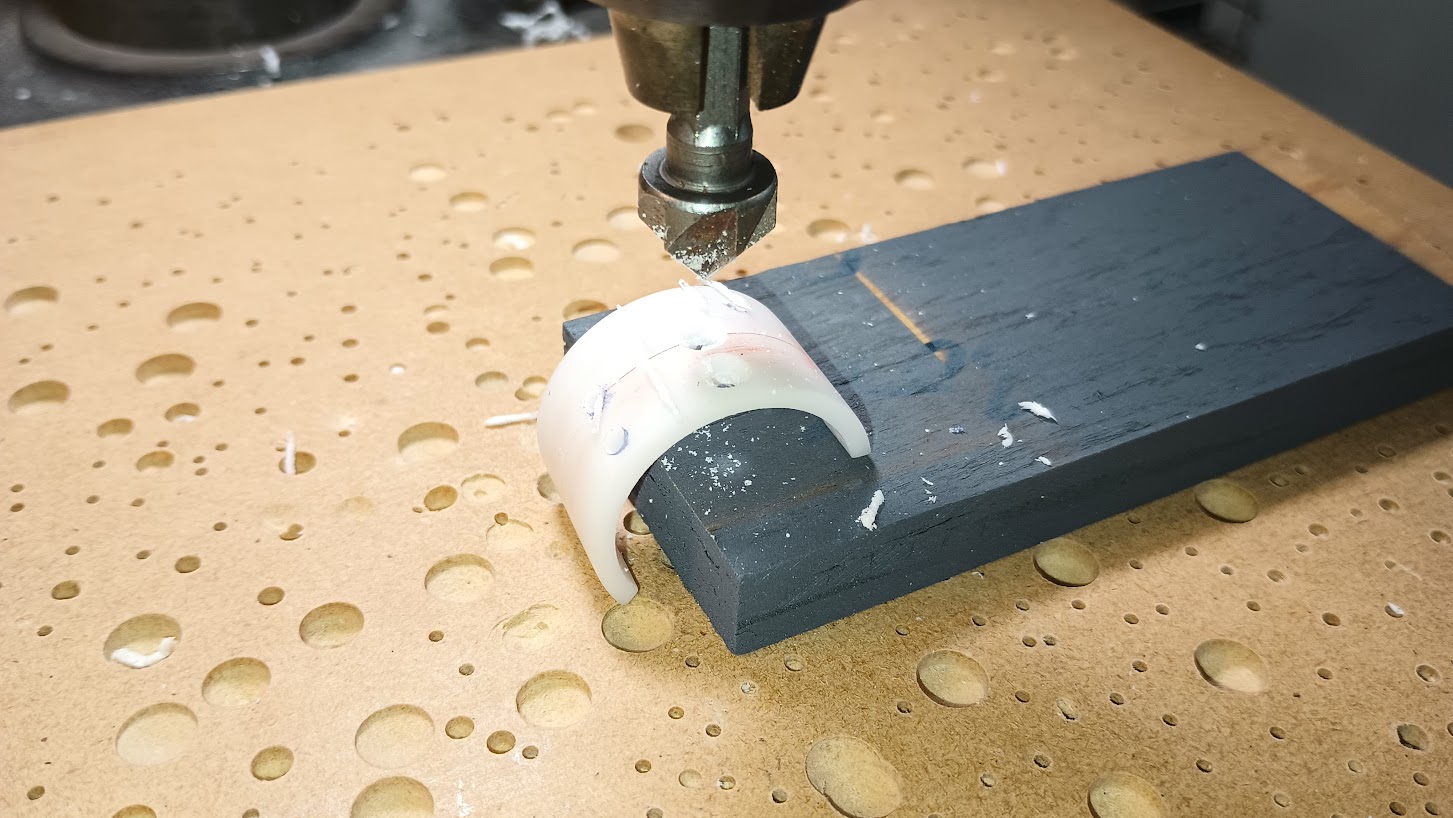

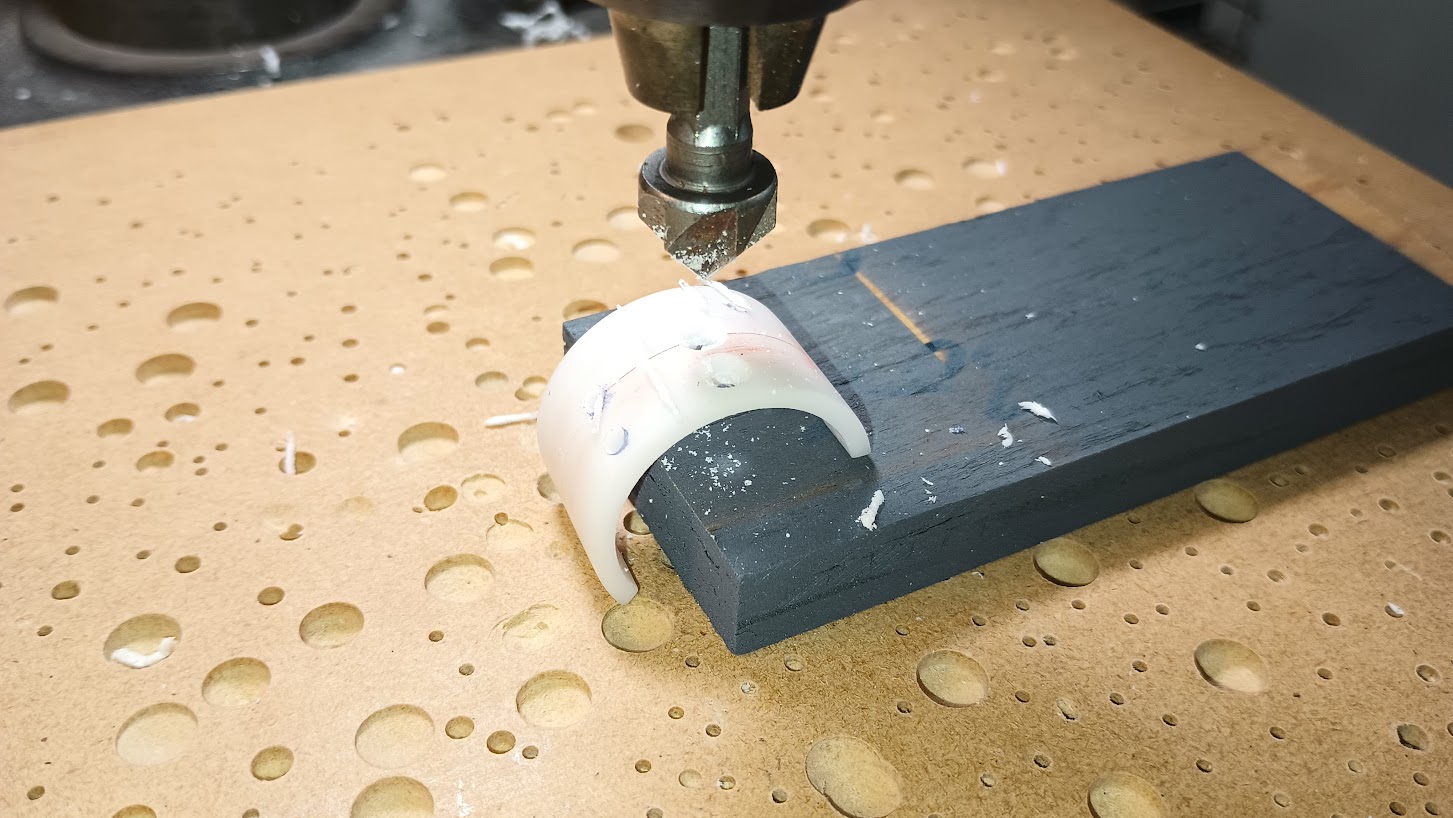

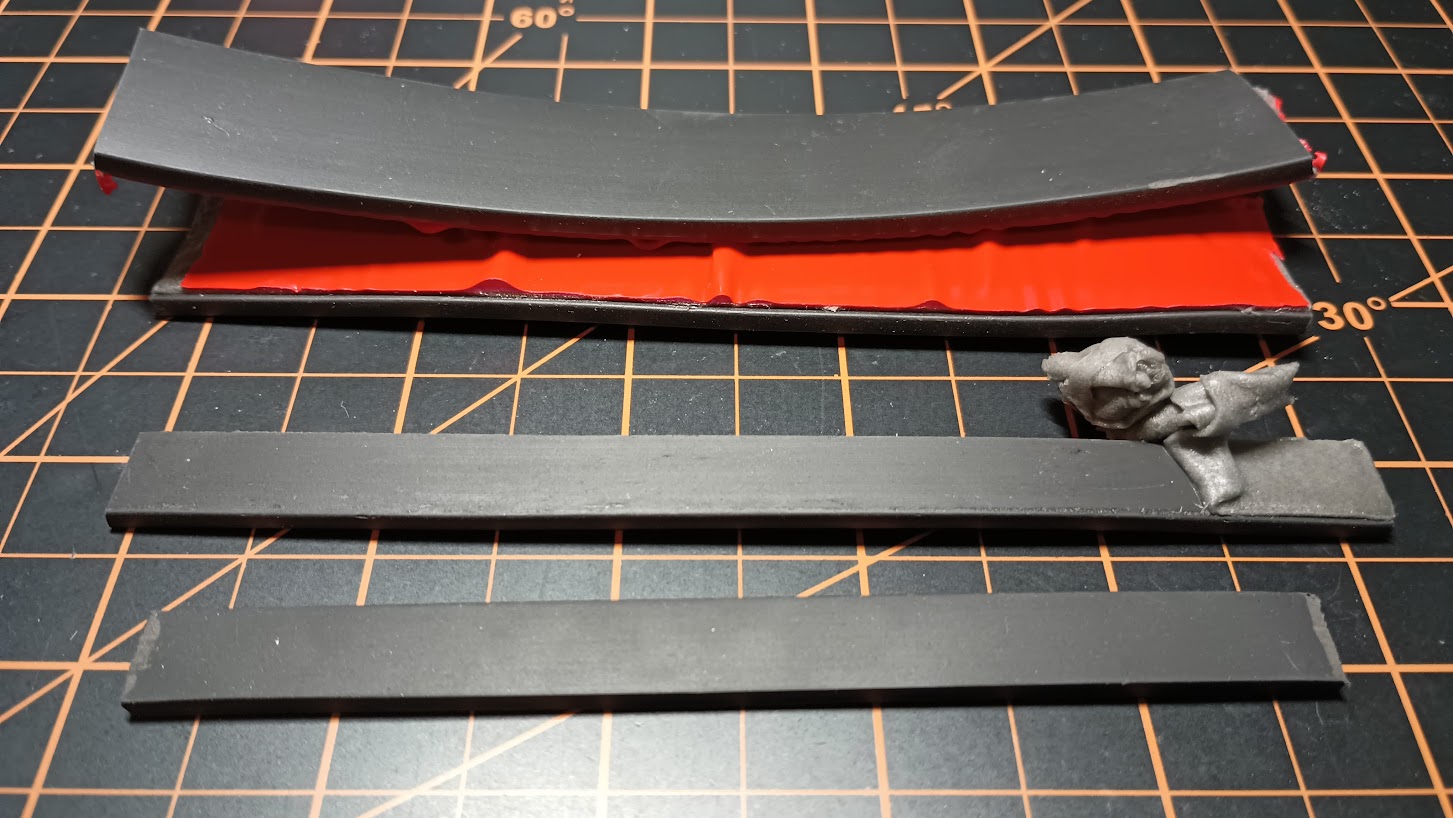

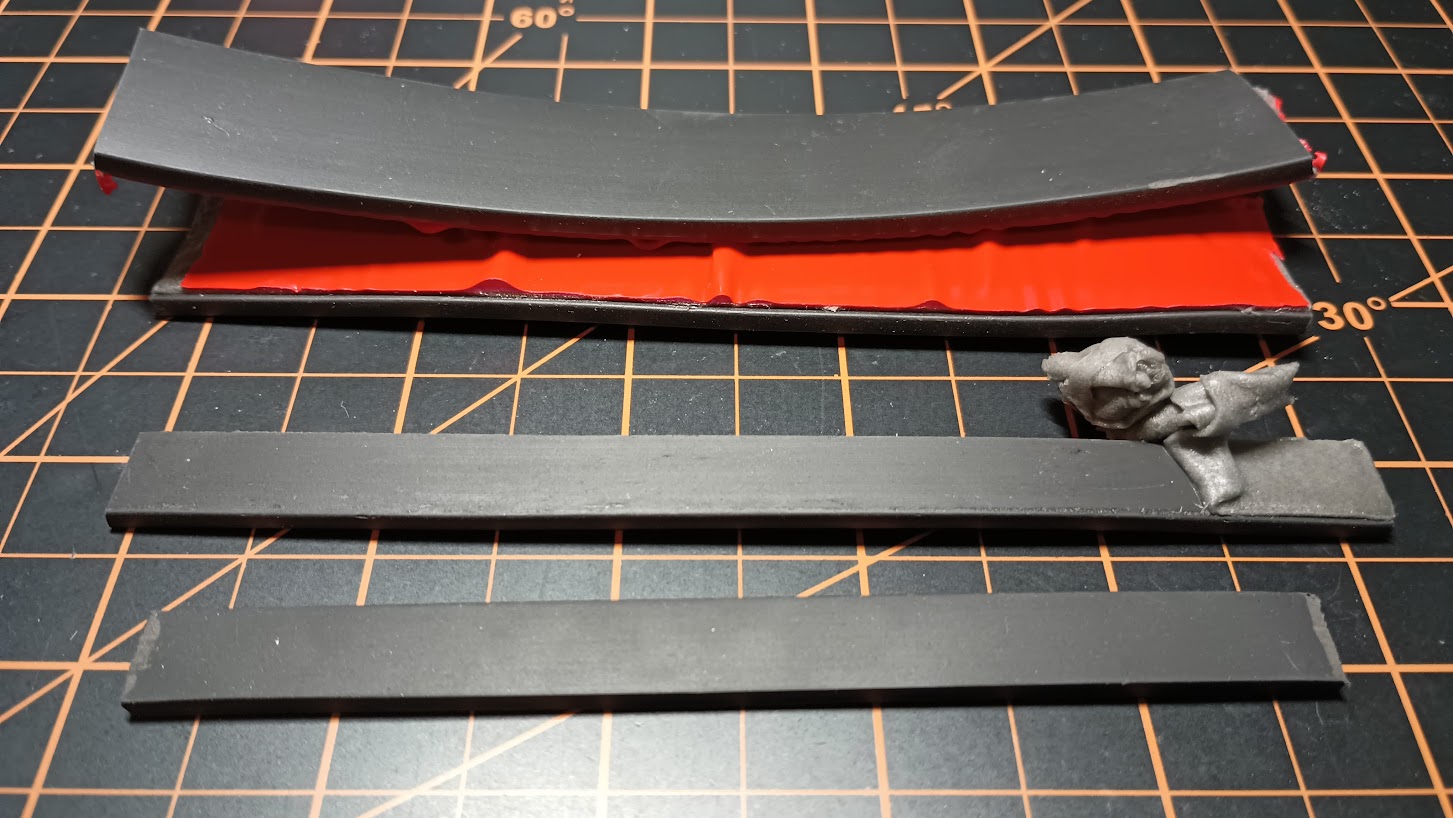

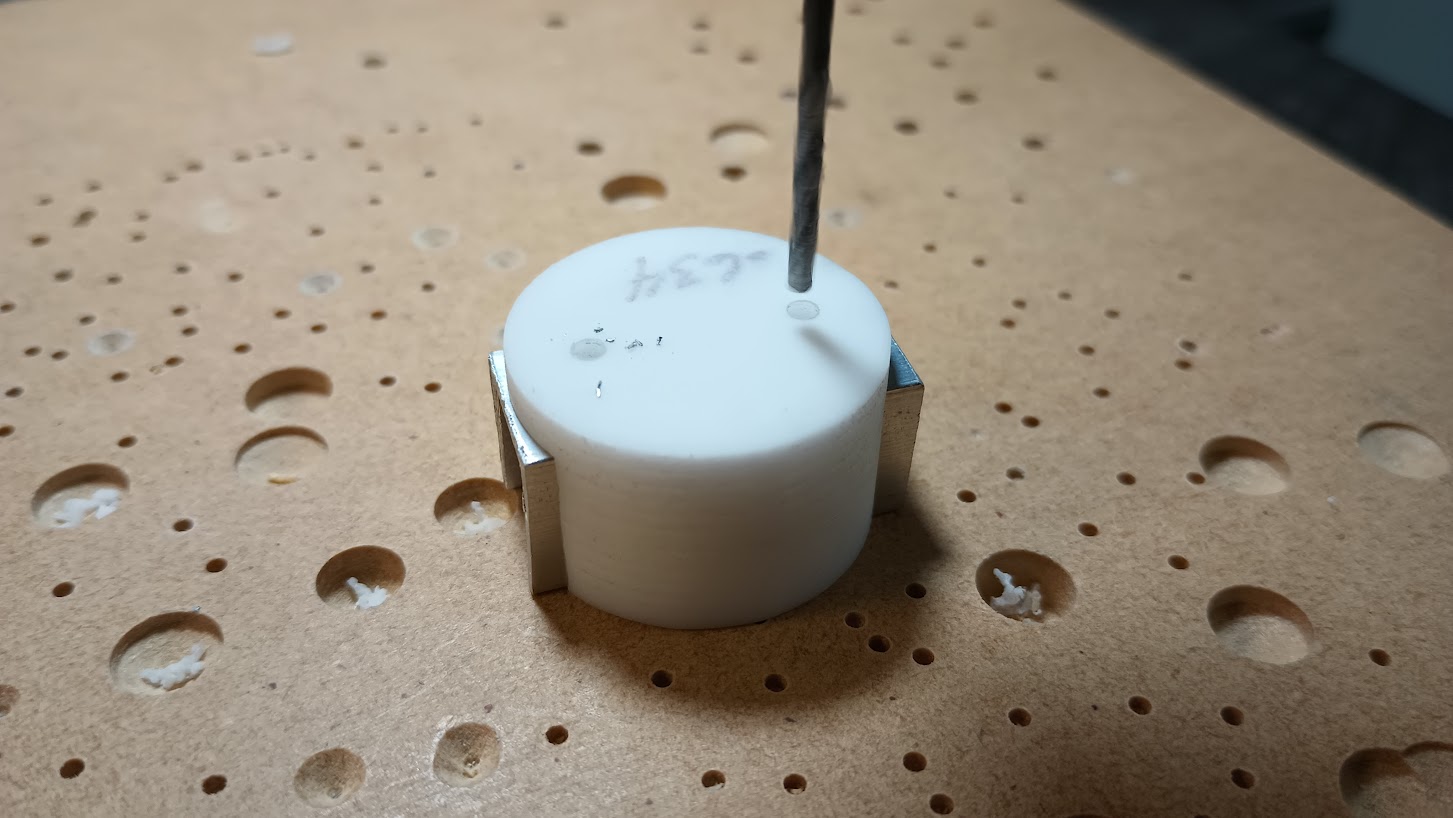

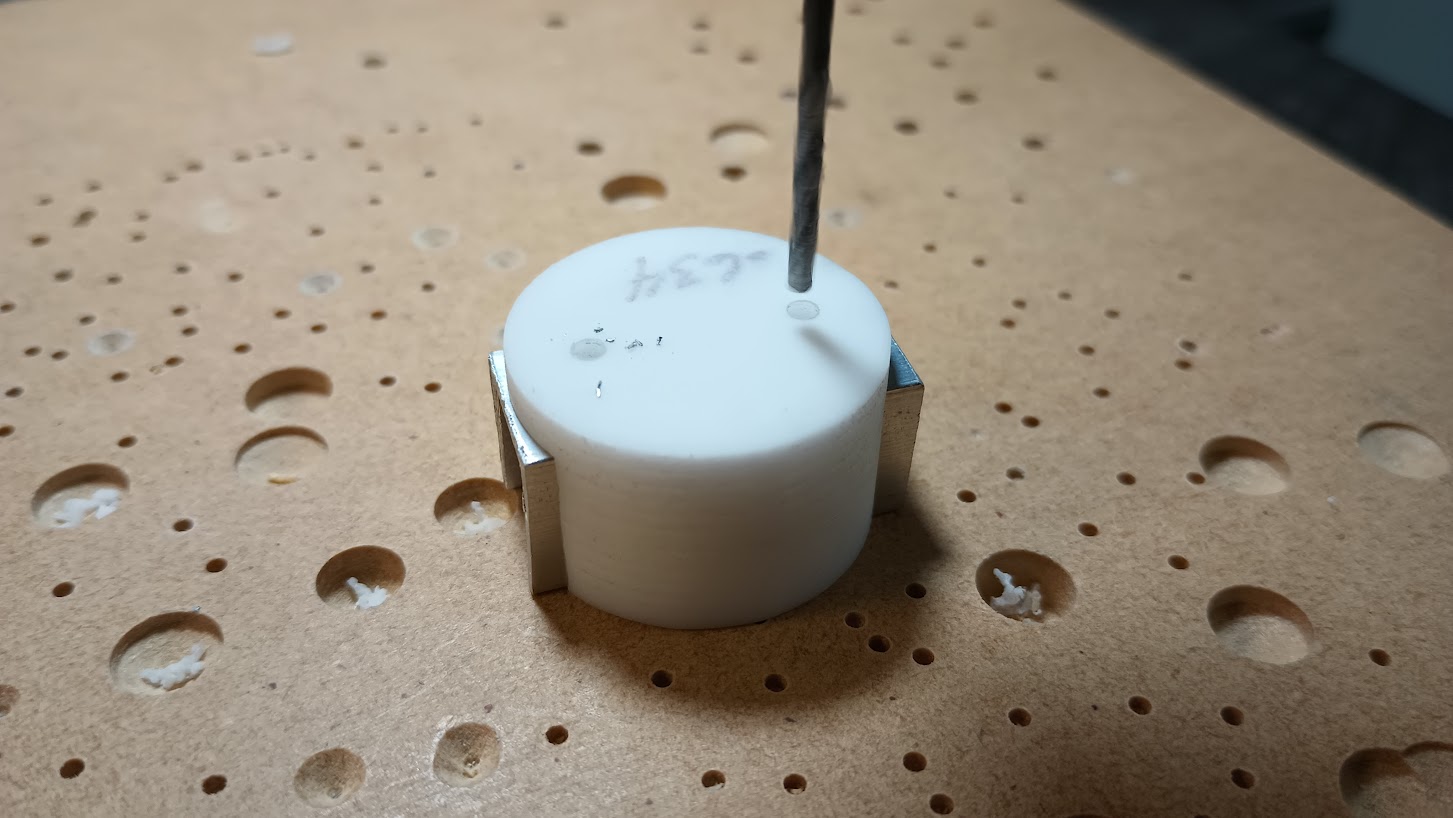

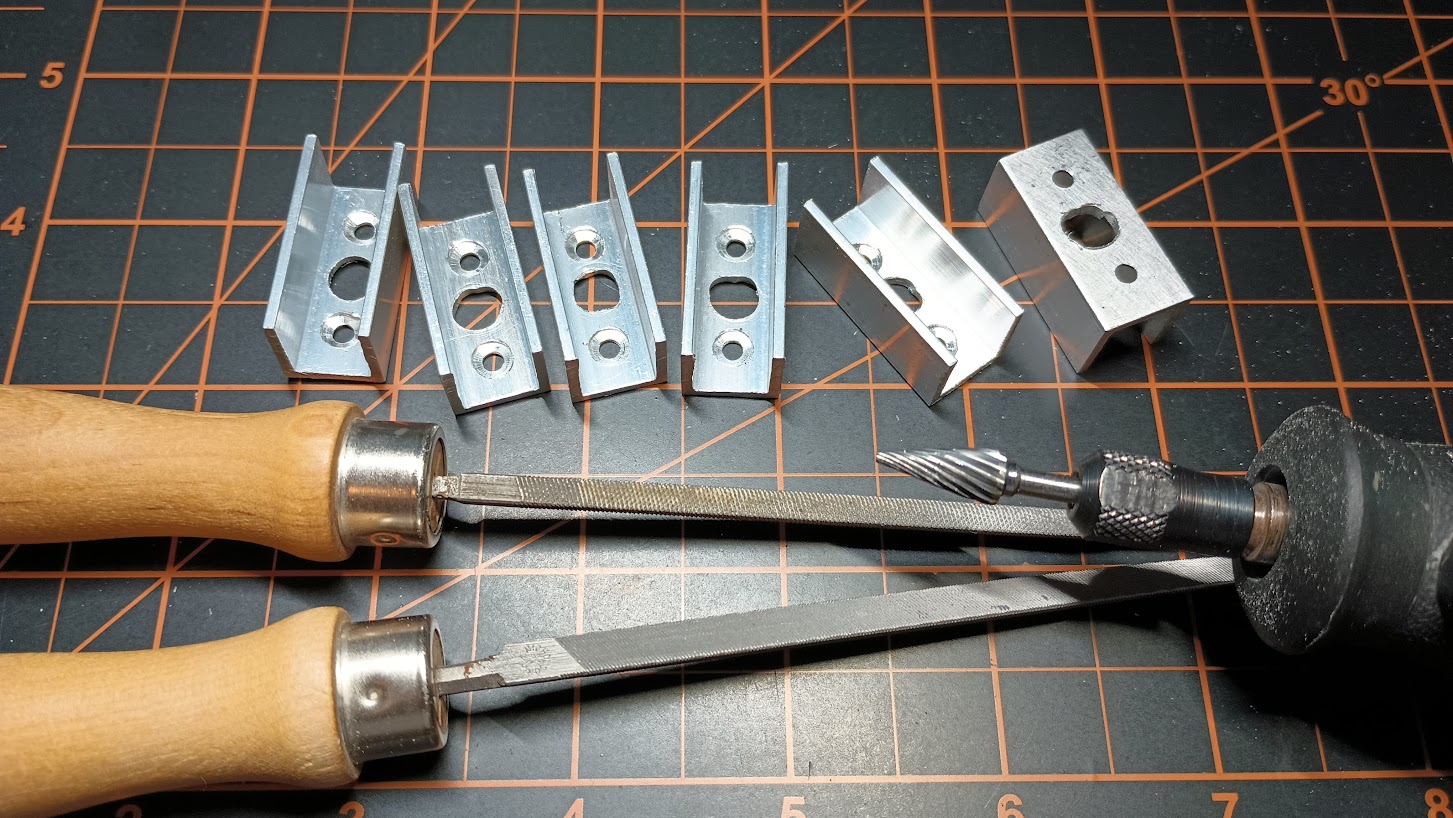

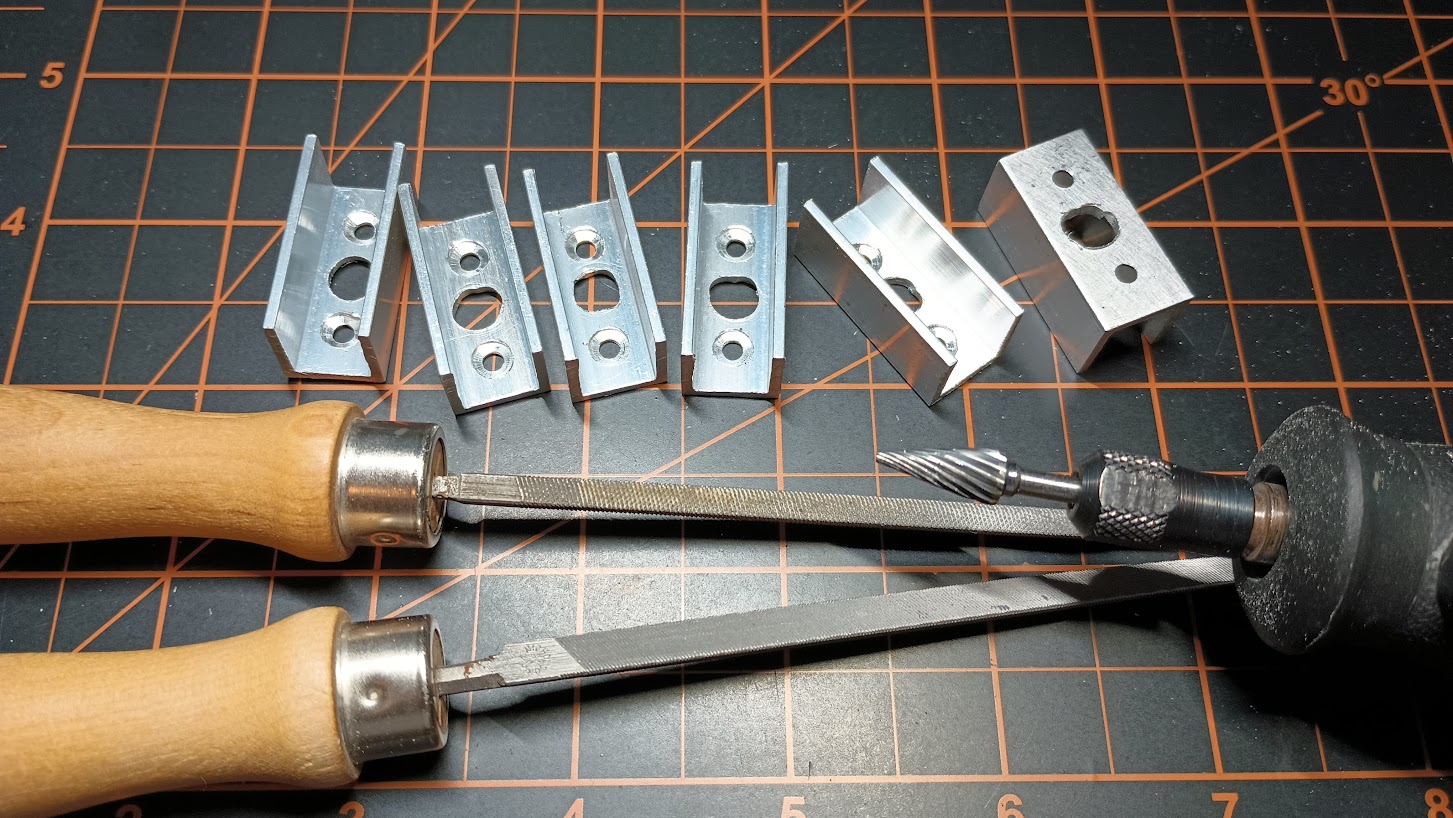

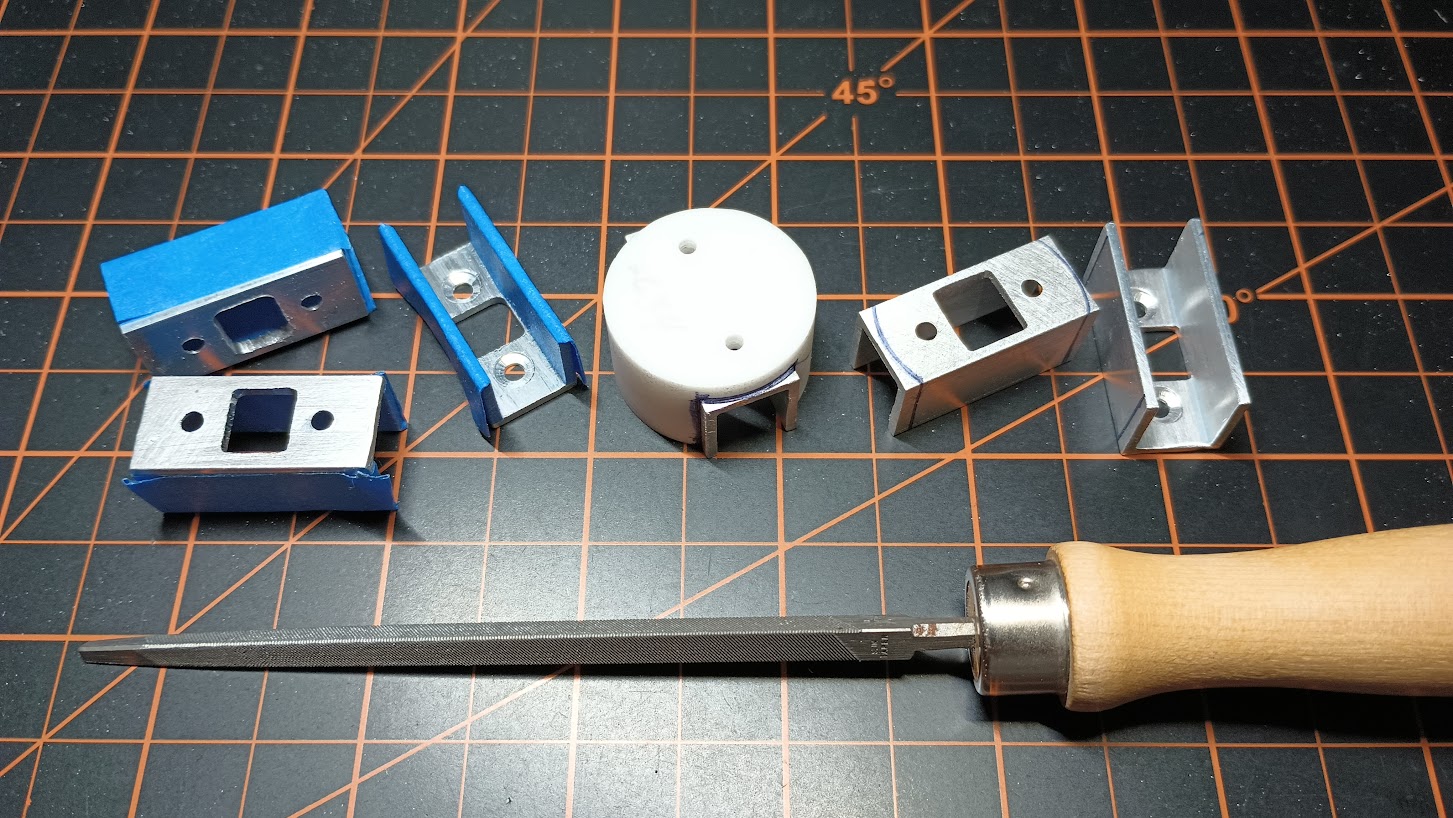

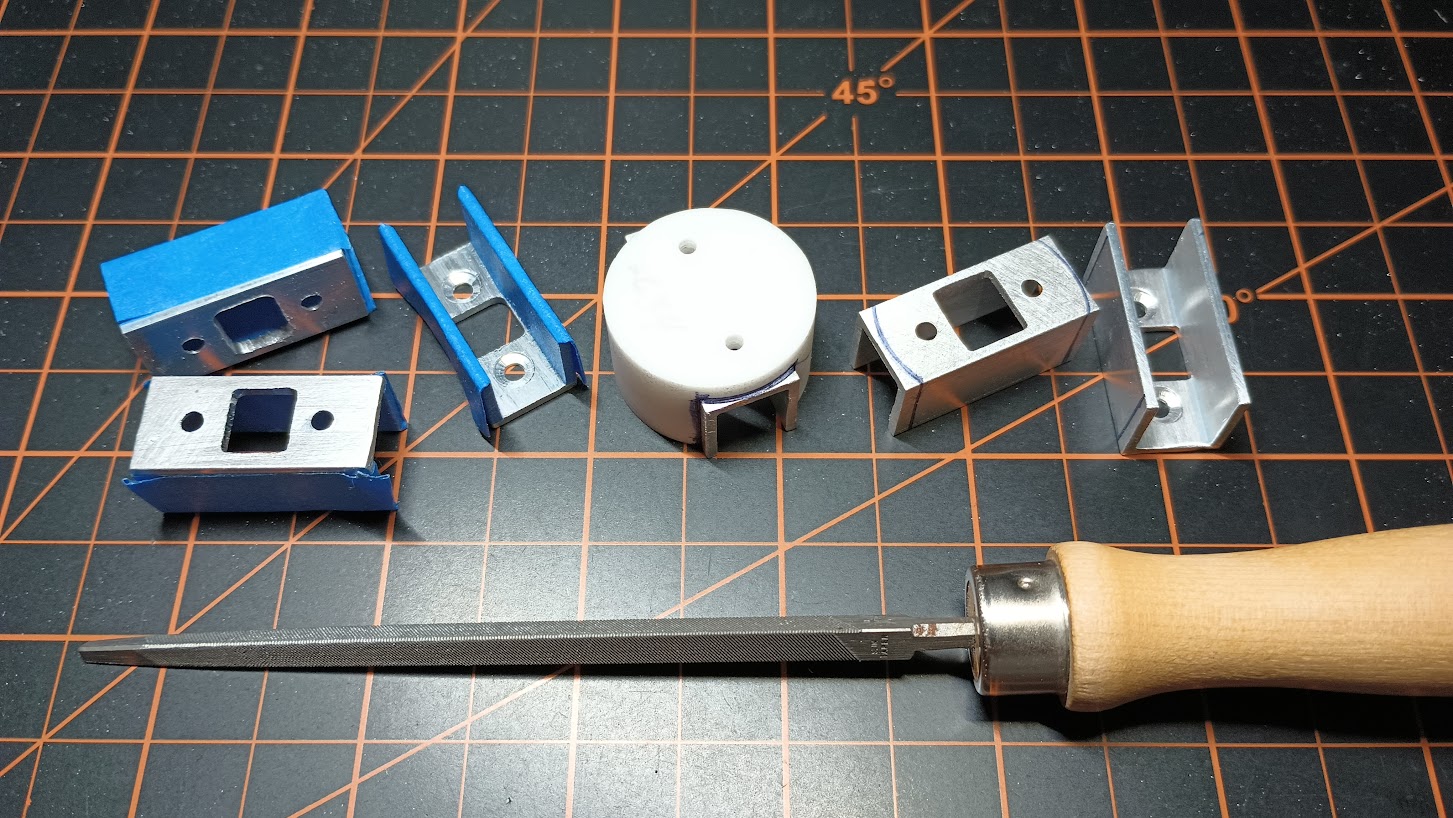

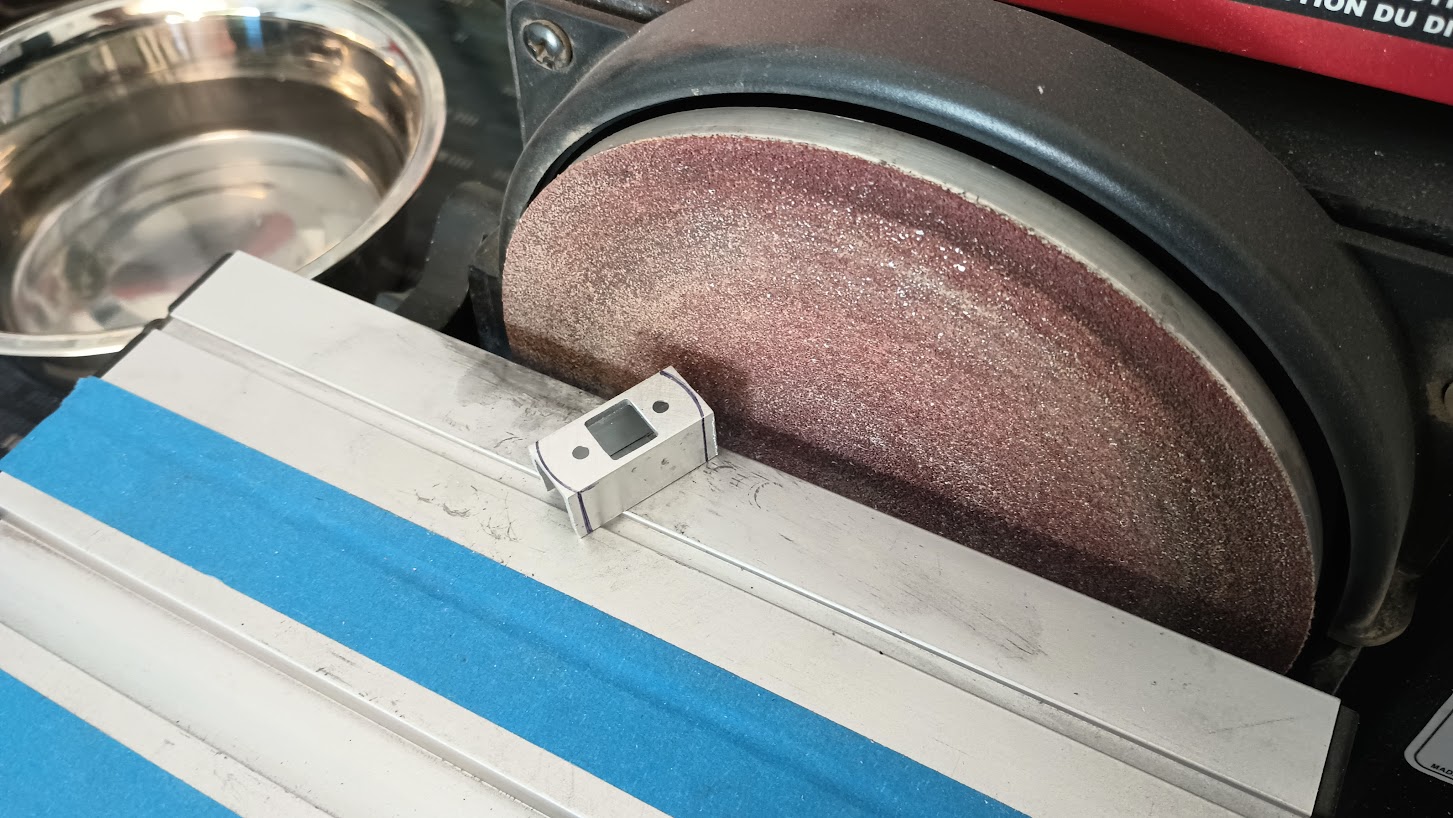

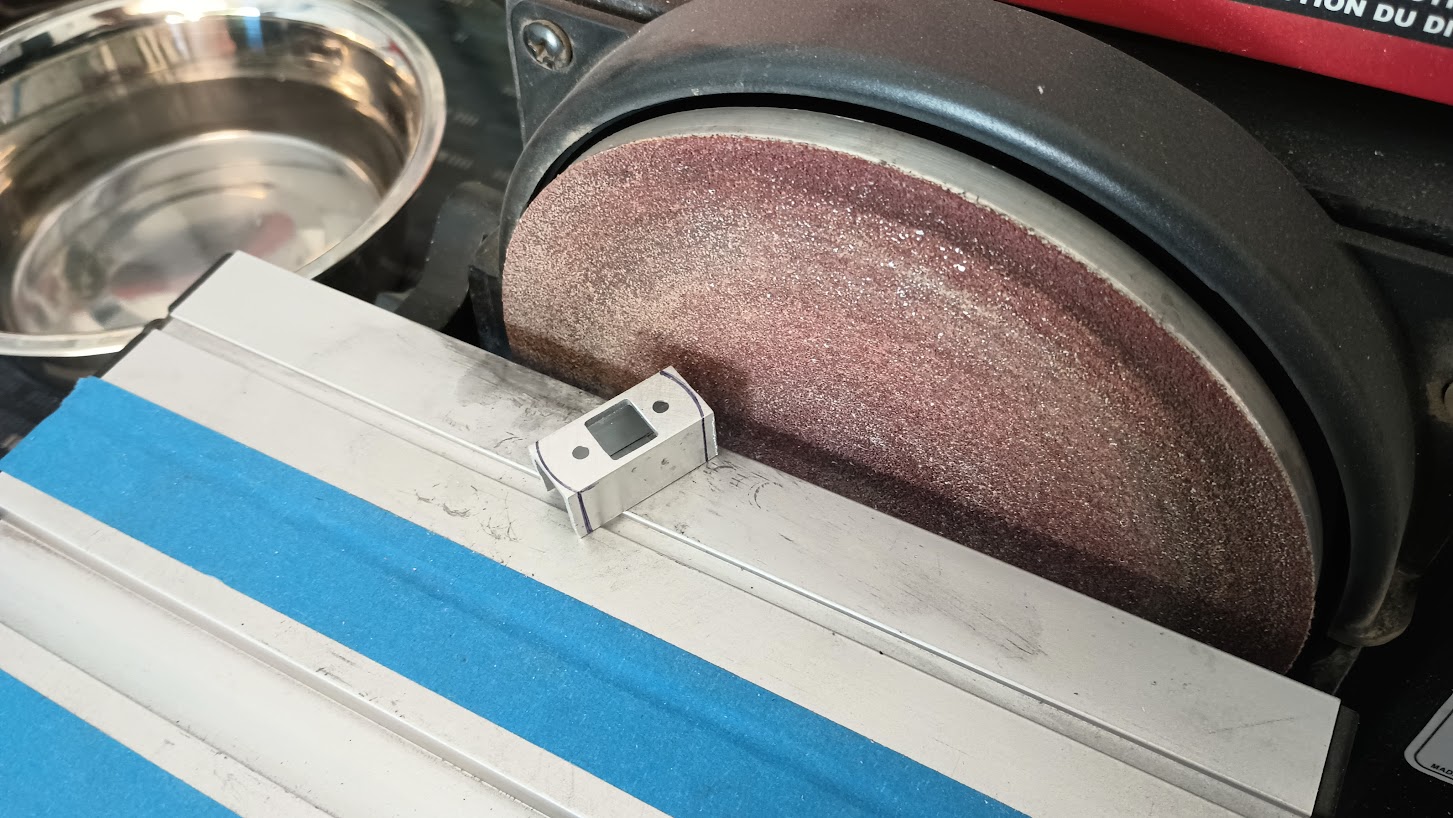

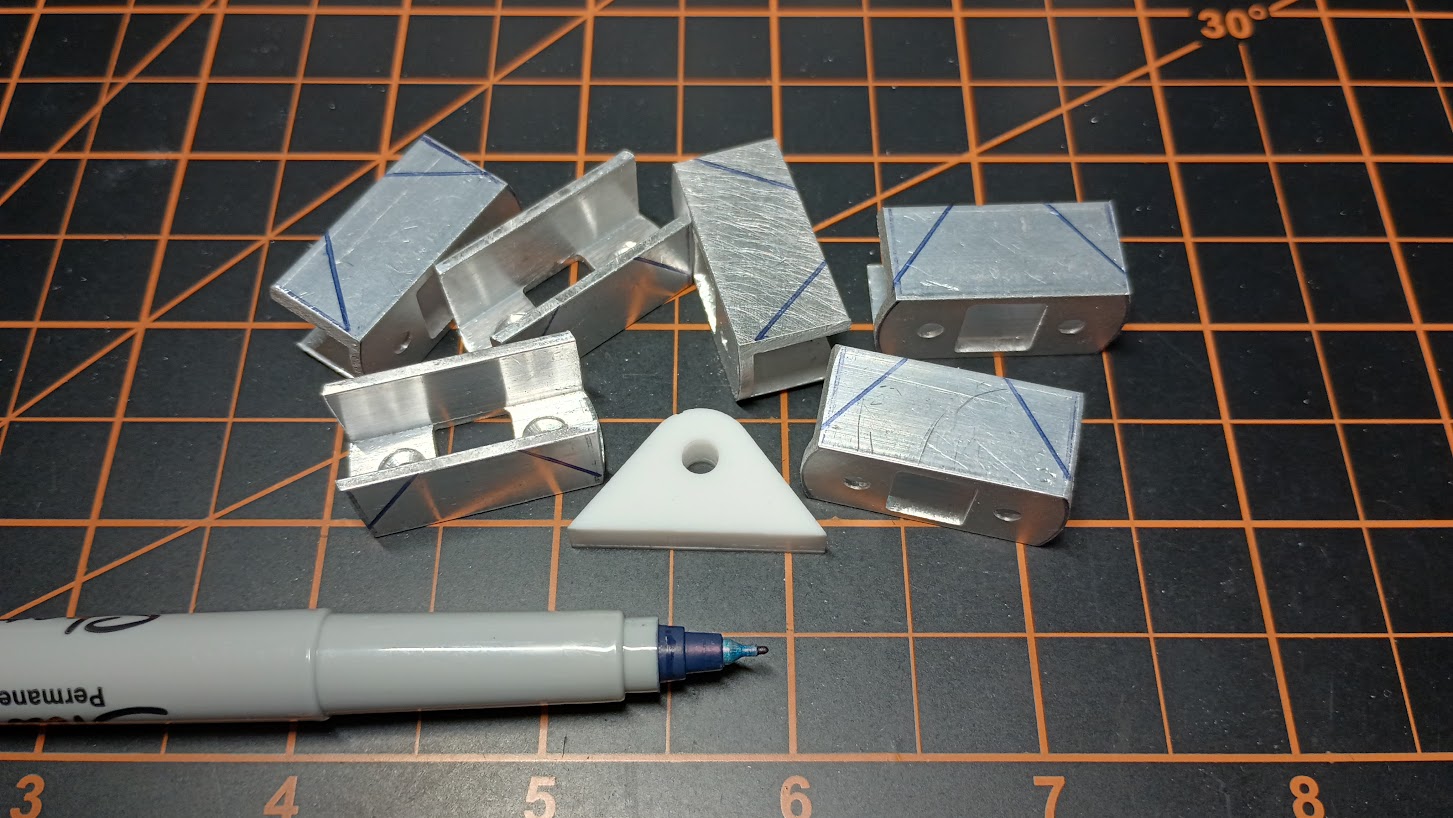

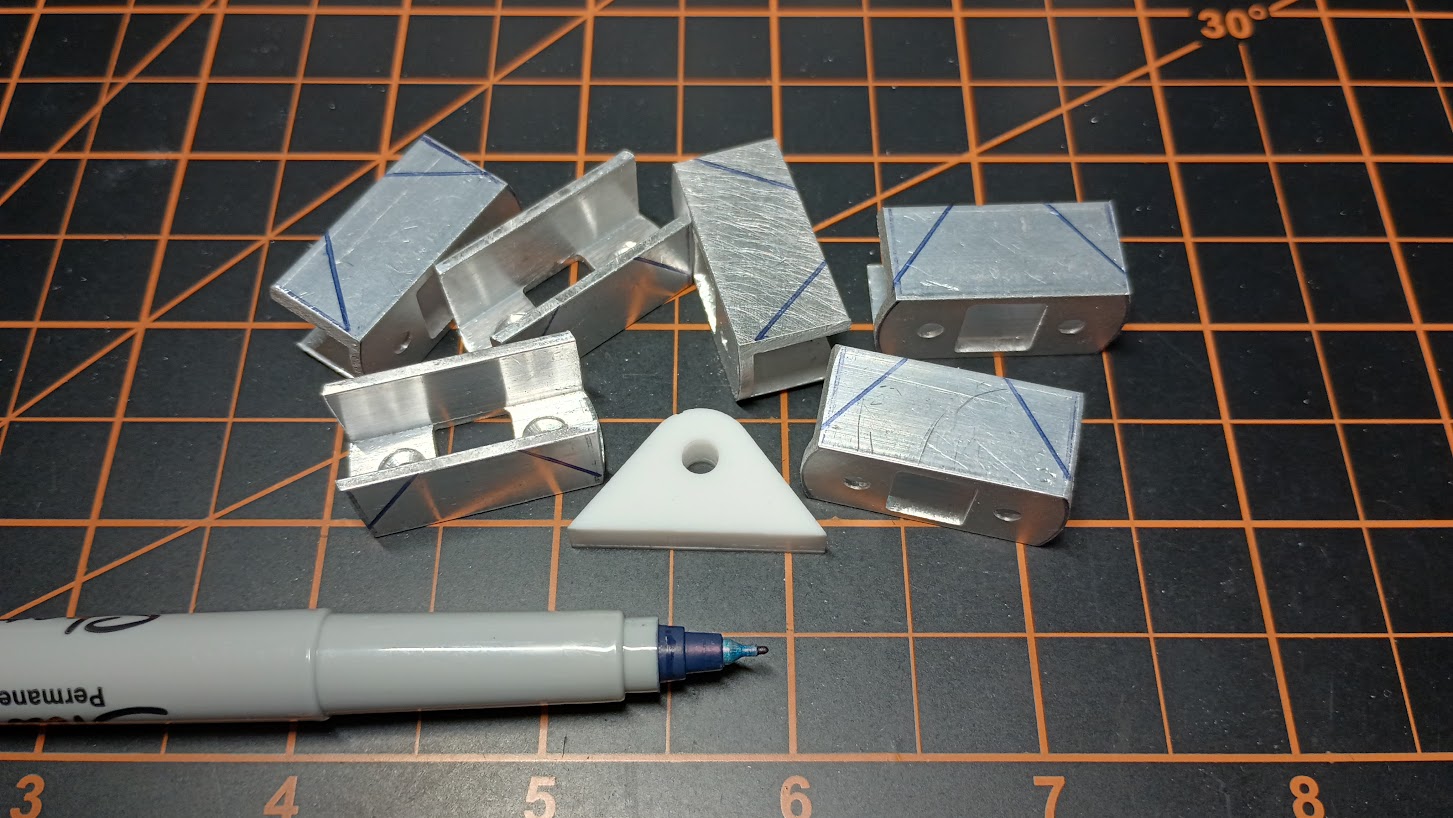

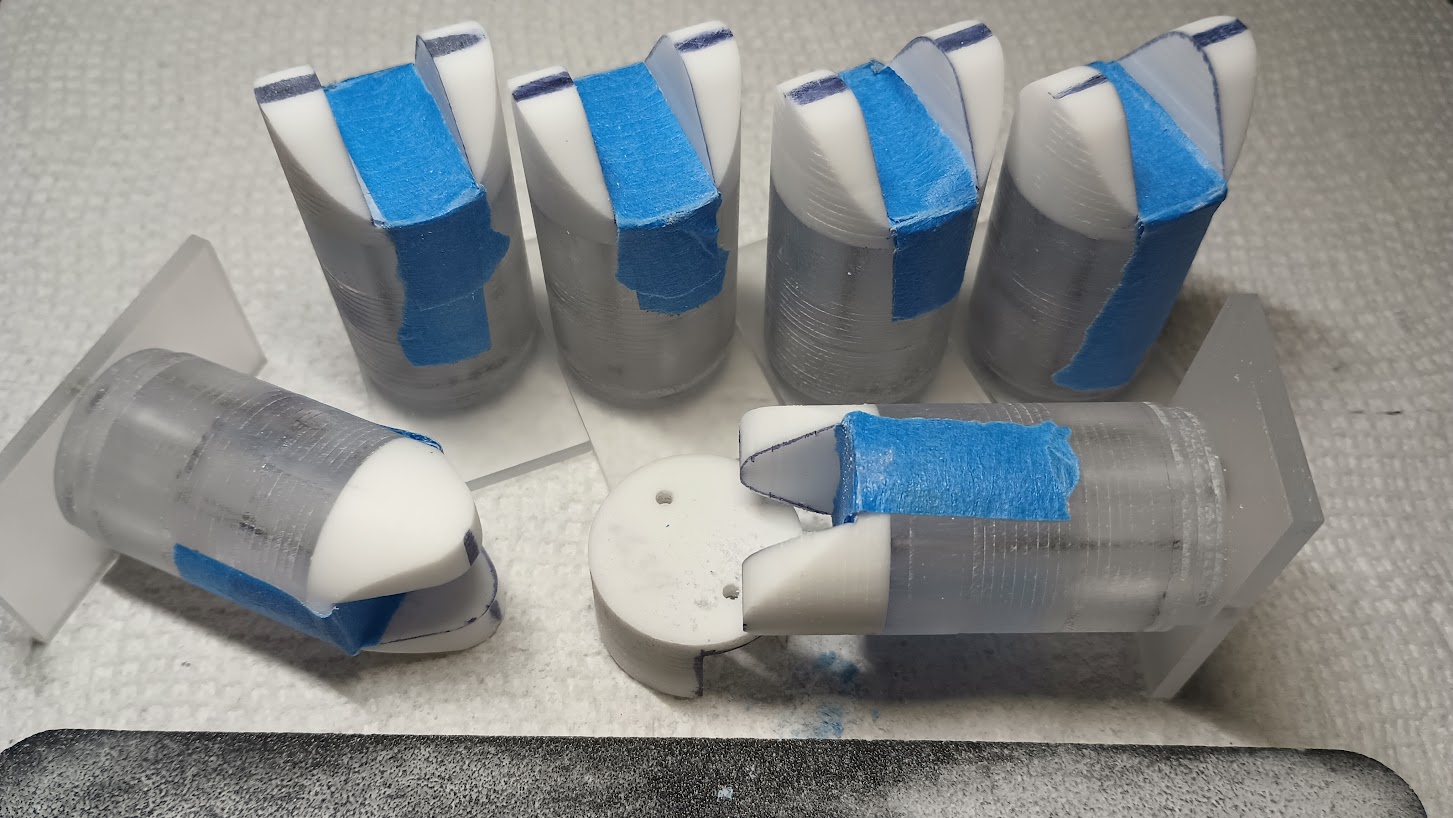

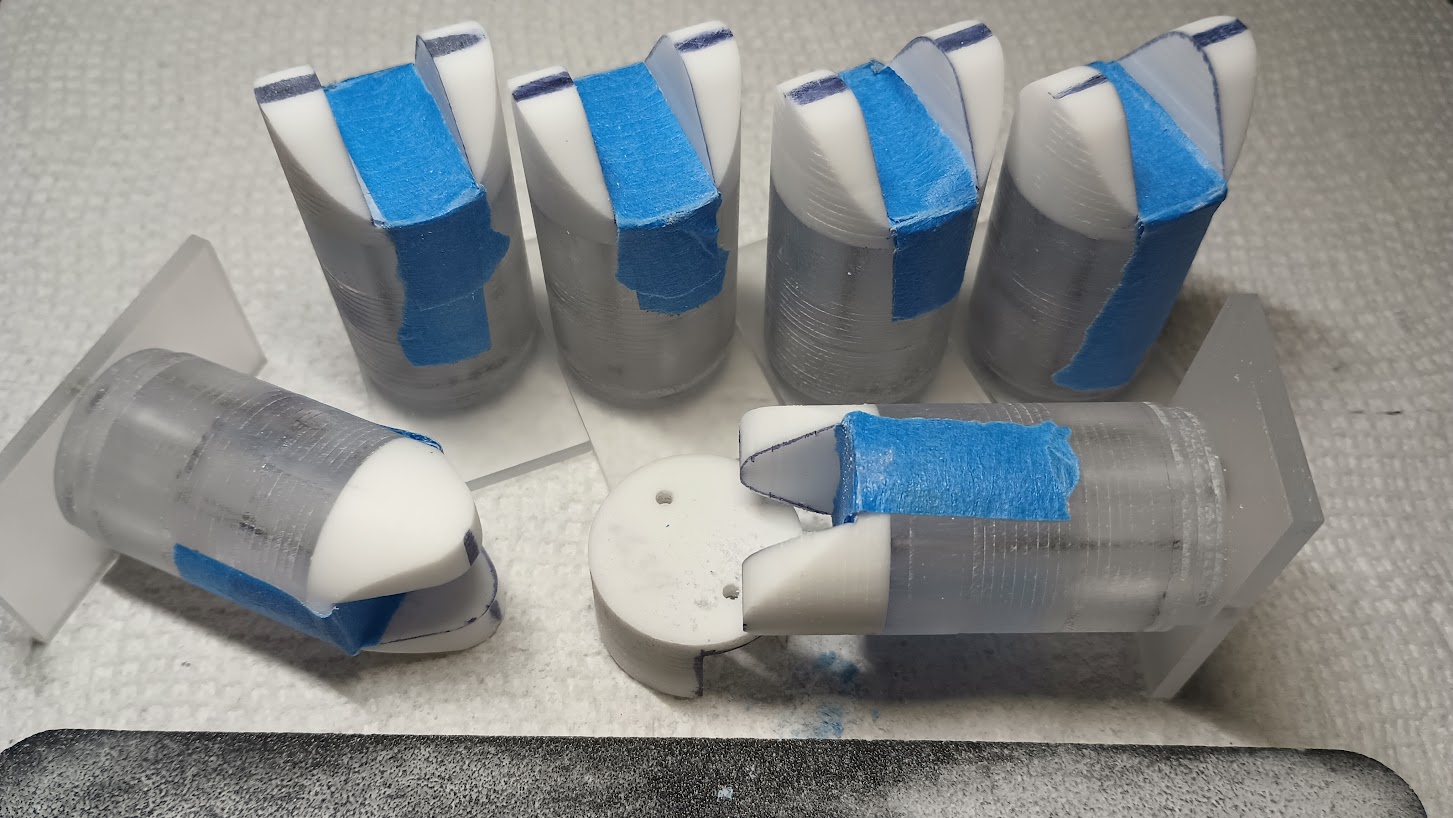

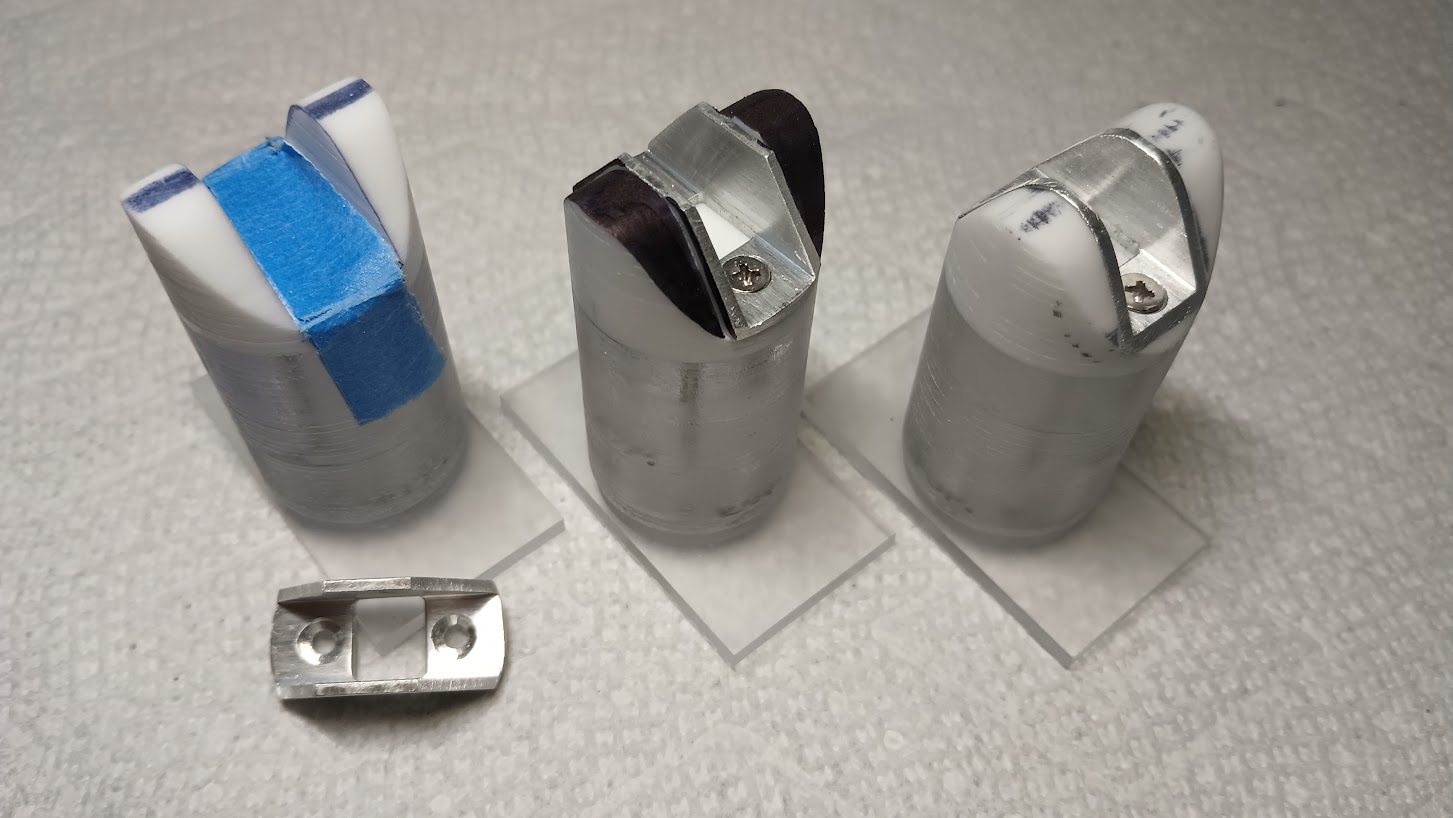

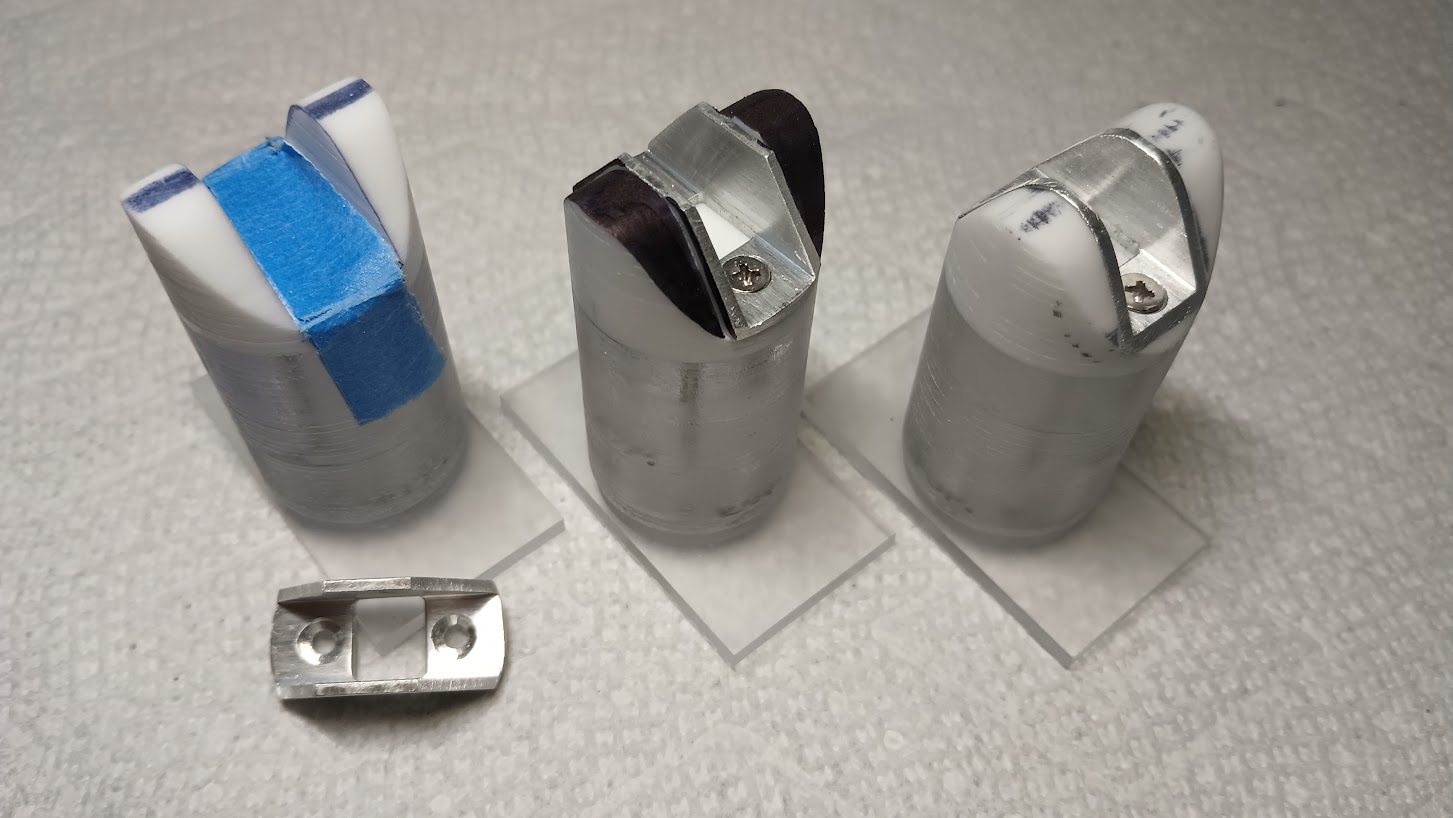

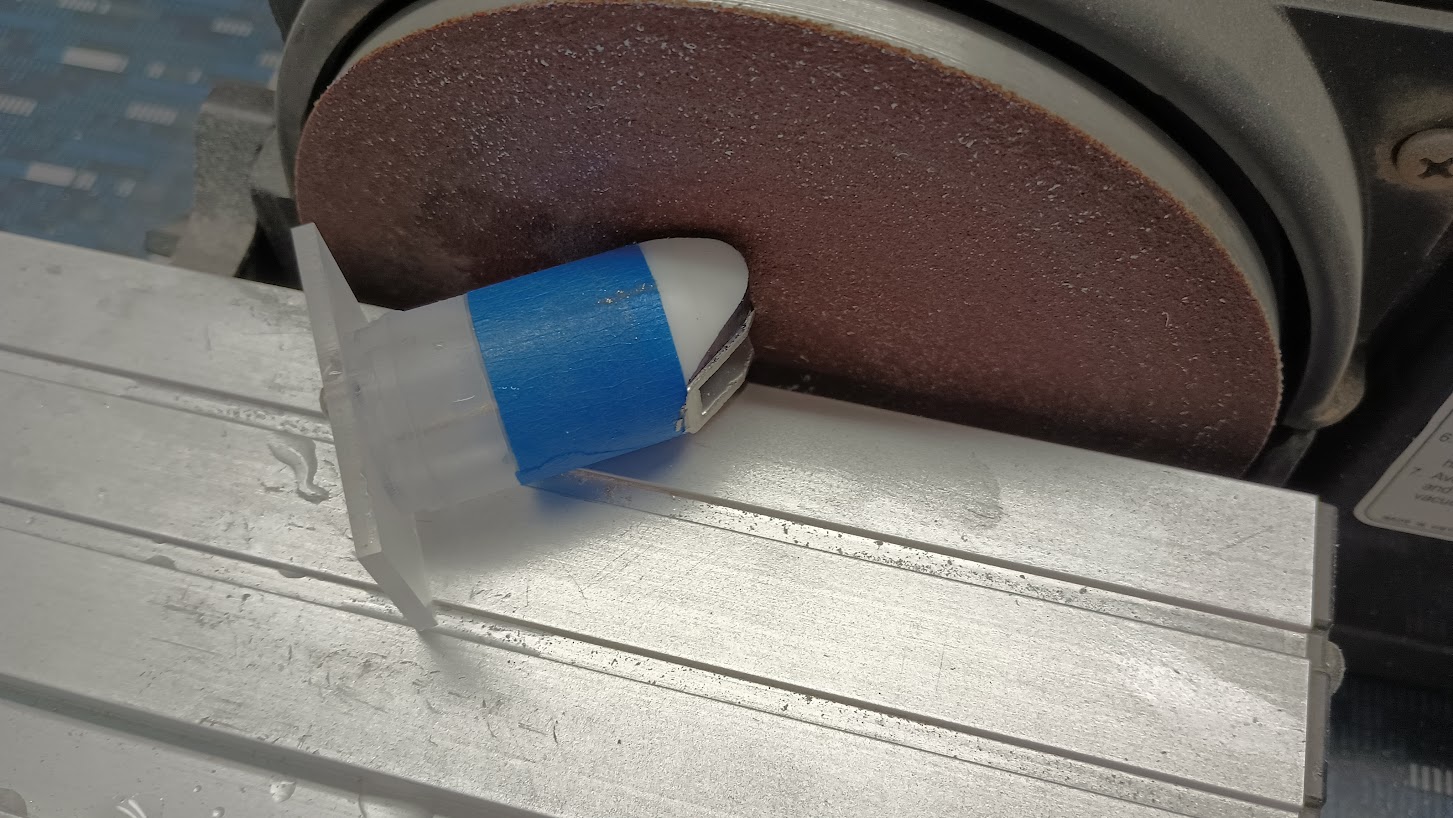

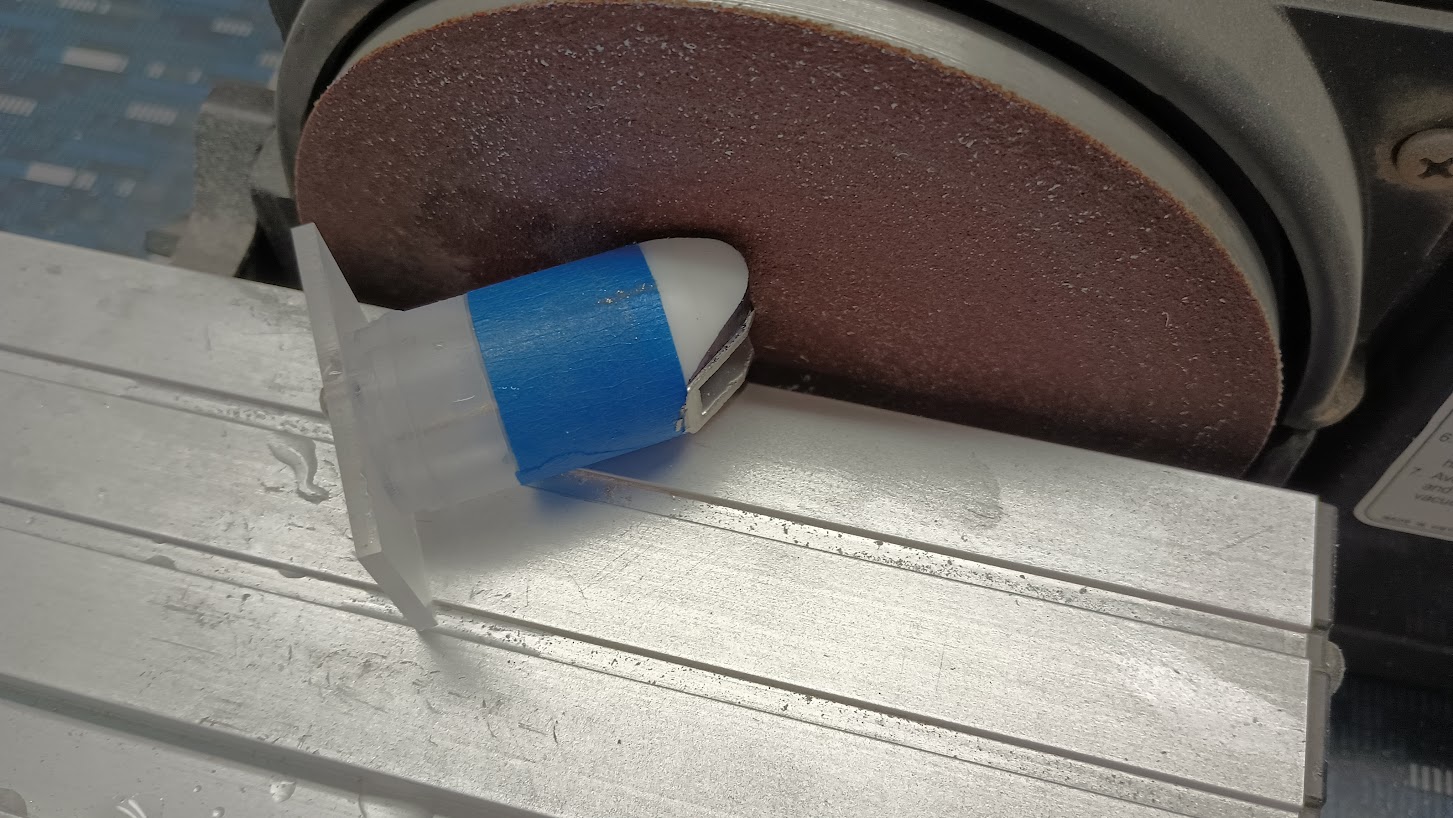

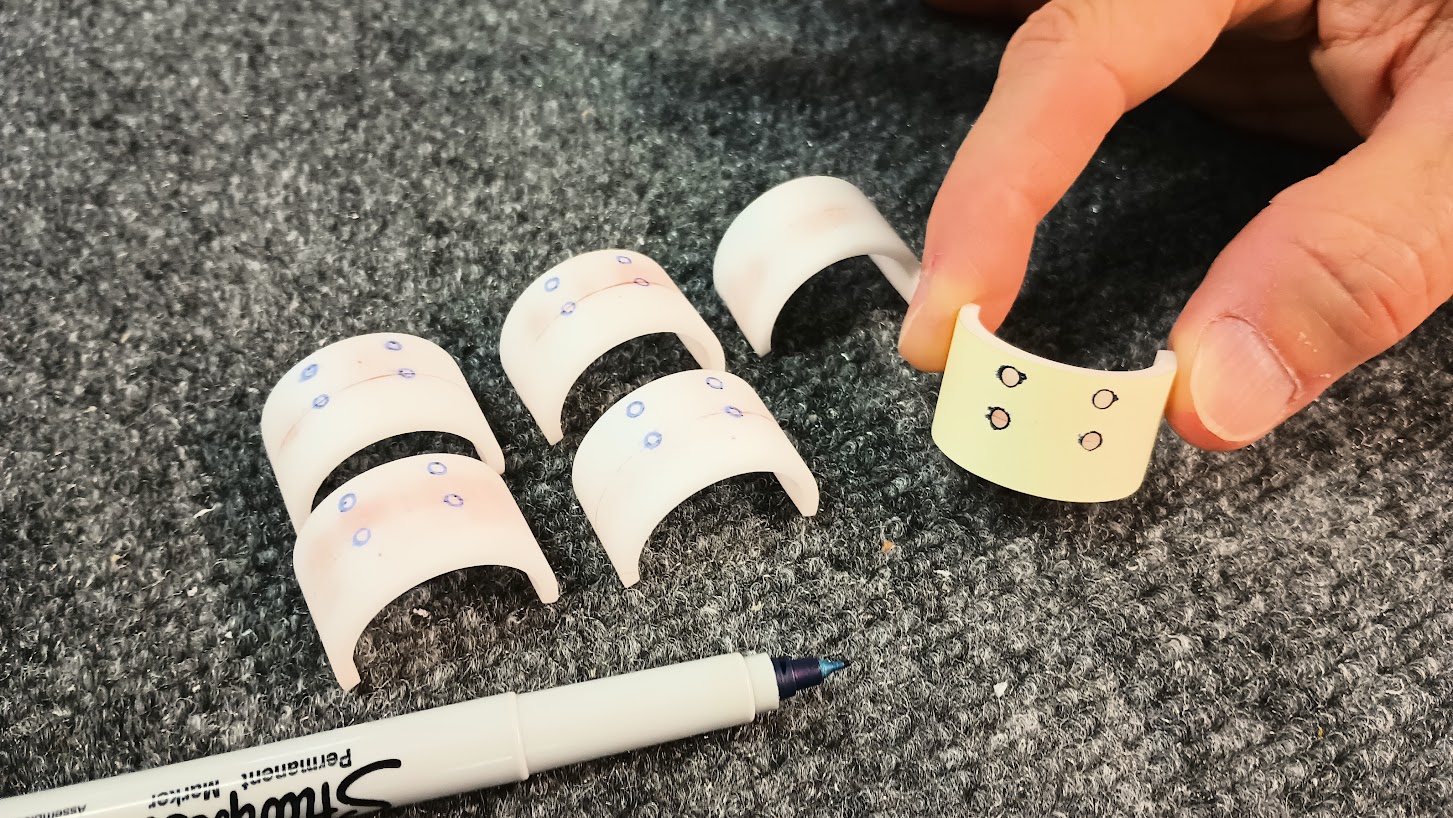

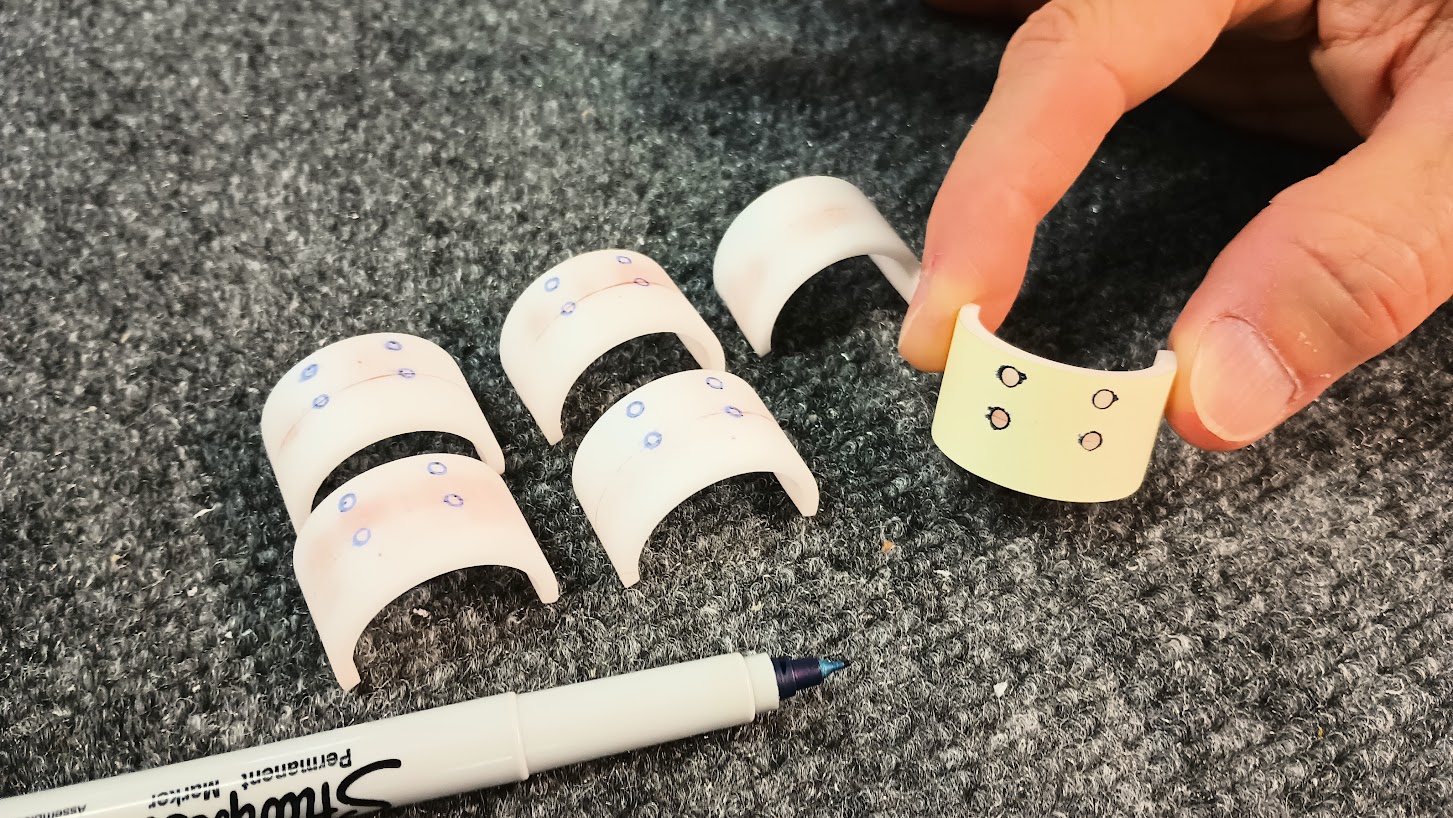

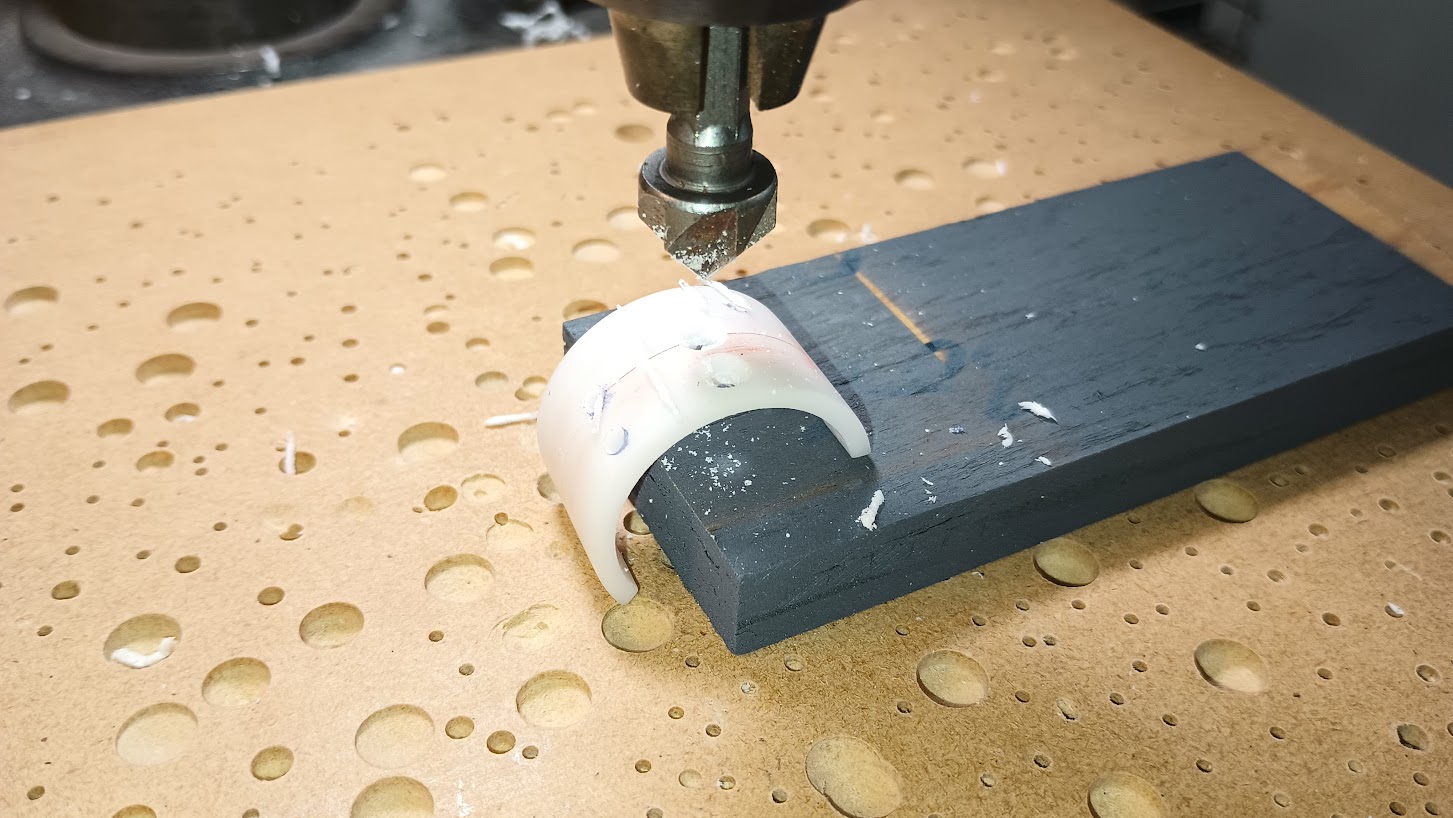

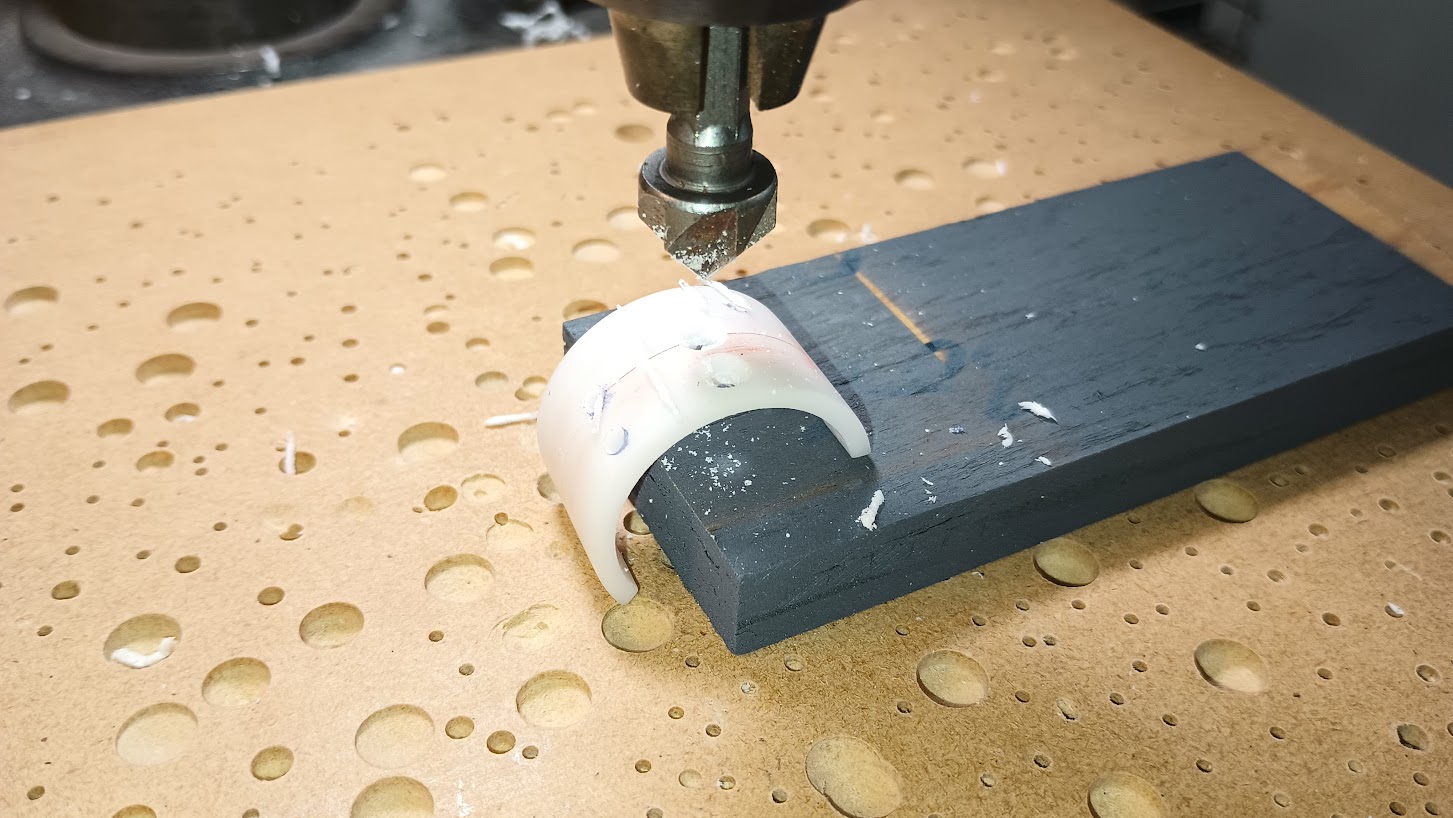

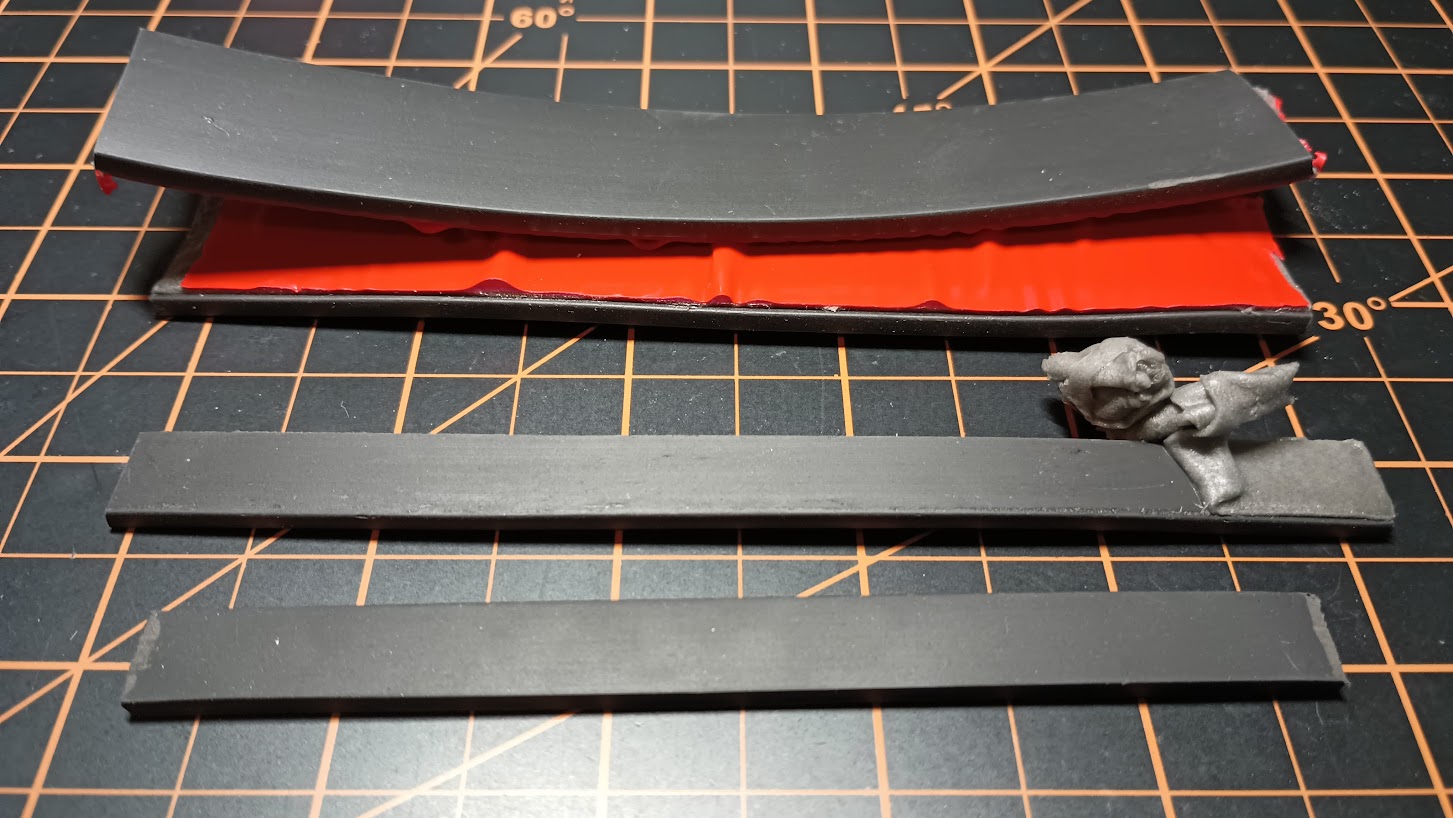

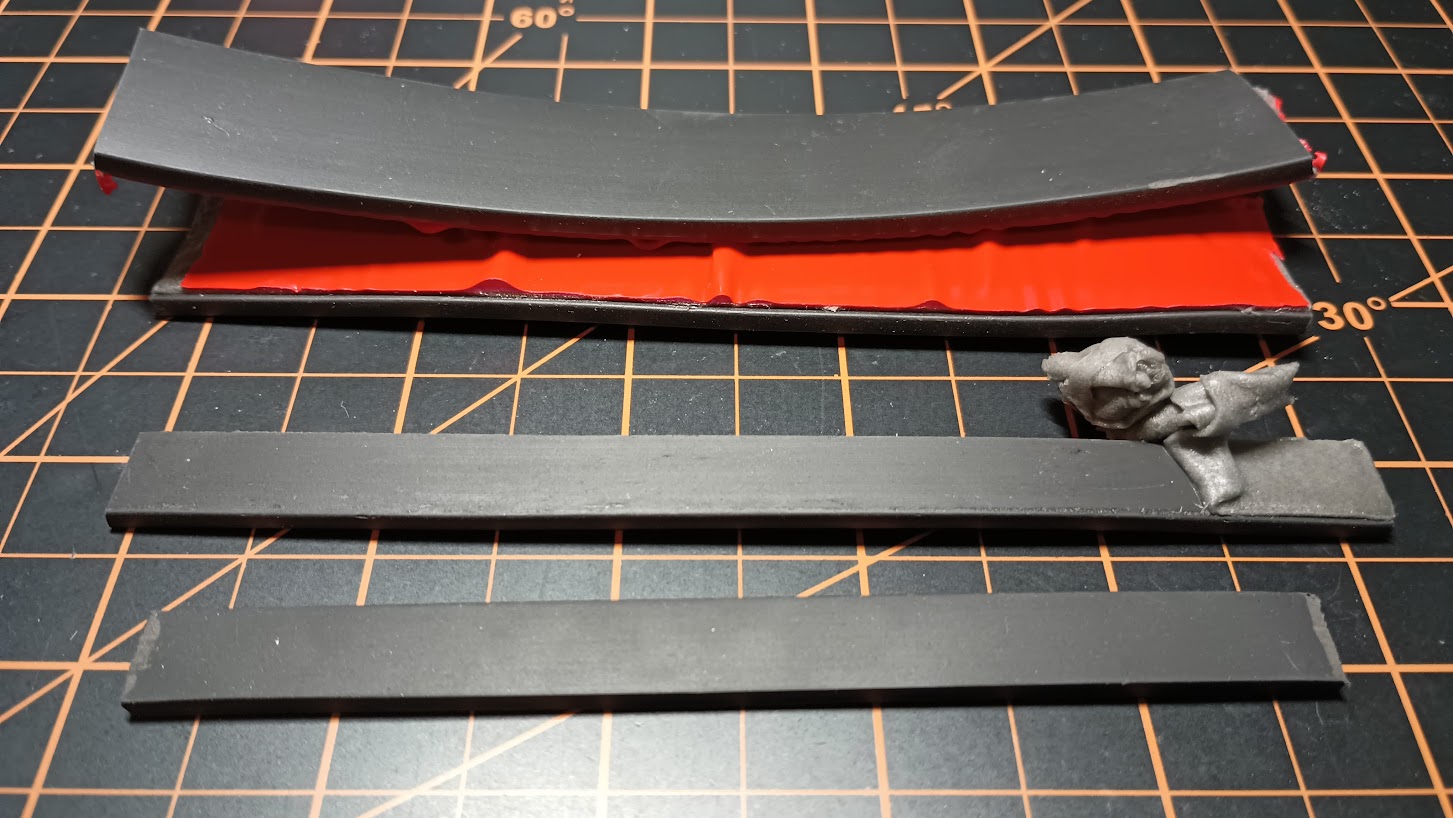

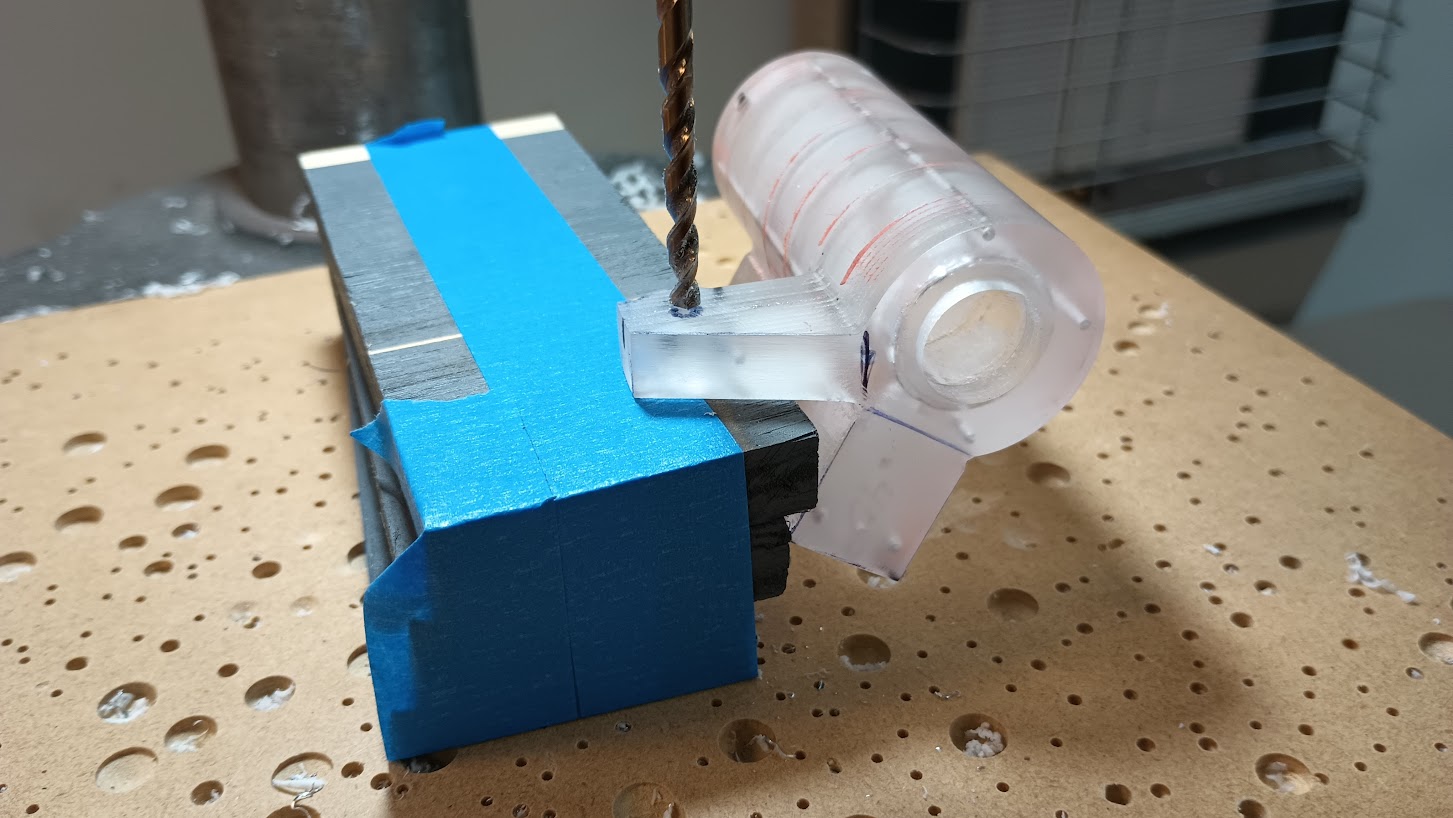

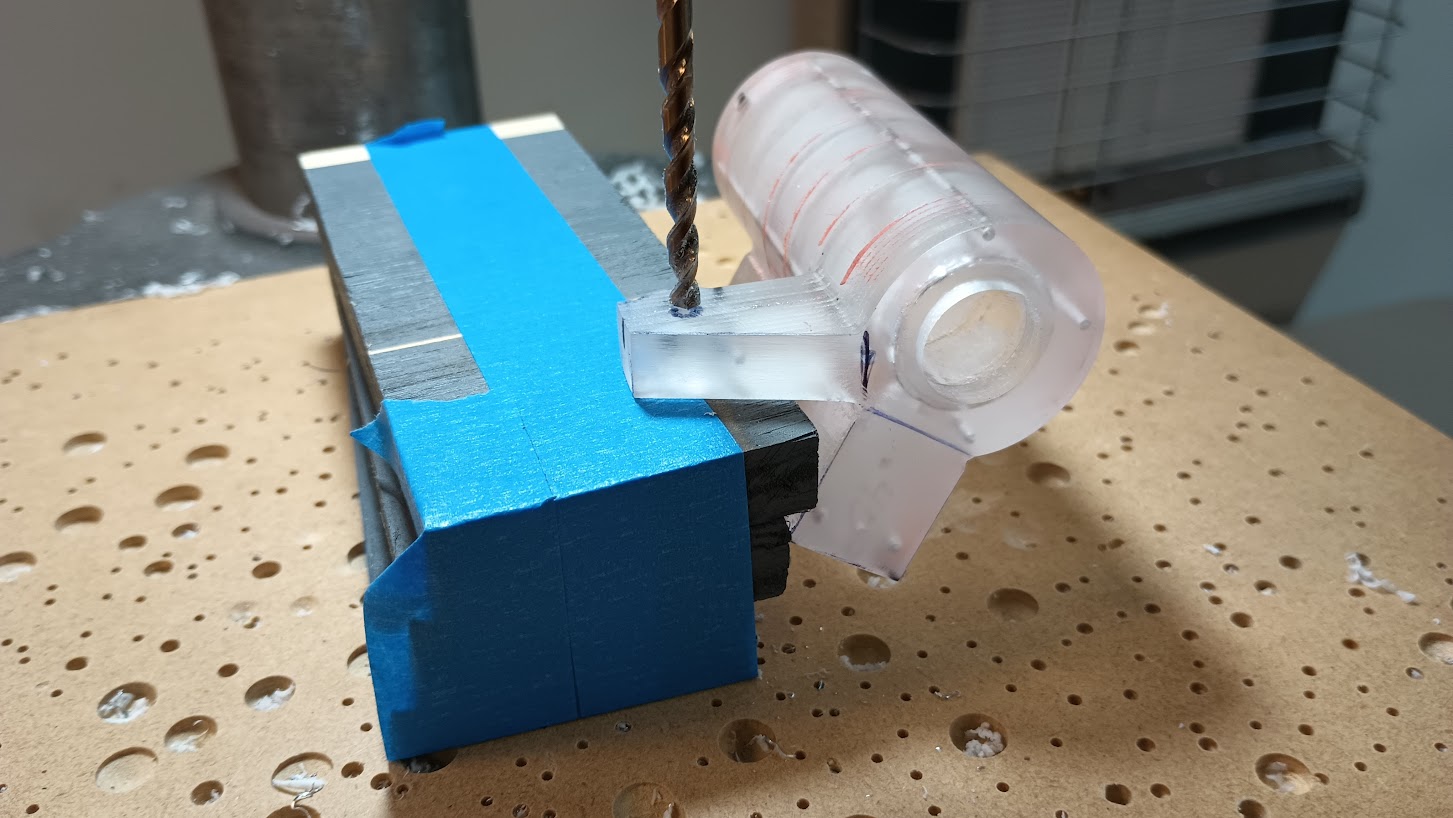

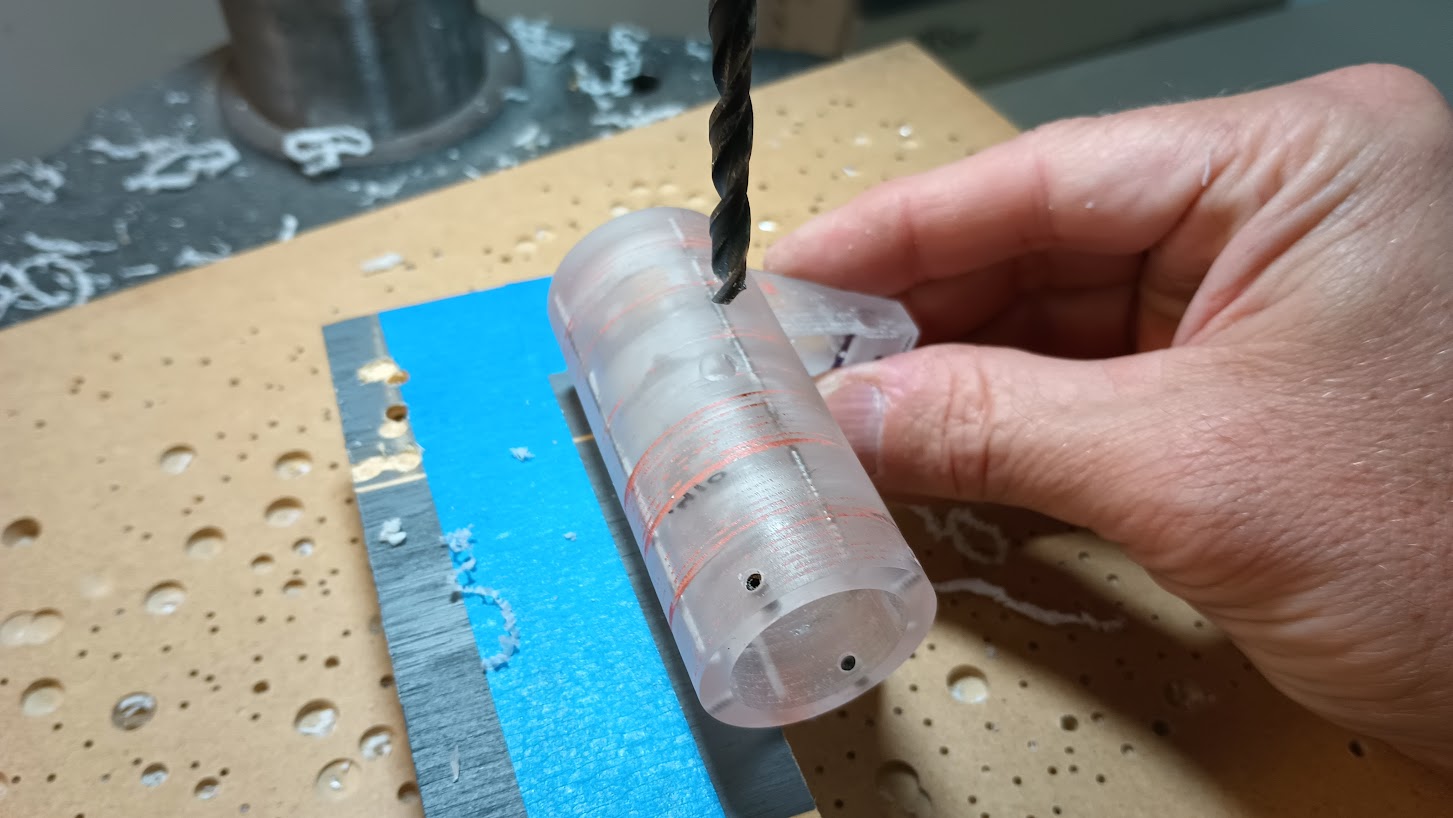

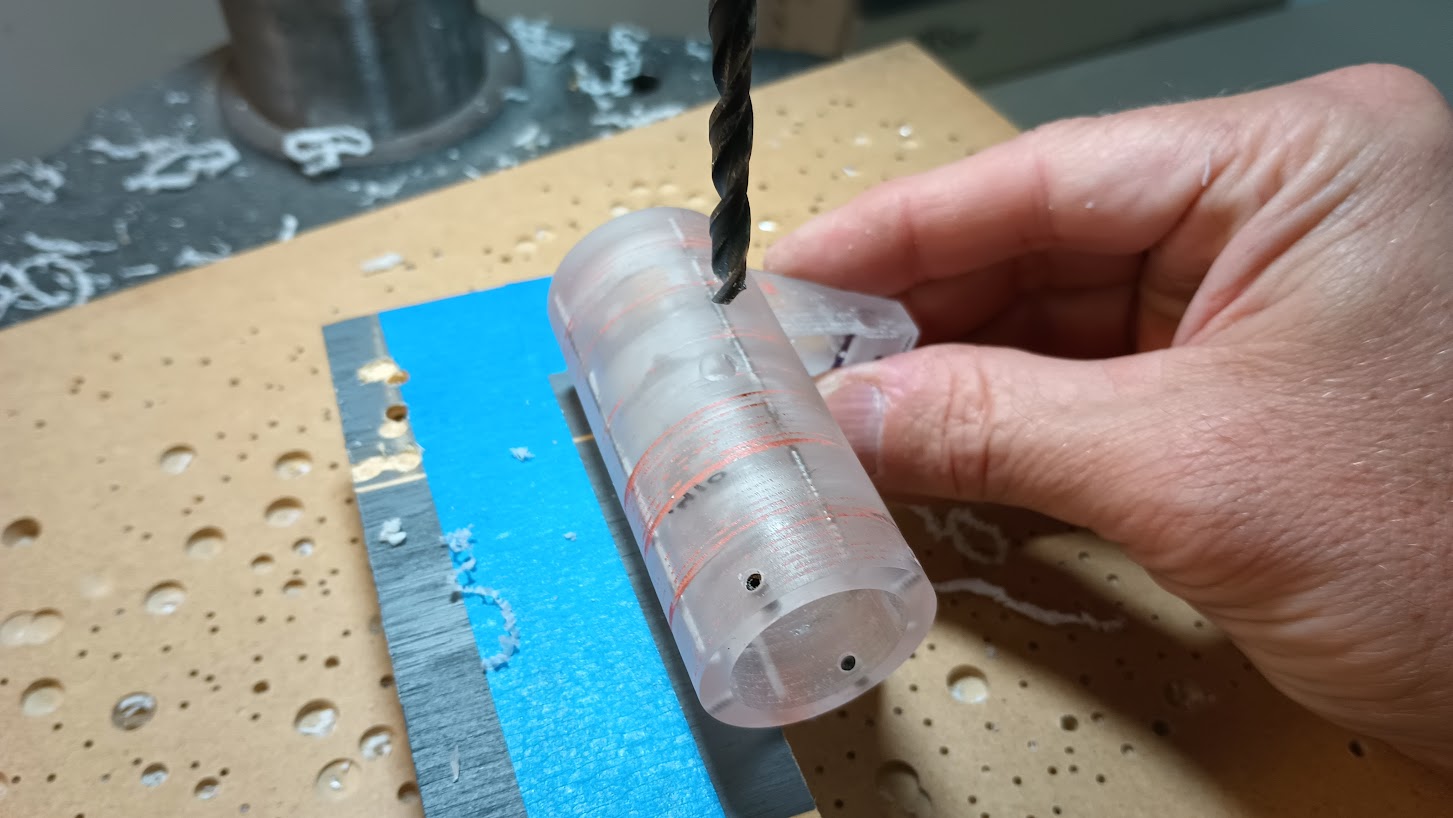

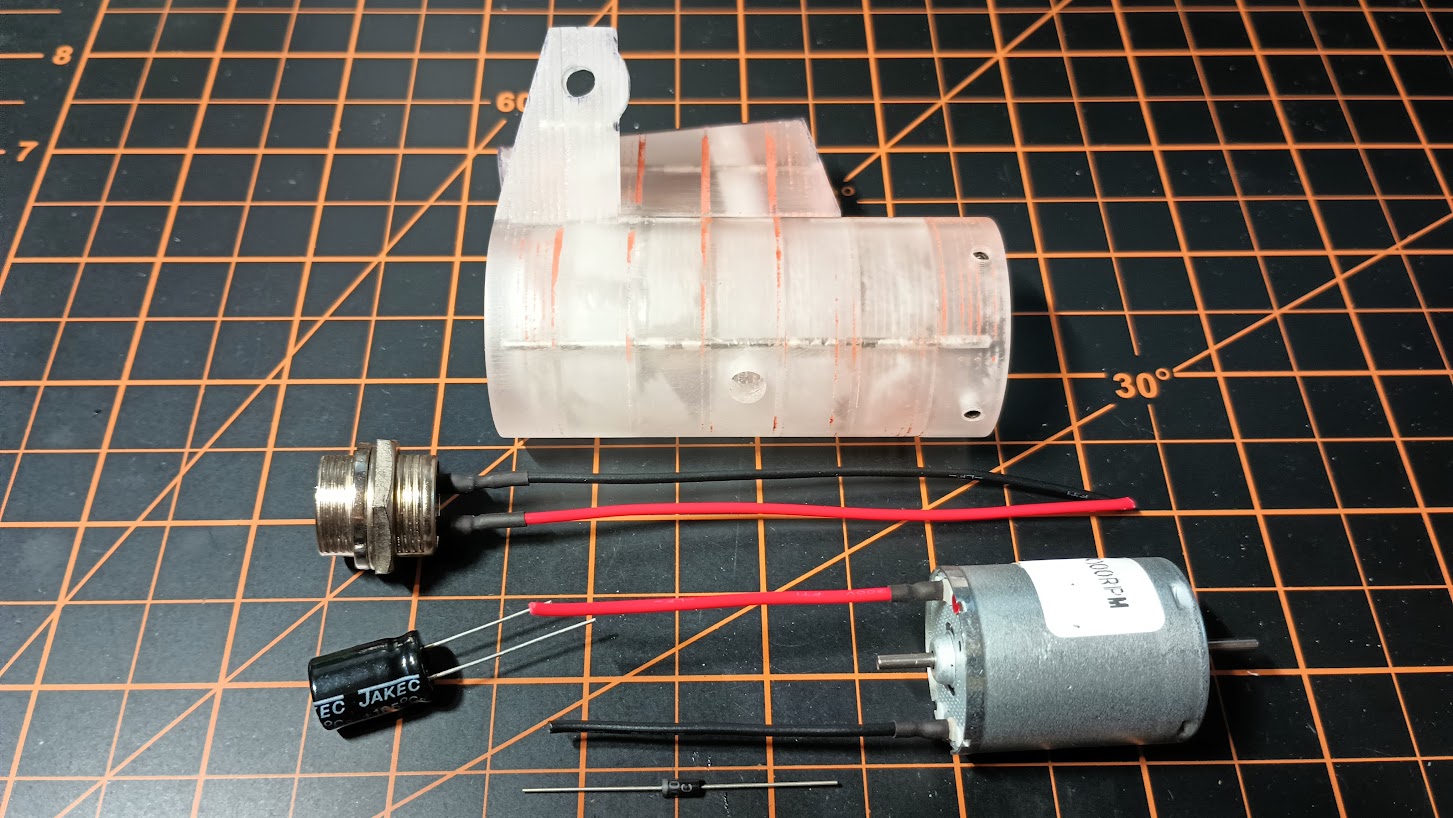

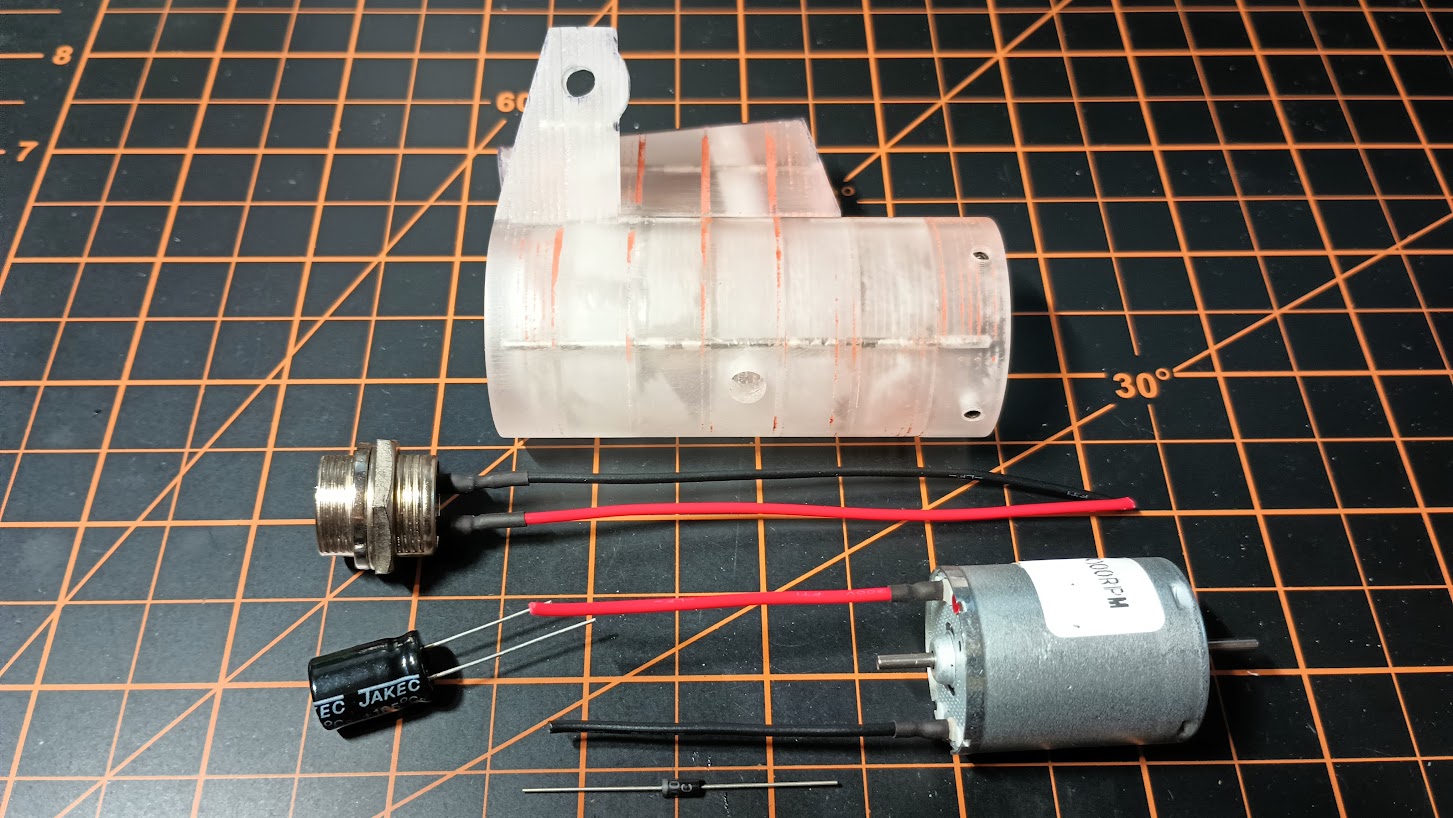

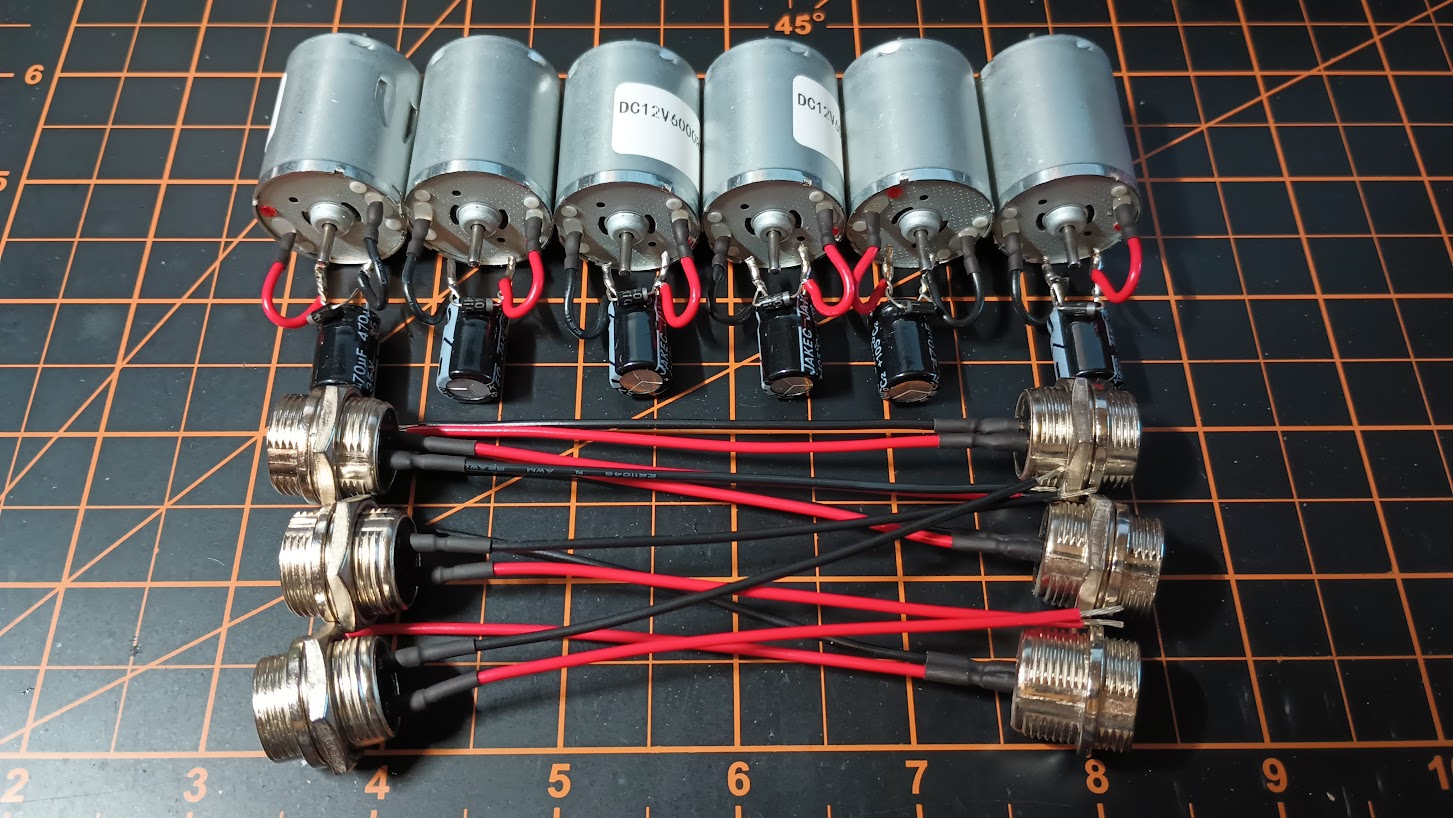

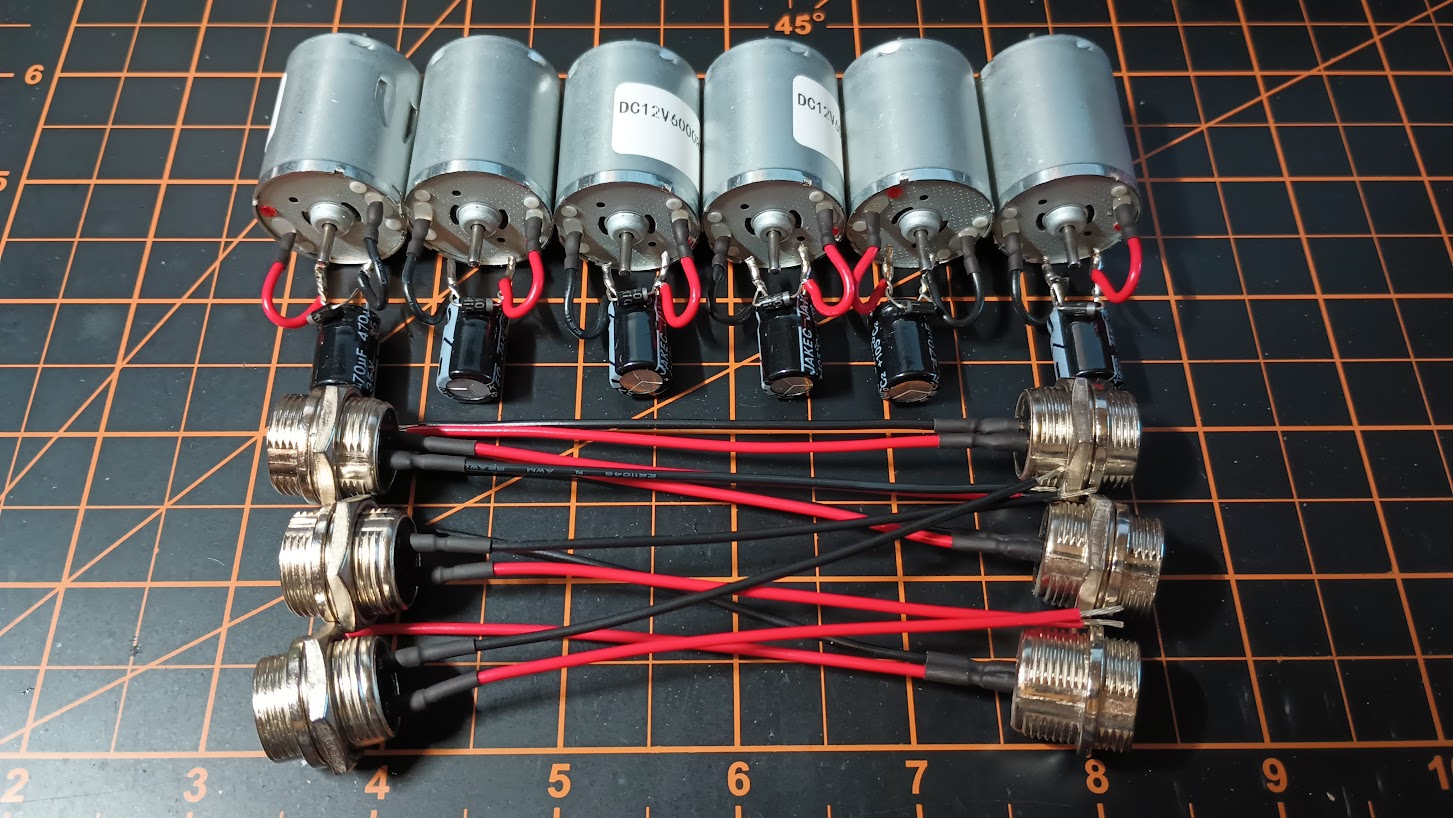

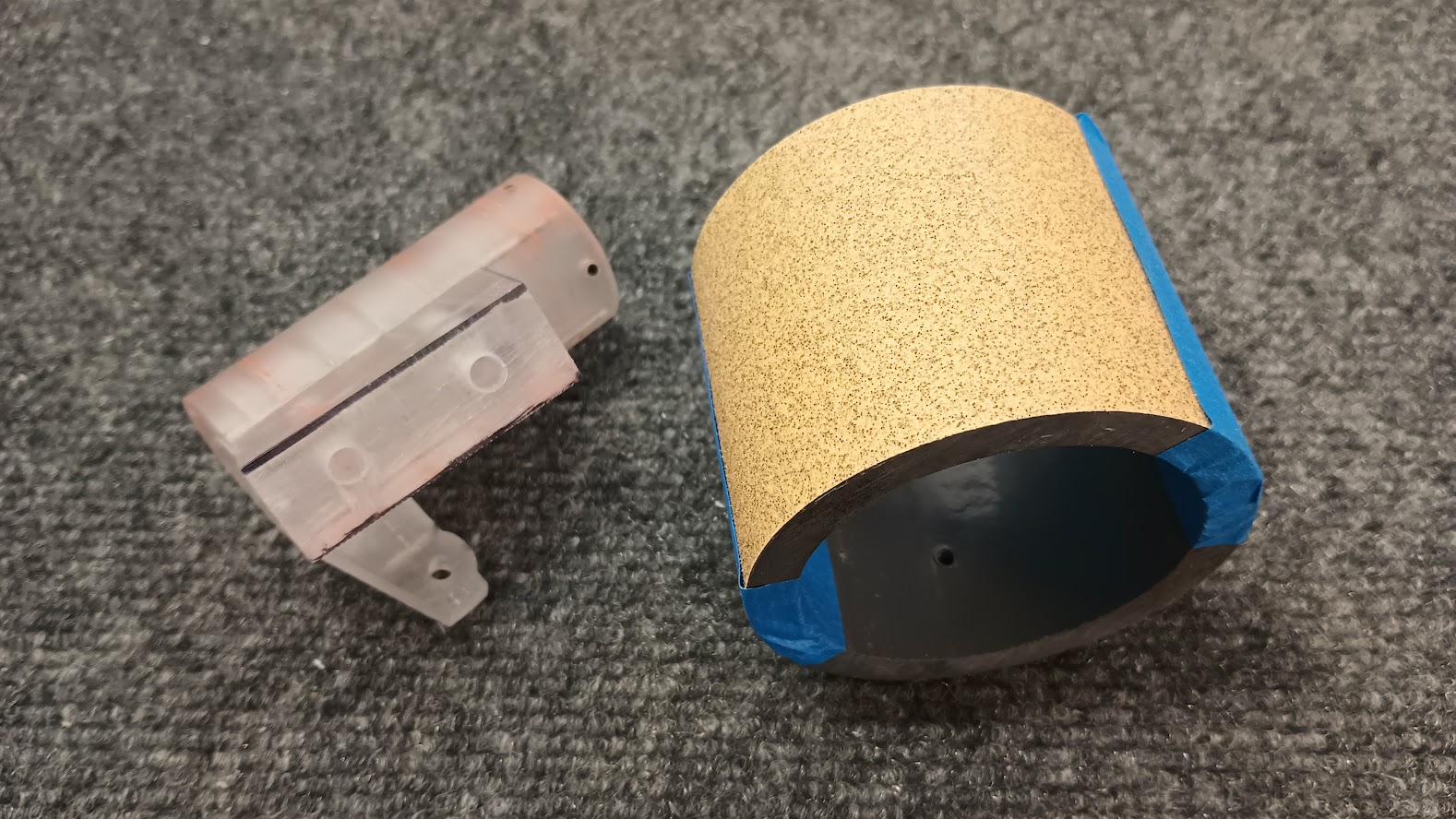

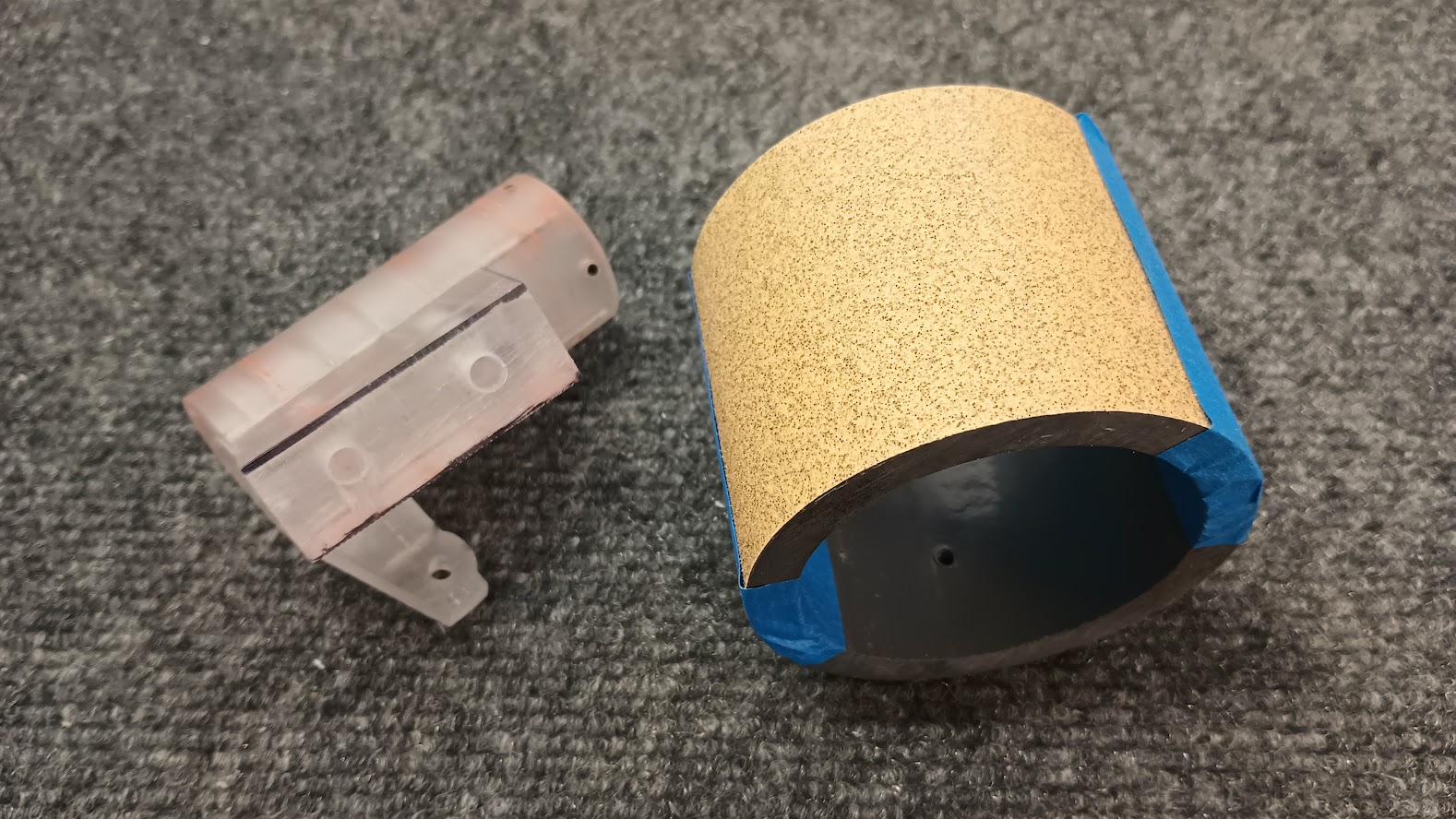

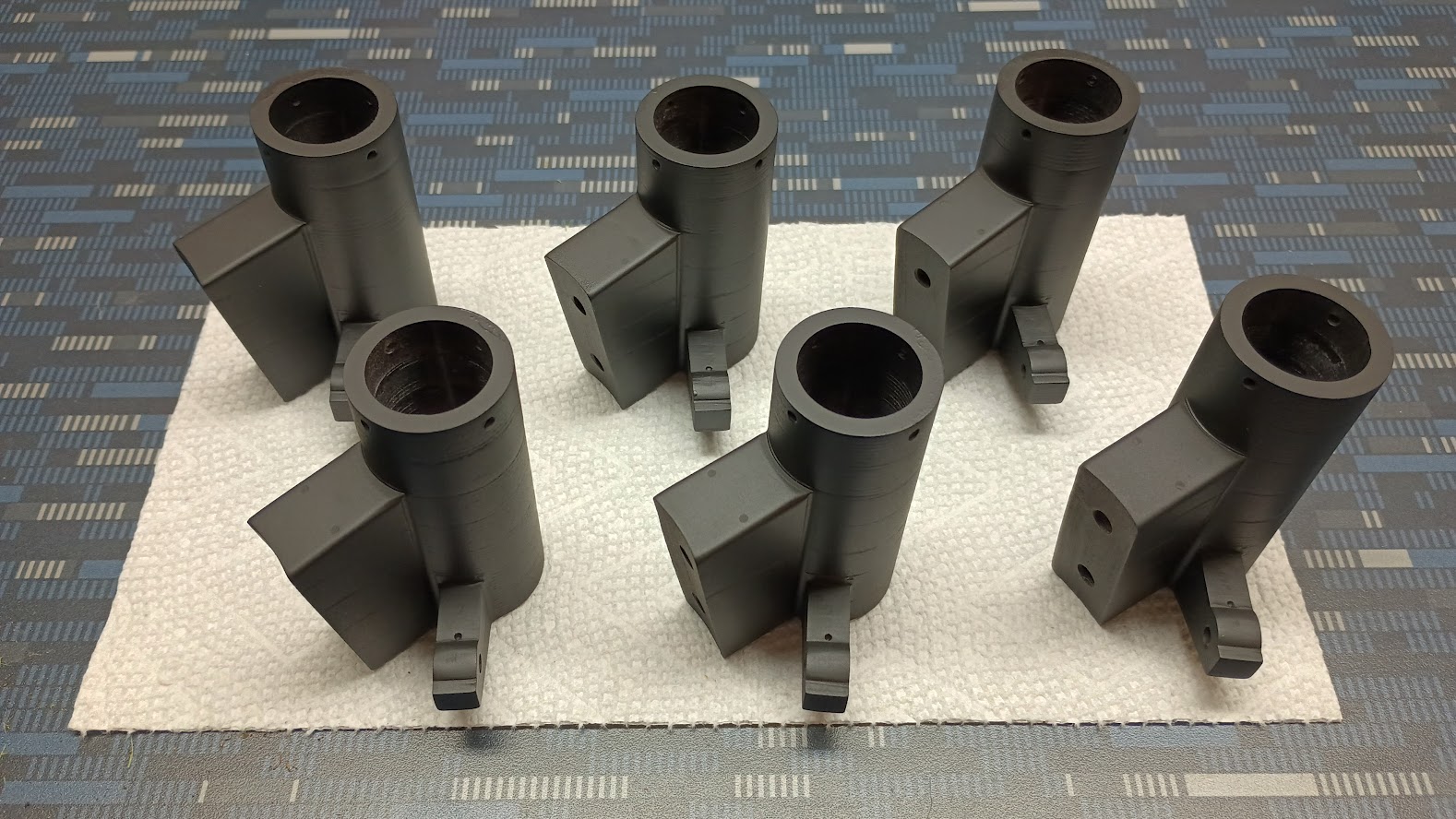

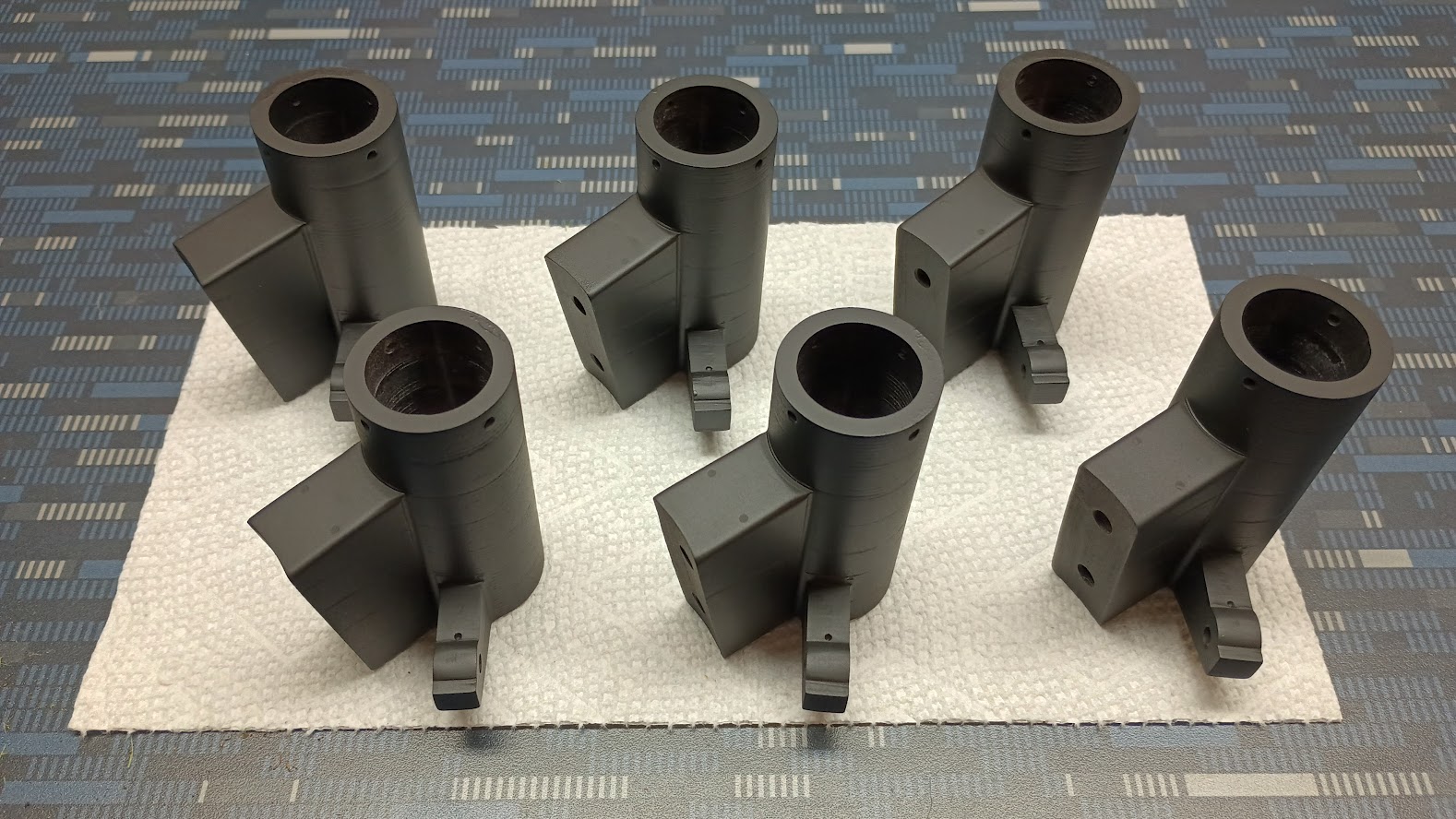

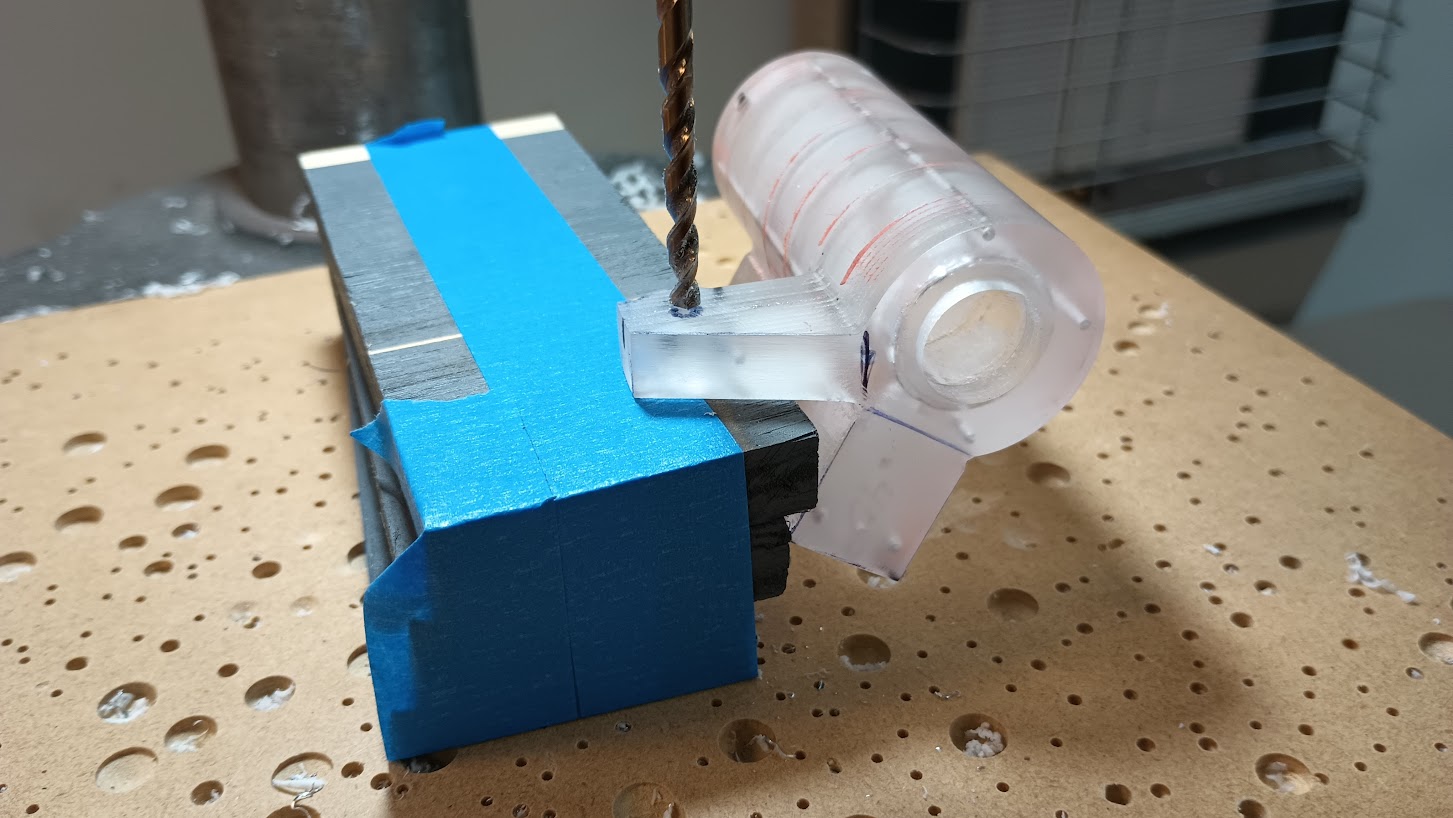

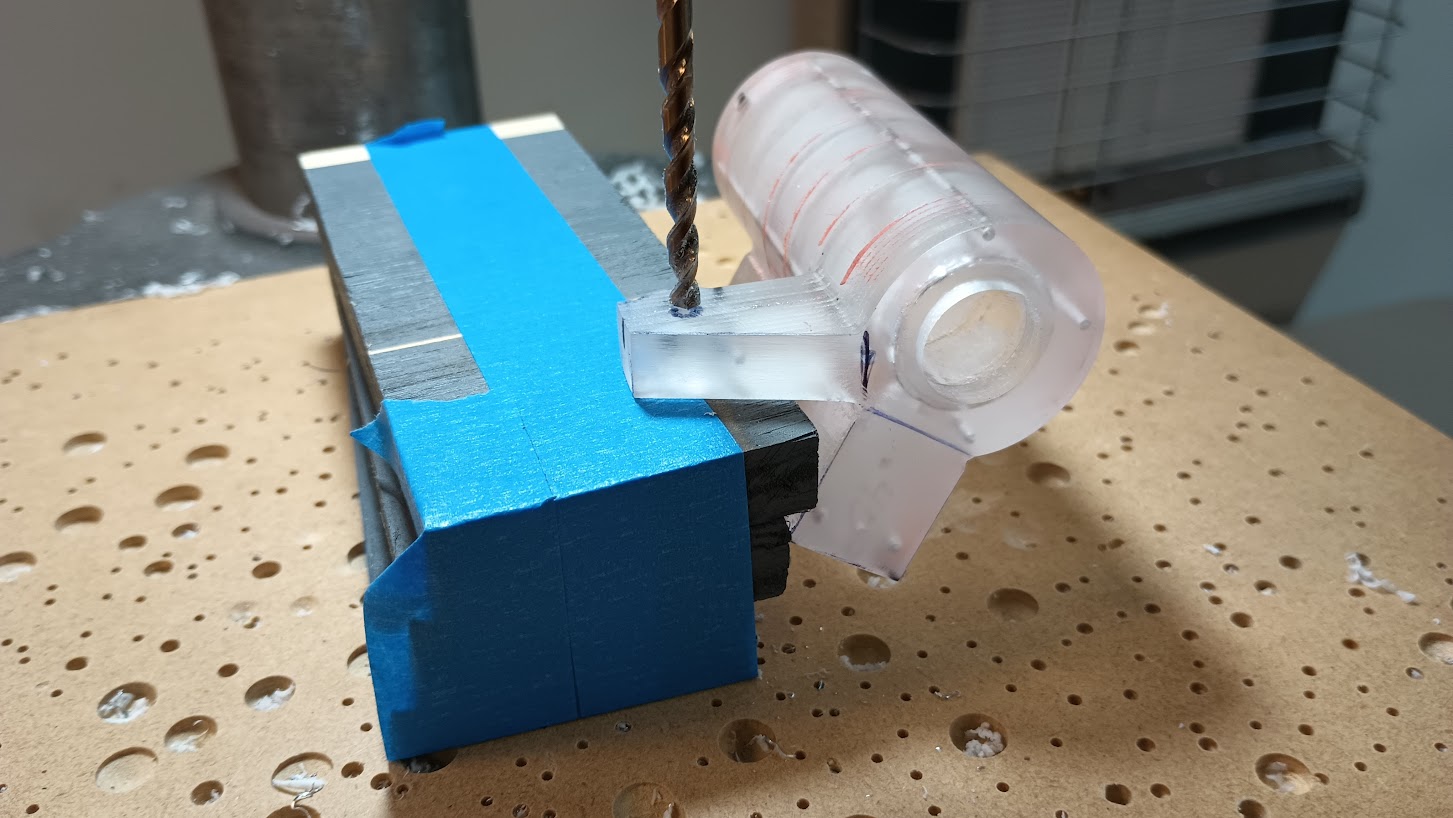

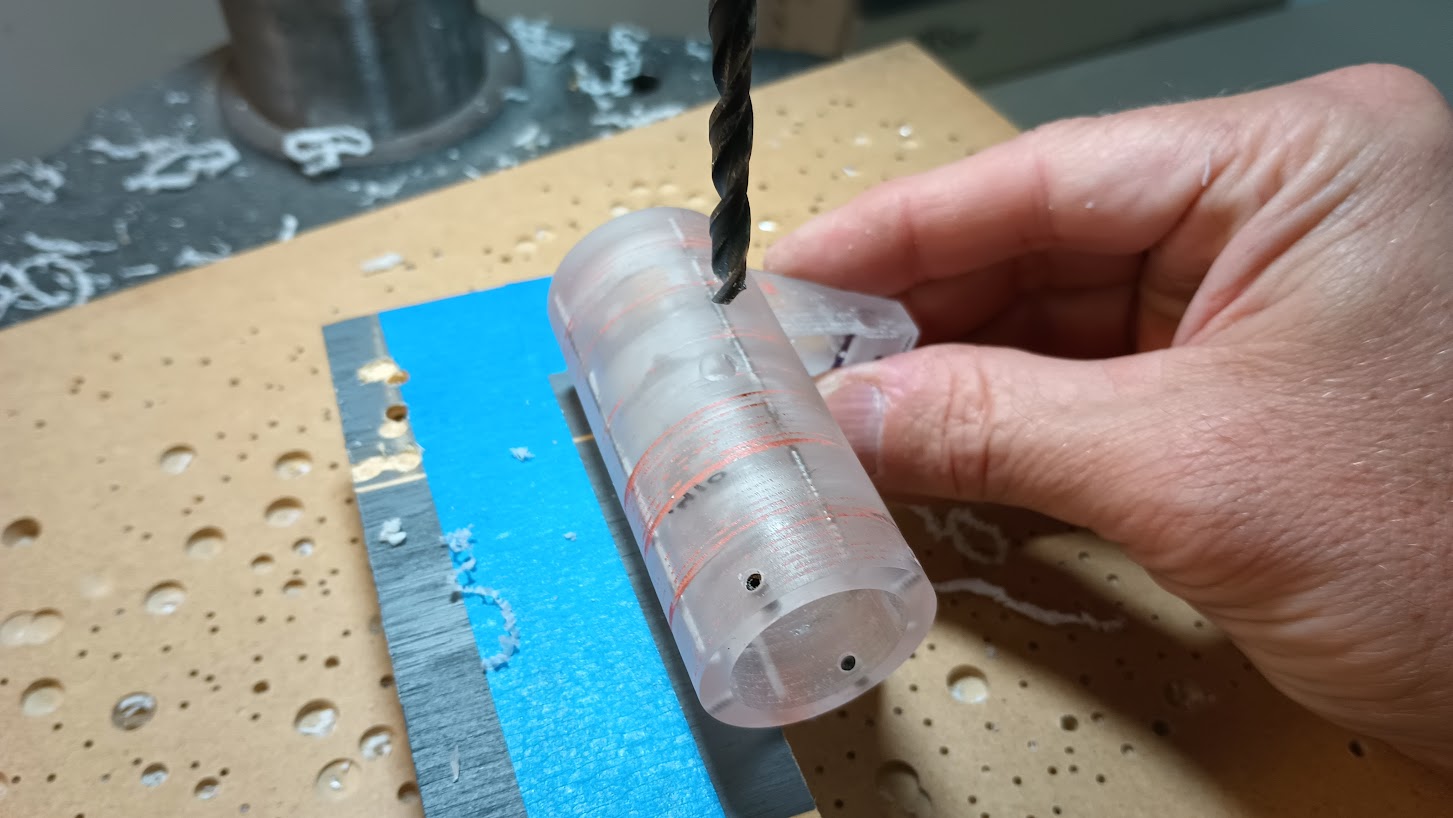

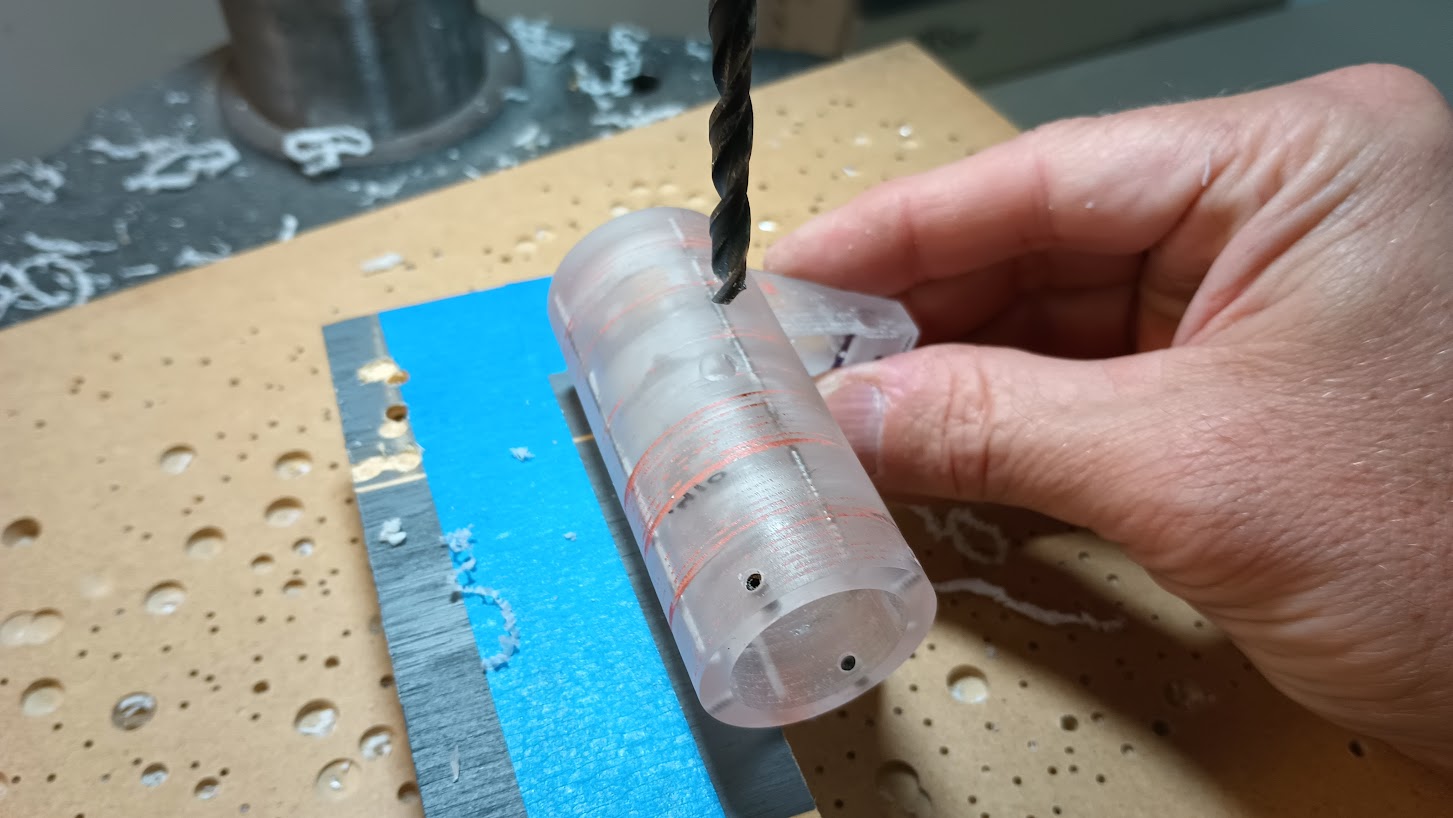

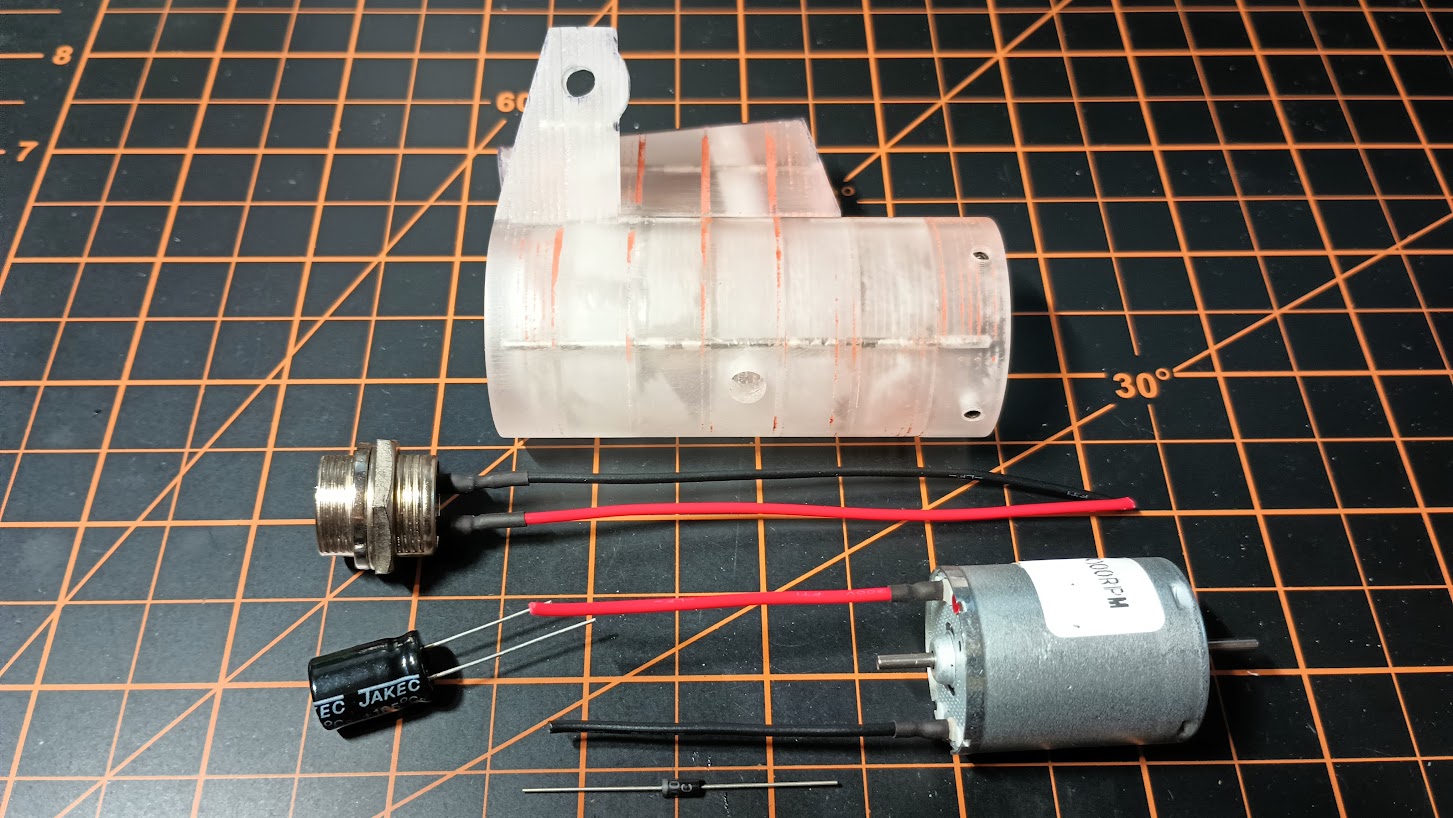

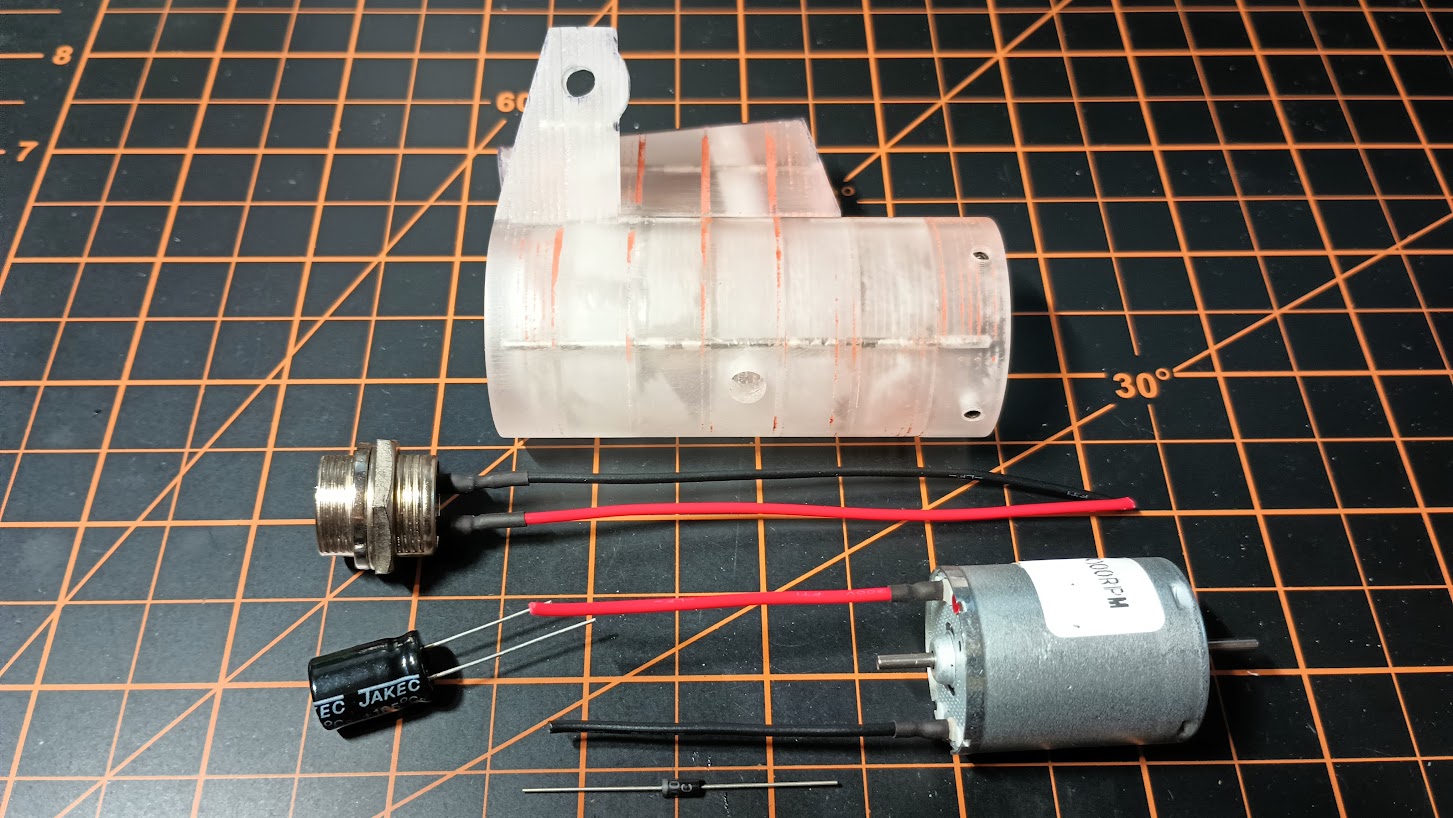

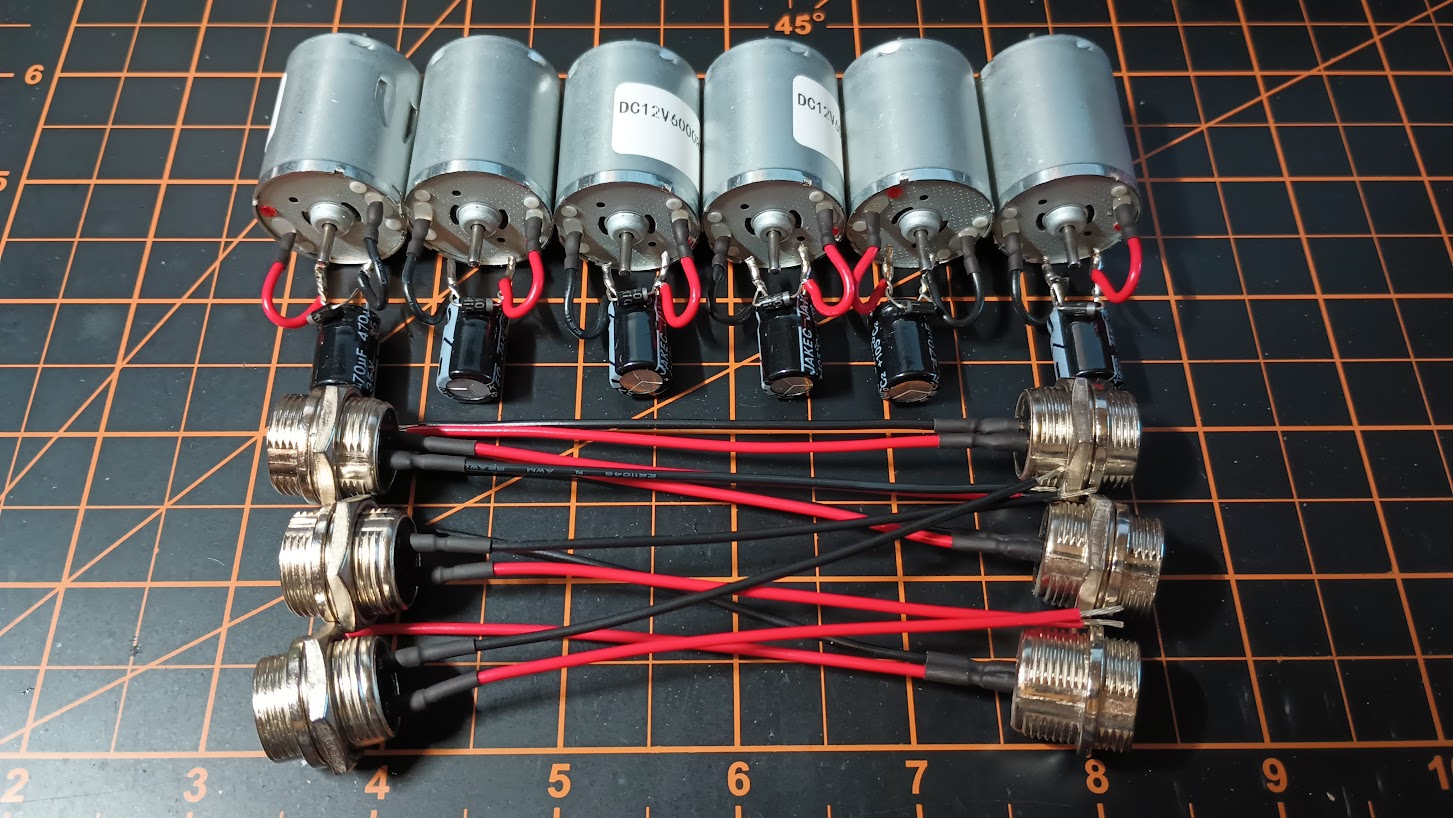

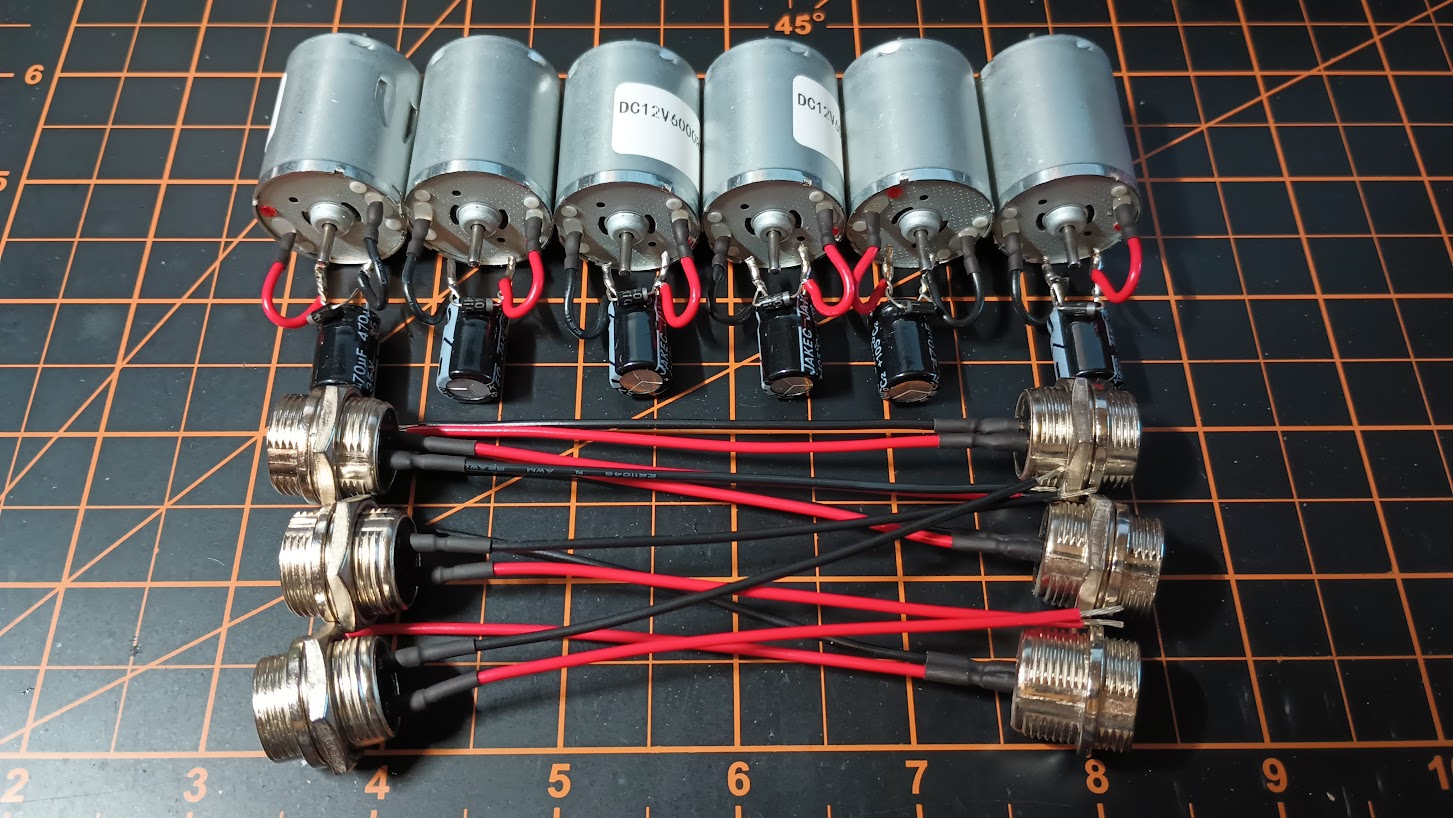

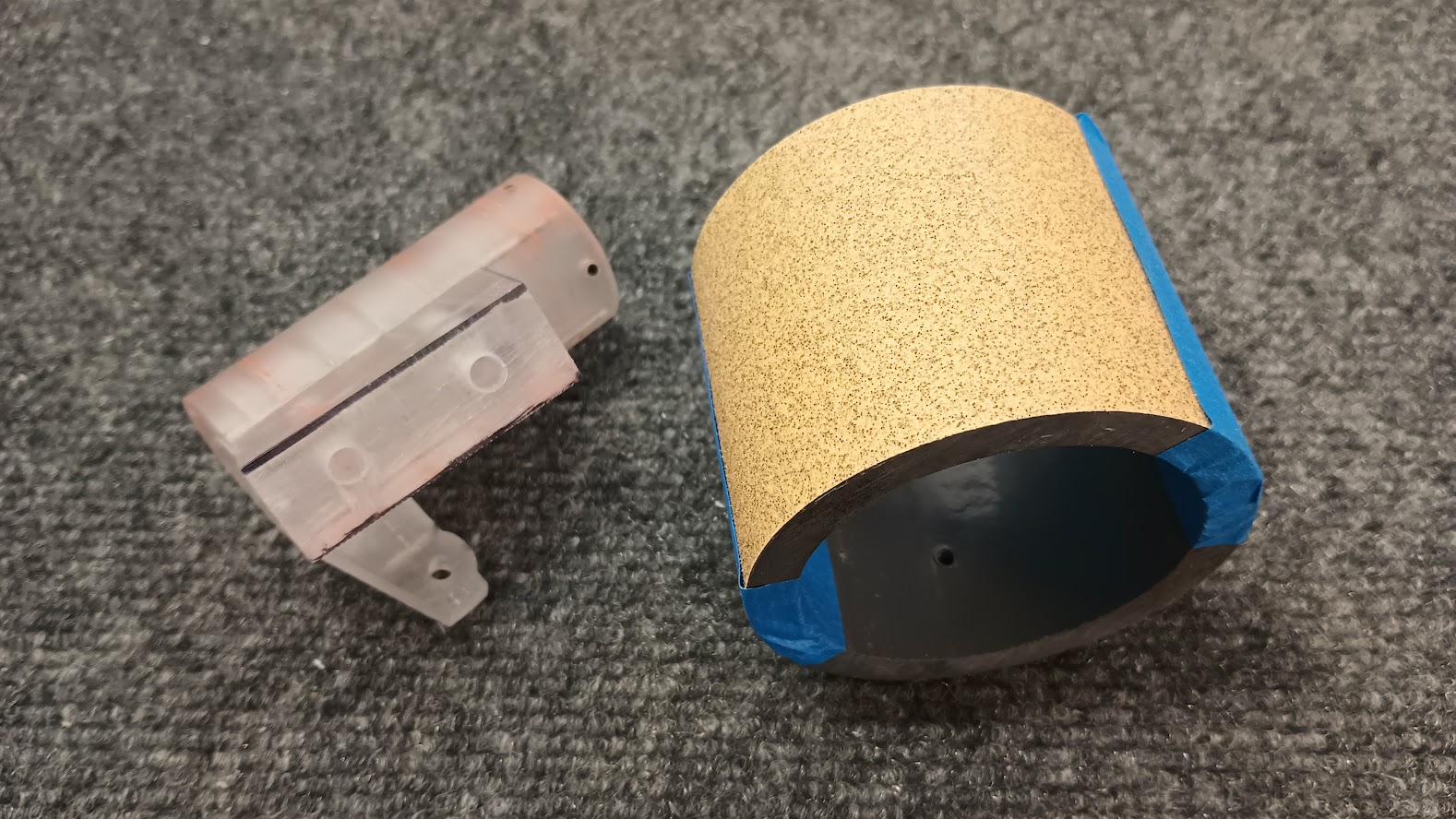

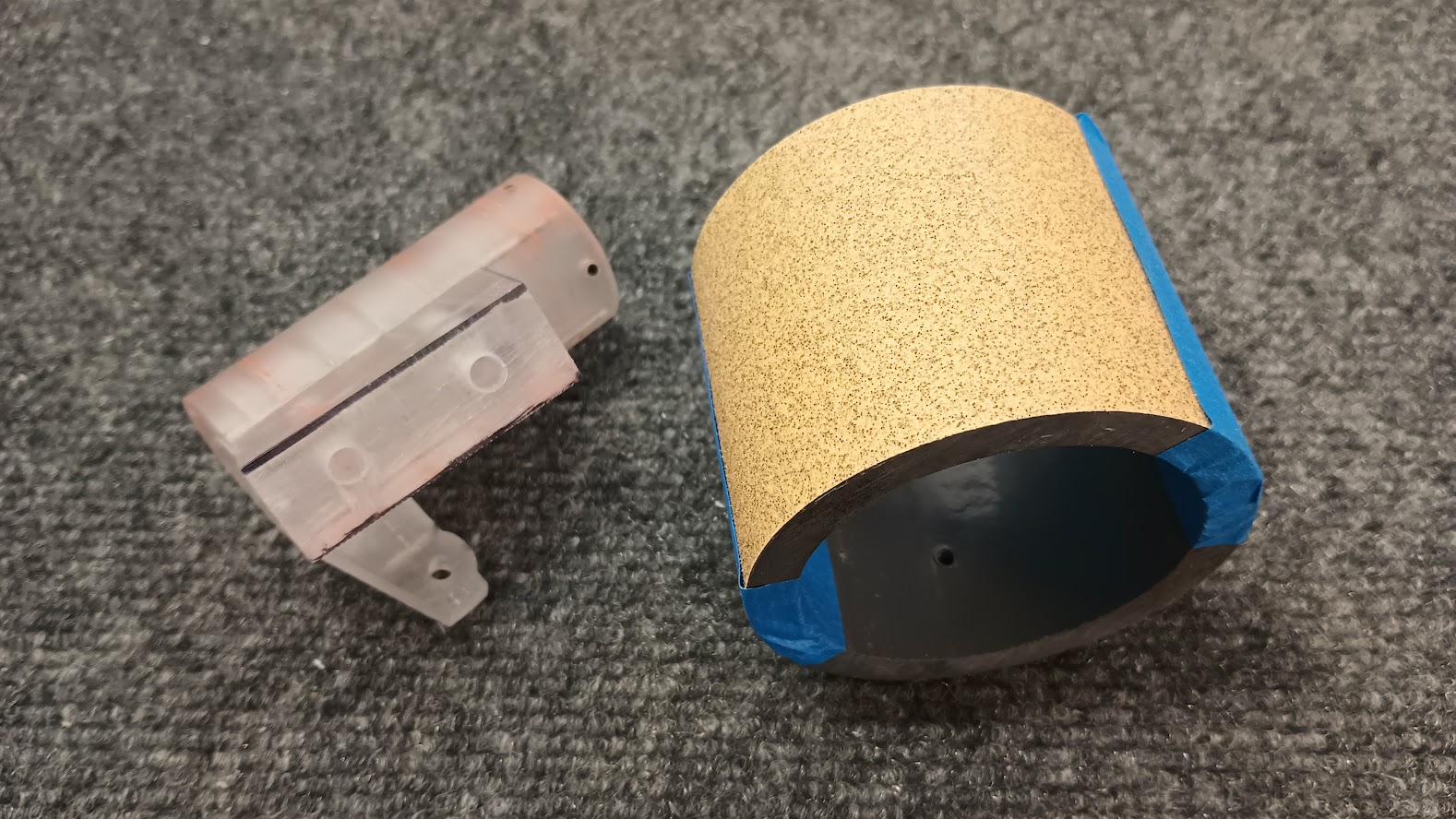

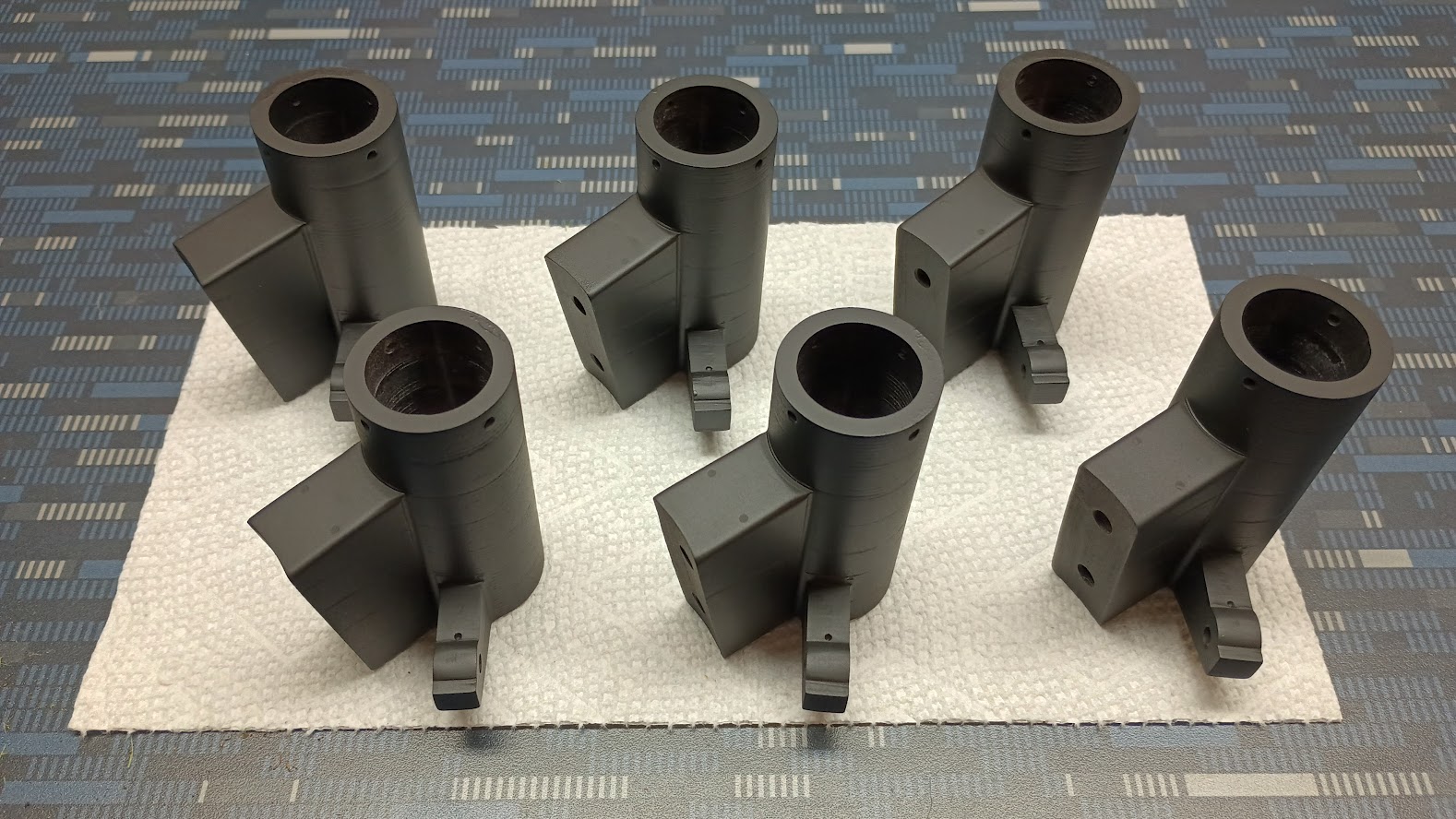

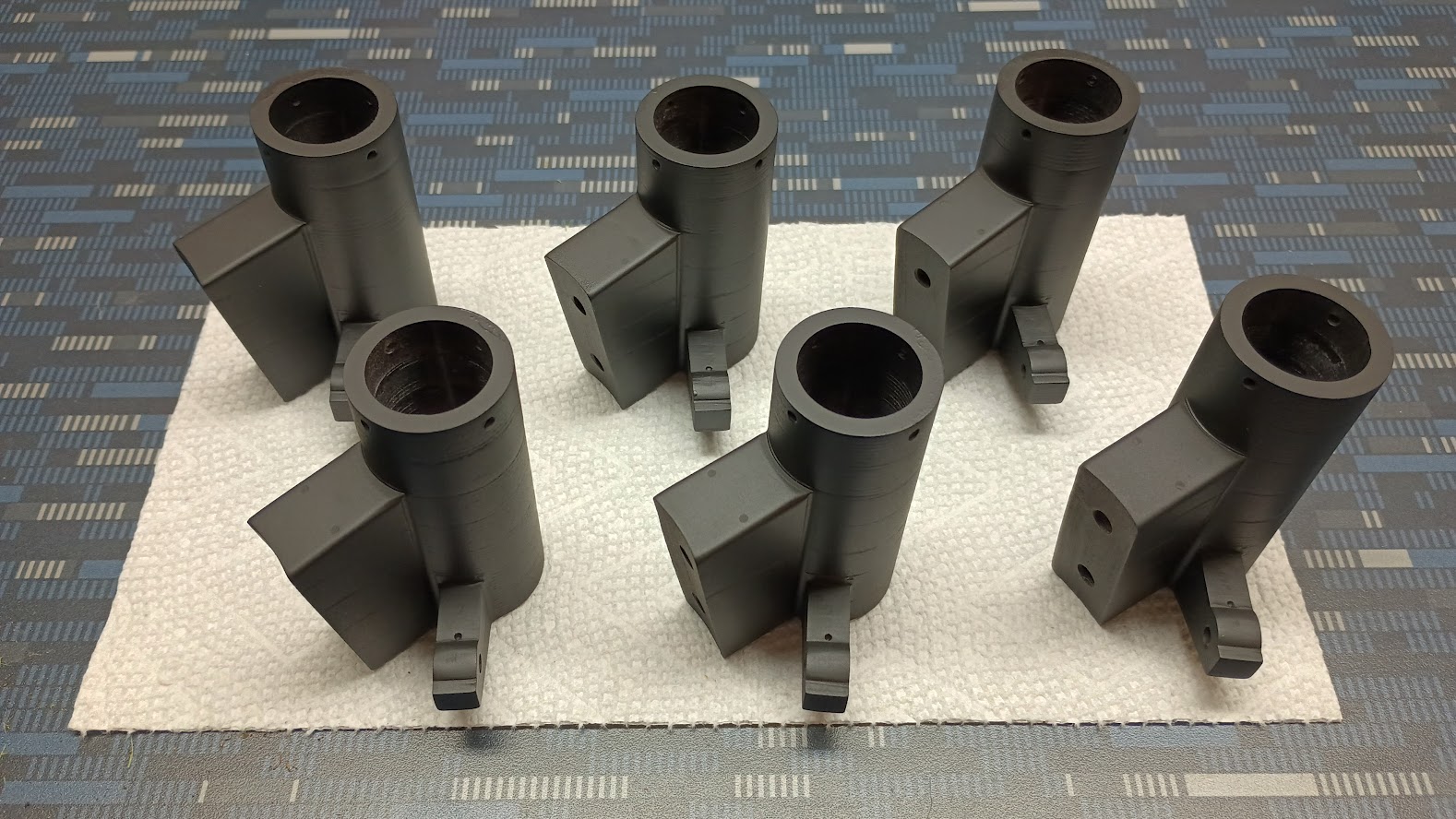

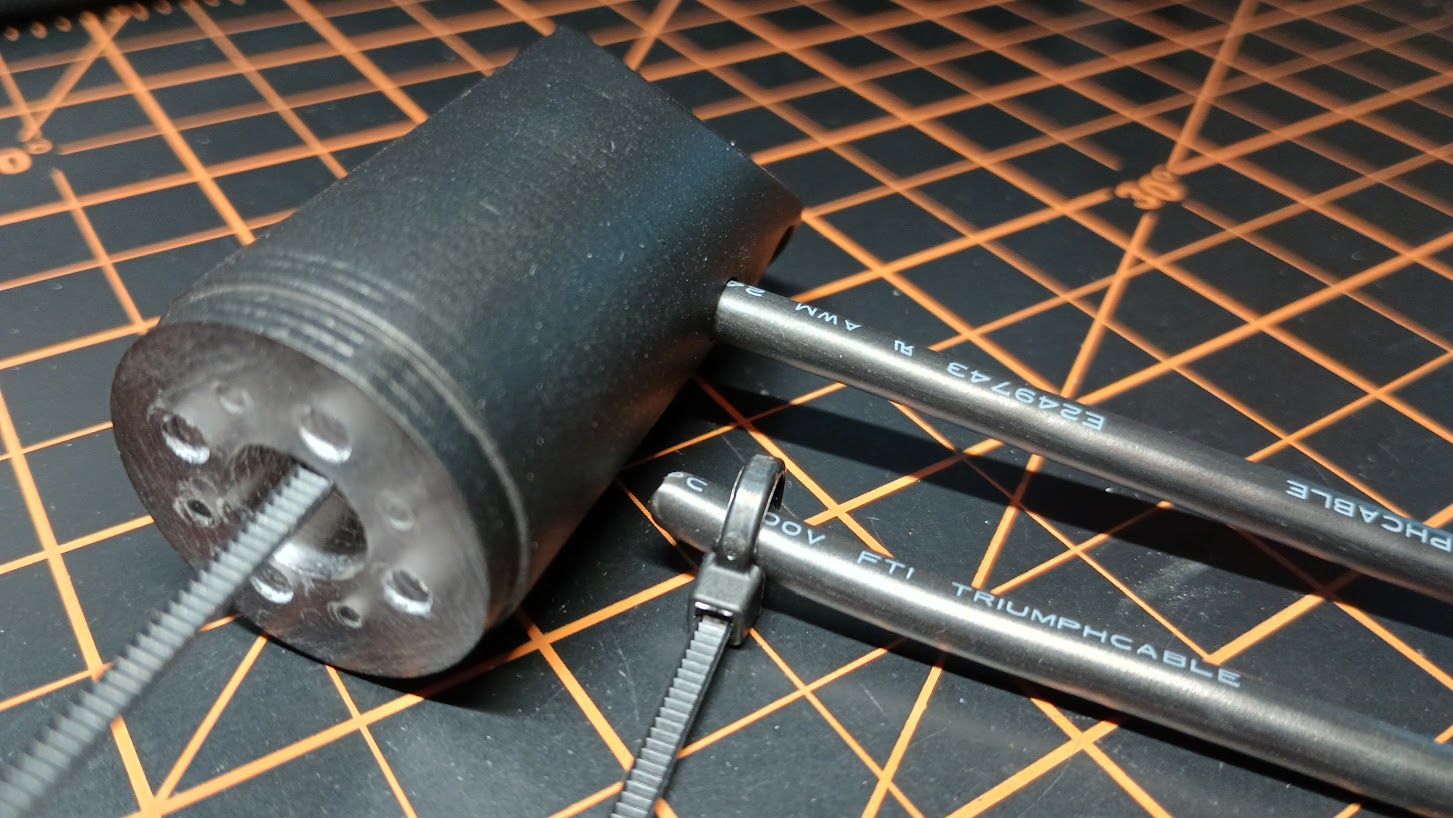

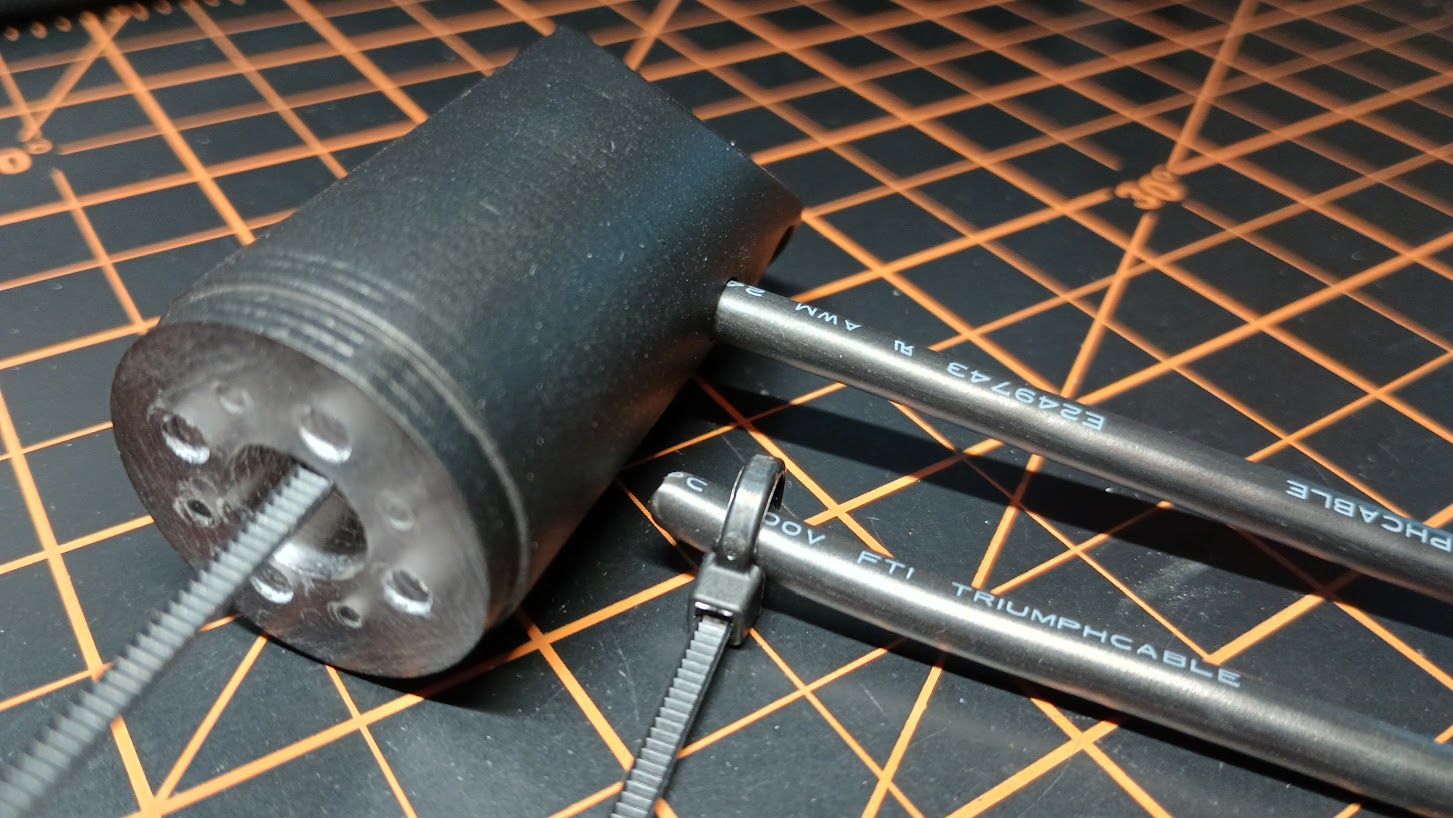

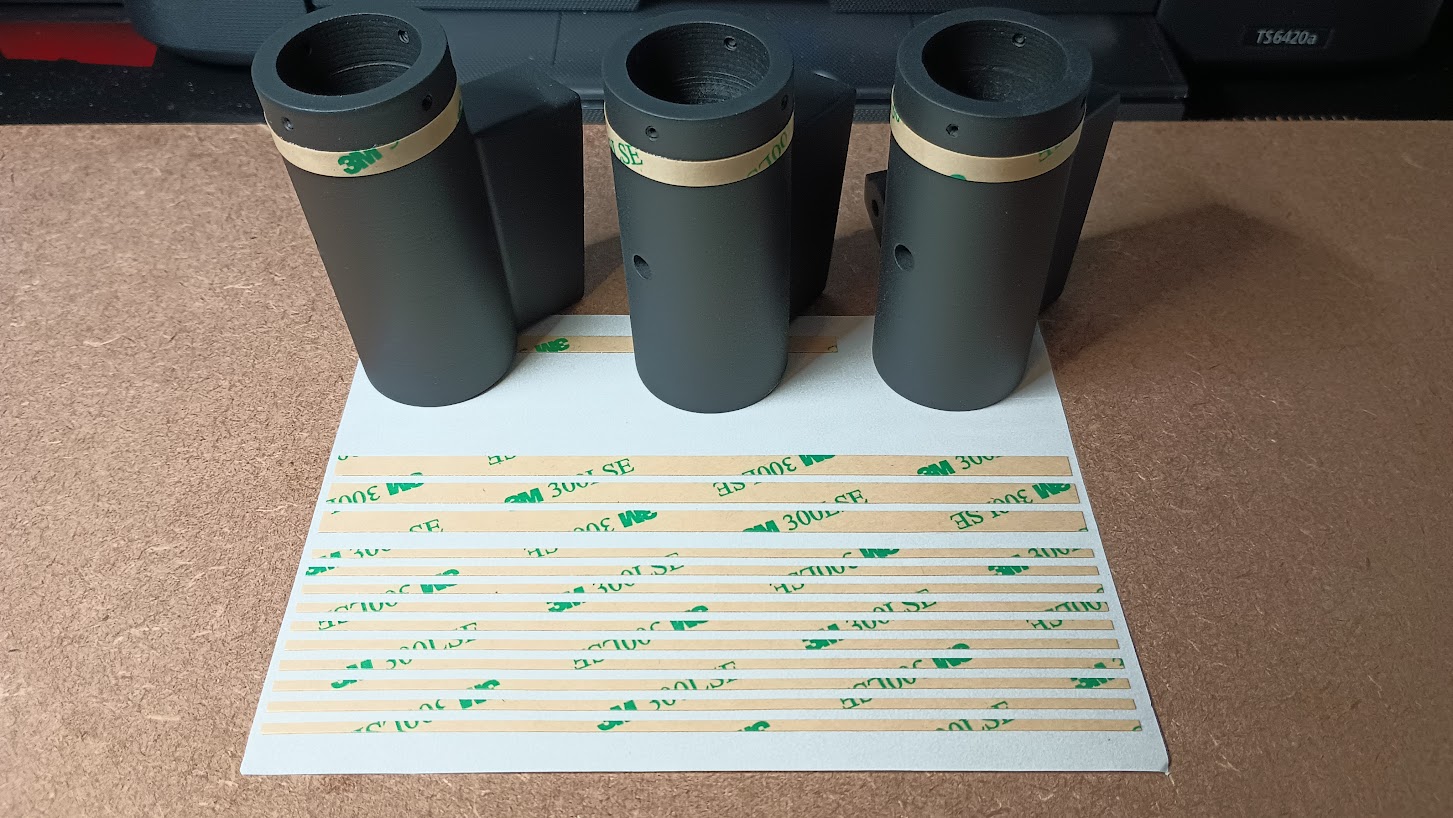

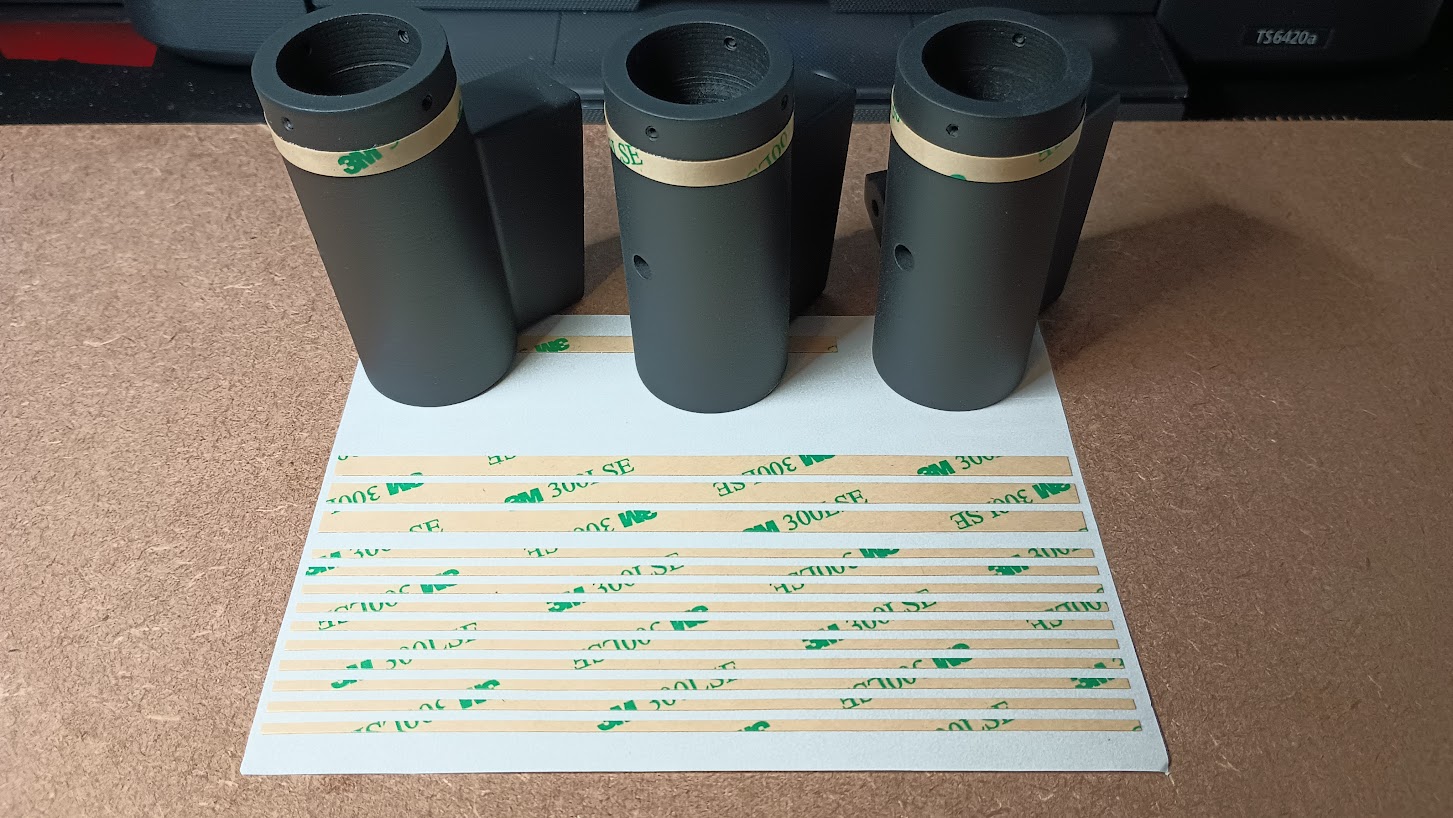

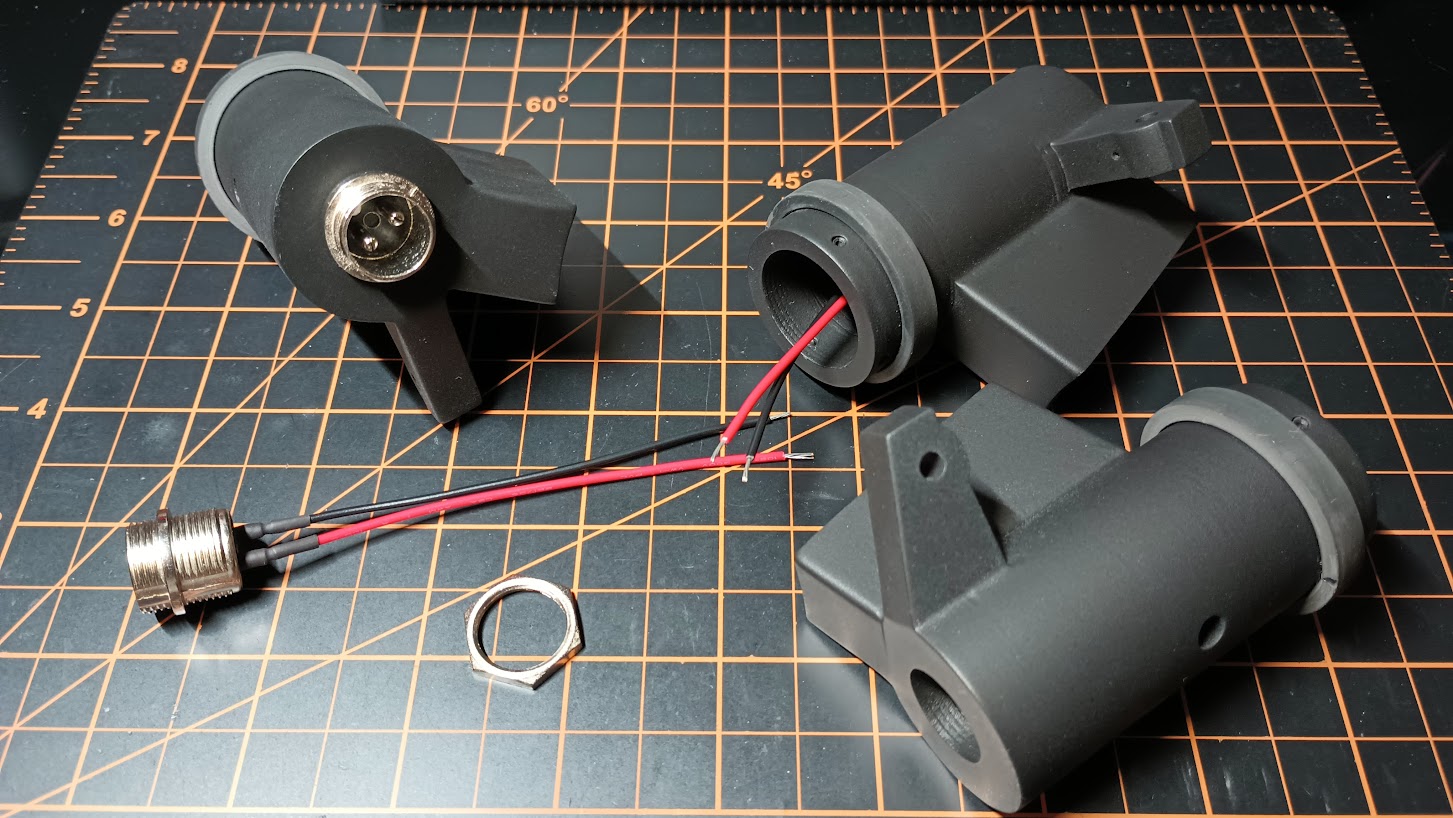

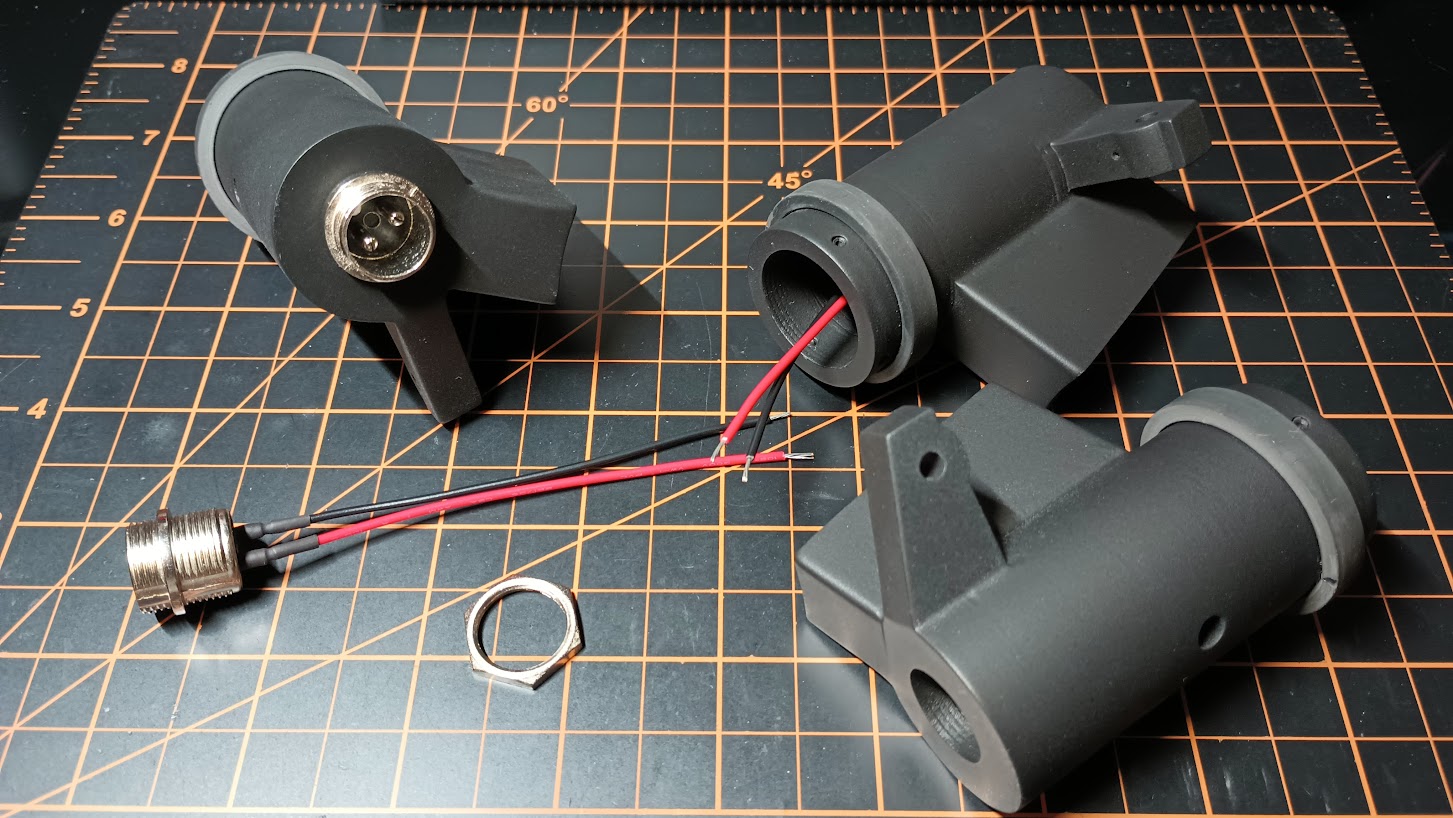

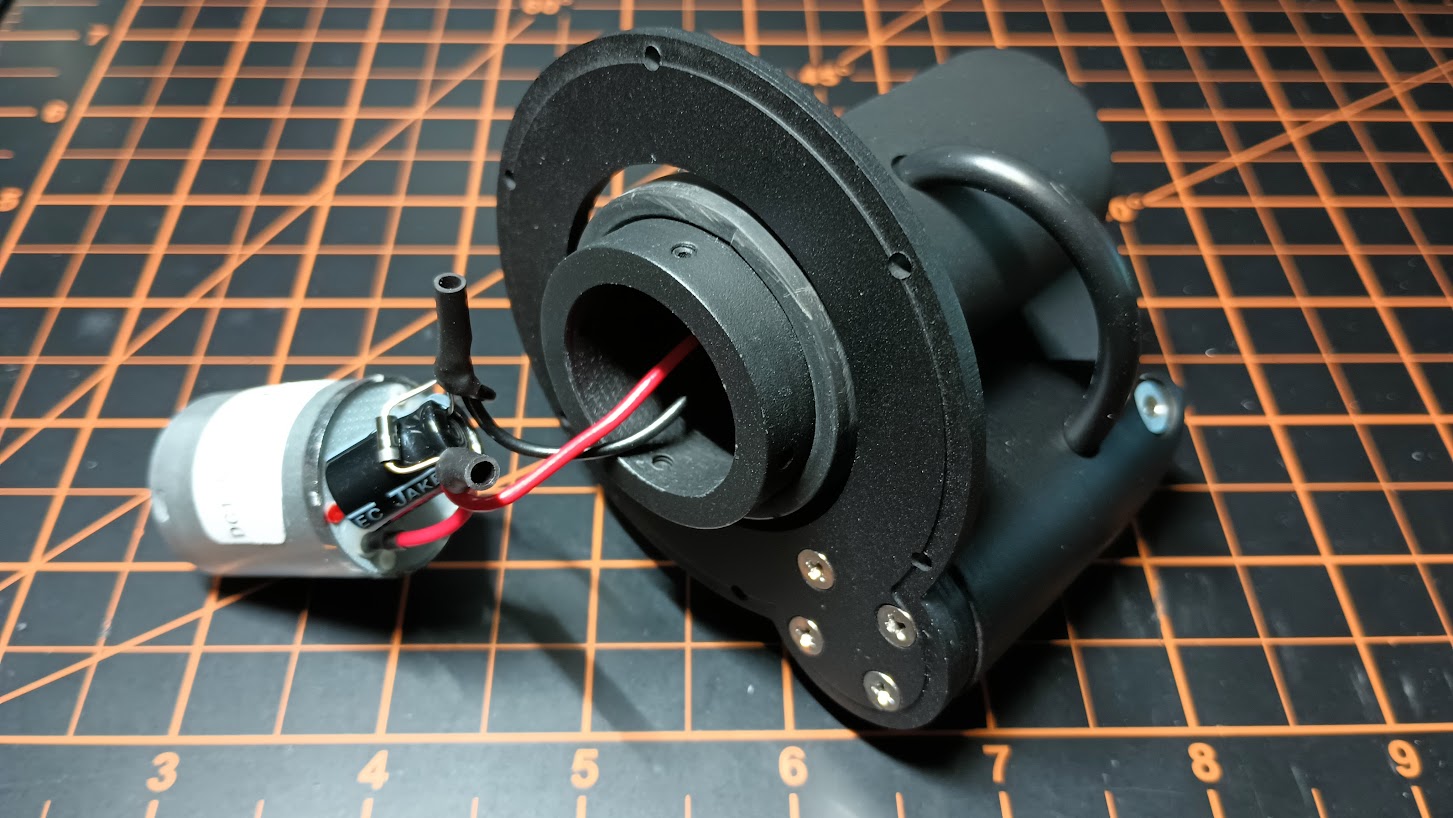

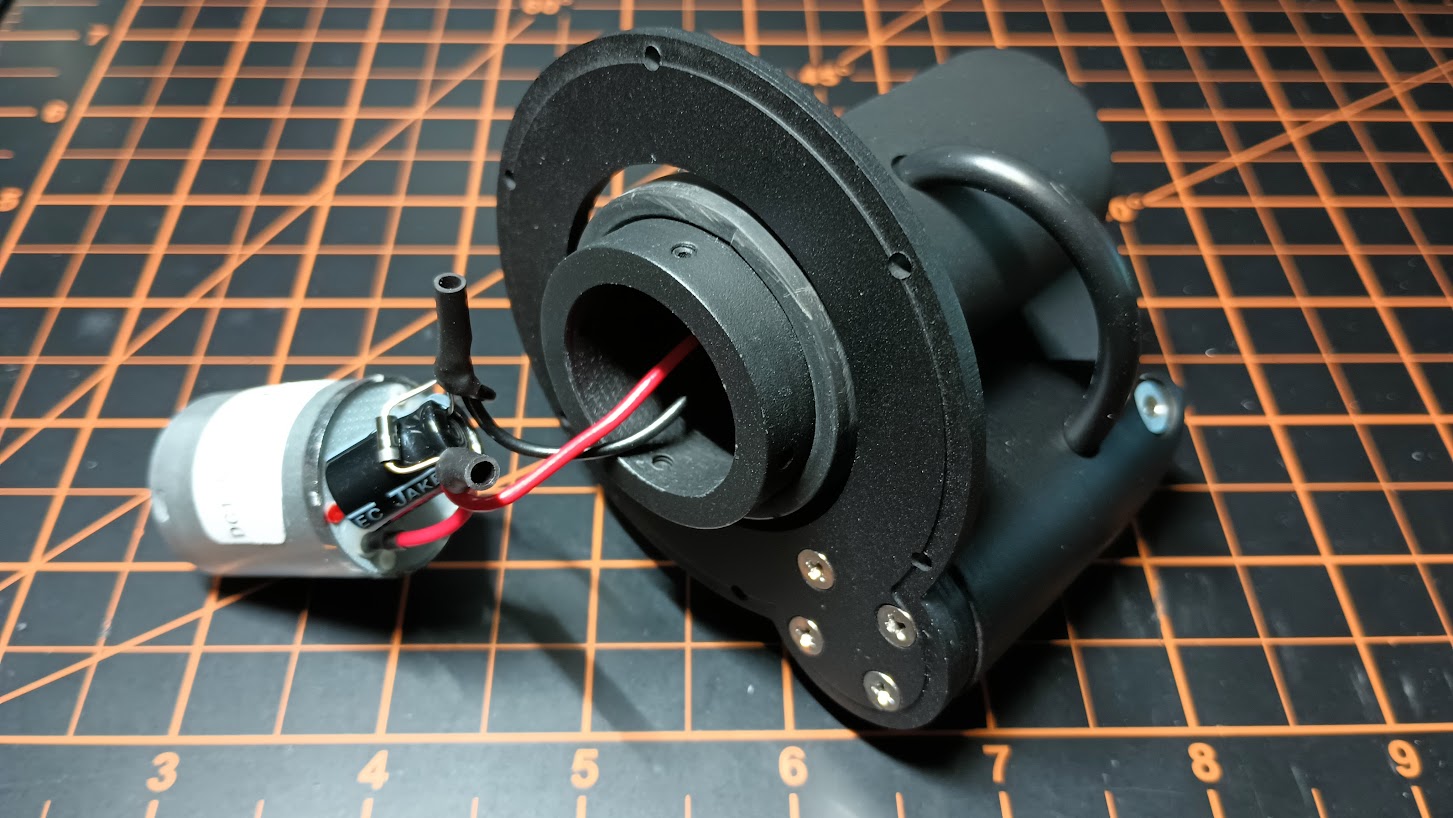

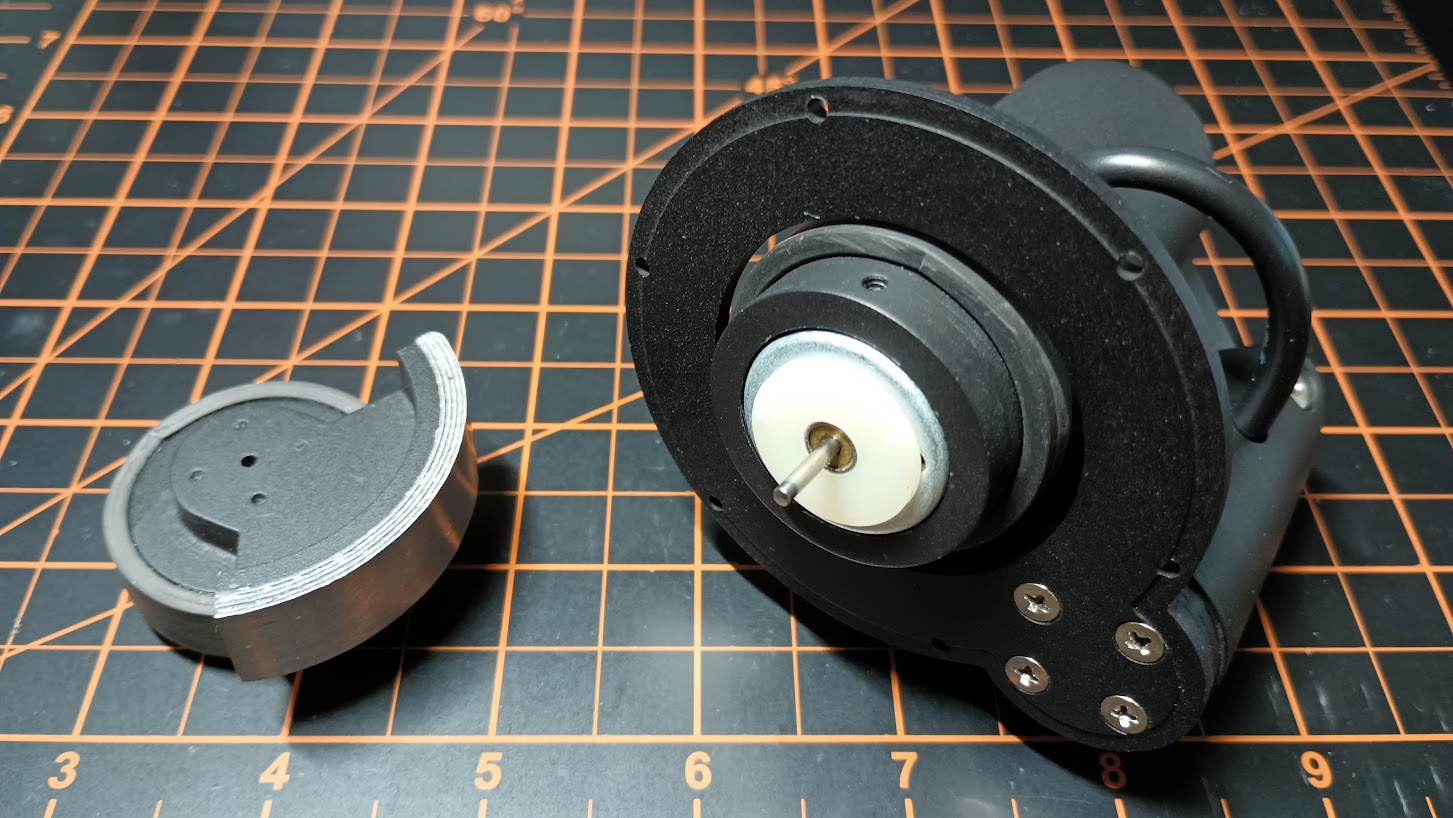

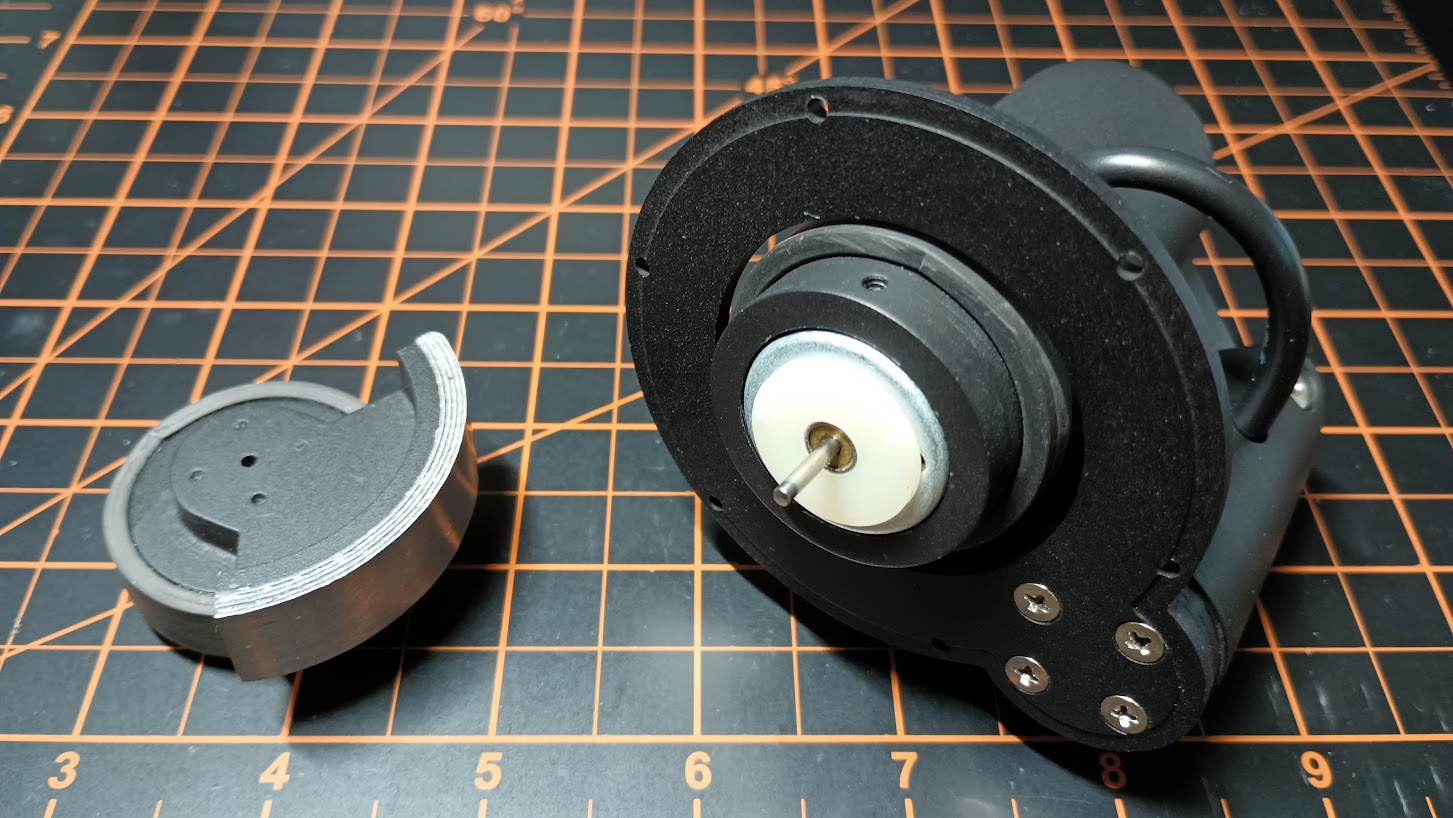

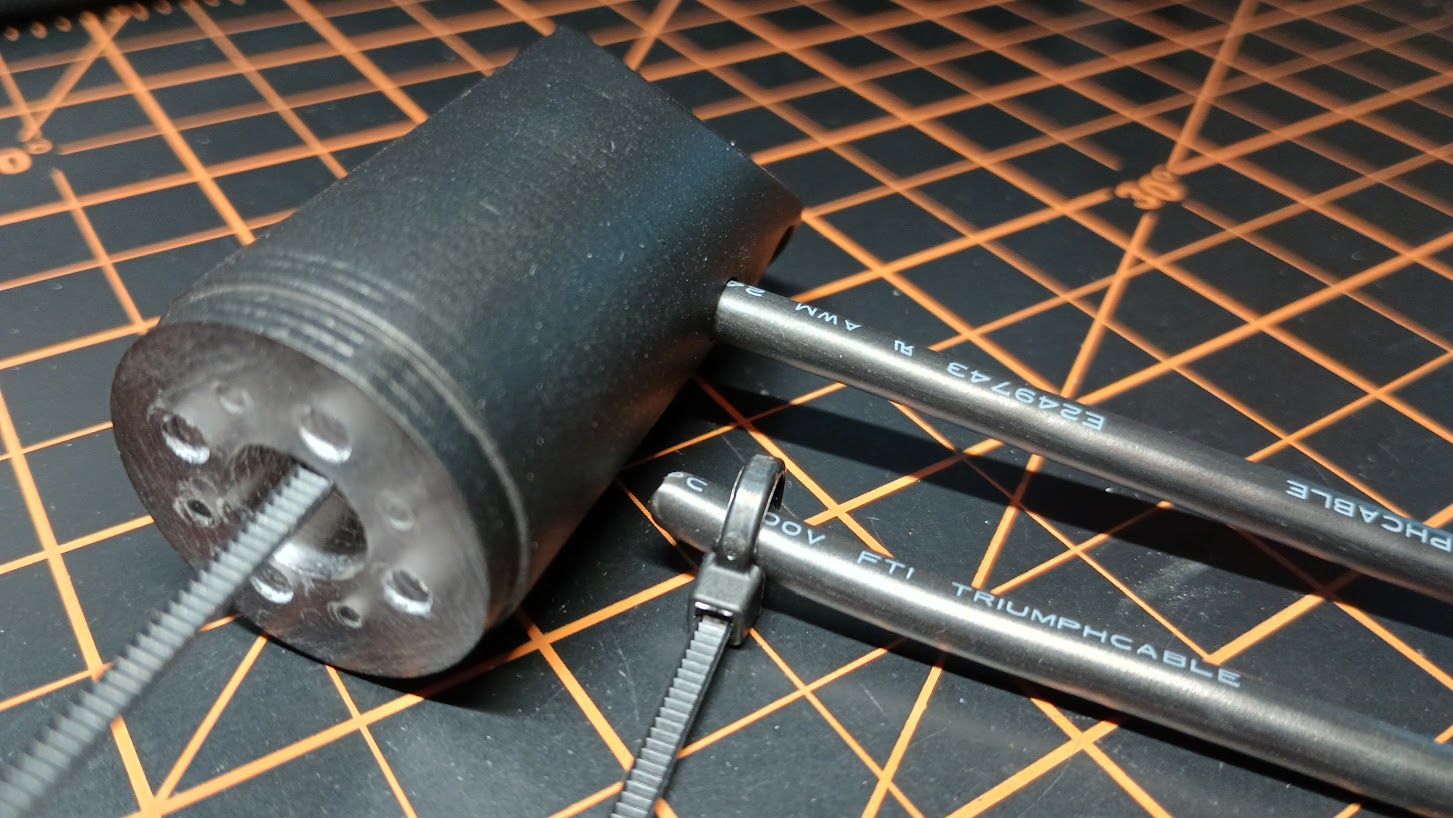

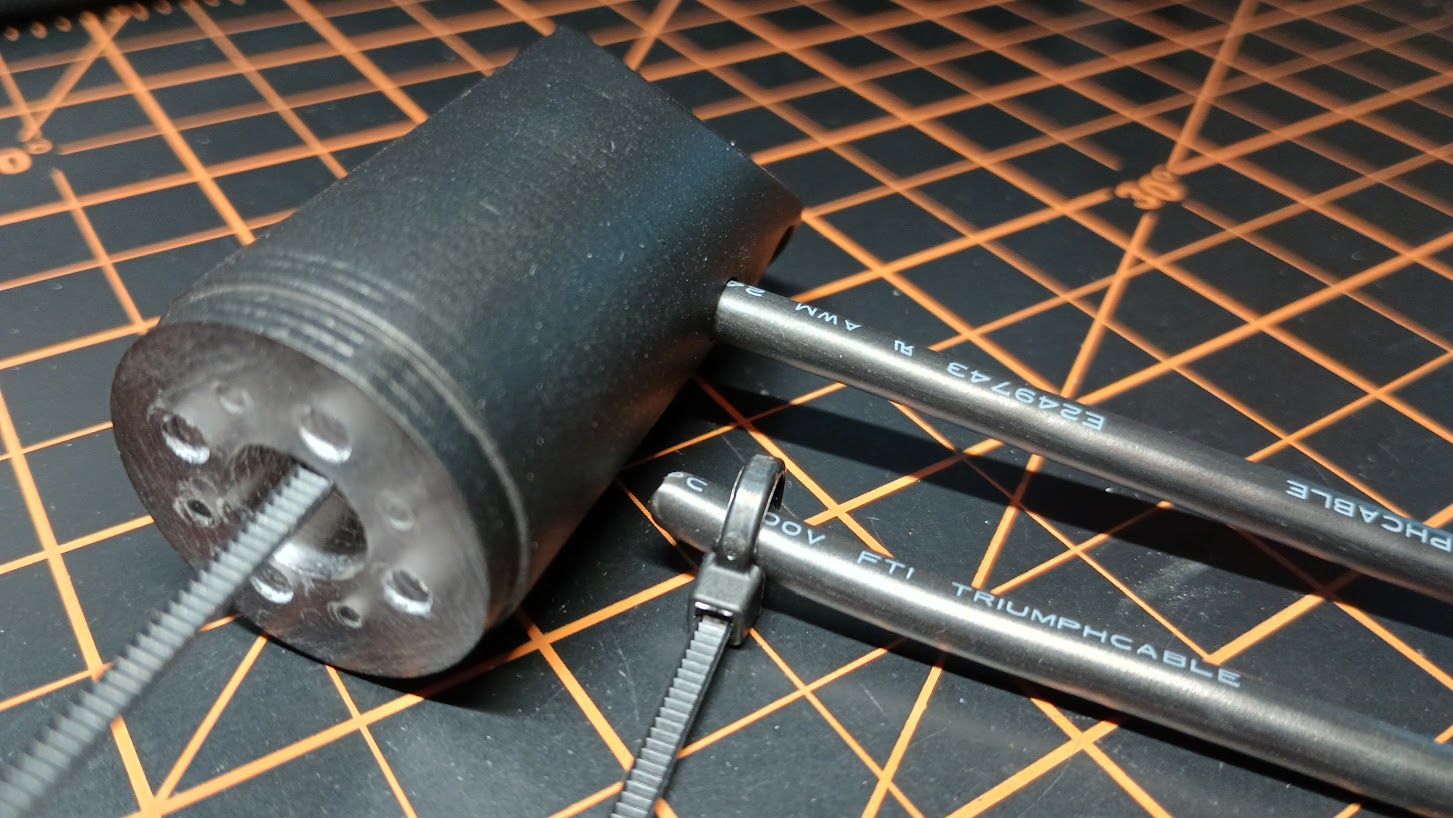

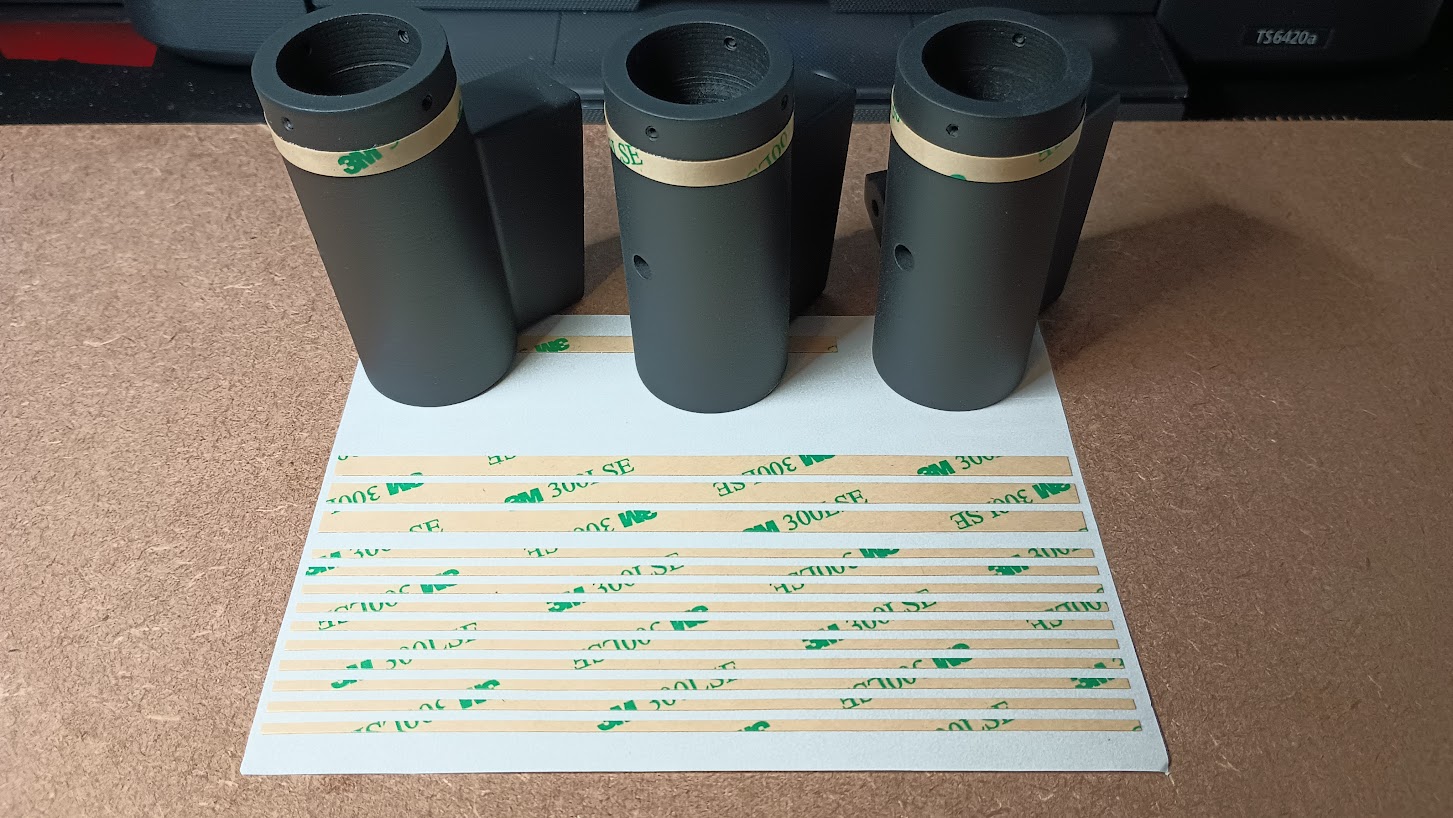

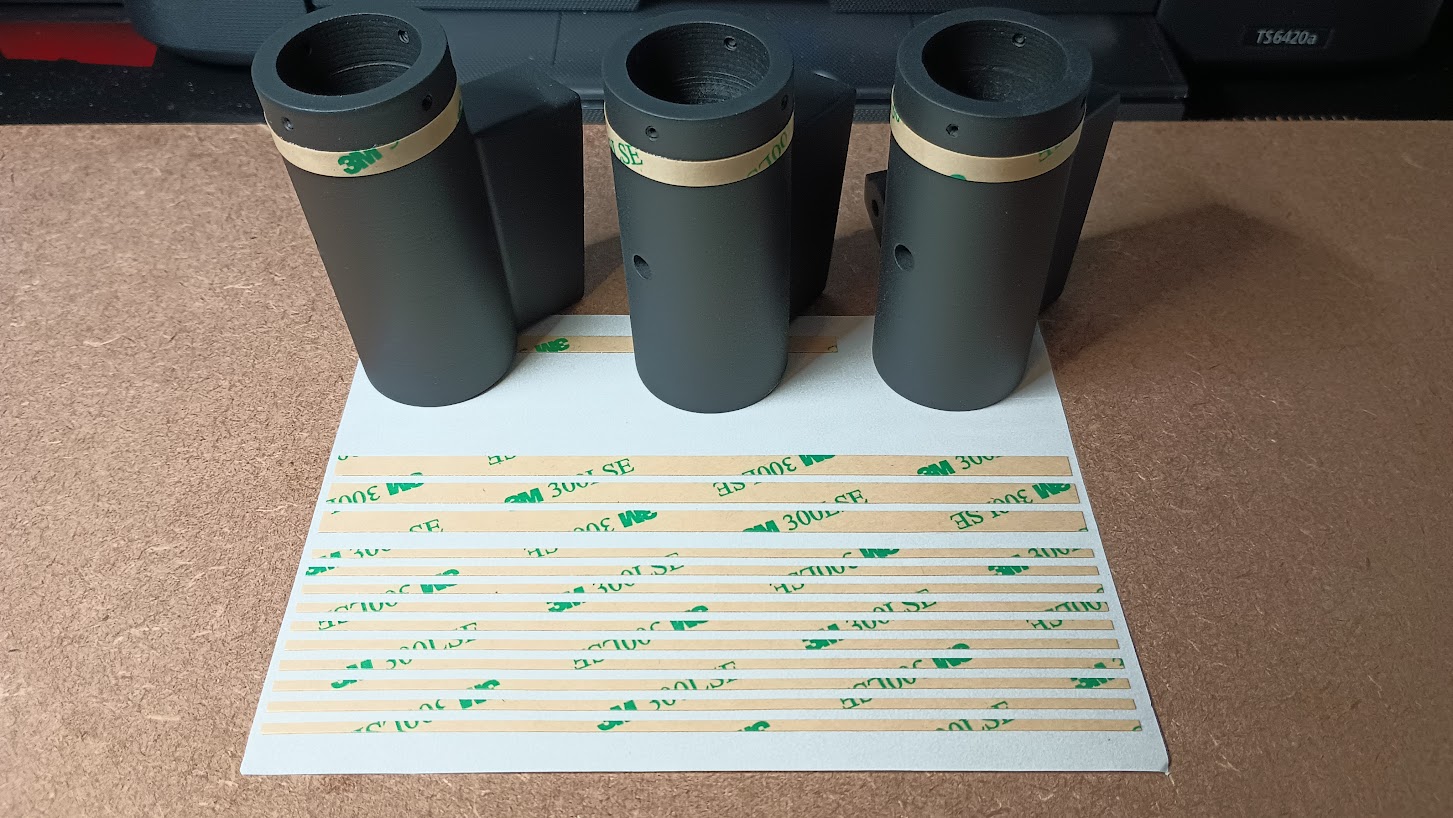

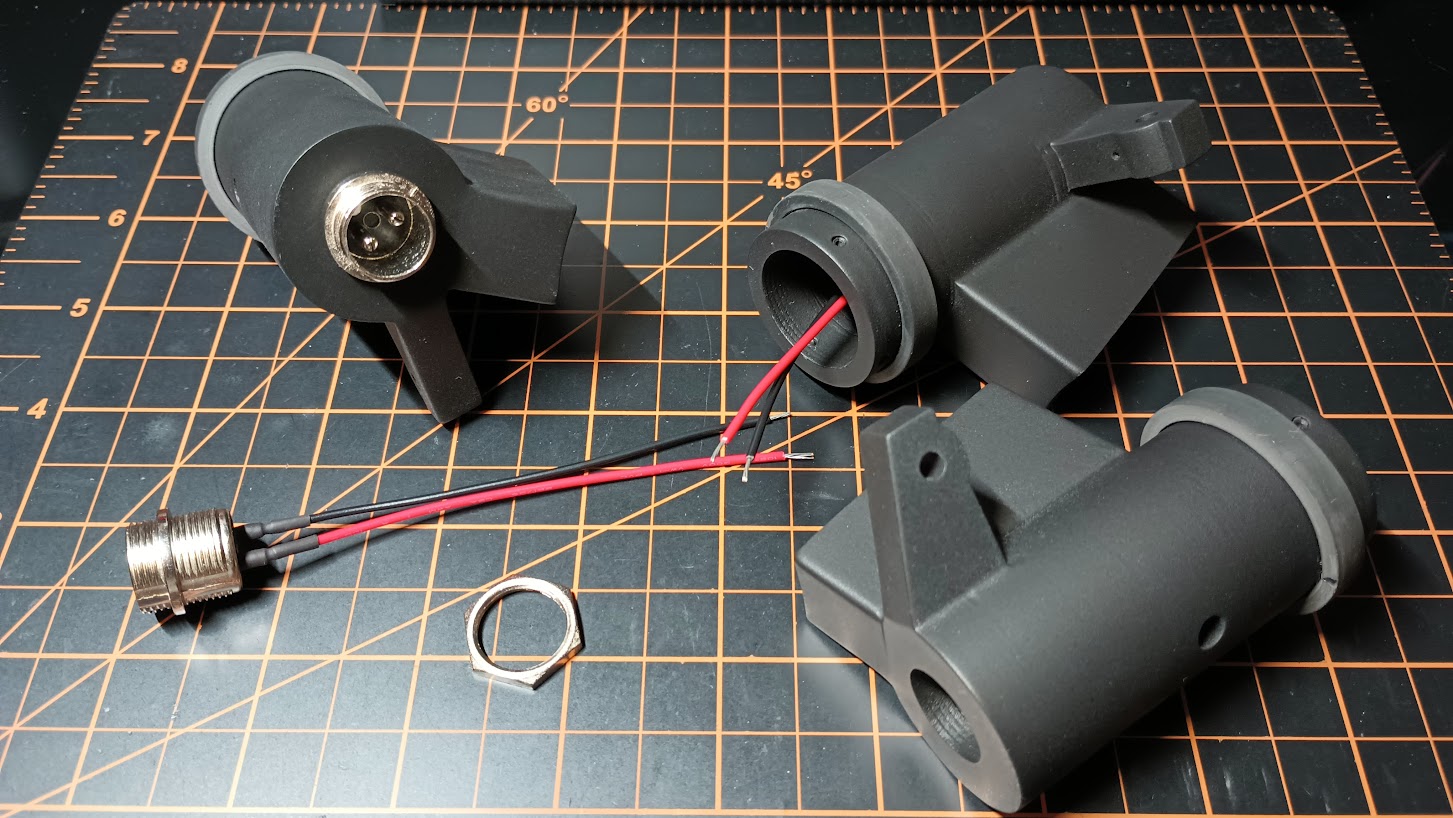

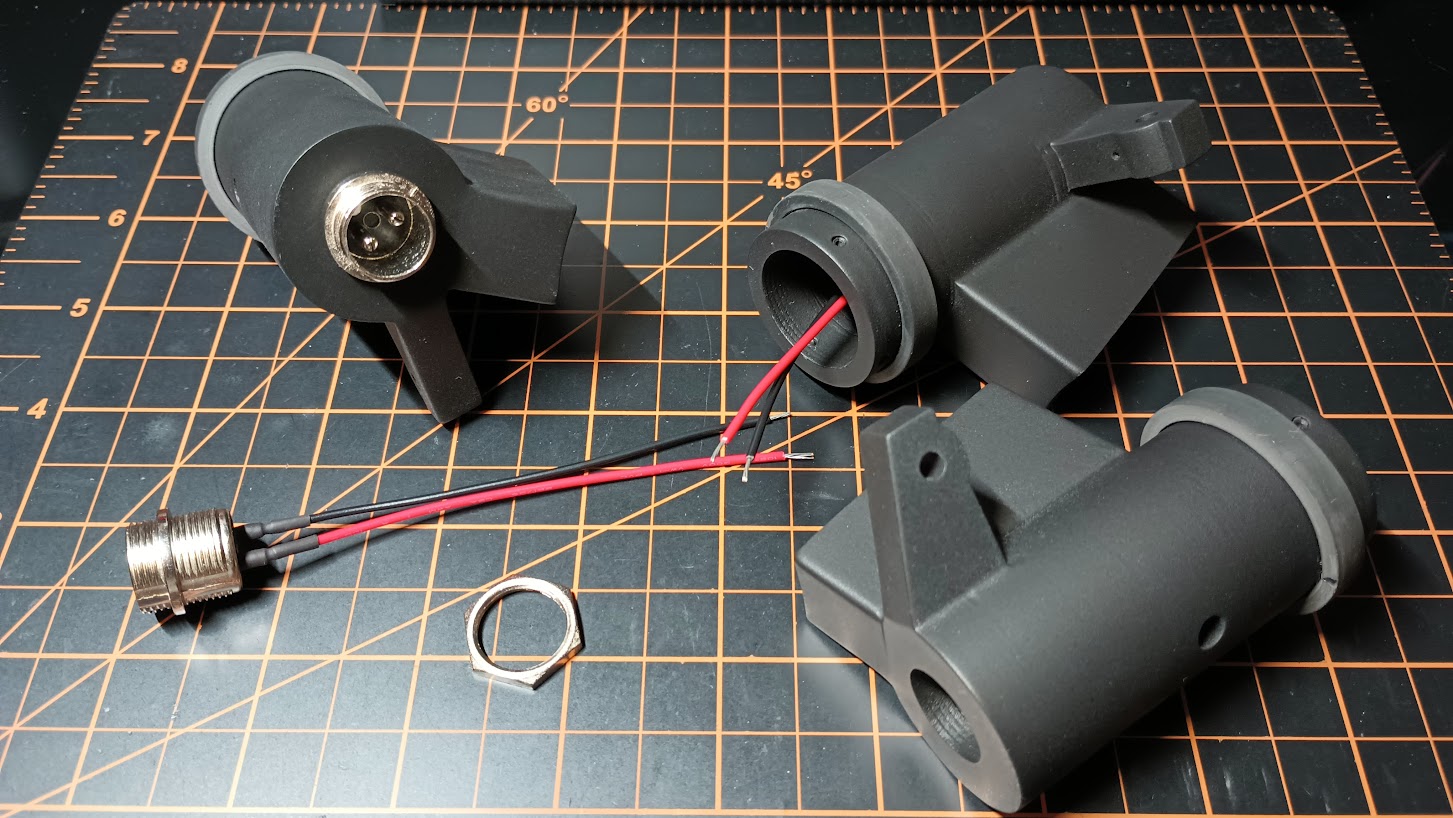

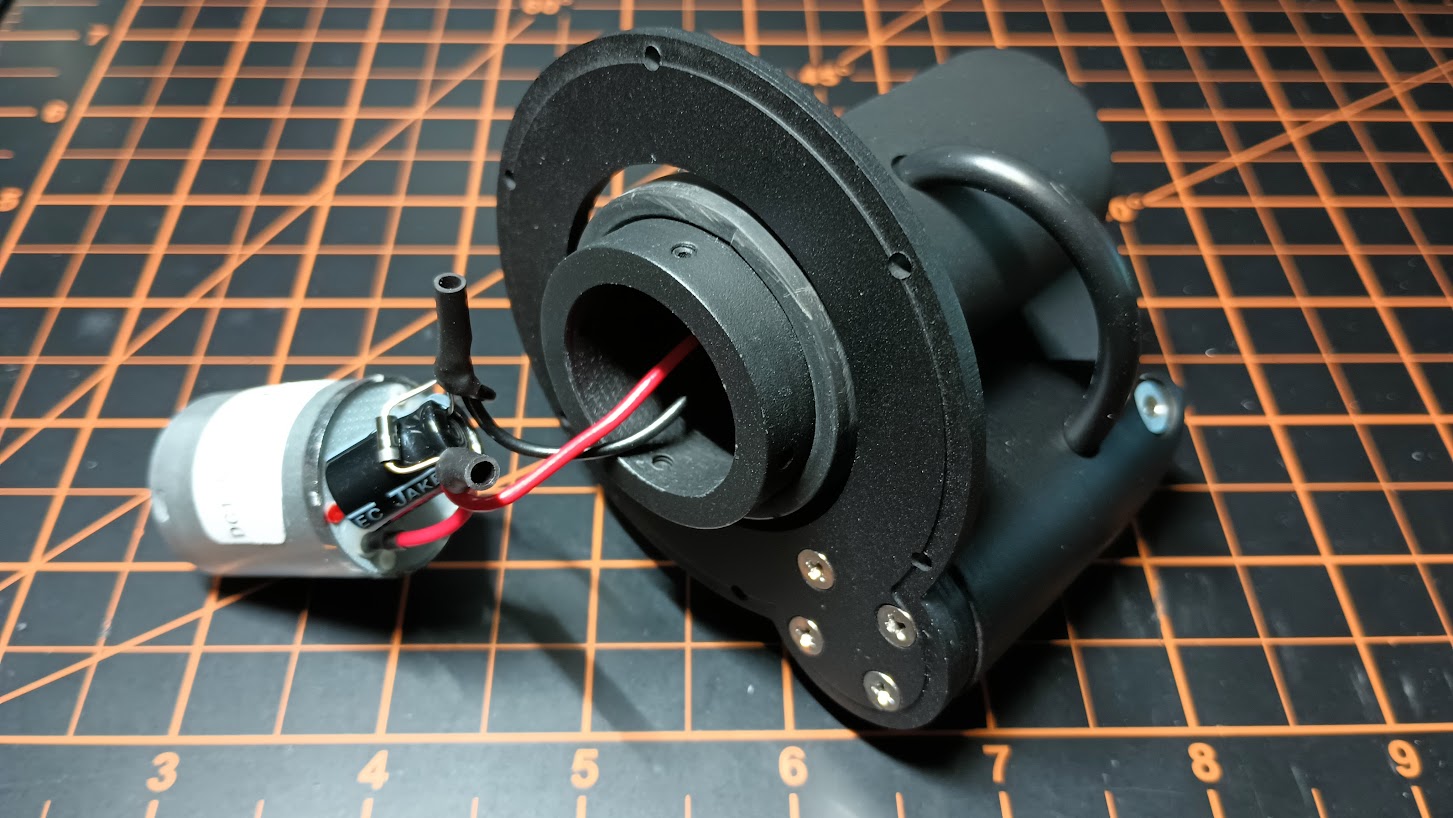

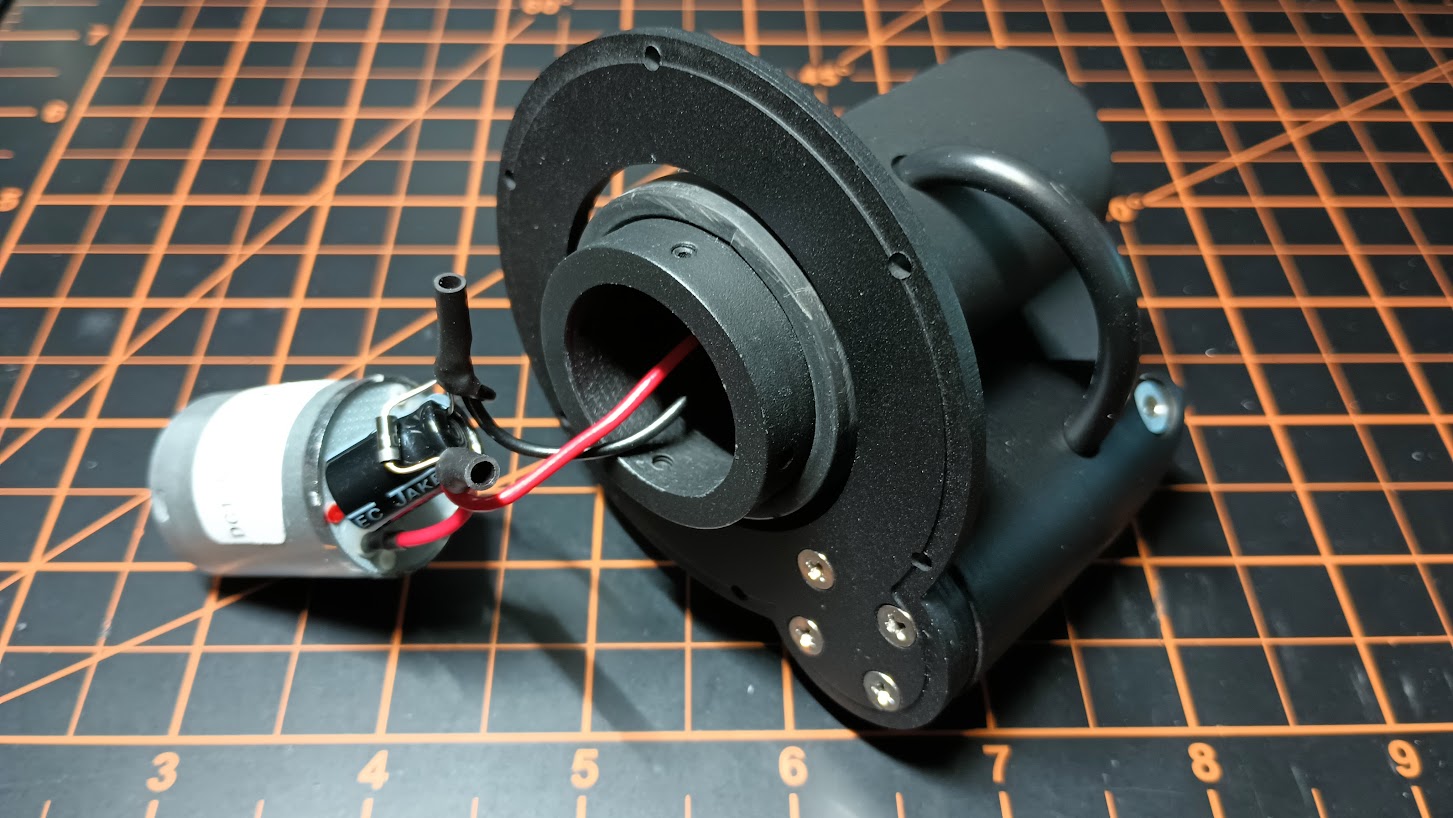

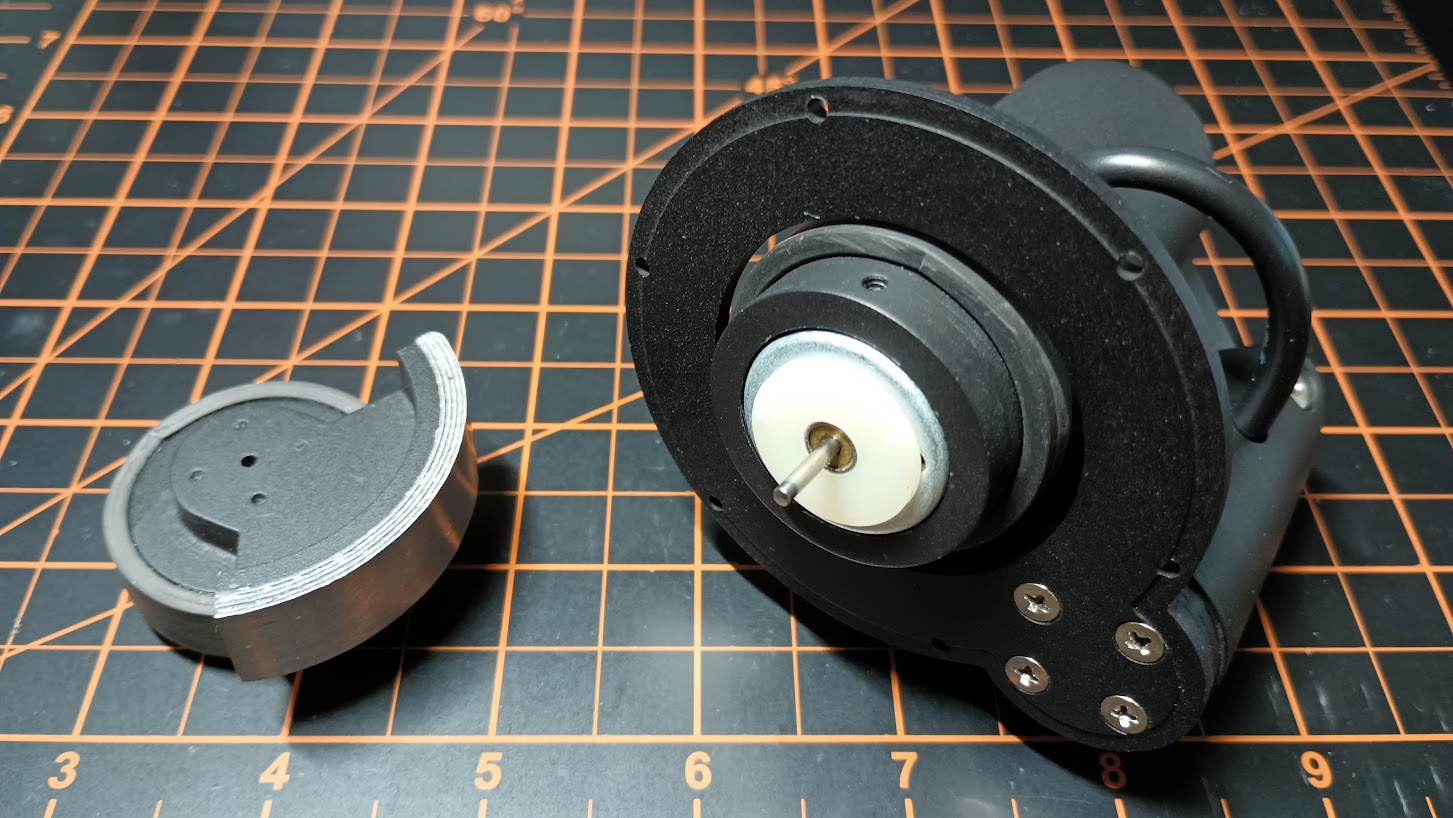

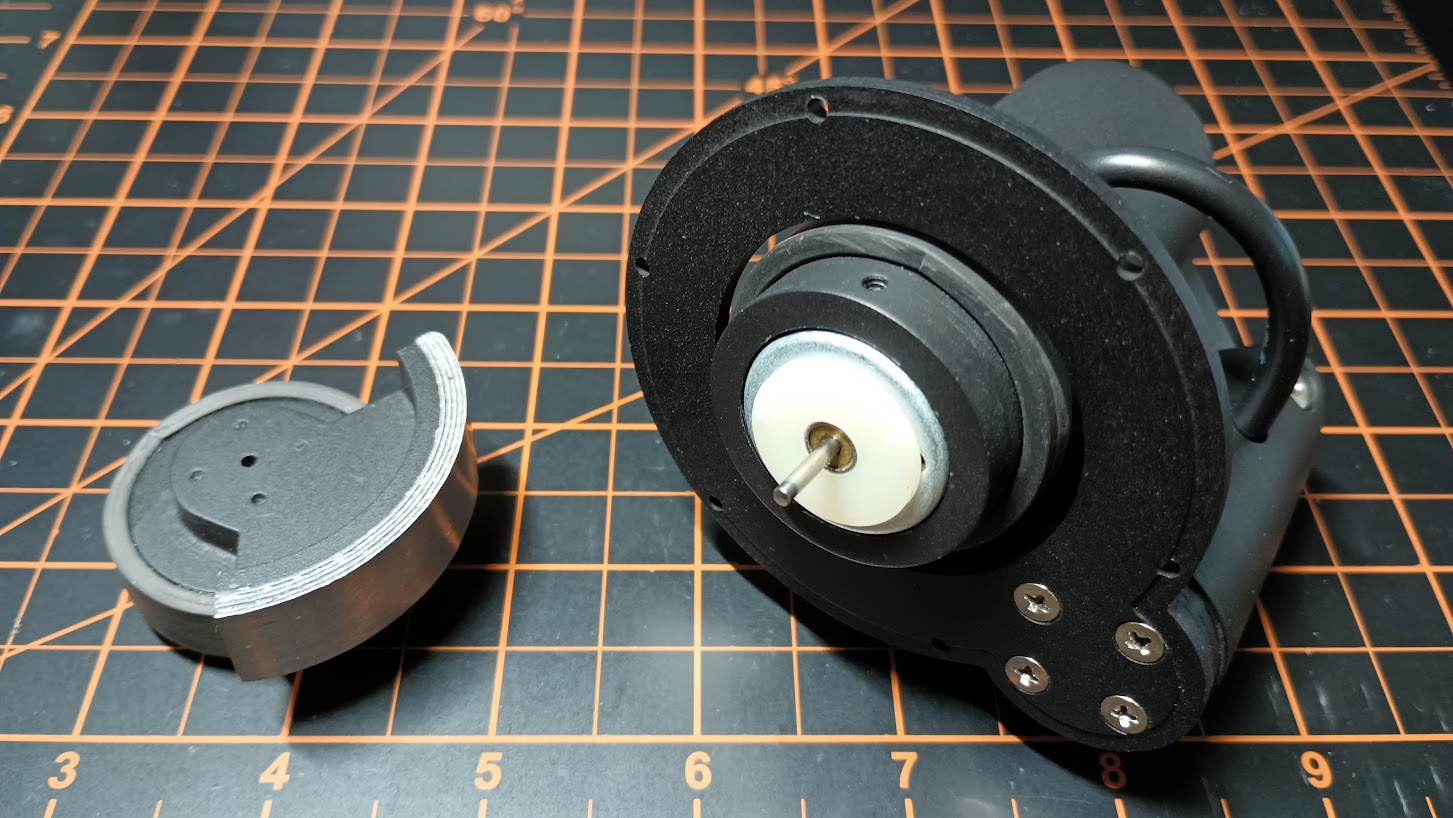

(Original thread started on 10-08-09 by Shane Barnes) What triggers the "stick shaker" in a joystick? I know when I first started FS a few years ago I used a joystick and it would react to stall situations. I know if you look in the cfg file there is something close to the end in the force feedback section and stall warning section. Just don't know how to interface to it. Would this not act like an input such as an LED if we wanted it to light when condition met? Anyone have any knowledge on how to make our stick shakers operate? Here is a wiring diagram example of a set of stick shakers in a sim: FOR ILLUSTRATION PURPOSES ONLY! (Posted by Ron Rollo on 10-08-09) Thanks Shane for starting this thread. The only thing that I am not 100% clear on is how do we interface with MSFS to tell the electric motors when the aircraft is approaching a stall condition and to start shaking. Here is a picture of the copilot's stick shaker in the L45: (Posted by Mark L. on 10-08-09) By watching offset 036C which is the stall warning. Now the question is, is it to late when this offset goes from 0 to 1, or is that when the system alerts that you are about to stall? Testing I guess would prove the outcome. (Posted by DonnyRay Jones on 10-09-09) Monitor the AOA variable. When it crosses a certain threshold which signifies the onset of a stall, spin the stick shaker. This is easy to do externally if you are already driving a real AOA gauge. The real AOA gauge requires a small dc current, which you can monitor with a comparator IC. The comparator output will drive (through the proper circuitry) the motor in the stick shaker. Be aware that this method is not *entirely* aerodynamically correct, but it is pretty easy to implement and is pretty good for the limited amount of modeling that MSFS performs. An AOA system cannot detect the onset of all kinds of stalls, particularly if the aircraft is performing some high-angle or unusual maneuver. But for our purposes here monitoring the AOA variable will cover most cases. A source of motors which may be useful for stick shakers is at: http://www.goldmine-elec-products.com/products.asp?dept=1107 Another source of cheap motors useful for making stick shakers: http://www.allelectronics.com/make-a-store/item/DCM-344/VIBRATOR-MOTOR/1.html These are tiny vibrator motors used in pagers and cell phones, but they are cheeeeeeeeep enough that you can use three of them in a bundle to get more "shaking". Not as powerful as the real deal, but remember, we don't have the same stick forces to contend with in our sims. I'm using three on each control column and they work well for me. Another method of making a larger shaker is to use a simple Adel clamp on the shaft of whatever motor you choose. The Adel clamp has a hole in it which makes it very easy to fasten a weight of your choosing to the shaft. We're talking "Lazy Boy Vibrator Chair" here but if that's what you want that's the easy way to make it. (Posted by Ron Rollo on 05-13-12) I picked up a couple stick shakers on eBay a year ago. They are dated 1961 and came out of a helicopter. They are also 27volt which is common in most aircraft so the challenge will be getting them to work on a 12 volt system and to operate when the aircraft goes into or is approaching a stall condition: (Posted by Eric Tomlin on 05-23-12) Yes, you can get stick shakers to work in FS as there is a Stall Warning offset 036C. Remember, if there's an offset for an item, we can almost always get data out of the sim to activate hardware. Thankfully, there's not a whole lot that we can not get to work in a sim. Some things are useless to some folks, but for the 'core' builder, things like this are great added items. However, don't go getting a call from the virtual FAA about doing unauthorized stall tests in the LJ45. (Posted by Shane Barnes on 05-23-12) I have tried the stick shakers that I have that call for 27vdc with 12v and they do not function with 12v. I plan on getting a 24vdc power supply and seeing if that will work . . according to DonnyRay they should work with 24vdc power supply. I will update once I get the power supply unless someone beats me to it! (Posted by Ron Rollo on 05-23-12) I tested mine and they [b]DO[/b] work with 12 volt power. However, I can tell that it is working with voltage lower than it would like. My stick shakers were built back in the early 60's. They are dated AUG 31 1961. I plan to paint them black and build a bracket for them to attach to the columns. Even with only 12 volts of power, the shack the mess out of themselves! And remember the fact, a normal flight, flying within the envelope, will never trigger the stall system. So unless you wanna show it off to your friends, it is another nice to have but never used feature. But it is cool! (Posted by Eric Tomlin on 05-24-12) Another point- The System Test Panel has a position to test the STALL system and once a certain sequence has been completed, the Stick Shakers will be activated momentarily. So, it will be nice to "test" them and have them move even when not flying if you choose to install them. (Posted by Alan Norris on 05-24-12) Ron, that is interesting that you got yours to work but Shane couldn't. Shane, do you think yours were faulty or maybe a different make? (Posted by Shane Barnes on 05-24-12) Hey Alan, they are not faulty . . they are a different style than Ron's. The ones that I have are out of a Lear 25 or 35. I have had the tops off and the motor moves the weight that is offset to produce the shaking but it is very slow . . 12v is not enough to produce the shake. If I remove the weight then the shaft will rotate at a higher speed . . so it comes down to not enough power to spin the weight. Most likely just a difference in design. I have ordered a 24v power supply so in a few days I should know whether that is the issue. (Posted by Alan Norris on 05-24-12) I've asked the guy selling the stick shakers on eBay to test them to see if they work on 12VDC. Will let you know what he says. Having said that, you can buy 12VDC motors with eccentric weights for about $10 that may do the same job. Ron, any idea what model number yours are so I can ensure I order one that will work on 12v? (Posted by Ron Rollo on 05-30-12) Hey Alan, here is the information you were asking for: Looks like model number 0-71602. I wonder if the others that we have our hands on would work if full 28 volts was applied to them..... (Posted by Shane Barnes on 06-28-12) I have the 27v version and am powering them with 24v. If someone does buy a stick shaker and it does not work try removing the cap that covers the counterweight and try turning the counterweight. One of mine would not operate until I removed the cover and turned the counterweight a couple of times. My thoughts it that the stick shaker had sat for a period of time and some light corrosion had developed on the shaft . . just enough that it would not spin with power applied. (Original thread started on 10-08-09 by Shane Barnes) What triggers the "stick shaker" in a joystick? I know when I first started FS a few years ago I used a joystick and it would react to stall situations. I know if you look in the cfg file there is something close to the end in the force feedback section and stall warning section. Just don't know how to interface to it. Would this not act like an input such as an LED if we wanted it to light when condition met? Anyone have any knowledge on how to make our stick shakers operate? Here is a wiring diagram example of a set of stick shakers in a sim: FOR ILLUSTRATION PURPOSES ONLY! (Posted by Ron Rollo on 10-08-09) Thanks Shane for starting this thread. The only thing that I am not 100% clear on is how do we interface with MSFS to tell the electric motors when the aircraft is approaching a stall condition and to start shaking. Here is a picture of the copilot's stick shaker in the L45: (Posted by Mark L. on 10-08-09) By watching offset 036C which is the stall warning. Now the question is, is it to late when this offset goes from 0 to 1, or is that when the system alerts that you are about to stall? Testing I guess would prove the outcome. (Posted by DonnyRay Jones on 10-09-09) Monitor the AOA variable. When it crosses a certain threshold which signifies the onset of a stall, spin the stick shaker. This is easy to do externally if you are already driving a real AOA gauge. The real AOA gauge requires a small dc current, which you can monitor with a comparator IC. The comparator output will drive (through the proper circuitry) the motor in the stick shaker. Be aware that this method is not *entirely* aerodynamically correct, but it is pretty easy to implement and is pretty good for the limited amount of modeling that MSFS performs. An AOA system cannot detect the onset of all kinds of stalls, particularly if the aircraft is performing some high-angle or unusual maneuver. But for our purposes here monitoring the AOA variable will cover most cases. A source of motors which may be useful for stick shakers is at: http://www.goldmine-elec-products.com/products.asp?dept=1107 Another source of cheap motors useful for making stick shakers: http://www.allelectronics.com/make-a-store/item/DCM-344/VIBRATOR-MOTOR/1.html These are tiny vibrator motors used in pagers and cell phones, but they are cheeeeeeeeep enough that you can use three of them in a bundle to get more "shaking". Not as powerful as the real deal, but remember, we don't have the same stick forces to contend with in our sims. I'm using three on each control column and they work well for me. Another method of making a larger shaker is to use a simple Adel clamp on the shaft of whatever motor you choose. The Adel clamp has a hole in it which makes it very easy to fasten a weight of your choosing to the shaft. We're talking "Lazy Boy Vibrator Chair" here but if that's what you want that's the easy way to make it. (Posted by Ron Rollo on 05-13-12) I picked up a couple stick shakers on eBay a year ago. They are dated 1961 and came out of a helicopter. They are also 27volt which is common in most aircraft so the challenge will be getting them to work on a 12 volt system and to operate when the aircraft goes into or is approaching a stall condition: (Posted by Eric Tomlin on 05-23-12) Yes, you can get stick shakers to work in FS as there is a Stall Warning offset 036C. Remember, if there's an offset for an item, we can almost always get data out of the sim to activate hardware. Thankfully, there's not a whole lot that we can not get to work in a sim. Some things are useless to some folks, but for the 'core' builder, things like this are great added items. However, don't go getting a call from the virtual FAA about doing unauthorized stall tests in the LJ45. (Posted by Shane Barnes on 05-23-12) I have tried the stick shakers that I have that call for 27vdc with 12v and they do not function with 12v. I plan on getting a 24vdc power supply and seeing if that will work . . according to DonnyRay they should work with 24vdc power supply. I will update once I get the power supply unless someone beats me to it! (Posted by Ron Rollo on 05-23-12) I tested mine and they [b]DO[/b] work with 12 volt power. However, I can tell that it is working with voltage lower than it would like. My stick shakers were built back in the early 60's. They are dated AUG 31 1961. I plan to paint them black and build a bracket for them to attach to the columns. Even with only 12 volts of power, the shack the mess out of themselves! And remember the fact, a normal flight, flying within the envelope, will never trigger the stall system. So unless you wanna show it off to your friends, it is another nice to have but never used feature. But it is cool! (Posted by Eric Tomlin on 05-24-12) Another point- The System Test Panel has a position to test the STALL system and once a certain sequence has been completed, the Stick Shakers will be activated momentarily. So, it will be nice to "test" them and have them move even when not flying if you choose to install them. (Posted by Alan Norris on 05-24-12) Ron, that is interesting that you got yours to work but Shane couldn't. Shane, do you think yours were faulty or maybe a different make? (Posted by Shane Barnes on 05-24-12) Hey Alan, they are not faulty . . they are a different style than Ron's. The ones that I have are out of a Lear 25 or 35. I have had the tops off and the motor moves the weight that is offset to produce the shaking but it is very slow . . 12v is not enough to produce the shake. If I remove the weight then the shaft will rotate at a higher speed . . so it comes down to not enough power to spin the weight. Most likely just a difference in design. I have ordered a 24v power supply so in a few days I should know whether that is the issue. (Posted by Alan Norris on 05-24-12) I've asked the guy selling the stick shakers on eBay to test them to see if they work on 12VDC. Will let you know what he says. Having said that, you can buy 12VDC motors with eccentric weights for about $10 that may do the same job. Ron, any idea what model number yours are so I can ensure I order one that will work on 12v? (Posted by Ron Rollo on 05-30-12) Hey Alan, here is the information you were asking for: Looks like model number 0-71602. I wonder if the others that we have our hands on would work if full 28 volts was applied to them..... (Posted by Shane Barnes on 06-28-12) I have the 27v version and am powering them with 24v. If someone does buy a stick shaker and it does not work try removing the cap that covers the counterweight and try turning the counterweight. One of mine would not operate until I removed the cover and turned the counterweight a couple of times. My thoughts it that the stick shaker had sat for a period of time and some light corrosion had developed on the shaft . . just enough that it would not spin with power applied. Hey guys, It has been a while since any of us have talked about the Stick Shakers. In our early days, the quick solution was to pick up a pair of REAL stick shakers and simply install them in our projects. However, there are a couple problems with this solution: If you can find a set that meets all these requirements, congratulations, you would be the first! The real matching set that I was able to obtain several years ago "look" close to what you would find in the Lear45 and were a couple hundred dollars. The problem is they operate on 27.5v. We are building our sims to operate on a 12v system. In order to use these stick shakers, you would have two options: As an example, I opted to run my real set on 12v power and let them run sluggishly while Shane opted to run his set off of a 24v power supply. Neither solution was 100%. This is our dilemma in a nut shell, not to mention the EMI issues stick shakers can cause. So maybe the solution is to develop replica stick shakers? First, we have to know what we are modeling. Here are a couple photos of the real deal in the Lear45. Believe it or not, these are the best photos we have of the stick shakers in the Lear45. Thankfully, DonnyRay was able to supply me with a drawing with a few basic dimensions. This in conjunction with the real set I have on hand was more than enough information to put together a decent plan and drawing. Jason is credited for getting me started on this project! He asked me to take one of mine apart to see how it operates. It is actually a pretty cool design. An electric motor is mounted on the side of the axial shaft and spins a gear in the top ring. On this ring a heavy weight is mounted on one side which makes the ring wobble out of balance. When the stick shaker is activated, the motor spins the gear in the top ring with the weight mounted to it causing an imbalance. By design, the stick shaker acts as if it is coming apart, shaking and make a heck of a racket....and that's the idea after all, to get the pilot's attention. These photos will help illustrate how they are designed and work. Again, these are 27.5v shakers. Another quick thought, these devices go by a couple different names: This is good information to know if you are doing a www search for them. Now that you have a good idea of WHAT we are trying to model, the next question is HOW to model them. As you know, the real units are made of metal and most of us are limited in tools, especially metal fabricating tools. Therefore, I opted to make this version of replica stick shakers using "stacked" cast plastic via the cnc machine. However, this could potentially be a good project to take on with a 3D printer. But even if I had a 3D printer, I might still opt to use the cnc because if there was ever a project that needs to be as solid as possible, it's the Stick Shakers. In other words, it might be faster and result in a stronger bond to cut cast plastic and stack it up rather than build up a single piece via a 3D printer with a spool of plastic filament. If using a 3D printer, I would not recommend taking shortcuts and making hollow areas in the design to save time. Another area that I opted to do differently was to move the 12v motor to the center axial shaft and turn the top third of the center axial shaft into an offset spinner that looks like the real thing. In other words, this design will look like the real thing and operate on 12v. Based on early testing of this design, it will also sound like the real thing and shake around so much that it will be hard to tell that it's not the ring doing the shaking! I also had to change the way the stick shakers mount to the control columns, but they will look the same as the real thing. Basically, because I am building them using cast plastic, I have the ability to group the center axial shaft and the mounting bracket together in one piece of plastic. This will actually make the stick shakers stronger and easier to build. And that brings us to today....... Today I just finished cutting out all the pieces to complete three sets of stick shakers. Most of the parts needed are pictured here. In all, there will be no less than 110 parts in each unit believe it or not. Now for the fun part......assembly. As I proceed forward, I will include photos in a tutorial so that anyone can take on this project as long as you have a cnc machine. Also feel free to take the attached dxf and convert it to make 3D files to be cut with a 3D printer. This would be interesting to see. If this works as well as I expect it will, this solves the problems pointed out at the top of this post. I will have an update on this project shortly! Hey guys, It has been a while since any of us have talked about the Stick Shakers. In our early days, the quick solution was to pick up a pair of REAL stick shakers and simply install them in our projects. However, there are a couple problems with this solution: If you can find a set that meets all these requirements, congratulations, you would be the first! The real matching set that I was able to obtain several years ago "look" close to what you would find in the Lear45 and were a couple hundred dollars. The problem is they operate on 27.5v. We are building our sims to operate on a 12v system. In order to use these stick shakers, you would have two options: As an example, I opted to run my real set on 12v power and let them run sluggishly while Shane opted to run his set off of a 24v power supply. Neither solution was 100%. This is our dilemma in a nut shell, not to mention the EMI issues stick shakers can cause. So maybe the solution is to develop replica stick shakers? First, we have to know what we are modeling. Here are a couple photos of the real deal in the Lear45. Believe it or not, these are the best photos we have of the stick shakers in the Lear45. Thankfully, DonnyRay was able to supply me with a drawing with a few basic dimensions. This in conjunction with the real set I have on hand was more than enough information to put together a decent plan and drawing. Jason is credited for getting me started on this project! He asked me to take one of mine apart to see how it operates. It is actually a pretty cool design. An electric motor is mounted on the side of the axial shaft and spins a gear in the top ring. On this ring a heavy weight is mounted on one side which makes the ring wobble out of balance. When the stick shaker is activated, the motor spins the gear in the top ring with the weight mounted to it causing an imbalance. By design, the stick shaker acts as if it is coming apart, shaking and make a heck of a racket....and that's the idea after all, to get the pilot's attention. These photos will help illustrate how they are designed and work. Again, these are 27.5v shakers. Another quick thought, these devices go by a couple different names: This is good information to know if you are doing a www search for them. Now that you have a good idea of WHAT we are trying to model, the next question is HOW to model them. As you know, the real units are made of metal and most of us are limited in tools, especially metal fabricating tools. Therefore, I opted to make this version of replica stick shakers using "stacked" cast plastic via the cnc machine. However, this could potentially be a good project to take on with a 3D printer. But even if I had a 3D printer, I might still opt to use the cnc because if there was ever a project that needs to be as solid as possible, it's the Stick Shakers. In other words, it might be faster and result in a stronger bond to cut cast plastic and stack it up rather than build up a single piece via a 3D printer with a spool of plastic filament. If using a 3D printer, I would not recommend taking shortcuts and making hollow areas in the design to save time. Another area that I opted to do differently was to move the 12v motor to the center axial shaft and turn the top third of the center axial shaft into an offset spinner that looks like the real thing. In other words, this design will look like the real thing and operate on 12v. Based on early testing of this design, it will also sound like the real thing and shake around so much that it will be hard to tell that it's not the ring doing the shaking! I also had to change the way the stick shakers mount to the control columns, but they will look the same as the real thing. Basically, because I am building them using cast plastic, I have the ability to group the center axial shaft and the mounting bracket together in one piece of plastic. This will actually make the stick shakers stronger and easier to build. And that brings us to today....... Today I just finished cutting out all the pieces to complete three sets of stick shakers. Most of the parts needed are pictured here. In all, there will be no less than 110 parts in each unit believe it or not. Now for the fun part......assembly. As I proceed forward, I will include photos in a tutorial so that anyone can take on this project as long as you have a cnc machine. Also feel free to take the attached dxf and convert it to make 3D files to be cut with a 3D printer. This would be interesting to see. If this works as well as I expect it will, this solves the problems pointed out at the top of this post. I will have an update on this project shortly! Hey guys, I've been busy working on the stick shakers! This past week it has been all about building up the main pieces from a bunch of smaller pieces. This is one of the only projects that I have taken on that is more three dimensional than flat, as an example the backlit panels. Therefor, I have had to come up with new procedures (new to me anyway) and methods to achieve my goals. As I mentioned in the previous post, I opted to move forward with making these parts with the CNC machine to take advantage of the heavier and stronger cast plastic. Most of the pieces that make up larger parts are made of .5" clear cast plastic. The dense cast plastic when bonded properly will result in stronger and heavier parts. I designed all the larger parts to include "rebar"..........actually 1/16" steel rods. This helps greatly with the alignment process during bonding and adds incredible strength. As you know, when using "Super Glue", it sets within a couple seconds so when you put the two pieces together, make sure they are exactly where you want them because rarely will you get them apart without causing damage. I started off with the easier and smaller parts first. This first piece is what I call the top spinner. It mounts to the 12v motor shaft and spins at 6,000 RPM. Actually, once the strip weights are added, the RPMs will drop slightly. (Keep in mind this is not how the real stack shakers are designed. This is a unique way to achieve our goals while looking the part!) This next piece is what I call the Top Arm Trim. The design calls for this piece to be .75" thick and I don't have easy access to .75" thick plastic, let alone the endmill bits to cut plastic that deep. So the work around solution is to bond two .35" pieces together. Here is the Ring Cap assembly where there are three pieces to this part. Notice the steel rods that help with alignment and strength. Next is the Axial Shaker stack. This piece is made up of eight parts in total, not including the steel rods. During the CNC process, I took the time to measure the thickness of all the parts. My concern was that being there are eight parts making up the final piece, my luck is I would have all the thicker parts stacked together to make up one piece and all the thinner parts stacked up to make up another piece. Hundredths of an inch here or there in this case is not a big deal but add them up and then we would be talking 16ths of an inch here or there! This process insures all assembled parts are within a hundredth of an inch of one another. In other words, the Cpt side parts won't be noticeably different in size compared to the FO side parts. The steel rods work great to help keep things lined up properly during the bonding process! Once the Axial Shaker stack is built up, there is one last step that needs to be completed. I made marking jigs to properly mark where some of the material still needs to be removed from the brackets that branch out off the sides to create their final shape. Later on in this tutorial I will cover the trimming and shaving processes. This next set of parts make up the Side Arm. The same process of using the steel rods is used here as the previous parts, everything lines up perfectly. Sanding, filling and paint will be much easier. "You gotta have some skin in the game!" If you have any experience using "Super Glue", you know how fast it sets and how easy it is to glue your fingers to your work. And with all the bonding needed to be done working with these six sets of stick shaker parts, I don't have enough skin on my fingers! The solution here is to protect the tips of your fingers with a little painters tape. I have had my fingers wrapped for the whole bonding process and so far, so good! I opted to use painter tape on my fingertips over Latex gloves because in my experience, once you get a little glue on the gloves, they rip open. The painters tape allowed me to get through a complete set of parts without needing to replace them. Another important step is tapping out the screw holes. Most of the screw holes are 4-40 size. The screw holes in the Ring Cap are 2-56. Tapping into plastic is fairly easy with a hand tap tool and as long as your starter holes are the correct size, there will be no issues. Here I am about half way through the process of tapping the Side Arm holes. This is another one of those areas where I am insuring that all the final parts are within a hundredth of an inch of one another in an effort to avoid issues later on. This process takes a few extra minutes to sort out but well worth the time. And this is the last set of pieces that require bonding. Because I have an aluminum bracket built into the design to add strength to the bottom end of the Side Arms, I did not need to run the steel rods down into this piece. Two screws will hold the aluminum bracket in place and screw up into both bonded pieces. However, I still needed a way to insure alignment of the two pieces being bonded. In this case, I used the shaft ends of two 7/64" drill bits. Here is a complete set of parts that will help make up one unit. And just to show the full scope of the project I have on my hands, here is a photo of all the parts for six units. (three sets) It's a lot of work but I am very excited seeing how well they are all coming along! At this point, 90% of the "dirty work" is complete. Cutting out the parts with the CNC machine, bonding all the parts together and rough sanding to insure the parts are lined up properly. The next steps coming up will be making the aluminum bottom brackets, column mounting plates, shaving the Axial Shaker pieces and a few other odds and ends. Another update shortly! Hey guys, I've been busy working on the stick shakers! This past week it has been all about building up the main pieces from a bunch of smaller pieces. This is one of the only projects that I have taken on that is more three dimensional than flat, as an example the backlit panels. Therefor, I have had to come up with new procedures (new to me anyway) and methods to achieve my goals. As I mentioned in the previous post, I opted to move forward with making these parts with the CNC machine to take advantage of the heavier and stronger cast plastic. Most of the pieces that make up larger parts are made of .5" clear cast plastic. The dense cast plastic when bonded properly will result in stronger and heavier parts. I designed all the larger parts to include "rebar"..........actually 1/16" steel rods. This helps greatly with the alignment process during bonding and adds incredible strength. As you know, when using "Super Glue", it sets within a couple seconds so when you put the two pieces together, make sure they are exactly where you want them because rarely will you get them apart without causing damage. I started off with the easier and smaller parts first. This first piece is what I call the top spinner. It mounts to the 12v motor shaft and spins at 6,000 RPM. Actually, once the strip weights are added, the RPMs will drop slightly. (Keep in mind this is not how the real stack shakers are designed. This is a unique way to achieve our goals while looking the part!) This next piece is what I call the Top Arm Trim. The design calls for this piece to be .75" thick and I don't have easy access to .75" thick plastic, let alone the endmill bits to cut plastic that deep. So the work around solution is to bond two .35" pieces together. Here is the Ring Cap assembly where there are three pieces to this part. Notice the steel rods that help with alignment and strength. Next is the Axial Shaker stack. This piece is made up of eight parts in total, not including the steel rods. During the CNC process, I took the time to measure the thickness of all the parts. My concern was that being there are eight parts making up the final piece, my luck is I would have all the thicker parts stacked together to make up one piece and all the thinner parts stacked up to make up another piece. Hundredths of an inch here or there in this case is not a big deal but add them up and then we would be talking 16ths of an inch here or there! This process insures all assembled parts are within a hundredth of an inch of one another. In other words, the Cpt side parts won't be noticeably different in size compared to the FO side parts. The steel rods work great to help keep things lined up properly during the bonding process! Once the Axial Shaker stack is built up, there is one last step that needs to be completed. I made marking jigs to properly mark where some of the material still needs to be removed from the brackets that branch out off the sides to create their final shape. Later on in this tutorial I will cover the trimming and shaving processes. This next set of parts make up the Side Arm. The same process of using the steel rods is used here as the previous parts, everything lines up perfectly. Sanding, filling and paint will be much easier. "You gotta have some skin in the game!" If you have any experience using "Super Glue", you know how fast it sets and how easy it is to glue your fingers to your work. And with all the bonding needed to be done working with these six sets of stick shaker parts, I don't have enough skin on my fingers! The solution here is to protect the tips of your fingers with a little painters tape. I have had my fingers wrapped for the whole bonding process and so far, so good! I opted to use painter tape on my fingertips over Latex gloves because in my experience, once you get a little glue on the gloves, they rip open. The painters tape allowed me to get through a complete set of parts without needing to replace them. Another important step is tapping out the screw holes. Most of the screw holes are 4-40 size. The screw holes in the Ring Cap are 2-56. Tapping into plastic is fairly easy with a hand tap tool and as long as your starter holes are the correct size, there will be no issues. Here I am about half way through the process of tapping the Side Arm holes. This is another one of those areas where I am insuring that all the final parts are within a hundredth of an inch of one another in an effort to avoid issues later on. This process takes a few extra minutes to sort out but well worth the time. And this is the last set of pieces that require bonding. Because I have an aluminum bracket built into the design to add strength to the bottom end of the Side Arms, I did not need to run the steel rods down into this piece. Two screws will hold the aluminum bracket in place and screw up into both bonded pieces. However, I still needed a way to insure alignment of the two pieces being bonded. In this case, I used the shaft ends of two 7/64" drill bits. Here is a complete set of parts that will help make up one unit. And just to show the full scope of the project I have on my hands, here is a photo of all the parts for six units. (three sets) It's a lot of work but I am very excited seeing how well they are all coming along! At this point, 90% of the "dirty work" is complete. Cutting out the parts with the CNC machine, bonding all the parts together and rough sanding to insure the parts are lined up properly. The next steps coming up will be making the aluminum bottom brackets, column mounting plates, shaving the Axial Shaker pieces and a few other odds and ends. Another update shortly! Hey guys, This little project is proving to be one of the most detailed oriented that I have ever taken on! There is nothing hard about anything, just a lot of little individual tasks that have to be done in a particular order, each a little time consuming. With that said, remember, I am taking on this stick shaker project without any special tools to prove that any of us can replicate these replicas and maybe some of these techniques I am using will give you ideas in other projects you are working on! These next steps will cover finishing the Axial Shaker part. I created some jig templates to mark where the pieces still need to be trimmed manually with a bench sander. (You will notice I sorta skipped ahead and did the first layer of spot filler and sanding) A good bench sander is a MUST for this project! Double check to insure the support platform is perfectly set at 90 degrees, not so much for these next few trims but for the ones following. I took 98% of the material down with the bench grinder and the last 2% with a set of hand files. If you look closely, notice that the bench grinder could only reach so far without risking damage to the main tube part of the Axial Shaker. A hand file is needed for the last bit. As long as you start with a sharp metal file, it will cut fast and get you to where you want to be. Then finish with a "fingernail" file. Last but not least when it comes to hand filing, there is a small area around where the Side Arm part hinges in place via a single bolt. This is the most critical area of the whole project when it comes to strength, therefor, as much material as possible needs to remain in this area while at the same time, allowing easy movement. I have to remind everyone again that the way I designed these replica stick shakers is not the way the real ones are made. The real stick shakers are made of metal and the brackets that hold the stick shakers to the columns is also made of metal. The bracket is actually spot welded to the main body of the stick shaker. Because this version is made of cast plastic, strength was a major concern while at the same time designing something that still looks similar to the real deal. The solution was to bolt an aluminum bracket to the Axial Shaker part. Here we have another template jig to help locate exact hole locations. The trick here is to find a way to lift one end of the part so that the holes are being drilled at a 90 degree angle. A small level helps with this task. I used a 1/4" 20 thread count tap and a makeshift hand tool to complete the screw holes. Now the mounting holes are ready for the aluminum mounting bracket. I will be using low profile hex head screws. Another case of using a temporary jig to find exact hole placements. The design requires four size 4-40 set screws to hold the 12v motor in place. Call them "motor mounts". The holes are undersized so that they can be tapped with a 4-40 tap tool. At this point, 98% of the work needing to be done to the Axial Shaker parts are complete. Here is an overview photo to date. Aluminum mounting brackets. I used .0625" thick aluminum for the brackets. I first cut them using a table saw in extra long strips to the proper height. That was easy. If you have ever tried to drill into aluminum, you might be aware that your drill bit can "wonder around" if either dull and or filled with aluminum shavings from the previous drilling. To prevent this and to insure exact hole placement, I have yet another template jig, but this time extra thick. Perfect holes and this jig also helps show where the final length from left to right will fall. If you are wondering why the extra material, it's to help capture the curve of the bracket all the way to the edges. No special tools, just some PVC pipe. The smaller gray piece is what the columns are made of. The larger white piece used to form the curve in the bracket has a smaller diameter. When rolling it by hand, a smaller diameter pipe is needed to in order to capture the correct curve. Pretty darn close I would say! Now to trim off those ends. A hacksaw with a fine tooth blade does the trick. Just be careful starting the cut. I used two fingers against the blade to protect the bracket from the blade wanting to wonder over until the cut channel was established. Once the cut is about half way through, it is very easy to bend the end over and off. I used a metal tube, the same O.D. as the one used to do the manual rolling, to gently hammer out any high points which occurred near the two center large holes where the aluminum was weaker. Use a hammer with soft heads like this one. Back to the bench sander again to clean up the ends. I actually used a set of calipers measuring from the inside of the mounting holes to the ends of the brackets to insure they were all within .001" of one another. Some final finish sanding and giving all the corners a slight curve and done! No special tools required. As you can see from this update, there are a lot of little things that have to be done in order to reach the end goal. Getting closer! Another update shortly. Hey guys, This little project is proving to be one of the most detailed oriented that I have ever taken on! There is nothing hard about anything, just a lot of little individual tasks that have to be done in a particular order, each a little time consuming. With that said, remember, I am taking on this stick shaker project without any special tools to prove that any of us can replicate these replicas and maybe some of these techniques I am using will give you ideas in other projects you are working on! These next steps will cover finishing the Axial Shaker part. I created some jig templates to mark where the pieces still need to be trimmed manually with a bench sander. (You will notice I sorta skipped ahead and did the first layer of spot filler and sanding) A good bench sander is a MUST for this project! Double check to insure the support platform is perfectly set at 90 degrees, not so much for these next few trims but for the ones following. I took 98% of the material down with the bench grinder and the last 2% with a set of hand files. If you look closely, notice that the bench grinder could only reach so far without risking damage to the main tube part of the Axial Shaker. A hand file is needed for the last bit. As long as you start with a sharp metal file, it will cut fast and get you to where you want to be. Then finish with a "fingernail" file. Last but not least when it comes to hand filing, there is a small area around where the Side Arm part hinges in place via a single bolt. This is the most critical area of the whole project when it comes to strength, therefor, as much material as possible needs to remain in this area while at the same time, allowing easy movement. I have to remind everyone again that the way I designed these replica stick shakers is not the way the real ones are made. The real stick shakers are made of metal and the brackets that hold the stick shakers to the columns is also made of metal. The bracket is actually spot welded to the main body of the stick shaker. Because this version is made of cast plastic, strength was a major concern while at the same time designing something that still looks similar to the real deal. The solution was to bolt an aluminum bracket to the Axial Shaker part. Here we have another template jig to help locate exact hole locations. The trick here is to find a way to lift one end of the part so that the holes are being drilled at a 90 degree angle. A small level helps with this task. I used a 1/4" 20 thread count tap and a makeshift hand tool to complete the screw holes. Now the mounting holes are ready for the aluminum mounting bracket. I will be using low profile hex head screws. Another case of using a temporary jig to find exact hole placements. The design requires four size 4-40 set screws to hold the 12v motor in place. Call them "motor mounts". The holes are undersized so that they can be tapped with a 4-40 tap tool. At this point, 98% of the work needing to be done to the Axial Shaker parts are complete. Here is an overview photo to date. Aluminum mounting brackets. I used .0625" thick aluminum for the brackets. I first cut them using a table saw in extra long strips to the proper height. That was easy. If you have ever tried to drill into aluminum, you might be aware that your drill bit can "wonder around" if either dull and or filled with aluminum shavings from the previous drilling. To prevent this and to insure exact hole placement, I have yet another template jig, but this time extra thick. Perfect holes and this jig also helps show where the final length from left to right will fall. If you are wondering why the extra material, it's to help capture the curve of the bracket all the way to the edges. No special tools, just some PVC pipe. The smaller gray piece is what the columns are made of. The larger white piece used to form the curve in the bracket has a smaller diameter. When rolling it by hand, a smaller diameter pipe is needed to in order to capture the correct curve. Pretty darn close I would say! Now to trim off those ends. A hacksaw with a fine tooth blade does the trick. Just be careful starting the cut. I used two fingers against the blade to protect the bracket from the blade wanting to wonder over until the cut channel was established. Once the cut is about half way through, it is very easy to bend the end over and off. I used a metal tube, the same O.D. as the one used to do the manual rolling, to gently hammer out any high points which occurred near the two center large holes where the aluminum was weaker. Use a hammer with soft heads like this one. Back to the bench sander again to clean up the ends. I actually used a set of calipers measuring from the inside of the mounting holes to the ends of the brackets to insure they were all within .001" of one another. Some final finish sanding and giving all the corners a slight curve and done! No special tools required. As you can see from this update, there are a lot of little things that have to be done in order to reach the end goal. Getting closer! Another update shortly. Hey guys, Another update in the same day! Actually I had to break it up because there is so much stuff to cover. This first bit is going to cover the Side Arm part and the aluminum bottom bracket that helps add strength at the bottom of the Side Arm where it mounts to the Axial Shaker part. I used a three foot long piece of stock .5" X .375" "U" channel. You can find this at your local hardware store. I rough cut them in small manageable 1.25" long pieces. Using a spare ARM S1 piece as a hole jig, a couple holes are drilled in the aluminum bottom bracket. Both holes are countersunk so that the head of the screws are perfectly flush with the aluminum. Next a hole in the middle is opened up and needs to be squared off in all four corners. This will create a notched pocket for that raised area on the Axial Shaker to fit into, almost like a hip socket. Nothing hard here, just tedious and time consuming. I feel like I was making tiny door latches! In the end, they all turned out great. Also note where I have marked on the brackets the area where some more material needs to be removed by the bench grinder. Here is where it is important to insure the bench grinding deck is set exactly at 90 degrees. Because these parts are small, it doesn't take long for the parts to heat up from the friction. A small tub of water to dip the parts in is needed to cool them down. More temporary marking jigs! This one is designed to show where the bulk of the remaining material needs to be removed from these small bottom brackets. Back to the bench grinder.......and the tub of water to cool them down. Using another marking jig, the majority of the material at the bottom of the Side Arm can now be taken down. Be careful not to remove too much at one time. Going from metal to plastic grinding is a big difference in the amount of time it takes to grind down to your goal. Now this part is starting to take shape! It's also now clear to see how complex this part would be to make in one solid piece with a CNC machine. I won't go as far as to say it would be impossible, but it is for me and my three axis hobby level machine. Notice I have a temporary plate screwed in place at the top end of the Side Arm. This insures the part stays perfectly flat on the deck and both sides of the part match each other during the grinding process. Now that the bottom end of the Side Arms have been properly shaped, it's time to screw the aluminum bottom brackets in place. I also marked the edges of the plastic with a black marker to let me know if I am going too hard in one area and to help work to bring the parts together for a perfect match. The photo below shows the steps from left to right. Here's one on the bench grinder in the process of becoming a perfect match! Last but not least, some spotting filler and sanding. This takes the Side Arms up to about 95% complete. Also in this photo are the parts I call the Arm Trim. This piece fits near the top of the Side Arm and helps support the Arm Ring. This is a good stopping point on the Side Arms while working to advance some of the other pieces. The Arm Trim also require............you guessed it, a paper jig to help locate proper hole locations. I used the laser engraver to cut these templates. Maybe only two screws are needed but the real stick shaker I am modeling have four screws so four it is. One side of the part has to be lifted up with a piece of scrap wood in order to drill and countersink at perfect 90 degree angles. There are a lot of pieces in this project, in total, there are no less than 110 parts in each stick shaker. There are three main parts once everything has been assembled. The Axial Shaker, the Side Arm/Ring and last but not least, the Spinner. The spinner is what makes this thing work. It's what shakes the stick shaker after all! To date, the main parts of the Spinner have been assembled, but now it's time to add a few things and finish it up. First, the Top Cap, another part easily found at any decent hardware store or even online. But like everything else in this project, these metal caps need a little modification to make them fit properly. The twelve tabs around the edge need to be bent over slightly. Now they fit tight and flush. But to insure they don't ever fall out and they can be removed in the future, I used a hot glue gun to help hold them in place. Now they won't come off but can still be removed if necessary. I used flat black and a light coat of flat clear to paint these parts. Next step is "the thing" that makes the stick shakers shake..........weight! I used .5" wide lead tape. It's heavy and easy to cut with a razor. Each spinner requires five strips stacked on top of each other. With the 3M double sided tape included on the weight, I think this will be enough to hold the weights in place. I have done a couple test spins and it feels pretty powerful. Before the test, I was wondering if I would need to add more weight, but now I am wondering if I should remove a strip or two! For now, we will stick with five strips until a full test can be completed. Next, the spinner bumper needs to be installed. The real stick shakers use one solid bumper that is about 1.5" tall. My design has the bumper in two pieces, one piece is around the top part of the spinner and the second piece is around the Axial Shaker. I found a suitable rubber that is the right thickness but it has to be cut to size. And the sticky tape that comes with it is too thick and not strong enough to hold the bumper in a perfect loop around the spinner. The sticky tape has to be removed. In place of the original sticky tape, thinner 3M double sided sticky tape is used. Here are a couple installed on the spinners and a couple cut ready to be installed. Most of my photos are neat and clean, but I wanted to show you this messy photo so you don't think everything fits perfectly the first time. It took a couple times to cut the rubber just right to get it to fit perfectly! Additionally, Superglue is needed to hold the rubber ends together. At first, I was not sure this solution was going to work because I didn't want the seam to show or at least not be as noticeable. It's actually not too bad as is..........see photo. But I found if I trimmed the seam with an Exacto knife and then sanded it with 500 grit sandpaper, the seam all but disappears. I can now say the Spinners are 100% complete! At this point, it feels like there is still so much work to be done so I can't say for sure how much longer it will take until completion. Let's say two more weeks but an update most likely in a few days! Hey guys, Another update in the same day! Actually I had to break it up because there is so much stuff to cover. This first bit is going to cover the Side Arm part and the aluminum bottom bracket that helps add strength at the bottom of the Side Arm where it mounts to the Axial Shaker part. I used a three foot long piece of stock .5" X .375" "U" channel. You can find this at your local hardware store. I rough cut them in small manageable 1.25" long pieces. Using a spare ARM S1 piece as a hole jig, a couple holes are drilled in the aluminum bottom bracket. Both holes are countersunk so that the head of the screws are perfectly flush with the aluminum. Next a hole in the middle is opened up and needs to be squared off in all four corners. This will create a notched pocket for that raised area on the Axial Shaker to fit into, almost like a hip socket. Nothing hard here, just tedious and time consuming. I feel like I was making tiny door latches! In the end, they all turned out great. Also note where I have marked on the brackets the area where some more material needs to be removed by the bench grinder. Here is where it is important to insure the bench grinding deck is set exactly at 90 degrees. Because these parts are small, it doesn't take long for the parts to heat up from the friction. A small tub of water to dip the parts in is needed to cool them down. More temporary marking jigs! This one is designed to show where the bulk of the remaining material needs to be removed from these small bottom brackets. Back to the bench grinder.......and the tub of water to cool them down. Using another marking jig, the majority of the material at the bottom of the Side Arm can now be taken down. Be careful not to remove too much at one time. Going from metal to plastic grinding is a big difference in the amount of time it takes to grind down to your goal. Now this part is starting to take shape! It's also now clear to see how complex this part would be to make in one solid piece with a CNC machine. I won't go as far as to say it would be impossible, but it is for me and my three axis hobby level machine. Notice I have a temporary plate screwed in place at the top end of the Side Arm. This insures the part stays perfectly flat on the deck and both sides of the part match each other during the grinding process. Now that the bottom end of the Side Arms have been properly shaped, it's time to screw the aluminum bottom brackets in place. I also marked the edges of the plastic with a black marker to let me know if I am going too hard in one area and to help work to bring the parts together for a perfect match. The photo below shows the steps from left to right. Here's one on the bench grinder in the process of becoming a perfect match! Last but not least, some spotting filler and sanding. This takes the Side Arms up to about 95% complete. Also in this photo are the parts I call the Arm Trim. This piece fits near the top of the Side Arm and helps support the Arm Ring. This is a good stopping point on the Side Arms while working to advance some of the other pieces. The Arm Trim also require............you guessed it, a paper jig to help locate proper hole locations. I used the laser engraver to cut these templates. Maybe only two screws are needed but the real stick shaker I am modeling have four screws so four it is. One side of the part has to be lifted up with a piece of scrap wood in order to drill and countersink at perfect 90 degree angles. There are a lot of pieces in this project, in total, there are no less than 110 parts in each stick shaker. There are three main parts once everything has been assembled. The Axial Shaker, the Side Arm/Ring and last but not least, the Spinner. The spinner is what makes this thing work. It's what shakes the stick shaker after all! To date, the main parts of the Spinner have been assembled, but now it's time to add a few things and finish it up. First, the Top Cap, another part easily found at any decent hardware store or even online. But like everything else in this project, these metal caps need a little modification to make them fit properly. The twelve tabs around the edge need to be bent over slightly. Now they fit tight and flush. But to insure they don't ever fall out and they can be removed in the future, I used a hot glue gun to help hold them in place. Now they won't come off but can still be removed if necessary. I used flat black and a light coat of flat clear to paint these parts. Next step is "the thing" that makes the stick shakers shake..........weight! I used .5" wide lead tape. It's heavy and easy to cut with a razor. Each spinner requires five strips stacked on top of each other. With the 3M double sided tape included on the weight, I think this will be enough to hold the weights in place. I have done a couple test spins and it feels pretty powerful. Before the test, I was wondering if I would need to add more weight, but now I am wondering if I should remove a strip or two! For now, we will stick with five strips until a full test can be completed. Next, the spinner bumper needs to be installed. The real stick shakers use one solid bumper that is about 1.5" tall. My design has the bumper in two pieces, one piece is around the top part of the spinner and the second piece is around the Axial Shaker. I found a suitable rubber that is the right thickness but it has to be cut to size. And the sticky tape that comes with it is too thick and not strong enough to hold the bumper in a perfect loop around the spinner. The sticky tape has to be removed. In place of the original sticky tape, thinner 3M double sided sticky tape is used. Here are a couple installed on the spinners and a couple cut ready to be installed. Most of my photos are neat and clean, but I wanted to show you this messy photo so you don't think everything fits perfectly the first time. It took a couple times to cut the rubber just right to get it to fit perfectly! Additionally, Superglue is needed to hold the rubber ends together. At first, I was not sure this solution was going to work because I didn't want the seam to show or at least not be as noticeable. It's actually not too bad as is..........see photo. But I found if I trimmed the seam with an Exacto knife and then sanded it with 500 grit sandpaper, the seam all but disappears. I can now say the Spinners are 100% complete! At this point, it feels like there is still so much work to be done so I can't say for sure how much longer it will take until completion. Let's say two more weeks but an update most likely in a few days! Another update on the stick shaker replicas! One of the scariest steps being that so much time has been put into these parts so far and it would only take a few seconds to screw them up drilling this pivot point hole. Fortunately the temporary plate at the rear helps insure the hole is as straight as possible. Next, the countersink holes on both sides. Now that the pivot point hole has been made through the aluminum bracket, here is a photo of the bare aluminum stock compared to the finished part temporarily removed. A lot of work to get to this point! Another scary key moment, the other half of the pivot point hole but this time in the Axial Shaker. Besides locating the exact point where the hole needs to be drilled, I had to find a way to build up a makeshift platform for these odd shaped parts. The real stick shakers have a power line running from the main body to the side arm because that is actually where the motor is located. I wanted these replicas to look the part by adding a "dummy" line between the two parts. The hole placement is not as critical as the previous pivot point holes but still I wanted to insure they were very close to the same locations as the real ones. Here I have a piece of shielded cables running between the two parts. It's just a "dummy" line but you would never know once it's all assembled. Changing gears, next up the internal wiring and hooking up the 12v motor. I found some, what they call "aviation" plugs. I doubt these would actually be found in a real aircraft, but they will work fine for this project. Notice the two terminals are numbers. Pin 1 is for 12v power and pin 2 is for ground. Here is a set ready for installation. I used 22 gauge shielded cable. The 12v motors are actually listed as "massage" motors. The weights need to be removed from both ends. One weight can easily be removed by twisting it off by holding the other one from spinning. Which ones comes loose first is a surprise! To remove the second weight, you will need a set of vice grips. Now for the fun part.....putting 10 lbs of "stuff" in a 5 lbs bag. The 12v motor, a 470 uF 35V capacitor, a 1N4004 400v diode and last but not least the female half of the plug. (The cap and diode are to help suppress any EMI that the motor may put out) After some test fitting and careful measuring, I think I came up with a way to get it all in this small space. Here's everything soldered up ready to be installed in the Axial Shaker. Now we are getting down to the final steps of shaping the parts. This last step is adding the curve so that the aluminum mounting plate fits flush. The first step is to mark the edges. These edges must not get touched during the grinding process. I used the bench sander to take down 90% of the material. Then using a hand file, I was able to take down another 8% of the material and start to take the uneven areas out caused by the bench grinder. Last step, I used 100 grit sandpaper wrapped around a piece of PVC that is the same diameter as the control columns. This did the trick and gave me the exact radius needed. The heavy shaping, grinding, filing, filling and sanding is now complete! Everything has been given a heavy coat of black primer. The parts don't look bad but sanding and some filler is still needed. One more update and this set should be complete! Another update on the stick shaker replicas! One of the scariest steps being that so much time has been put into these parts so far and it would only take a few seconds to screw them up drilling this pivot point hole. Fortunately the temporary plate at the rear helps insure the hole is as straight as possible. Next, the countersink holes on both sides. Now that the pivot point hole has been made through the aluminum bracket, here is a photo of the bare aluminum stock compared to the finished part temporarily removed. A lot of work to get to this point! Another scary key moment, the other half of the pivot point hole but this time in the Axial Shaker. Besides locating the exact point where the hole needs to be drilled, I had to find a way to build up a makeshift platform for these odd shaped parts. The real stick shakers have a power line running from the main body to the side arm because that is actually where the motor is located. I wanted these replicas to look the part by adding a "dummy" line between the two parts. The hole placement is not as critical as the previous pivot point holes but still I wanted to insure they were very close to the same locations as the real ones. Here I have a piece of shielded cables running between the two parts. It's just a "dummy" line but you would never know once it's all assembled. Changing gears, next up the internal wiring and hooking up the 12v motor. I found some, what they call "aviation" plugs. I doubt these would actually be found in a real aircraft, but they will work fine for this project. Notice the two terminals are numbers. Pin 1 is for 12v power and pin 2 is for ground. Here is a set ready for installation. I used 22 gauge shielded cable. The 12v motors are actually listed as "massage" motors. The weights need to be removed from both ends. One weight can easily be removed by twisting it off by holding the other one from spinning. Which ones comes loose first is a surprise! To remove the second weight, you will need a set of vice grips. Now for the fun part.....putting 10 lbs of "stuff" in a 5 lbs bag. The 12v motor, a 470 uF 35V capacitor, a 1N4004 400v diode and last but not least the female half of the plug. (The cap and diode are to help suppress any EMI that the motor may put out) After some test fitting and careful measuring, I think I came up with a way to get it all in this small space. Here's everything soldered up ready to be installed in the Axial Shaker. Now we are getting down to the final steps of shaping the parts. This last step is adding the curve so that the aluminum mounting plate fits flush. The first step is to mark the edges. These edges must not get touched during the grinding process. I used the bench sander to take down 90% of the material. Then using a hand file, I was able to take down another 8% of the material and start to take the uneven areas out caused by the bench grinder. Last step, I used 100 grit sandpaper wrapped around a piece of PVC that is the same diameter as the control columns. This did the trick and gave me the exact radius needed. The heavy shaping, grinding, filing, filling and sanding is now complete! Everything has been given a heavy coat of black primer. The parts don't look bad but sanding and some filler is still needed. One more update and this set should be complete! The first batch of stick shakers are finally complete! A six pack of stick shakers (three sets) and they turned out better than I could have hoped for. They are built strong enough to hold up to the abuse they will be giving themselves and also have built in EMI protection. And they run off of 12 volt power. This solves all the problems we were facing prior to the creation of these replicas. Here is the final tutorial covering how to build them up. First step, adding the "dummy" cable from the main axial shaker to the side arm. It's an easy process, insert the cable into the side hole and hook it with the zip tie. Once it is hooked, pull it tight and tuck the end back into the pocket. The ring base is held in place with four screws. It's starting to resemble parts you might be familiar with! Next step is adding the second half of the bumper. The real stick shakers use one solid bumper, but because this design has the top 1/3rd spinning, the bumper is split in two pieces. Here I have some 3M double sided tape applied and waiting for the rubber bumpers. Careful trimming and cutting of the bumpers. The same rules apply as they did with the top spinner bumper. Superglue is needed to bond the two ends together. Then some light sanding and it's hard to see where the seam is. How strong are they? I made a mistake putting one together and had to pull it apart. It took a lot of effort to pull it apart, so much I am not worried about it ever failing on it's own. We will see if time and continuous use has anything to say about that. Next up is installing the two pin plug at the bottom of the axial shaker body. Because the inside of the opening is so tight, I could not get a socket down in the pocket to tighten the nut properly. The head of a screw driver did the job holding the nut in place while tightening and for extra security, I applied a couple drops of superglue on the nut and threads. (Inside the tube) Here is an overall photo of all the parts finished and ready for final assembly. So much work has gone into these parts! Time to install the side arm caps. I used the caps as templates, drilled the holes and then tapped them with a 4-40 tap tool. The photo below shows the three steps from left to right. Here is another big moment, attaching the side arm to the axial shaker with a shoulder screw. Next, wiring in the 12v motor and installing shrink tube over the wire joints to prevent shorting. Notice the capacitor and diode are also wired in and will fit inside the void under the motor. Next, installing the 12v motors. Five out of the six motors went in fine. The sixth took a little extra sanding of the inside where the rings of plastic did not line up exactly perfect. But with a little work, they all went in. The spinner cap simply presses onto the motor shaft. Notice I have a Nylon washer sitting on top of the motor to act as a buffer between the motor and the bottom side of the spinner. I don't think this is necessary but I don't think it will hurt anything either. This is a GREAT photo illustrating exactly how this stick shakers works. Much different than the authentic design. Last step, installing the top ring cover which takes six 2-56 screws. For extra security, I dipped each screw into a little Thread Lock because after all, if this thing works as intended, it "could" shake itself apart if not built properly. Here is the final product! A couple mounting bracket gaskets and all the screws are included along with the shielded cable with the plugs already installed. I still need to install a set on my own control columns to do proper testing. I have one more update coming and that will basically cover how to mount them to the control columns. But before I can do that, I need to do some updates to the raised floor area in order to find the exact location to mount the stick shakers to the control columns. If you have any questions or comments, don't be afraid to post! The first batch of stick shakers are finally complete! A six pack of stick shakers (three sets) and they turned out better than I could have hoped for. They are built strong enough to hold up to the abuse they will be giving themselves and also have built in EMI protection. And they run off of 12 volt power. This solves all the problems we were facing prior to the creation of these replicas. Here is the final tutorial covering how to build them up. First step, adding the "dummy" cable from the main axial shaker to the side arm. It's an easy process, insert the cable into the side hole and hook it with the zip tie. Once it is hooked, pull it tight and tuck the end back into the pocket. The ring base is held in place with four screws. It's starting to resemble parts you might be familiar with! Next step is adding the second half of the bumper. The real stick shakers use one solid bumper, but because this design has the top 1/3rd spinning, the bumper is split in two pieces. Here I have some 3M double sided tape applied and waiting for the rubber bumpers. Careful trimming and cutting of the bumpers. The same rules apply as they did with the top spinner bumper. Superglue is needed to bond the two ends together. Then some light sanding and it's hard to see where the seam is. How strong are they? I made a mistake putting one together and had to pull it apart. It took a lot of effort to pull it apart, so much I am not worried about it ever failing on it's own. We will see if time and continuous use has anything to say about that. Next up is installing the two pin plug at the bottom of the axial shaker body. Because the inside of the opening is so tight, I could not get a socket down in the pocket to tighten the nut properly. The head of a screw driver did the job holding the nut in place while tightening and for extra security, I applied a couple drops of superglue on the nut and threads. (Inside the tube) Here is an overall photo of all the parts finished and ready for final assembly. So much work has gone into these parts! Time to install the side arm caps. I used the caps as templates, drilled the holes and then tapped them with a 4-40 tap tool. The photo below shows the three steps from left to right. Here is another big moment, attaching the side arm to the axial shaker with a shoulder screw. Next, wiring in the 12v motor and installing shrink tube over the wire joints to prevent shorting. Notice the capacitor and diode are also wired in and will fit inside the void under the motor. Next, installing the 12v motors. Five out of the six motors went in fine. The sixth took a little extra sanding of the inside where the rings of plastic did not line up exactly perfect. But with a little work, they all went in. The spinner cap simply presses onto the motor shaft. Notice I have a Nylon washer sitting on top of the motor to act as a buffer between the motor and the bottom side of the spinner. I don't think this is necessary but I don't think it will hurt anything either. This is a GREAT photo illustrating exactly how this stick shakers works. Much different than the authentic design. Last step, installing the top ring cover which takes six 2-56 screws. For extra security, I dipped each screw into a little Thread Lock because after all, if this thing works as intended, it "could" shake itself apart if not built properly. Here is the final product! A couple mounting bracket gaskets and all the screws are included along with the shielded cable with the plugs already installed. I still need to install a set on my own control columns to do proper testing. I have one more update coming and that will basically cover how to mount them to the control columns. But before I can do that, I need to do some updates to the raised floor area in order to find the exact location to mount the stick shakers to the control columns. If you have any questions or comments, don't be afraid to post!Column Stick Shaker Discussion

![]()

2017-10-10